Brazing material and preparing method thereof

A technology of brazing materials and flux paste, applied in the direction of welding/cutting media/materials, welding equipment, welding media, etc., can solve problems such as difficult connection, stable chemical properties, and lower brazing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

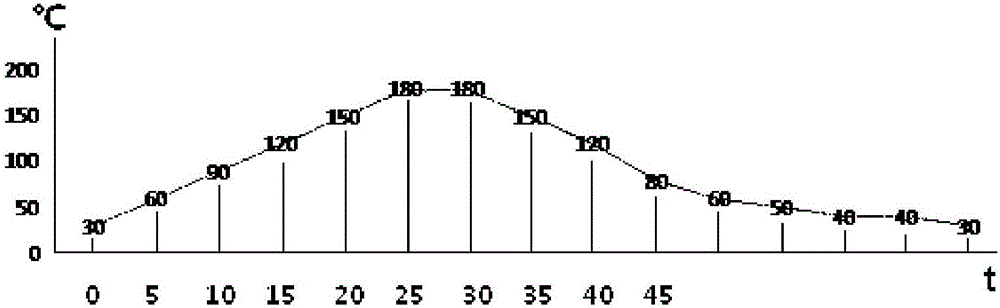

Image

Examples

Embodiment 1

[0032] Brazing materials include the following materials:

[0033] 80 parts by weight of metal alloy powder and 20 parts by weight of solder paste;

[0034] Wherein the metal alloy powder consists of the following materials: 1 part by weight of metal bismuth Bi, 1 part by weight of metal silver Ag and 98 parts by weight of metal tin Sn;

[0035] The purity of the above-mentioned metal bismuth is 99.99%;

[0036] The purity of the above-mentioned metallic silver is 99.99%;

[0037] The purity of the above-mentioned metallic tin is 99.99%;

[0038] The parts by weight of each material in the soldering paste are: 4.8 parts by weight of polymerized rosin, 4.8 parts by weight of polydimethylsiloxane, 9.6 parts by weight of tetraethoxysilane, 0.95 parts by weight of triethanolamine, and 0.48 parts by weight of phytic acid, SiO24.37 parts by weight.

[0039] Method of preparing brazing material:

[0040] Step 1, preparation of Sn-Bi alloy intermediate

[0041] Weigh 2 parts by ...

Embodiment 2

[0052] Brazing materials include the following materials:

[0053] 90 parts by weight of metal alloy powder, 10 parts by weight of solder paste;

[0054] Wherein the metal alloy powder consists of the following materials: 20 parts by weight of Bi, 0.1 parts by weight of Ag and Sn79.9 of parts by weight;

[0055] The purity of the above-mentioned metal bismuth is 99.99%;

[0056] The purity of the above-mentioned metallic silver is 99.99%;

[0057] The purity of the above-mentioned metallic tin is 99.99%;

[0058] The parts by weight of the materials in the soldering paste are: 3.85 parts by weight of polymerized rosin, 3.85 parts by weight of phenylmethylsiloxane homopolymer, 0.38 parts by weight of triethanolamine, and 1.92 parts by weight of Al2O3.

[0059] Method for preparing brazing material:

[0060] Step 1, preparation of Sn-Bi alloy intermediate

[0061] Sn and Bi weigh 30 parts by weight of Sn and 20 parts by weight of Bi according to the weight ratio of 1.5:1, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com