Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

271 results about "Aluminothermic reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminothermic reactions are exothermic chemical reactions using aluminium as the reducing agent at high temperature. The process is industrially useful for production of alloys of iron. This specific reaction is however not relevant to the most important application of aluminothermic reactions, the production of ferroalloys. For the production of iron, a cheaper reducing agent, coke, is used instead via the carbothermic reaction.

Method for preparing vanadium-aluminum alloy material

InactiveCN101818270AReduce contentReduce production energy consumptionProcess efficiency improvementAlloyCopper

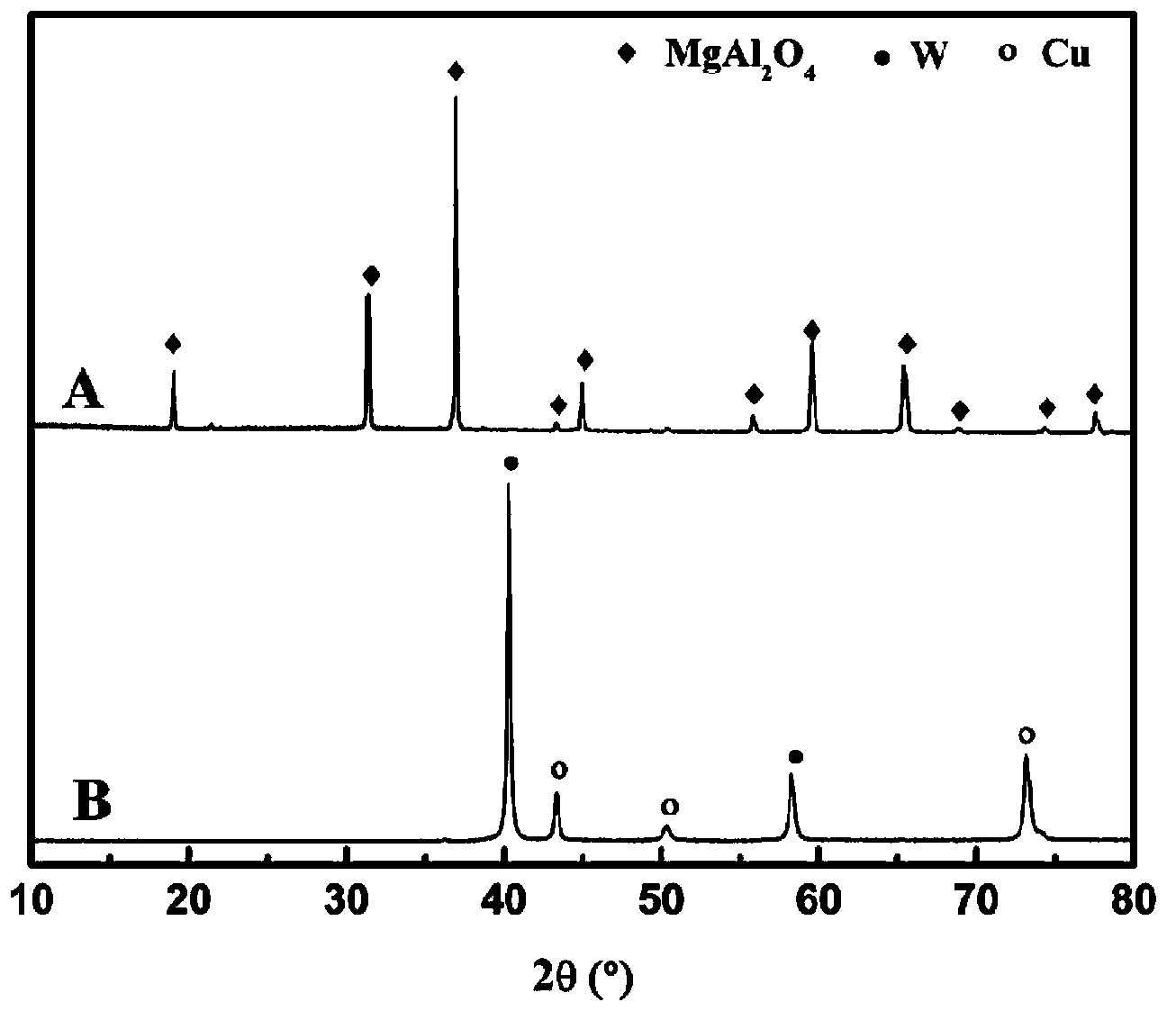

The invention discloses a method for preparing vanadium-aluminum alloy material, which comprises the following steps of: weighing 20 to 33.1 mass percent of powdery Al and 50 to 66.9 mass percent of V2O5, mixing the Al and the V2O5 for 8 to 16 hours in a ball mill, then putting the mixture into a copper die, pressing the mixture by using a press under the pressure of 60 to 80MPa, putting the die filled with the pressed reaction material into a thermit reaction container, putting an ignition agent on the material, blowing out the residual air by using inert gas, and heating the material to about 300 DEG C under the argon protection of 2 to 7MPa to perform reaction so as to obtain vanadium-aluminum alloy which contains 75 to 95 mass percent of vanadium and 5.0 to 25.0 mass percent of Al in percentage.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

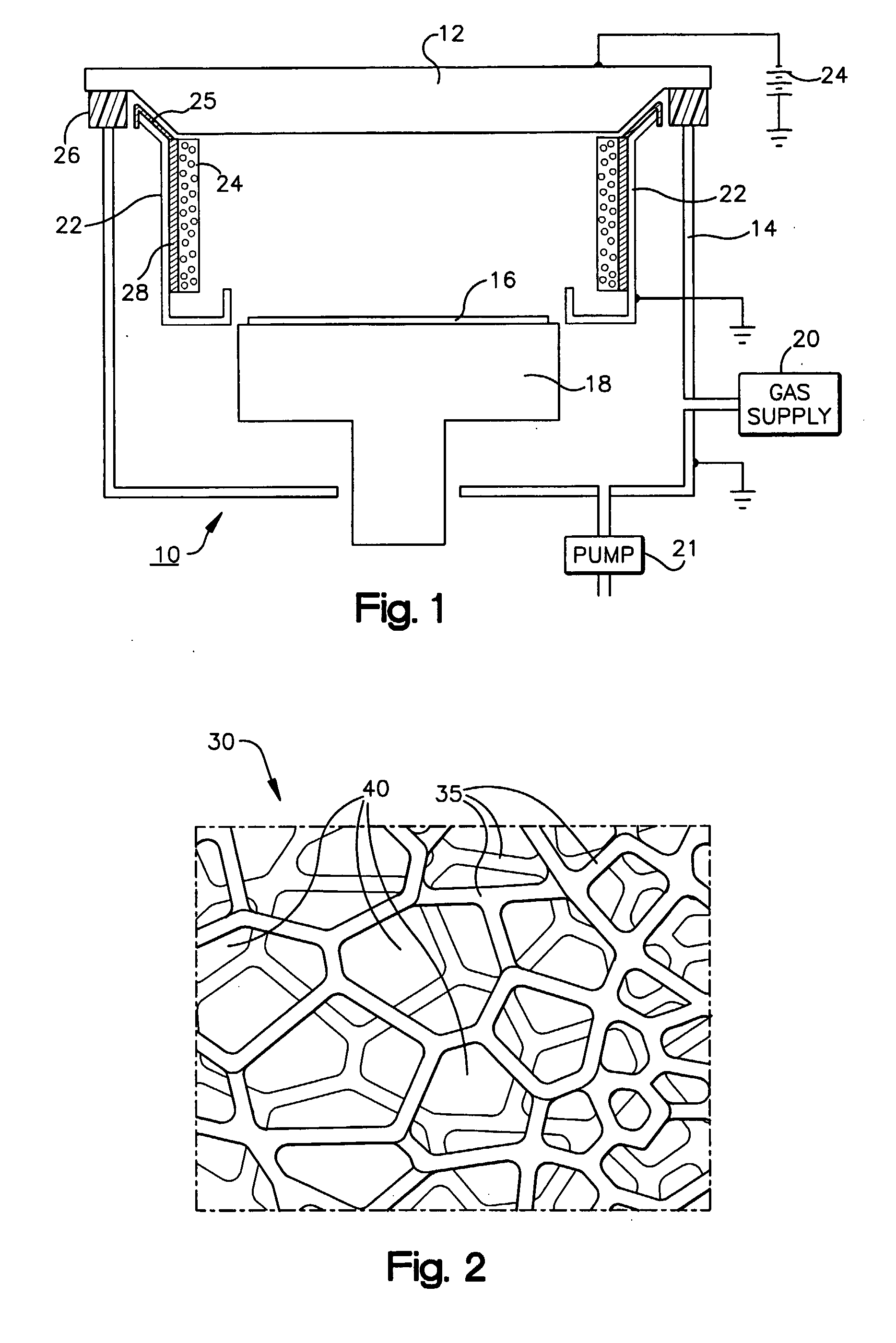

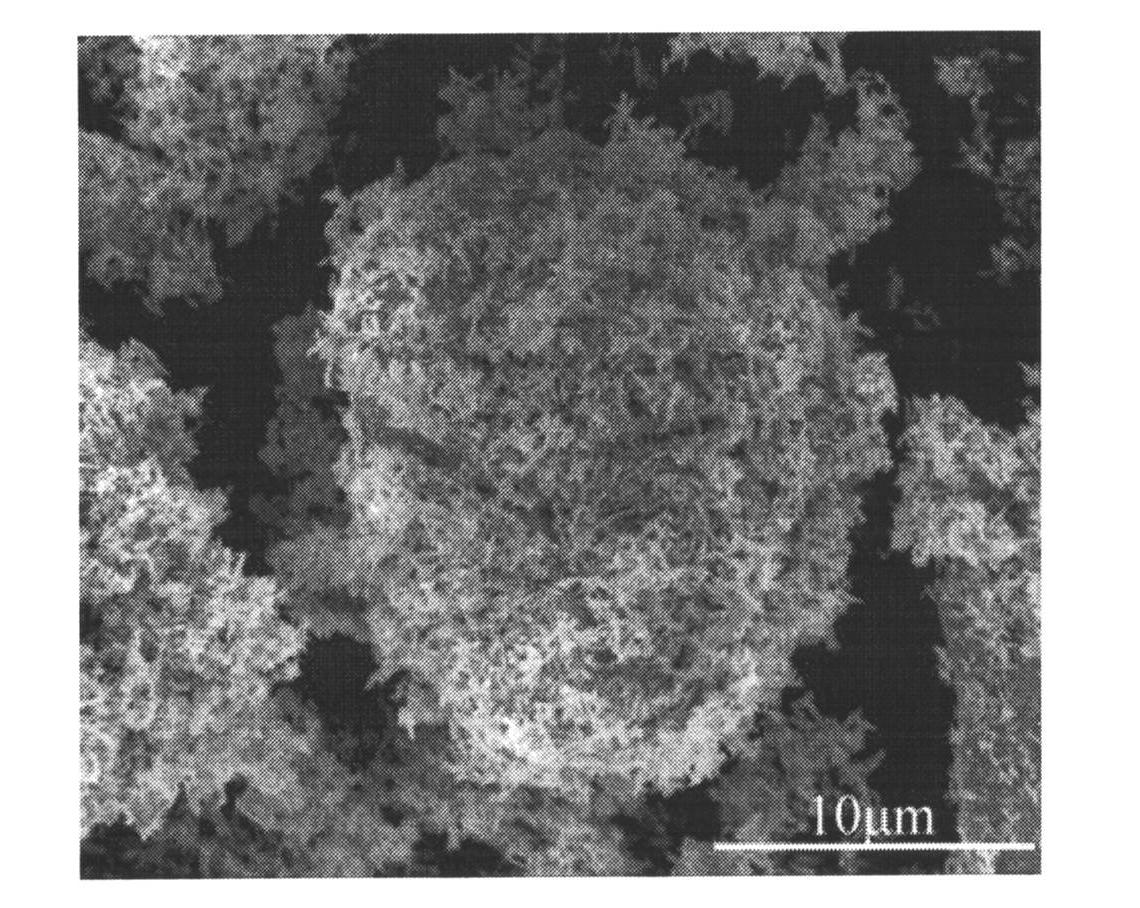

Metal foam shield for sputter reactor

InactiveUS20070158188A1Increase surface areaImprove adhesionCellsElectric discharge tubesSputteringParticulates

A shield (22) for protecting chamber walls (14) of a sputter reactor (10) comprising foam metal shaped into a desired shield shape. The foam metal inserts (24) are easily configured for mounting within the sputter reactor chamber. The foam metal shield material provides more surface area and better adhesion of the sputter coated particles, thereby reducing particulate emission and allowing longer use before replacement. The shields are also relatively inexpensive to fabricate. Once the shield is coated with sputter particles, the foam metal shield can be removed from the sputter chamber and heated in a thermite reaction, thereby reducing the particles collected on the foam metal shield to an elemental metal and thus facilitating recovery of the deposited sputter material. The apparatus has a target (12), vacuum pump (21), pedestal (18), substrate (16), gas supply system (20), clips (25), insulating ring (26), DC power supply (24), and metal layer (28).

Owner:TOSOH SMD

Micro-nano particle reinforced aluminum-based composite material and preparation method thereof

The invention relates to a micro-nano particle reinforced aluminum-based composite material and a preparation method thereof. The aluminum-based composite material takes aluminum or an aluminum alloy as a substrate material; micron-scale silicon carbide particles and nano alumina particles are uniformly dispersed in the substrate material; and the nano alumina particles are generated by undergoing a thermit reaction on nano copper oxide particles and a substrate alloy on the surfaces of the silicon carbide particles, so that a micron silicon carbide / nano alumina reinforced aluminum-based composite material is formed. The preparation method of the aluminum-based composite material comprises the following steps of: undergoing a reaction on micron-scale silicon carbide powder and soluble copper salt in an alkaline solution; filtering, baking and grinding to obtain silicon carbide / copper oxide composite powder; and undergoing a thermit reaction on the composite powder and an aluminum melt, and casting and molding to obtain a target product. By adopting the method, composite reinforcement of the substrate is realized by particles of multiple scales and multiple types, the obtained aluminum-based composite material has the advantages of high intensity, high wear resistance and the like, the bending resistance and Brinell hardness of the aluminum-based composite material are increased by over 50 percent and 73 percent compared with those of the conventional aluminum alloy respectively, and the friction coefficient is lowered by over 25 percent.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for preparing ceramic reinforced metal-based porous composite material

The invention discloses a low-cost low-temperature quick preparation method for nano Al2O3 ceramic original position enforcing Fe-Cr-Ni-base high temperature alloy porous compound material. Initializing powder is prepared in a powder metallurgy mixing component method, nano grade Fe2O3, Cr2O3, Ni2O3 powder and nano grade Al, Ni, Cr, and Fe primitive powder are converted into mass percentage according to the stoichiometric proportion of the reaction formula to be weighed and mixed, and are performed with non-pressure sintering at 800 DEG C under the vacuum condition after being compressed into billet, the whole sintering process is performed through the aluminum thermal reaction method, and minute multi-alloy elements are matched in the component compounding ratio to adjust the air hole rate and to enhance the mechanical property of the material. The method can greatly reduce the preparation temperature, reduce the preparation time, and also reduce the production cost.

Owner:XI AN JIAOTONG UNIV

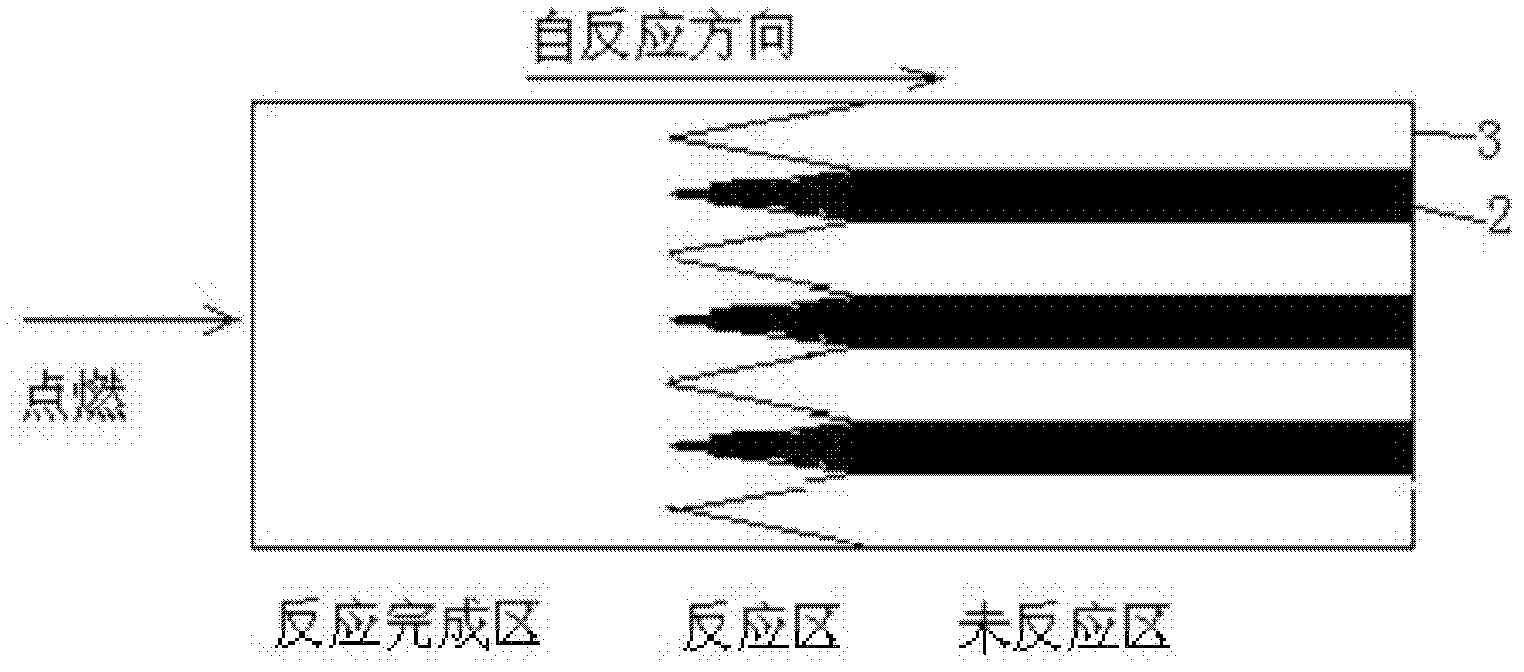

Thermit reaction foil, manufacturing method thereof and application thereof to welding process

InactiveCN102248280AQuick responseFast welding speedWelding/cutting media/materialsSoldering mediaThermal expansionUltimate tensile strength

The invention belongs to the technical field of thermit welding and discloses a thermit reaction foil. The thermit reaction foil consists of aluminum and a metal oxide capable of generating the thermit reaction with the aluminum, wherein each of the aluminum and the metal oxide has a laminated structure with at least one layer; and the aluminum layer and the metal oxide layer are arranged sequentially in an overlapping mode. When excitation with certain heat is applied to one end face of the thermit reaction foil, the thermit reaction foil generates self-propagating reaction instantly and other thermite or melting solder is ignited by heat released by the reaction, so that materials are welded. Therefore, compared with the prior art, the thermit reaction foil has reaction time of only several milliseconds, high reaction heat release, high welding speed and high welding strength, can weld the materials with different coefficient of thermal expansion, and is easy to operate, applicable to welding of various armors and parts and emergent welding repair of battlefields and also applicable to welding of various fine parts.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

WNbTaMoV high-entropy alloy and preparation method thereof

ActiveCN105886812ATypical body centered cubic structureNo pollution in the processCombustionHypergravity

The invention provides WNbTaMoV high-entropy alloy. The WNbTaMoV high-entropy alloy is composed of the elements of W, Nb, Ta, Mo and V and is of a single body-centered cubic structure. The invention further provides a preparation method of the WNbTaMoV high-entropy alloy. According to the preparation method of the WNbTaMoV high-entropy alloy, aluminothermic reaction in the combustion synthesis technology is combined with the hypergravity field separation technology, the preparation process is free of pollution and low in energy consumption, and the high-compactness WNbTaMoV high-entropy alloy can be rapidly prepared.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Molded cap ball composite heating agent and production process thereof

The invention discloses a molded cap ball composite heating agent and a production process thereof. The molded cap ball composite heating agent is mainly characterized by being prepared by processing the following raw materials: aluminum powder, sodium nitrate, ferric oxide powder, fluorite powder and acidified graphite. The production process comprises the following steps: proportioning and stirring the raw materials; pressing the mixture in a spherical mold in a double-pan friction press of 60 tons by a high-pressure screw machine to mold at high pressure; pushing the molded ball out of themold by the press to primarily package; and accurately measuring and proportioning a standard required amount of acidified graphite to secondarily package. The invention solves the problems of reduced thermite reaction speed, non-ideal heating temperature, deep shrinkage cavity and low yield of a traditional heating agent due to expansion after compounding the acidified graphite. The ball composite heating agent has rapid reaction and higher heating temperature of over 1600 DEG C, fully achieves secondary feeding effect, forms phialiform shrinkage at the head of a casting blank and improves the yield of the casting blank by more than 5 percent.

Owner:HENAN XINLONG METALLURGICAL MATERIAL GROUP

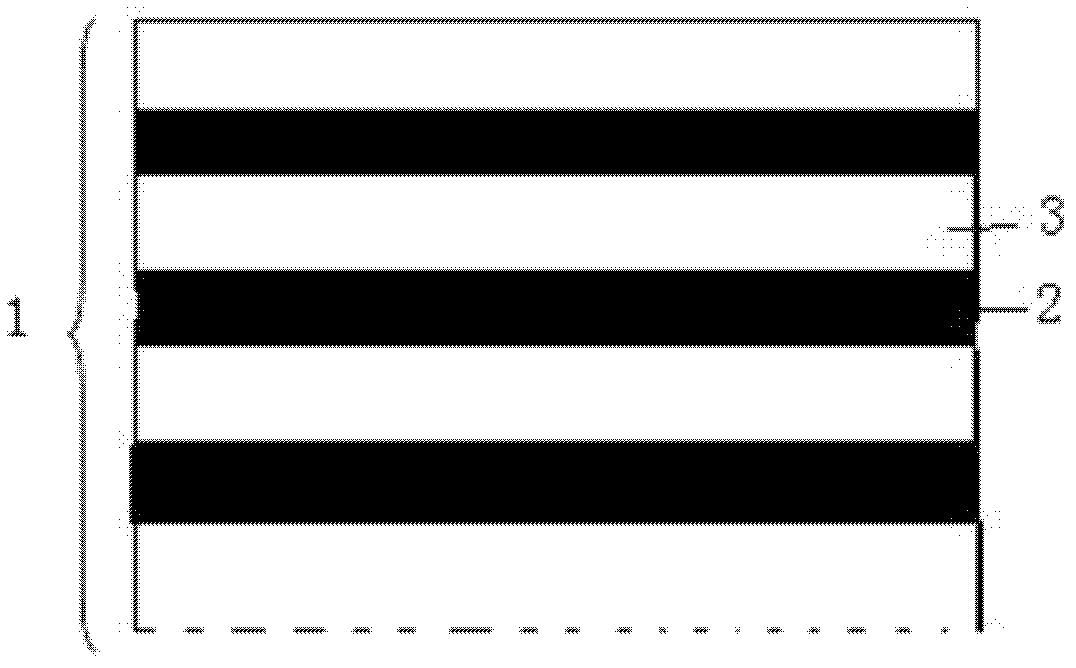

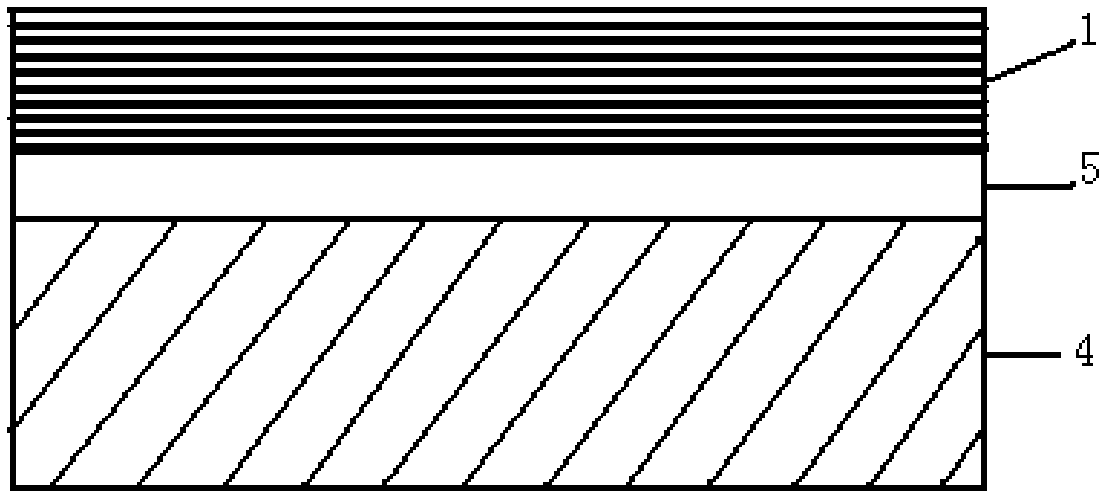

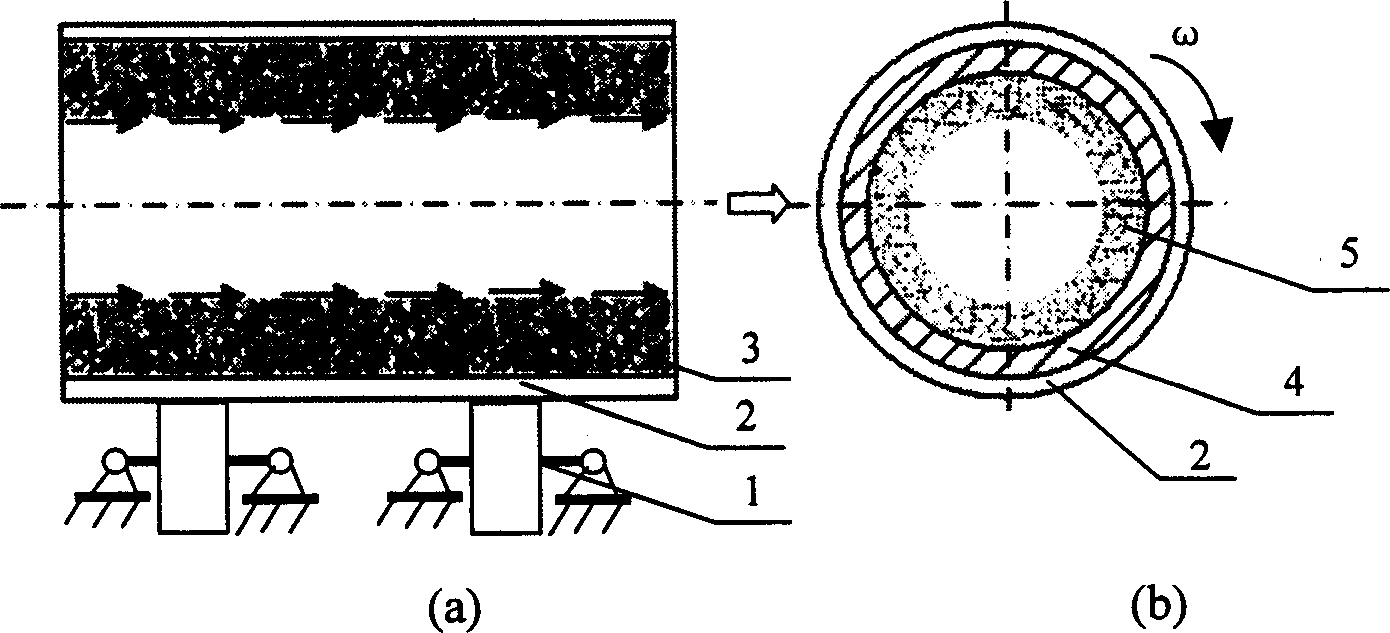

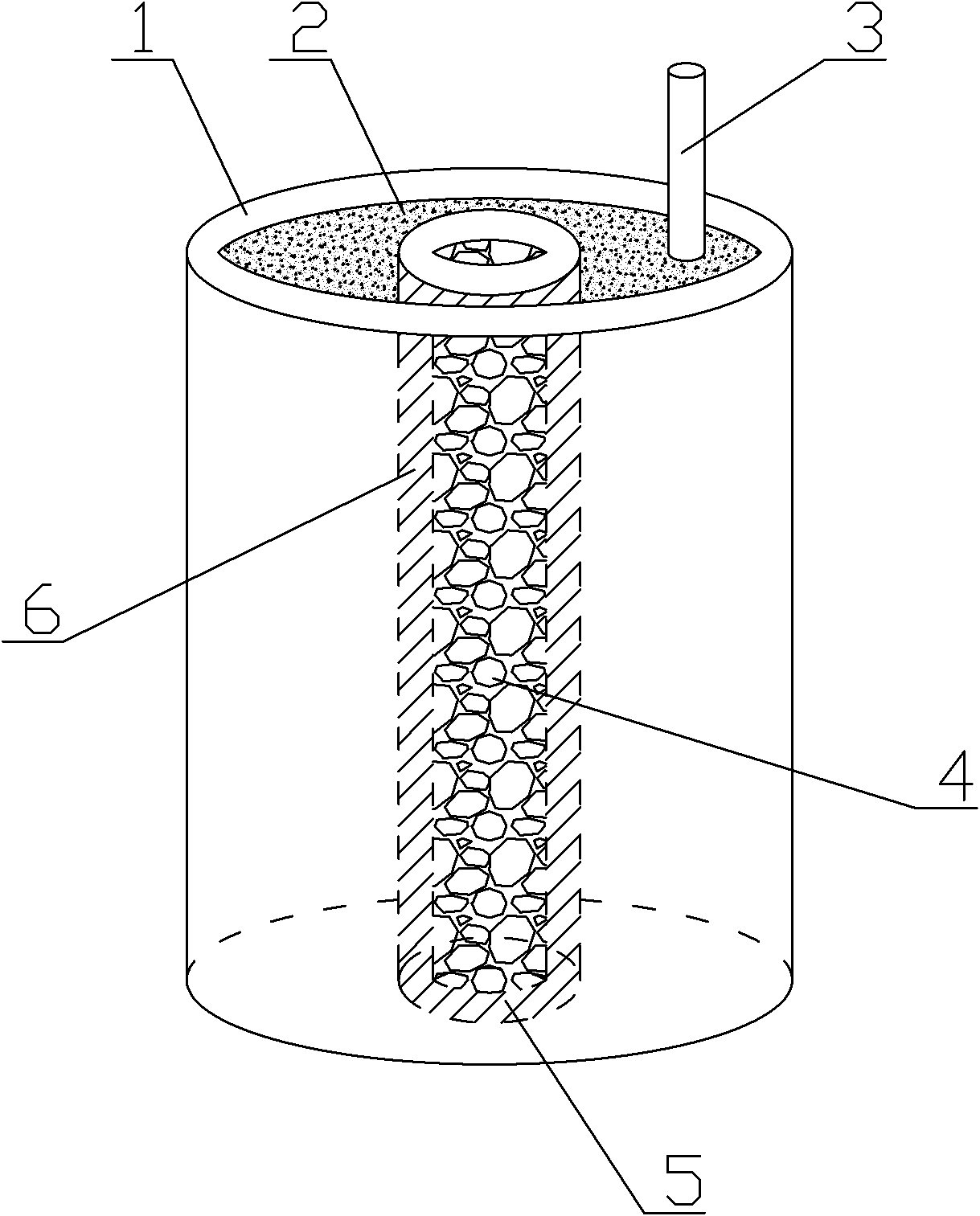

Method for preparing SHS ceramic liner metal tube from iron-based wastes

The invention relates to a method for preparing an SHS ceramic liner metal tube from iron-based wastes and discloses a method for manufacturing a corrosion-resistant and wear-resistant ceramic liner metal tube. The technical scheme is that: the treated iron-based wastes and Al powder are proportioned, mixed and sintered through an SHS centrifugal thermit reaction; an iron alloy layer and a ceramic layer are formed on an inner wall of the metal tube under the action of centrifugal force; and the prepared metal tube has the sandwich structural characteristic, namely the ceramic layer 1, the iron alloy layer 2 and a metal tube substrate layer 3 are formed from the interior to the exterior in turn. The method for preparing the SHS ceramic liner metal tube solves the problem that the conventional ceramic liner metal tube has over-high manufacturing cost and ceramic surface quality defect, and improves the wear resistance and corrosion resistance of the tube. The prepared metal tube can be widely applied to conveying powder, slurry and tailings in metallurgy, mines, electric power, coal and other industries.

Owner:UNIV OF SCI & TECH BEIJING

Method for smelting vanadium iron

The present invention provides a method for smelting vanadium iron, comprising the steps of: (1) contacting a raw material including quick lime, iron and a vanadium oxide and aluminum under the conditions of the first thermite reaction to obtain a first alloy liquid and a first slag; wherein the amount of aluminum used is 0.75-0.9 moles relative to per mole of oxygen in the vanadium oxide, and the total vanadium content is not higher than 0.2 wt% in the first slag resulted from the first thermite reaction conditions; (2) contacting the first alloy liquid and the slag including iron oxides and quick lime and without vanadium oxide under the conditions of the second thermite reaction to obtain a second alloy liquid and a second slag; wherein the aluminum element content in the second alloy liquid is not more than 1.5 wt% and the total vanadium content in the second slag is not more than 0.8 wt% resulted from the second thermite reaction conditions. By the method, the technical solution provided by the present invention effectively improves the recovery rate of vanadium.

Owner:PANZHIHUA IRON AND STEEL +1

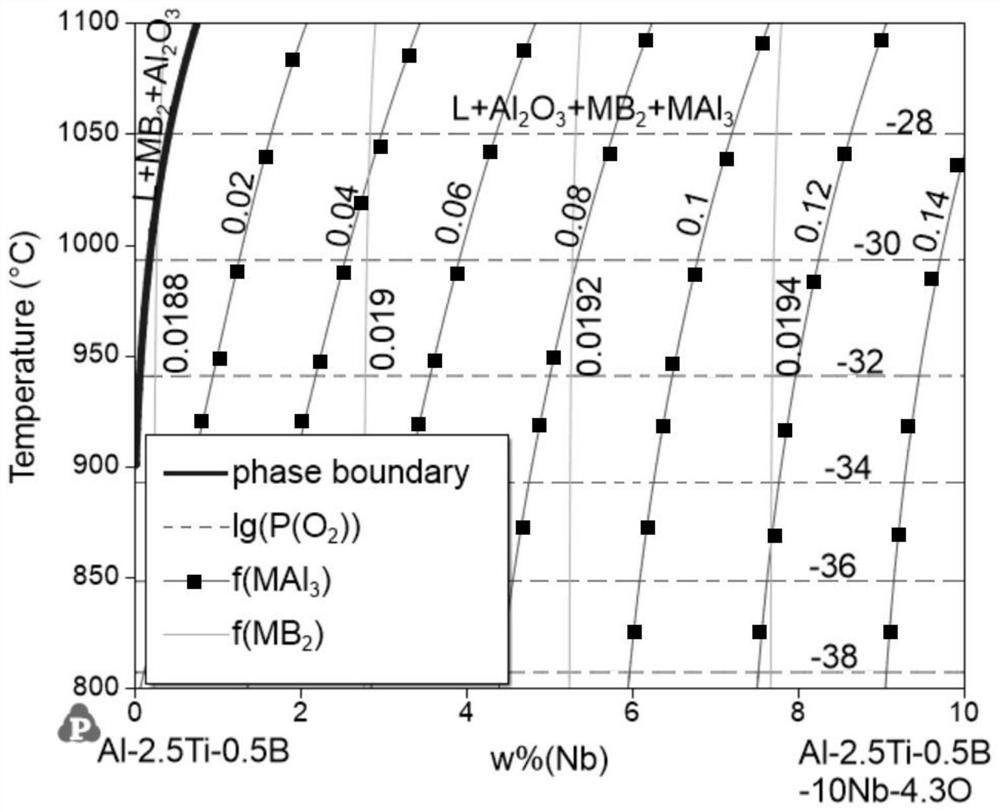

Preparation method of Al-Ti-Nb-B refiner for casting aluminum-silicon alloy

PendingCN112048629AImprove refinementMeet industry-accepted standardsFine dispersionAluminothermic reaction

The invention discloses a preparation method of an Al-Ti-Nb-B refiner for casting an aluminum-silicon alloy. The preparation method comprises the following steps that a, raw materials are weighted; and b, smelting of the Al-Ti-Nb-B refiner is carried out. According to the Al-Ti-Nb-B refiner prepared by the method, Nb2O5 is introduced as a Nb source, so that the raw material cost is greatly reduced; in the aspect of preparation effect, the grain size of alpha-Al in the aluminum-silicon alloy can be refined to 220 microns, and the industrial approval standard is met. Nb is introduced into the refiner through aluminothermic reaction, so that fine dispersion distribution of the second phases MB2 and MAl3 in the Al-Ti-Nb-B refiner is realized, and the refinement performance of the Al-Ti-Nb-B refiner is improved. The method can greatly reduce the preparation cost of the Al-Ti-Nb-B refiner, the preparation method is simple and convenient, and is suitable for industrial large-scale production.

Owner:SHANGHAI UNIV +1

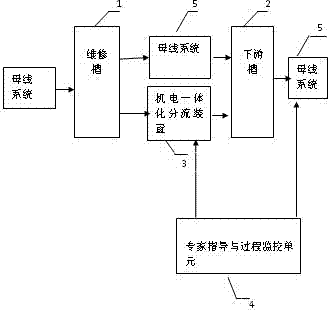

Aluminium electrolysis cell through-current body hot-line welding control system

The invention discloses an aluminium electrolysis cell through-current body hot-line welding control system, comprising a maintenance tank (1), a downstream tank (2) and a bus system (5), wherein a mechanical-electrical shunt device is arranged between the maintenance tank (1) and the downstream tank (2), the surfaces of the mechanical-electrical shunt device (3) and the bus system (5) are provided with thermoelectric sensors which are connected with an expert guiding and process monitoring unit (4) electrically. The aluminium electrolysis cell through-current body hot-line welding control system disclosed by the invention solves the problems that a thermit reaction has a high requirement on the spatial size of a welded position, a special thermit container is short in use period and high in cost, a reagent formula needs to be determined by exploration, a mode for shielding a dangerous magnetic field adopts an easily magnetized permeability material, and is not obvious in shielding effect and difficult to operate.

Owner:GUIYANG AL-MG DESIGN & RES INST

Composite containing high-entropy alloy/ceramic continuous-gradient composite coating and preparation method and device thereof

ActiveCN108085634ASimple stepsClever designMolten spray coatingHigh entropy alloysEnergy consumption

A composite containing high-entropy alloy / ceramic continuous-gradient composite coating comprises a matrix and the high-entropy alloy / ceramic continuous-gradient composite coating. The high-entropy alloy / ceramic continuous-gradient composite coating is 5-10 mm thick and contains high-entropy alloy and aluminum oxide, and the volume fraction of the aluminum oxide in the high-entropy alloy / ceramic continuous-gradient composite coating is in continuous gradient change from the bottom layer to the top layer. The invention further provides a preparation method and device of the composite. By the adoption of the composite containing the high-entropy alloy / ceramic continuous-gradient composite coating and the preparation method and device of the high-entropy alloy / ceramic continuous-gradient composite coating, a conventional preparation method of the high-entropy alloy coating is broken through, the composite containing the high-entropy alloy coating is prepared through an aluminum thermal reaction, the step of compounding high-entropy alloy powder first of all during conventional coating preparation is omitted, and the composite containing the high-entropy alloy coating can be prepared through simple steps; and the whole technological process is ingenious in design and concept, the energy consumption in the preparation process is low, the steps are simple, and operation is easy.

Owner:HUNAN UNIV

Method for preparing ZrB2-Al2O3 composite powder

The invention belongs to the technical field of ceramics and refractory materials, and particularly relates to a method for preparing ZrB2-Al2O3 composite powder. Fe2O3 powder and metal Al powder are taken as raw materials of a thermit, the metal Al powder, ZrO2 powder and B2O3 powder are taken as raw materials for synthesizing the ZrB2-Al2O3 composite powder, and the heat emitted by a thermit reaction is utilized to ignite a reaction for synthesizing the ZrB2-Al2O3 composite powder. The method has a simple preparation technology, does not need special equipment and atmosphere, has cheap needed raw materials and small energy consumption and using time, and is environment-friendly; and the synthesized powder has high purity, fine granularity, and low manufacturing cost.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for preparing point contact electrode at back of solar cell by utilizing laser induced thermit reaction

InactiveCN101546790AAvoid damageReduce compound rateFinal product manufactureSemiconductor devicesBack surface fieldMaterials science

The invention discloses a method for preparing a point contact electrode at the back of a solar cell by utilizing laser induced thermit reaction, which comprises the following steps in sequence: plating a passivation media layer on the back of a silicon substrate; steam-plating an aluminum layer on the passivation media layer; printing or coating thermite on the aluminum layer; and igniting the thermite by the radiation of laser to result in the thermit reaction for generating high temperature so that the aluminum layer and the silicon substrate are molten and then are crystallized and form better ohmic contact and aluminum back surface field. The invention adopts laser to indirectly sinter an electrode, i.e. the laser is used to induce spontaneous reaction of the thermite, high temperature generated by the reaction make aluminum and the silicon from better ohm contact, therefore, the prepared solar cell has smaller series resistance; meanwhile, the aluminum and the silico forms the aluminum back surface field, and the prepared solar cell has bigger short circuit current. By adopting the method of the invention, the laser does not directly radiate a metallic film, which reduces the damage to the silicon to be lowest and further improves the short circuit current of the solar cell.

Owner:SUN YAT SEN UNIV

Method for reducing pouring temperature of iron-based surface composite material

The invention relates to an iron-based composite material and especially relates to a method for reducing pouring temperature of iron-based surface composite material through heat release of thermit reaction, wherein the principle is as follows: triggering the thermit reaction by heating molten iron, counteracting the cooling effect of a ceramic particle pre-forming block on the molten iron through the heat release part of the thermit reaction, and simultaneously forming an alloy having the ingredients the same as that of a high-chromium iron substrate through the thermit reaction; in order to generate no effect on the distribution of the ceramic reinforcement particles and improve the wearing resistance of the hexagonal prism hole or honeycomb hole part, the reactant of the thermit reaction is processed to a cylindrical shape and is added in the hexagonal prism hole or honeycomb hole of the ceramic particle pre-forming block, the reactant powder is mixed and is pressed to the cylindrical shape so as to conveniently process and apply the cylindrical reactant, and the reactant powder is wrapped by an aluminum foil to prevent the cylinder from being broken and prevent the reactant powder from dropping.

Owner:XINGHUA PRECISION CASTING & FORGING IND RES INST CO LTD

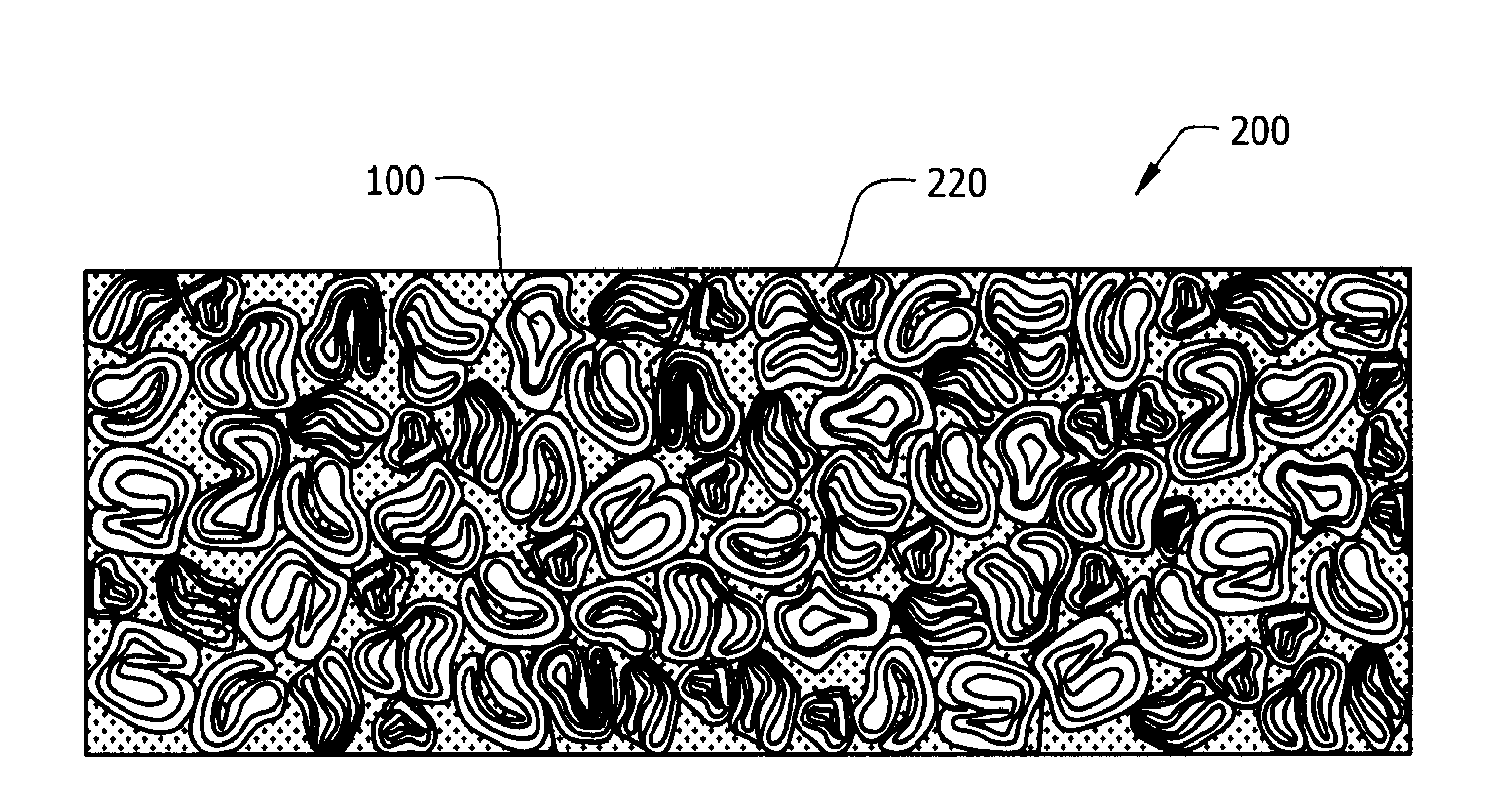

Thermite compositions, articles and low temperature impact milling processes for forming the same

ActiveUS20100193093A1Easy to controlLoomsExplosive working-up apparatusChemical compositionLayer thickness

A process for the preparation of composite thermite particles, and thermite particles and consolidated objects formed from a plurality of pressed composite particles. The process includes providing one or more metal oxides and one or more complementary metals capable of reducing the metal oxide, and milling the metal oxide and the metal at a temperature below −50° C., such as cryomilling, to form a convoluted lamellar structure. The average layer thickness is generally between 10 nm and 1 μm. The molar proportions of the metal oxide and metal are generally within 30% of being stoichiometric for a thermite reaction.

Owner:LOCKHEED MARTIN CORP +1

Thermite for hypergravity-assisted combustion synthesis of copper-based composite material

The invention belongs to the technical field of combustion synthesis preparation, and in particular relates to a thermite for hypergravity-assisted combustion synthesis of a copper-based composite material. According to the thermite provided by the invention, the formula employs a CuO powder with particle size in gradient distribution and an Al powder with particle size in gradient distribution, combustion rate and heat release amount in the preparation of the copper-based composite material is controlled by adding a Cu2O powder, a Cu powder, a MgO powder and a CaF2 powder, so as to realize stability and controllability of thermit reaction in the supergravity field. The thermite provided by the invention has the advantages of low sputtering rate, high heat release amount, stability and controllability, and is suitable for hypergravity-assisted combustion synthesis of various copper-based composite materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

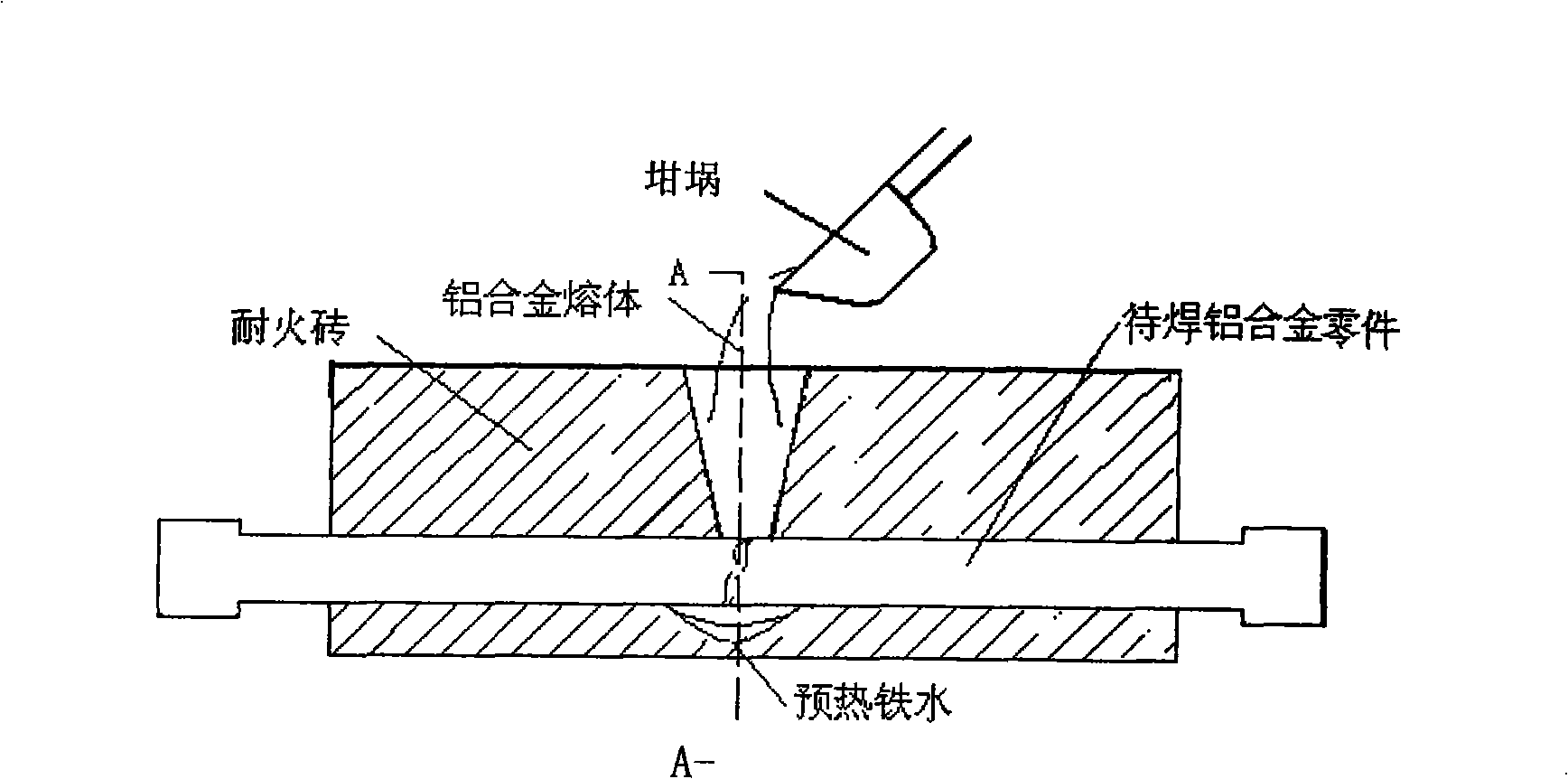

Aluminothermy welding method of aluminium alloy

InactiveCN101347868AEasy to carryImprove performanceAlumino-thermic welding apparatusCrucibleWeld seam

The invention relates to a thermit welding method of aluminium alloy, which comprises the following steps: preparing a thermit welding agent; placing the thermit welding agent in a crucible; embedding a TiC igniter into the thermit welding agent; exposing a part; igniting the exposed part; igniting the thermit welding agent in the crucible for thermit reaction; placing the solid aluminium alloy into the surface of reactants in the crucible immediately after the reaction is finished; using the residual heat to melt the solid aluminium alloy and obtaining the liquid aluminium alloy melt; preheating fractures of the aluminium alloy parts to be welded to the temperature of 390-410 DEG C when the former step is carried out; directly casting the aluminium alloy melt to the position of the fracture of the processed aluminium alloy parts; carrying out the densification processing by striking and extruding the welding seam when the metal to be seamed is just solidified and realizing the welding; and clearing weld flash by hands when the temperature is high. The thermit welding method of the invention is applicable to emergent and fast welding and repairing of aluminium alloy armor plates and aluminium alloy parts of armored equipment in battlefields and is also applicable to emergent welding and repairing of aluminium alloy parts of civilian vehicles or other machines in field working.

Owner:江阴东大新材料研究院

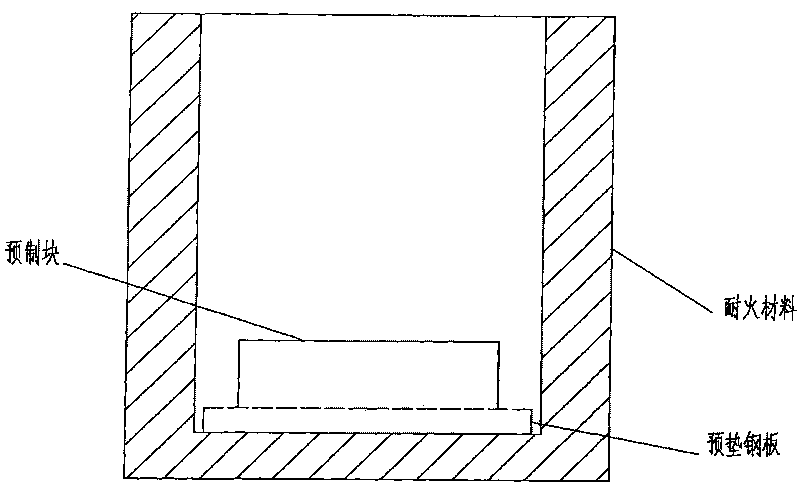

Production of abrasion-proof ceramic composite mold steel plate with self-propagating method

The invention relates to a manufacture technique for improving the wearing resistance of an extrusion forming mould material, and the manufacture technique can be applied to the industries such as a building material and a flame-proof material which need the extrusion forming mould. The manufacture technique aims to manufacture a ceramics iron and steel composite board, so as to improve the rigidity of the key place of the mould and strengthen the wearing resistance of the mould through cutting, inserting and welding the board to the extrusion mould. The manufacture technique mainly adopts the technical proposal that: with vibration and magnetic force, the separation problem of the thermit reaction liquid product of Fe and Al2O3 in self-spreading ceramics iron and steel composite manufacturing is solved, so as to reach the equal effect for separating the rotation inertia force. The main element of the mould comprises a flame-proof material box provided with the steel plate backing as the base, and reaction raw material Al as well as Fe2O3 mixed-powder which are filled-in at the upper opening of the flame-proof material box; one end of a steel mobile stage is fixedly provided with a speed-regulation vibration electric motor with eccentric quality, and the middle part of the steel mobile stage corresponding to the steel plate backing is punched with for fixing a permanent high magnet; the upper side of the magnet is parallel to the surface of a platform; the platform is connected with the base through a rolling bearing and a spring.

Owner:郑州大学橡塑模具国家工程研究中心

Molecular environment-friendly heat-release welding agent applicable to welding of copper conductor

InactiveCN101745756AMeet welding requirementsImprove welding qualityWelding/cutting media/materialsSoldering mediaCopper conductorAluminium powder

The invention discloses a heat-release welding agent for welding metal, and particularly relates to a novel molecular environment-friendly heat-release welding agent applicable to welding of copper conductors. The heat-release welding agent is prepared by the following ingredients according to weight part ratio: 50-75 parts of copper oxide with oxidation ratio of 50-60 percent and 40-80 meshes, 10-20 parts of aluminium powder with 60-80 meshes, 0.5-2 parts of aluminium oxide with 100-200 meshes, 0.5-2 parts of calcium fluoride with 200-400 meshes and 2-4 parts of graphite powder with 200-400 meshes. The novel molecular environment-friendly heat-release welding agent realizes the welding of copper conductors by the basic thermite reaction principle. By comprehensive experiment of the proportion and used materials of the formula, the novel molecular environment-friendly heat-release welding agent meets the temperature requirements of 3000 DEG C / 200g welding powder, so as to melt welding joints of the conductors completely and realize molecular welding. In addition, by adding the matters of graphite powder and aluminum oxide and the like to absorb harmful gases generated after reaction, the novel molecular environment-friendly heat-release welding agent realizes pollution-free welding.

Owner:XIAN JSBOUND TECH CORP

Process for integrally reducing solidified chromium slag

The invention discloses a process for integrally reducing solidified chromium slag, which comprises the following steps: firstly drying and refining chromium slag, uniformly mixing 15-20 parts of aluminum powder, 35-50 parts of oxidant and 30-45 parts of refined chromium slag, filling the mixture in a reactor, igniting to perform the solidifying reaction. Based on the thermit reaction, hexavalent chromium can be reduced as trivalent chromium with small toxicity, and the trivalent chromium can be fixed in lattice of a spinel to prevent the trivalent chromium from re-oxidizing as the hexavalent chromium, the extraction amount of the finally obtained solidified substance can achieve 10<-7>-10<-8> order of magnitude so as to completely detoxify the chromium slag. Furthermore, the process has the advantages of being energy-saving, large in slag-detoxifying amount and simple.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Method for preparing ceramic fiber and ceramic particle mixed composite coating on steel surface

The invention relates to a method for preparing a ceramic fiber and ceramic particle mixed composite coating on steel surface, which is applied to production of composite armored plates and wear-resistant and corrosion-resistant composite plates. The method comprises the following steps: soaking ceramic whiskers in distilled water, and stirring to disperse for 4 to 6 hours; adding water soluble organic sol in the soaked ceramic whiskers; performing ultrasonic oscillation and mixing; preparing a ceramic fiber precast block; drying the ceramic fiber precast block in a vacuum drying furnace or a drying furnace with protective argon; and putting a steel plate in a liquid forging die, putting the ceramic fiber precast block on the surface of the steel plate, preheating the die and the steel plate, casting a thermit reaction product onto the ceramic fiber precast block in the die for liquid forging, and preparing the steel plate with a metal matrix composite coating strengthened by ceramic fiber and ceramic particle multi-phase mixed ceramic. In the method, the strengthened particle surface is not polluted and has high bonding strength; and the method has simple and reliable process, and is easy to promote.

Owner:江阴东大新材料研究院

Environment-friendly sludge compound briquette fuel and preparation method thereof

The invention discloses an environment-friendly sludge compound briquette fuel and a preparation method thereof. The method comprises the steps of firstly, carrying out sludge dewatering pretreatment; uniformly mixing shell powder, aluminum powder and biomass powder to obtain a conditioner; then, cutting the dewatered sludge, mixing the dewatered sludge and the conditioner, pressing the mixture to form a granular material, drying, then, immersing the granular material into a layer of waste oil, and airing to obtain the environment-friendly sludge compound briquette fuel. The environment-friendly sludge compound briquette fuel is high in compressive strength larger than 95kPa and drop strength larger than 95% which are both far higher than the mechanical performance of briquette coal; the sulfur and chlorine fixation effects are good and can be respectively up to 85.4% and 87.8%; the calorific value can be up to 5025 kilocalories; the wet strength is up to 54.6kPa, the ignition point is reduced to 240 DEG C, the moisture resistance and waterproofness are remarkably improved, and the inflammability is enhanced; aluminum powder and combusting metal oxides can be subjected to reaction similar to aluminothermic reaction, so that the complete combustion of carbon granules is accelerated, reductive pollution gases are prevented from being generated, and the combustion activity is high; and in addition, the preparation method has the advantages of simplicity in operation, easiness for obtaining raw materials, low cost, little environment pollution and the like.

Owner:广州福之源环保科技有限公司

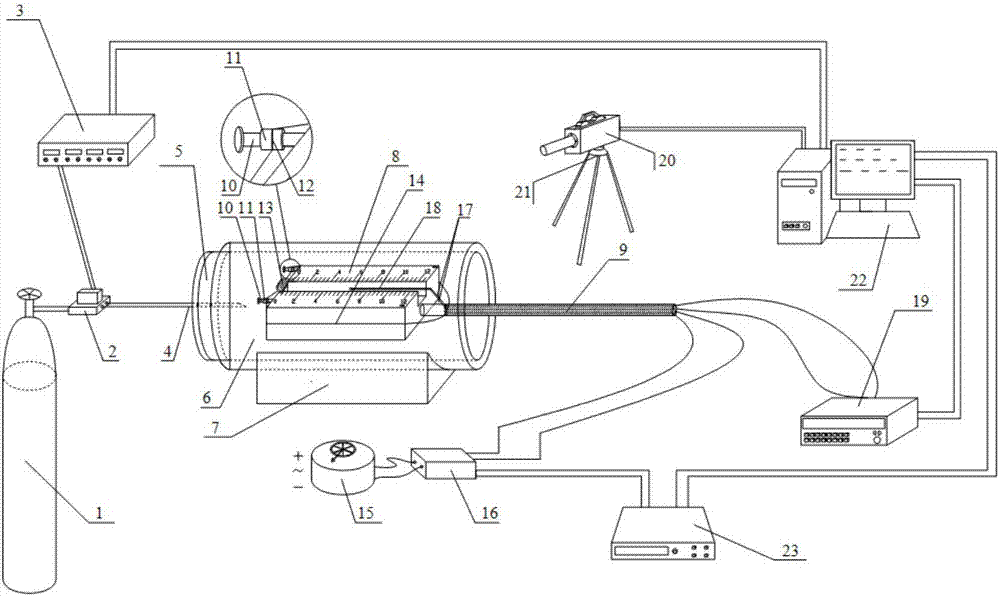

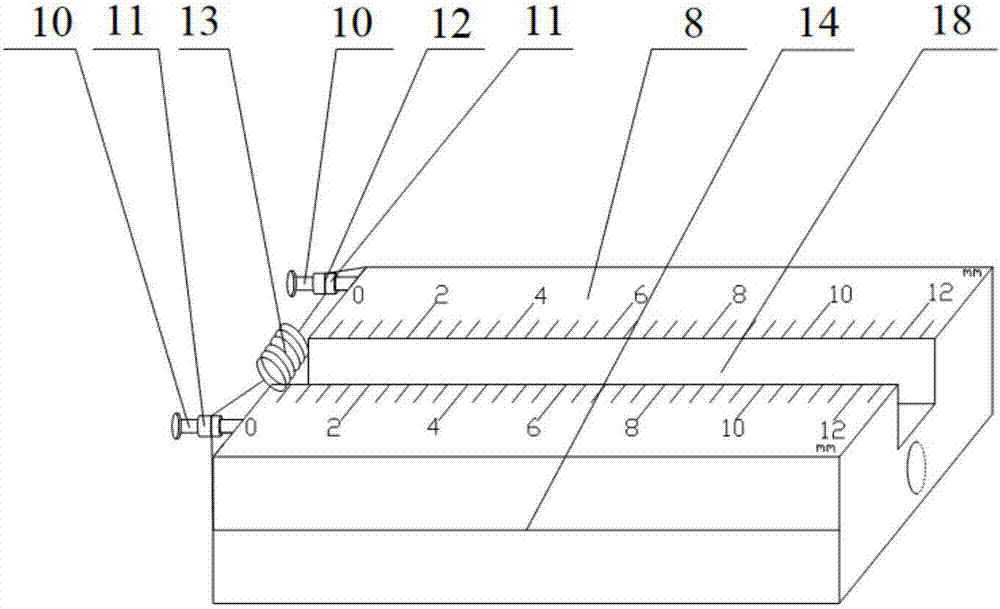

Thermit reaction temperature and combustion rate experimental measurement device and method

InactiveCN106908477AAccurate measurementAccurate flow adjustmentMaterial heat developmentMeasurement deviceCombustion

The invention discloses a thermit reaction temperature and combustion rate experimental measurement device and method and belongs to the technical field of energetic material performance testing. According to the thermit reaction temperature and combustion rate experimental measurement device, a high-temperature reaction mechanism comprises a protective pipe, a combustion tank and a tension bar, both ends of the protective pipe are provided with sealing plugs, the combustion tank is arranged inside the protective pipe, one end of the tension bar is detachably connected with the end portion of the combustion tank, and the other end of the tension bar penetrates one of the sealing plugs and extends out of the protective pipe; a gas supply mechanism is used for providing gas for thermit reaction of the high-temperature reaction mechanism; an ignition mechanism is used for igniting thermit reaction powder inside the high-temperature reaction mechanism; a combustion data collecting mechanism is used for collecting experimental data. The thermit reaction temperature and combustion rate experimental measurement device can achieve full-process monitoring of thermit reaction temperature and combustion rate change, meanwhile achieve the functions of combustion state visualization, experimental operation synchronous control and data collection and treatment integration and improve the accuracy and reliability of experimental results.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

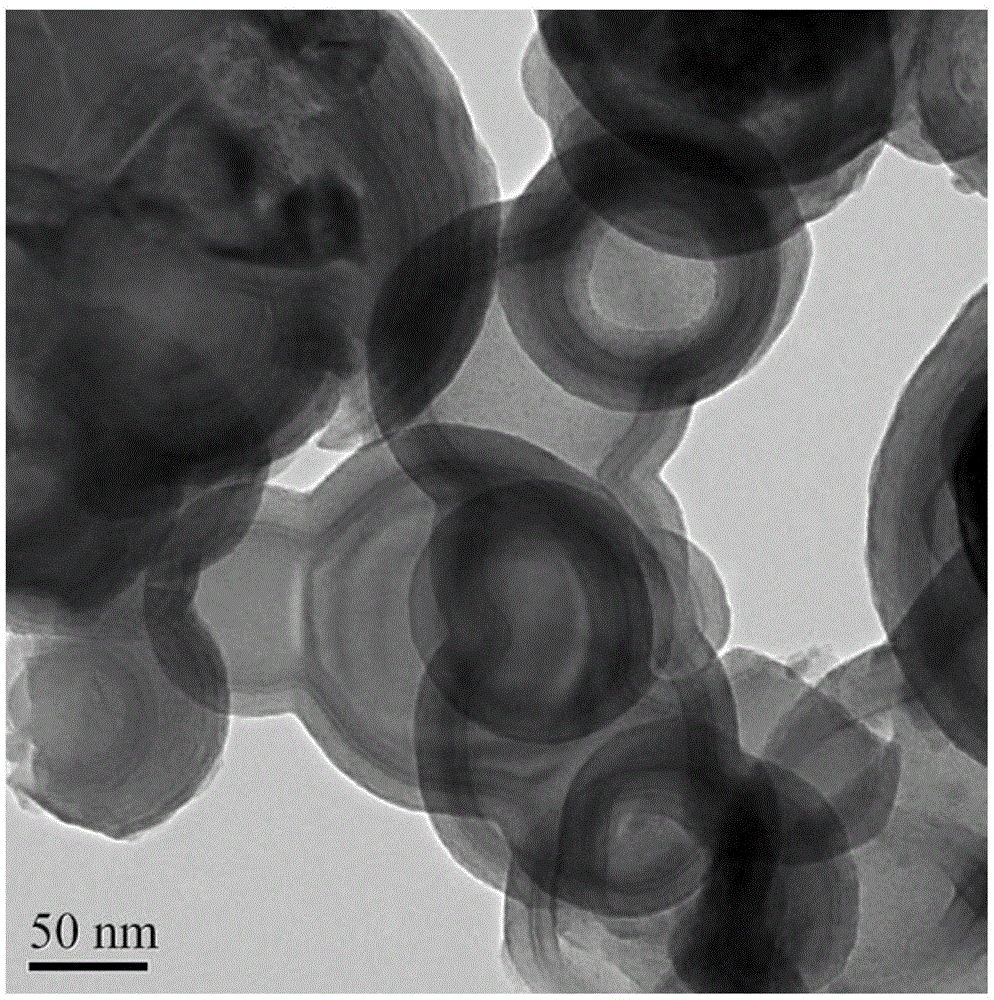

Preparation method of nanoscale core-shell structure super thermite

InactiveCN105624647AIncrease energy densityImprove controllabilityMaterial nanotechnologyChemical vapor deposition coatingMaterials preparationChemical reaction

The invention discloses a preparation method of a nanoscale core-shell structure super thermite and belongs to the technical field of nano material preparation. According to the method, two reaction former bodies alternatively pass through a reaction chamber, and chemical reaction is generated on the surfaces of nano aluminum powder particles to produce a metal oxide cladding shell. The cladding shell completely and uniformly covers on the overall outer surface of nano aluminum powder, and the thickness of the cladding shell can be accurately adjusted in a nanoscale scope according to the stoichiometric ratio of thermite reaction. The super thermite prepared by adopting the method disclosed by the invention has the characteristics of being accurate and adjustable in shell thickness in nanoscale, perfect in shell structure, high in ignition speed, high in energy release efficiency and complete in reaction. The method is high in automation degree and good in safety performance, and the nano aluminum powder particles can be directly used without aftertreatment after cladding is completed and are easy to realize and popularize in industry.

Owner:XIAN MODERN CHEM RES INST

Ceramic lining composite copper tube production method

InactiveCN1460731AImprove protectionSimple processMetallic material coating processesHardnessVolumetric Mass Density

The aluminothermics prepared with CuO and Al is placed in the copper pipe, the aluminothermics also contains 2%-8% of SiO2, 1%-5% of CrO3, 2%-4% of Na2B4O7 and 2%-8% of ZrO2, the copper pipe in which the aluminothermics is placed is placed on the centrifuge, then the centrifuge is started, and the aluminothermics is lighted to make it produce 3CuO+2Al-Al2O3+3Cu+1194.4 KJ / mol aluminothermal reaction, and the heat quantity of discharged by said aluminothermal reaction can make product be molten instantaneously, under the action of centrifugal force the molten product can be separated according to its different density, after cooled, the Al2O3 ceramic lined composite copper pipe can be formed. The composite pipe has high hardness ceramic layer, good abrasive resistance.

Owner:XI AN JIAOTONG UNIV

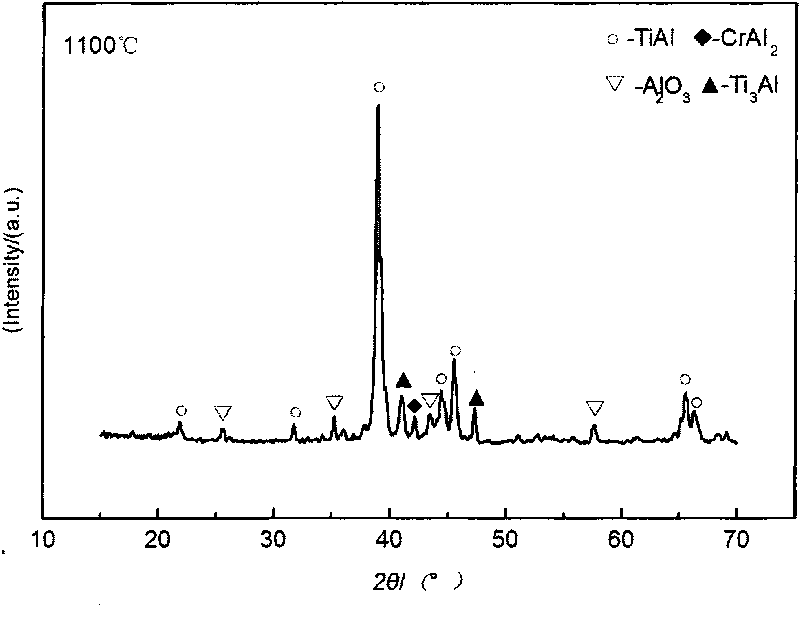

TiAl intermetallic compound composite material and preparation method thereof

InactiveCN101701305AThe ingredients are highly adjustableLower firing temperatureAl powderGeneration process

The invention relates to a TiAl intermetallic compound composite material and a preparation method thereof. 21.45-63.14% of Ti powder, 36.12-39.69% of Al powder and 0.74-38.87% of Cr2O3 powder in percentage by weight are utilized for hot pressed sintering process, particles reinforcement phase is automatically generated in the generation process of a matrix phase through thermit reaction, fine composite material of TiAl that an Al2O3 dispersed phase toughens a matrix phase, and microalloying improvement is carried out on the matrix phase by the generated Cr in the reaction; as the composite material has highly adjustable components, low firing temperature, even and compact structure, lower cost and excellent mechanical property, the application range is widened; in addition, the method reduces the firing temperature and hot pressing pressure, and realizes micritization of crystalline grains in rapid firing.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method for foamed aluminum composite material

The invention discloses a preparation method for foamed aluminum composite material, and belongs to the field of foamed aluminum material. According to the invention, stannic oxide, calcium carbonate and aluminum powder are adopted as raw material and are placed into a reaction still, the aluminum powder generates thermit reaction and is finally resolved into calcium oxide and carbon dioxide by guiding nitrogen gas into the reaction still and adopting magnesium rods as ignition agents, then the generated calcium oxide and the generated carbon dioxide are mixed with foaming agents ENJ-3029 and polyacrylamide and then are dissolved into water for forming slurry, the slurry is sprayed on manufactured foaming blanks, then the foaming blanks are dried, and finally the foamed aluminum composite material is obtained. Through the examples, the preparation method is unique and novel, the shortcomings that the cost is high and the resolving speed is high when TiH2 and calcium metal are adopted as foaming agents and thickening agents respectively are overcome, and the manufactured foamed aluminum material is high in yield and can be widely applied.

Owner:CHANGZHOU YAHUAN ENVIRONMENTAL PROTECTION TECH

Self-propagating brazing heat source medicinal powder, self-propagating brazing device and preparation method thereof

InactiveCN101972905AEasy to makeThe welding operation is simple, fast and safeWelding/cutting media/materialsAlumino-thermic welding apparatusHeat conductingThermal deformation

The invention discloses self-propagating brazing heat source medicinal powder, a self-propagating brazing device and a preparation method thereof. 20 to 45 mass percent of Fe2O3 powder, 10 to 30 mass percent of Al powder and 30 to 50 mass percent of CuO powder are uniformly ground to obtain heat source medicinal powder; the heat source medicinal powder is filled into a heat temperature-resistant container of which a bottom part is provided with a through hole, a brazing heat-conducting tank of which a bottom part is open is put into the heat temperature-resistant tank to squeeze the heat source medicinal powder between two containers, a brazing filler metal is positioned in the brazing heat-conducting tank, and a lead is inserted into the heat source medicinal powder. During the welding, the self-propagating brazing heat source medicinal powder is put at a to-be-welded position of a workpiece, the lead is ignited, welding powder performs thermit reaction and discharges heat to melt the brazing filler metal, and the brazing filler metal is dropped at the to-be-welded position to form a welding seam. In the invention, the welding powder is utilized to perform the thermit reaction and discharge heat to melt the brazing filler metal so as to realize welding without any welding equipment or a power supply, the welding operation is simple, convenient, rapid and safe, a thermit reaction product can be well separated from the brazing filler metal, the welding seam is relatively pure, the heat input is low, the thermal deformation of a parent metal is low, and controllability is high.

Owner:TIANJIN UNIV

Novel die cast cap port sphere composite heating agent and production method thereof

The invention discloses a novel die cast cap port sphere composite heating agent and a production method thereof. The novel die cast cap port sphere composite heating agent consists of spheres and sphere coatings, wherein the spheres are prepared by processing aluminum powder, sodium nitrate, ferric oxide powder, fluorite powder and bonding agent serving as raw materials; and the sphere coatings consist of acidized graphite. The production method comprises the following steps of: mixing and stirring the raw materials, pressing the raw materials into spheres, coating the spheres, and recoatingthe spheres to obtain a qualified product. According to the product obtained by the technical scheme of the invention, the spheres are basically not expanded with heating in the steelmaking casting use process, the raw material density (concentration) of the heating parts of the spheres is not changed, the heating reaction of the spheres is quick, the heating temperature can reach over 1,650 DEG C, secondary feeding effect is fully realized, the head of a casting blank forms good 'dish-shaped' shrinkage, the yield of the casting blank is improved by over 7 percent, and the content of the aluminum powder is greatly reduced so that the production cost is reduced.

Owner:HENAN XINLONG METALLURGICAL MATERIAL GROUP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com