Method for brazing CBN (Cubic Boron Nitride) abrasive particles at low temperature

A cubic boron nitride, abrasive grain technology, applied in welding media, welding equipment, welding/cutting media/materials, etc., can solve the problem of high brazing temperature, reduce the performance and dimensional accuracy of base metal materials, and limit cBN abrasive tools And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

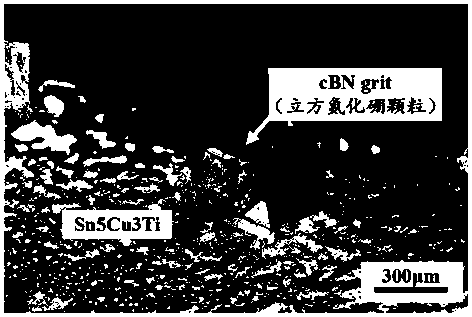

[0024] A method for low-temperature brazing cubic boron nitride abrasive grains, comprising:

[0025] Step 1, make Sn-Cu-Ti alloy powder, Sn-Cu-Ti refers to the powder that contains Sn, Cu, Ti, Sn, Cu, Ti mass ratio can be set according to configuration; In this specific embodiment: take Mix 0.6 grams of 8-12 μm titanium powder, 1.7 grams of 300-mesh Cu40Sn pre-alloyed powder and 17.7 grams of 300-mesh pure Sn powder into a ball mill; Small balls; close the lid and place it in a ball mill for ball milling for 8 hours and take it out to dry to configure the Sn-Cu-Ti alloy powder; wherein: the mass ratio of Cu and Sn in the Cu40Sn pre-alloyed powder is: 60:40; The mass ratio of Sn, Cu and Ti in Sn-Cu-Ti alloy powder is: 92:5:3, so if it can be specifically written as Sn-5Cu-3Ti;

[0026] Step 2, ultrasonic cleaning of cubic boron nitride abrasive grains with acetone and drying;

[0027] Step 3, spread Sn-Cu-Ti alloy powder and cubic boron nitride abrasive grains successively o...

Embodiment 2

[0030] A method for low-temperature brazing cubic boron nitride abrasive grains, comprising:

[0031] Step 1, making Sn-Cu-Ti alloy powder; in this specific example: get 0.3 gram of 8-12 μm titanium powder, 5 gram of 300 mesh Cu20Sn pre-alloyed powder and 14.7 gram of 300 mesh pure Sn powder and mix them into a ball mill jar ;Introduce 1.6 milliliters of acetone into the ball mill tank, put into the ceramic pellets with a total weight of 300 grams; close the lid and put it in the ball mill for 8 hours, take it out and dry it to configure Sn-21Cu-1.5Ti alloy powder;

[0032] Step 2, ultrasonic cleaning of cubic boron nitride abrasive grains with acetone and drying;

[0033] Step 3, spread Sn-Cu-Ti alloy powder and cubic boron nitride abrasive grains successively on the polished tool substrate; in this specific embodiment: spread Sn-21Cu-1.5Ti sequentially on the polished tool substrate Alloy powder and cubic boron nitride abrasive grain; the tool base adopts 45 steel base;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com