Micro-nano particle reinforced aluminum-based composite material and preparation method thereof

A technology of micro-nano particles and composite materials, applied in the field of aluminum-based composite materials and their preparation, can solve problems such as difficulty in uniform dispersion, and achieve the effects of improving interface wettability, reducing reaction temperature, and reducing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 The micro-nanoparticle reinforced aluminum-based composite material is prepared by the following process:

[0033] Step 1, preparation of silicon carbide / copper oxide composite powder:

[0034] a, respectively configure the copper sulfate solution A of 0.34mol / L and the sodium hydroxide solution B of 20mol / L;

[0035] b. Add the silicon carbide powder with a particle size of 50um to the molar ratio of 1:1 to the solution A and stir to obtain a mixed suspension of C. The stirring time is 15min;

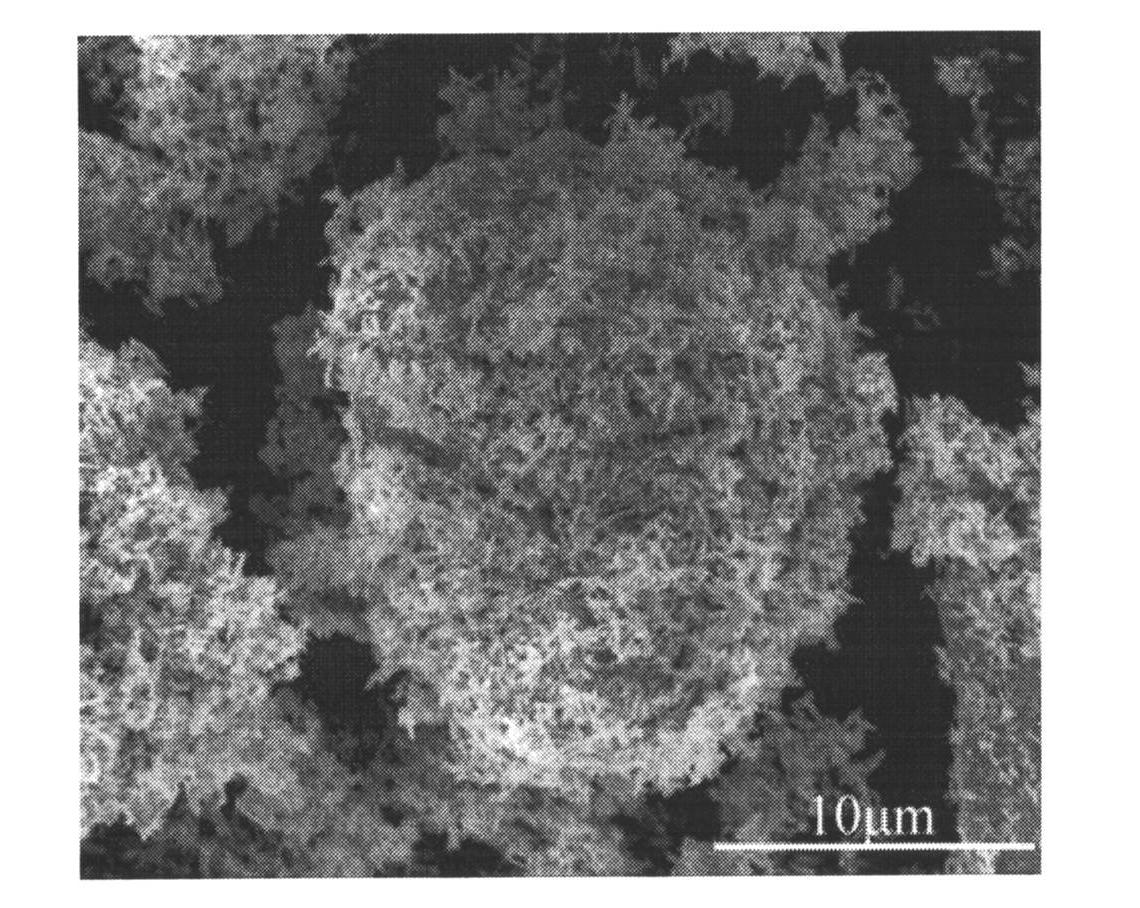

[0036] c. Mix B solution and C suspension to obtain D solution, stir at 20°C at a stirring speed of 100rpm for 30min; d, vacuum filter the product in D solution, bake at 150°C for 6h, and grind. Obtained composite powder, its morphology and structure are as follows Figure 2a , 2b shown;

[0037] Step two, see figure 1 , using the method of stirring casting combined with in-situ reaction to prepare micro-nanoparticle-reinforced aluminum matrix composites:

[0038...

Embodiment 2

[0042] The difference between this example and Example 1 is that the reaction temperature when solution B is added to solution C is 30°C. see Figure 3a , under the same conditions, the coating effect at a temperature of 30°C is not as good as that at a temperature of 20°C.

Embodiment 3

[0044]The difference between this example and Example 1 lies in that the reaction temperature when solution B is added to solution C is 40°C. see Figure 3b , it can be seen that the coating effect at a temperature of 40°C is not as good as that at a temperature of 20°C and 30°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com