Method for preparing ceramic fiber and ceramic particle mixed composite coating on steel surface

A technology of ceramic fiber and composite materials, which is applied in the field of material processing engineering, can solve the problems of surface pollution, low bonding strength, and easy peeling of reinforced particles, and achieve small size, clean surface, and small whisker aspect ratio loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

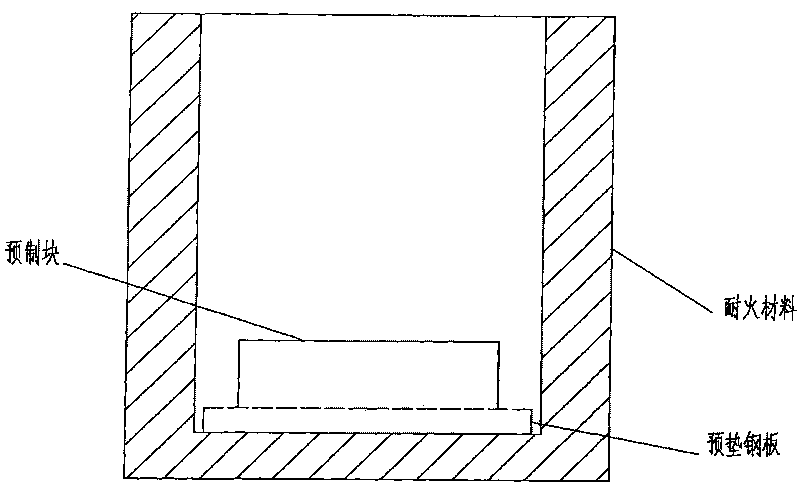

[0022] (1), making ceramic fiber prefabricated blocks

[0023] a. First soak ceramic whiskers (100g) in distilled water and stir and disperse them with a marine screw agitator for 4-6 hours. On the electric drill, put the stirring head into the beaker, stir and disperse for 4-6 hours, and pour out the water on the upper part of the whiskers after precipitation.

[0024] b. Add 1 g of water-soluble organic sol to the soaked ceramic whiskers. The mass ratio of the water-soluble organic sol is composed of: 80 parts of water, 3 parts of polyvinyl alcohol, 3 parts of glycerol, and 3 parts of silica sol .

[0025] c. After adding the water-soluble organic sol, perform ultrasonic oscillation and stirring. The output power of the ultrasonic wave is 150W-250W, and the oscillation and stirring time is 4-6 hours.

[0026] d. Pour the ceramic whiskers containing the water-soluble organosol into a mold with a filter screen at the bottom to filter.

[0027] e. According to the volume fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com