Improvement and heat treatment process of stainless steel 1.4740 material

A stainless steel and material technology, applied in the field of heat treatment, can solve problems such as uneven structure, long annealing cycle, and uncontrollable hardness, and achieve the effect of uniform structure, elimination of residual stress, and controllable hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: A heat treatment process for stainless steel 1.4740 material. The stainless steel 1.4740 material to be treated is normalized at a temperature of 850°C and kept for 5.5 hours.

Embodiment 2

[0023] Embodiment 2: A heat treatment process for stainless steel 1.4740 material. The stainless steel 1.4740 material to be treated is normalized at a temperature of 880°C, kept for 5 hours, and the carbon potential in the furnace is 0.18.

Embodiment 3

[0024] Embodiment 3: A heat treatment process for stainless steel 1.4740 material. The stainless steel 1.4740 material to be treated is normalized at a temperature of 900° C., kept for 4.55 hours, and the carbon potential in the furnace is 0.18. Then, it is directly air-cooled in the furnace to 200° C. and released from the furnace.

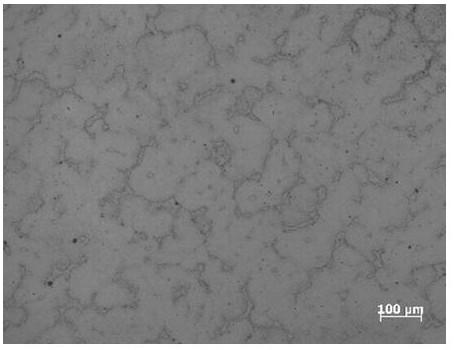

[0025] The as-cast microstructure is obtained as figure 1 shown.

[0026] Compared with the prior art, the present invention reduces hardness, improves processing efficiency, optimizes carbide form, and solves pitting caused by surface decarburization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com