Preparation method for flux-cored electrode

A flux-cored electrode and flux-cored wire technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of increased processing difficulty, poor deep processing performance of silver solder, and influence on the promotion of silver solder containing 20-45% silver Application and other problems, to achieve the effect of lowering the brazing temperature, simplifying the brazing process, and difficult to control the amount of flux added

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

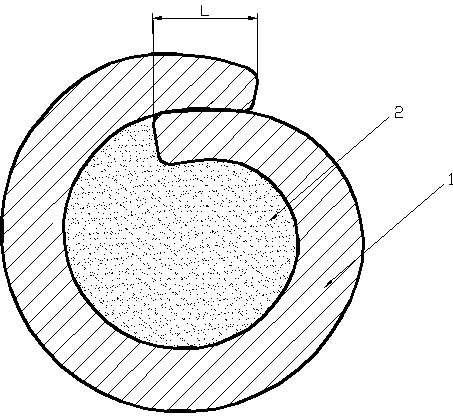

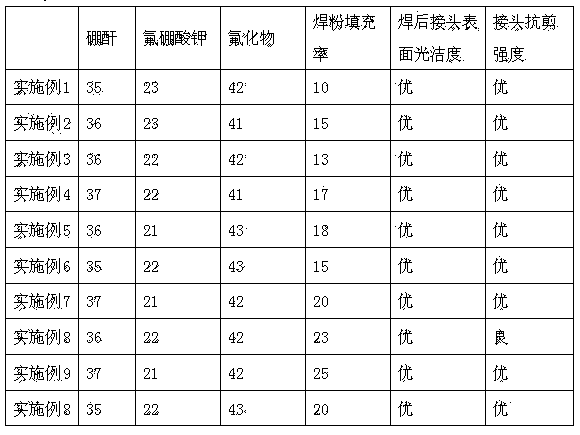

[0013] see figure 1 , the preparation method of the flux-cored electrode of the embodiment of the present invention is by the following steps: the silver-containing 20-45% silver brazing material 1 is prepared into a thin strip with a thickness of 0.1-0.5mm, which is treated by annealing and cleaned to remove surface dirt and Oxidation, roll crimp deformation again, form the U-shaped belt of upward opening, after powdery silver brazing flux 2 vibrates to conveyor belt from funnel, silver brazing flux 2 is transported in U-shaped belt by conveyor belt (the powdery silver flux 2 Silver brazing flux 2 is placed in a transparent funnel such as a visible glass funnel to visually check whether there is any powder, and the required powder is added regularly and timely), and then rolled and deformed to become an overlapping tubular structure (that is, U-shaped The open end of the belt overlaps to form a tubular solder) to form a flux-cored wire of the required specification. The width...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com