Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73results about How to "Reduce embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

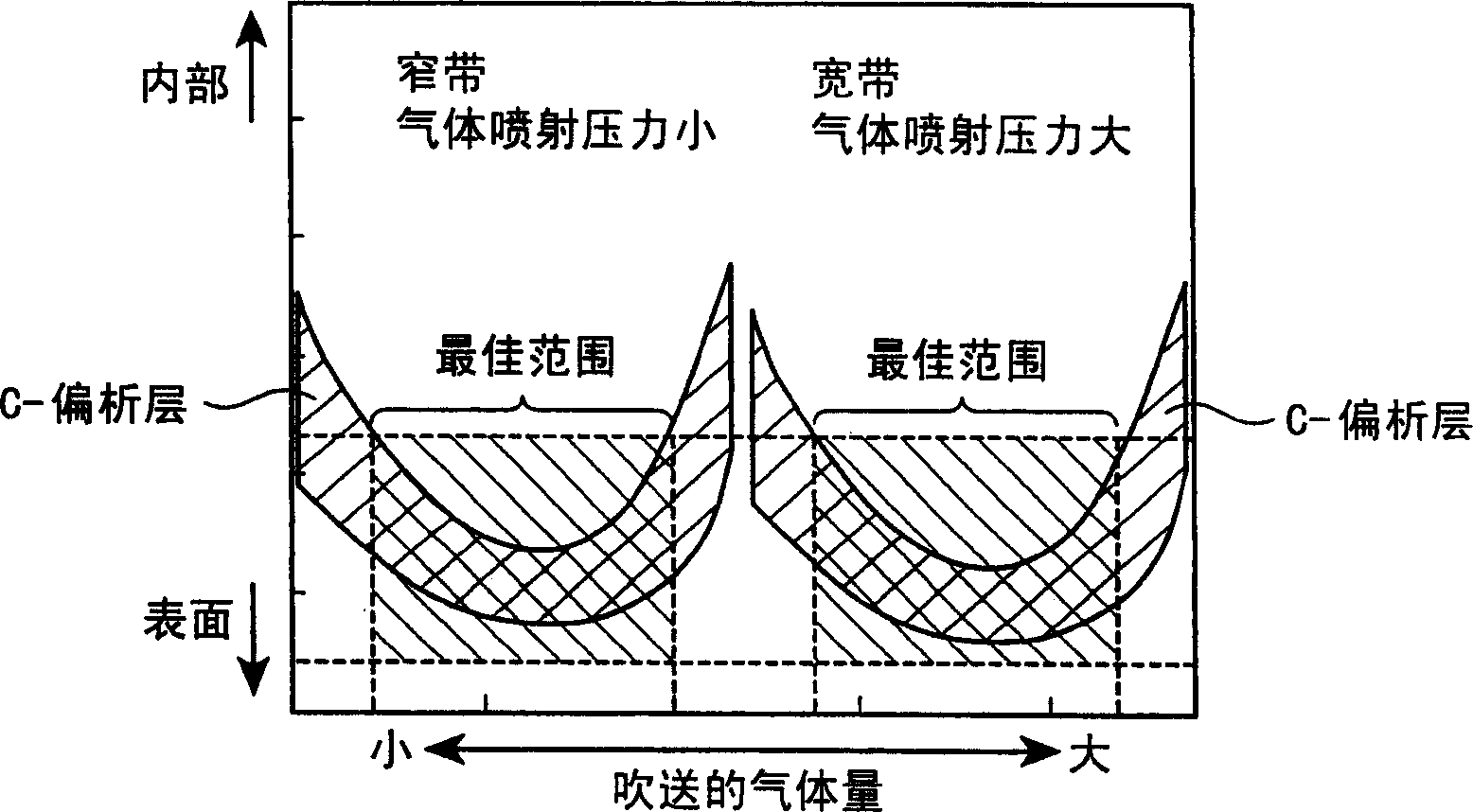

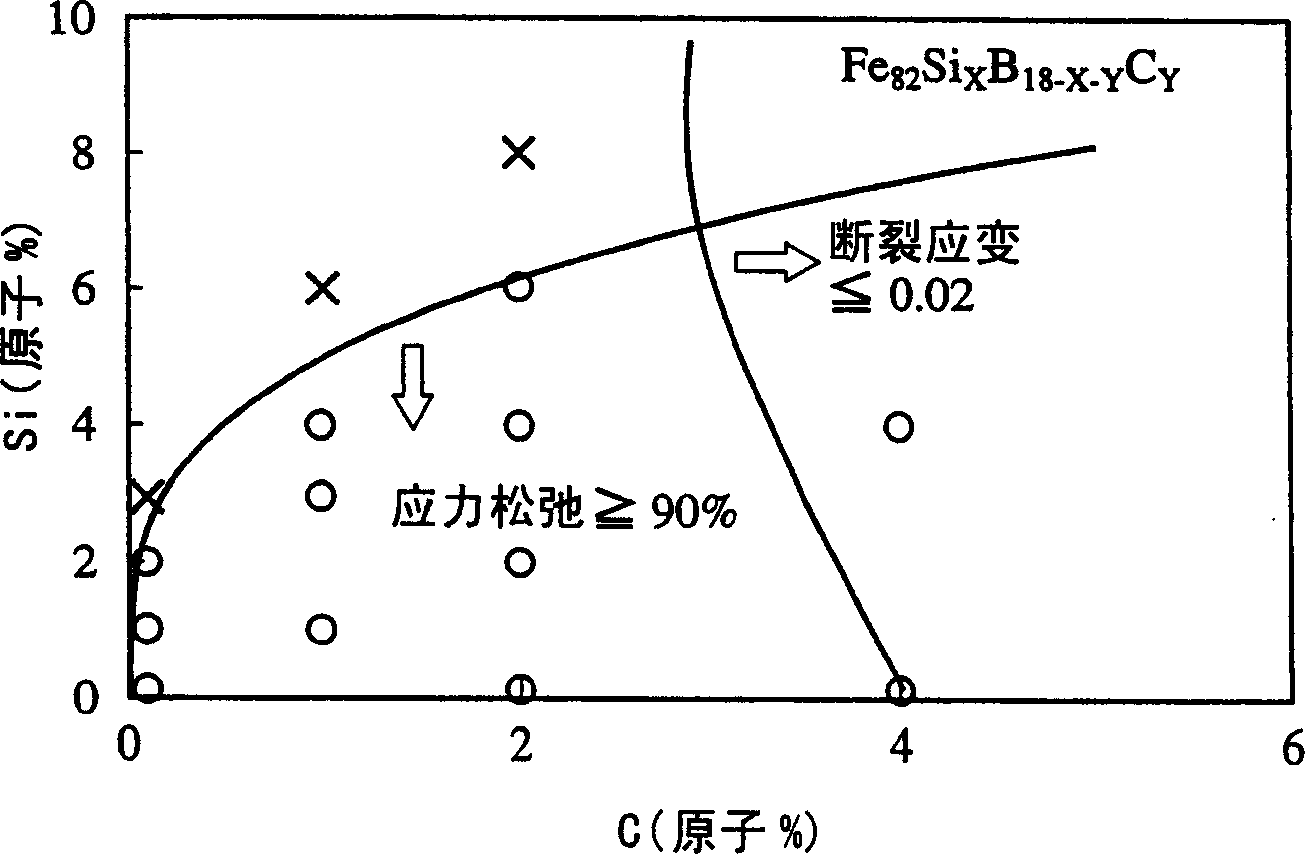

Fe-based amorphous alloy ribbon

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 76 to 83.5 atomic %, b is 12 atomic % or less, c is 8 to 18 atomic %, and d is 0.01 to 3 atomic %, the concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

Low-alloy heat-resistant steel submerged arc welding wire

InactiveCN101407000ASufficient creep strengthEnough lasting strengthArc welding apparatusWelding/cutting media/materialsCelsius DegreeToughness

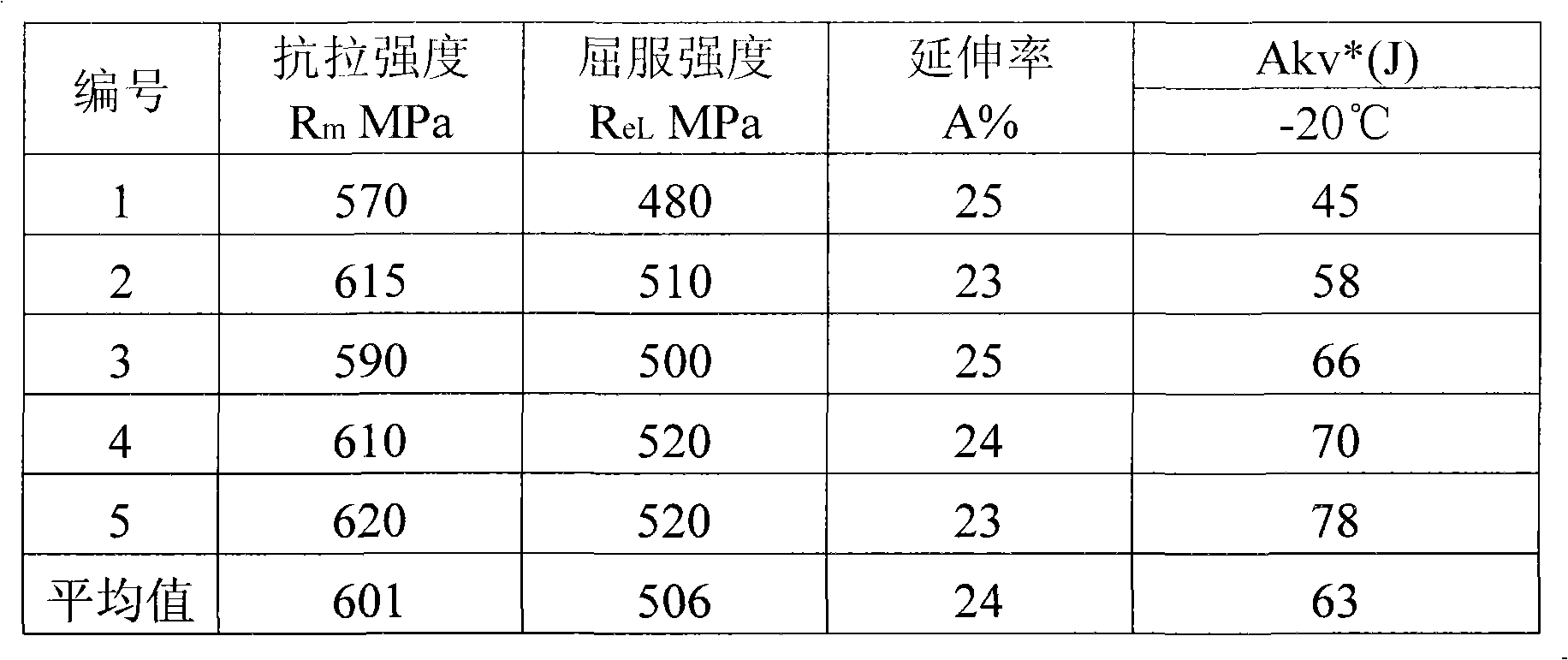

The invention relates to a low alloy heat-resisting steel submerged arc-welding wire, wherein the welding wire comprises the following components in weight percent: 0.05 to 016 of C, 0.40 to 1.00 of Mn, 0.05 to 0.35 of Si, less than and equal to 0.015 of S, less than and equal to 0.015 of P, less than and equal to 0.35 of Cu, 0.70 to 1.60 of Cr, less than and equal to 0.20 of Ni, 0.40 to 0.80 of Mo, less than and equal to 0.005 of V and the balance being Fe. Besides C, Si, Mn, S and P, the welding wire adopts a Cr-Mo alloy element heat-resisting system, the designed composition is simple, and the welding wire has the same strength, toughness and heat tolerance as the low alloy heat-resisting steel 12CrMo steel; the comprehensive performance of the deposited metal obtained by the welding wire is as follows: the yield strength is more than and equal to 485MPa, the tensile strength is more than and equal to 550MPa, and the elongation is more than and equal to 20 percent; and, the Akv at the temperature of 20 Celsius degrees below zero is more than and equal to 27J.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Nanostructure tungsten alloy and preparation method thereof

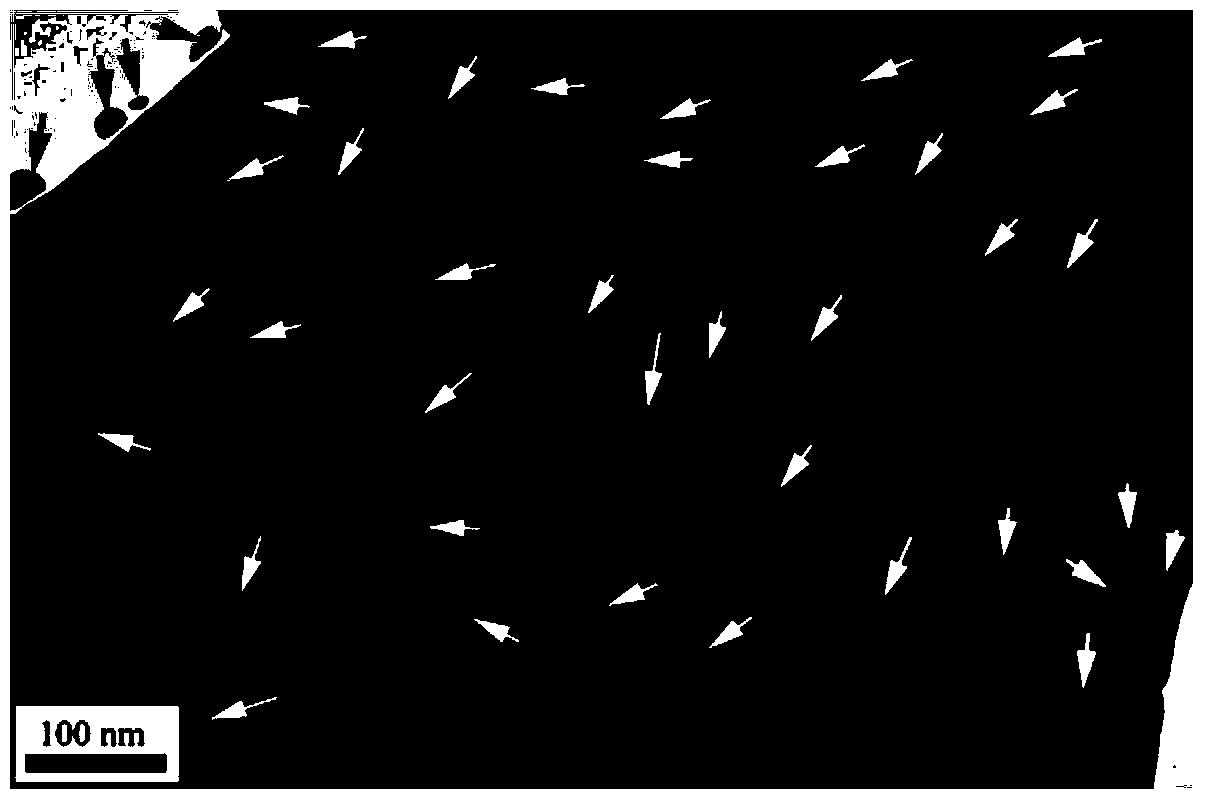

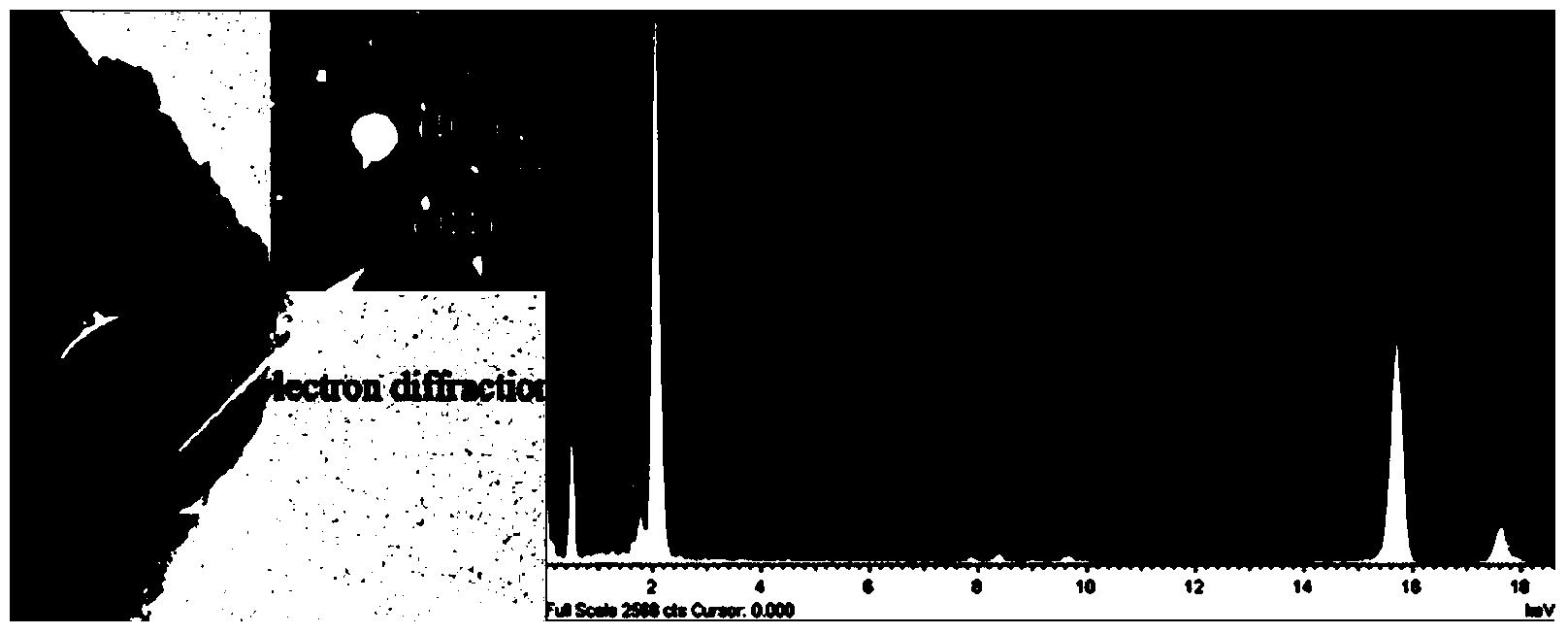

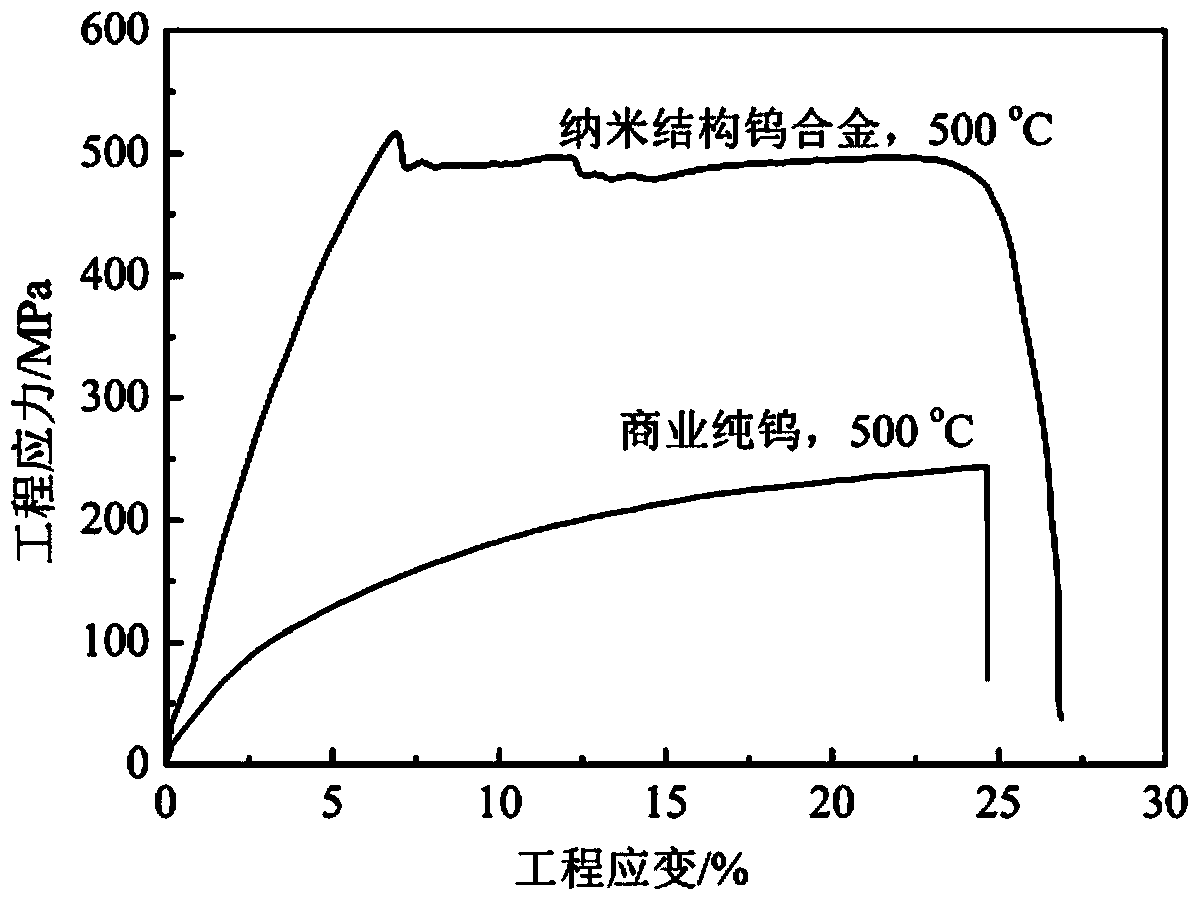

The invention discloses nanostructure tungsten alloy and a preparation method thereof. The alloy mainly comprises tungsten, and also comprises 0.05 to 1.0wt percent of zirconium and 0.2 to 2.0wt percent of rare-earth metal oxide particles, wherein the rare-earth metal oxide particle adopts yttrium oxide particles, lanthanum oxide particles or cerium oxide particles distributed in tungsten crystal particle. The method comprises the steps of firstly preparing ammonium paratungstate, rare-earth metal nitrate, citric acid and deionized water into transparent mixed liquor, stirring the transparent mixed liquor, obtaining gel after reaction, heating and drying the gel, then calcining the gel, so as to obtain a mixed powder of tungsten oxide and rare-earth metal oxide, putting the mixed powder into hydrogen atmosphere, so as to obtaining a mixed powder of tungsten and rare-earth metal oxide after reduction reaction, mixing the mixed powder with zirconium and zirconium hydride powder, so as to obtain a mixed powder of tungsten, zirconium, or zirconium hydride, and rare-earth metal oxide, and finally performing compaction and sintering to the mixed powder, so as to obtain the nanostructure tungsten alloy. The nanostructure tungsten alloy can be applied to fields of lighting, high-temperature components, aerospace devices, high temperature resistance containers and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

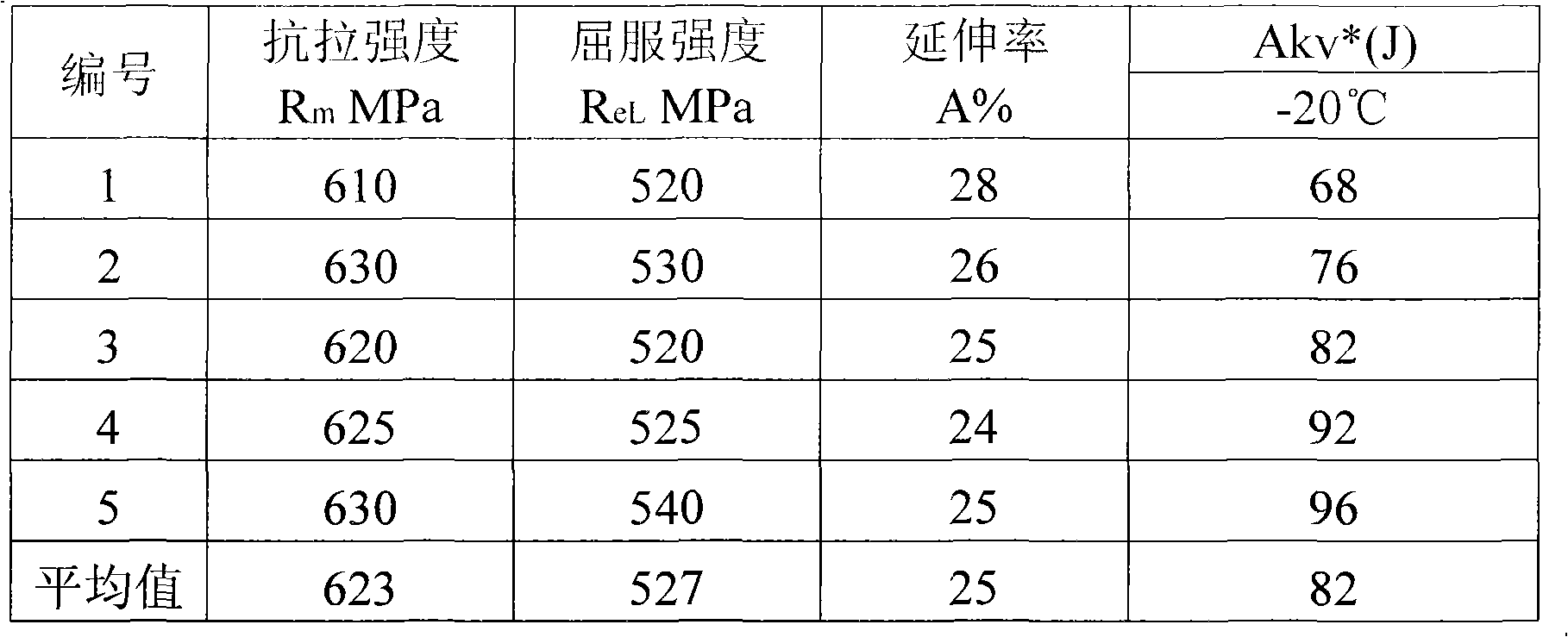

High-strength heat-resistant steel submerged arc welding wire

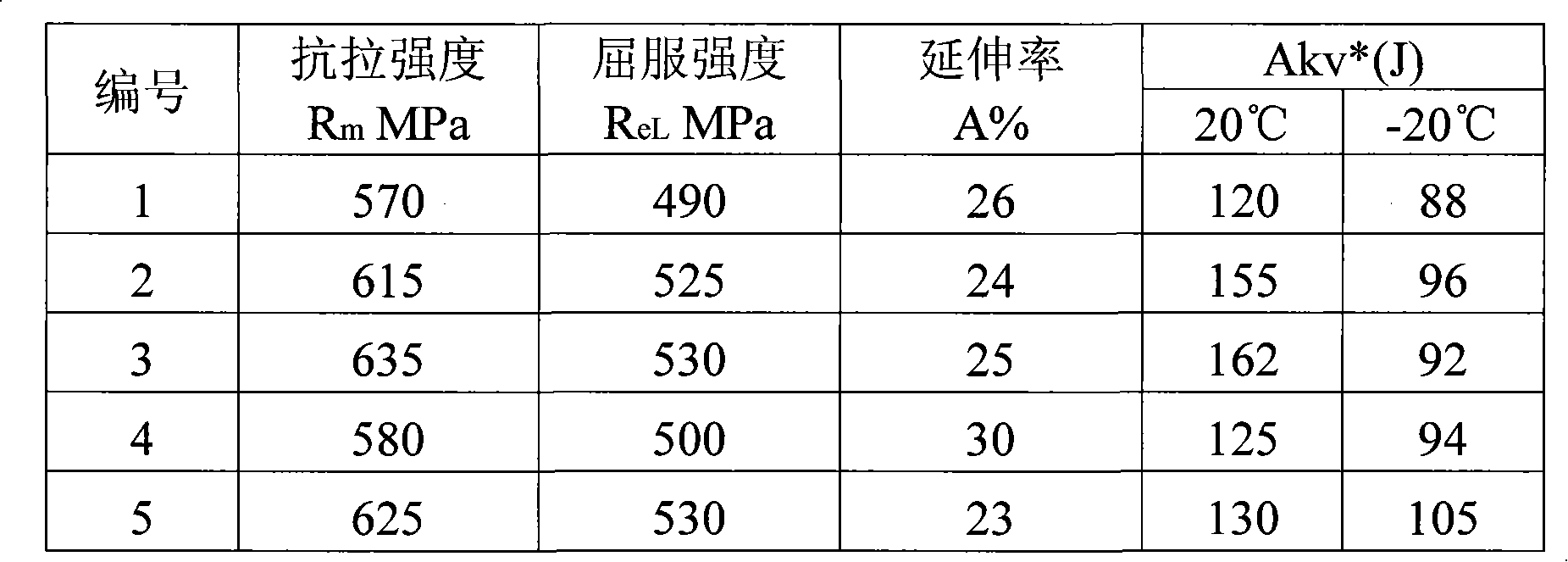

InactiveCN101332547ASimple designAchieve high strength, high toughness and high heat resistanceWelding/cutting media/materialsSoldering mediaHeat resistanceHigh intensity

The invention provides a high-intensity and heat-resisting steel submerged arc welding wire which comprises the following components and weight percentages: 0.10 - 0.16% of C, 0.60 - 1.10% of Mn, 0.30 - 0.60% of Si, not more than 0.025% of S, not more than 0.025% of P, not more than 0.35% of Cu, 1.10 - 1.85% of Cr, not more than 0.50% of Ni, 0.50 - 0.80% of Mo, and sufficient Fe. The high-intensity and heat-resisting steel submerged arc welding wire of the invention has simple design components, the obtained deposited metal and welding joint have good high-temperature and high-pressure resistance performance, and can reduce the occurrence of embrittlement resulted from long-time use under high temperature conditions and have good comprehensive properties particularly under high temperature working conditions; the high-intensity and heat-resisting steel submerged arc welding wire can ensure that the obtained deposited metal and welding joint have enough creep strength, endurance strength, persistent plasticity, good high-temperature structural stability and heat resistance and good obdurability, and good welding process property.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

Ultrathin cast film as well as preparation method thereof and application thereof

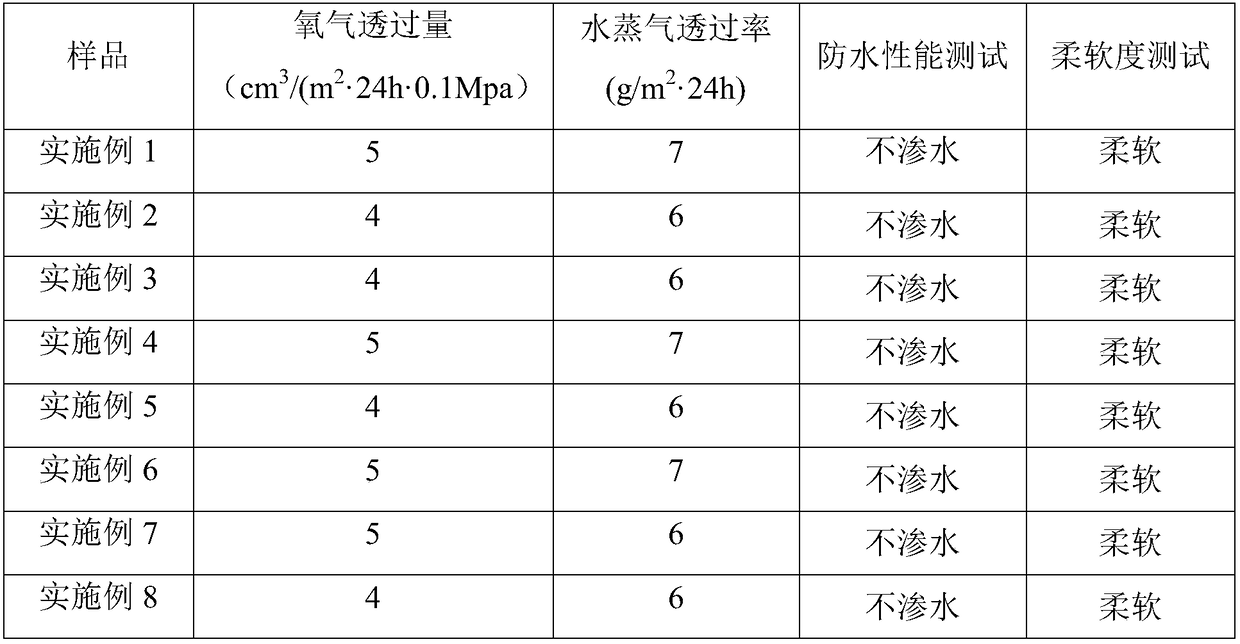

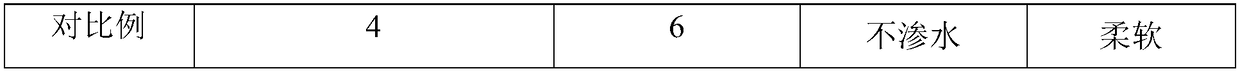

InactiveCN108129735AImprove water barrier effectEasily brokenFlexible coversWrappersCast filmsMaterials science

The invention discloses an ultrathin cast film. According to the technical scheme, the key point isThe ultrathin cast film is characterized that the ultrathin cast filmby comprises comprising the following components: 7-12 parts of LDPE, 20-25 parts of LLDPE, 30-55 parts of HDPE, 3-5 parts of MLLDPE, 1-3 parts of PP and 5-8 parts of color master batch. The invention further discloses a preparation method for the ultrathin cast film, and the preparation method comprises the following steps: adding materials; performing extrusion plastifying; , extrusion casting, calendaring, setting and cooling; performing corona treatment; and trimming and rolling, wherein during calendaring, setting and cooling, the temperature of a rubber roller is set to be 50-55 DEG C, the temperature of an embossed steel stick is set to be 60-65 DEG C and pulling speed is 60-80 m / min. On the premise of keeping barrier properties, waterproof properties, softness, tensile properties and breakage properties of the cast film, the thickness of the cast film is reduced, the unit weight yield is increased, and the cost is reduced.

Owner:天津市德利塑料制品有限公司

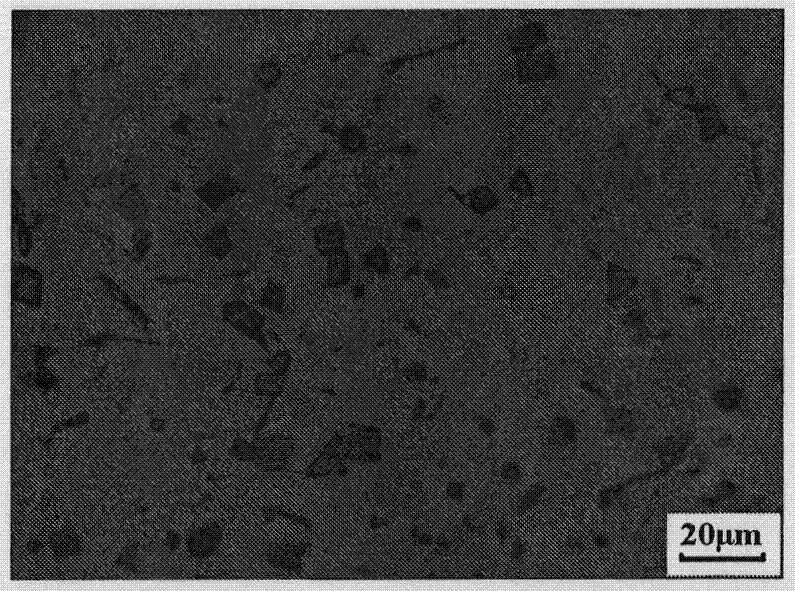

Forging technology of Hastelloy C-276

ActiveCN109590421AGrain Boundary Embrittlement Phase ReductionEliminate forging crackingHeating/cooling devicesEmbrittlementStaying time

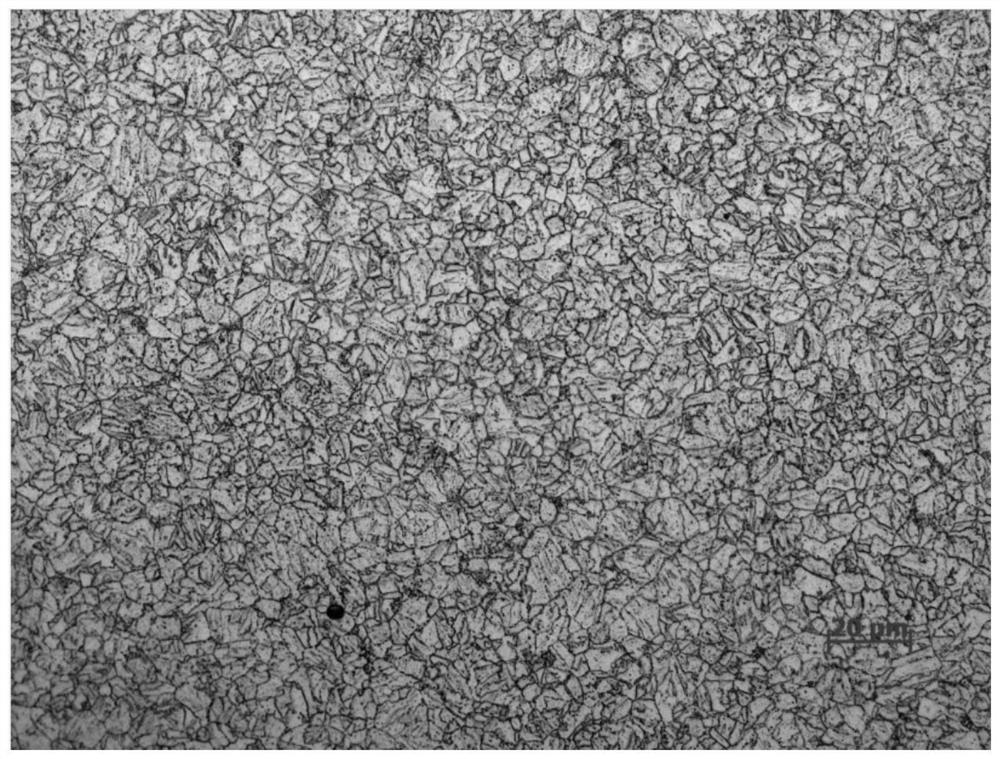

The invention discloses a forging technology of a Hastelloy C-276. The forging technology comprises a pre-forging heat treatment process, a heating process and a forging process. The pre-forging heattreatment process is characterized in that an alloy material is heated to 980 DEG C-1020 DEG C, and heat is preserved for 1-1.5 hours; the material is heated to 1080 DEG C-1120 DEG C again, and heat is preserved for 15-16 hours; and the material is taken out of a furnace for air cooling. The heating process is characterized in that the alloy material is heated to 980 DEG C-1020 DEG C, and heat ispreserved for 1-1.5 hours; and the material is heated to 1140 DEG C-1160 DEG C again, and heat is preserved for 5-6 hours. The forging process is characterized in that multi-heating-number forging isadopted, wherein a temperature compensation device of a forging machine is adopted for heating during forging, and the final forging temperature of each heating number is controlled to be 1000 DEG C or above. According to the technology, a heat treatment technology is adopted, a precipitated phase of the Hastelloy C-276 is redissolved, so that grain boundary embrittlement is reduced, and forging cracks caused by weakening of grain boundary are eliminated; and the temperature compensation device is used for carrying out temperature compensation on the material in the forging process, so that the staying time of a blank in the forging temperature interval is prolonged, and then the forging time of each heating number is prolonged.

Owner:HEBEI IRON AND STEEL

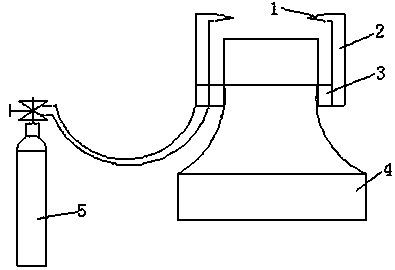

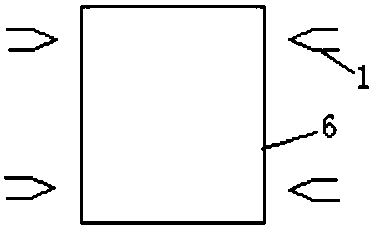

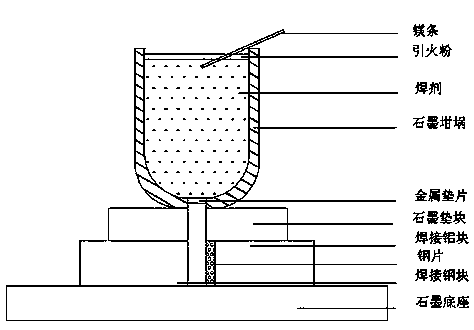

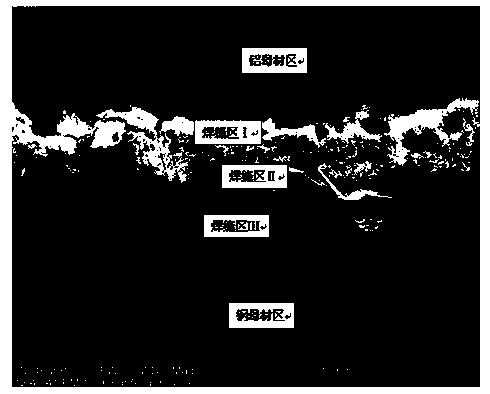

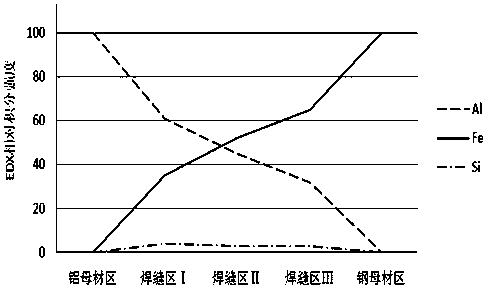

Aluminum-steel heat release welding method

InactiveCN103639589AReduce embrittlementIt conforms to the thermodynamic law that the temperature of the flow down gradually decreasesWelding/cutting media/materialsWelding/soldering/cutting articlesExothermic weldingAl powder

The invention discloses an aluminum-steel heat release welding method. The method comprises the steps that to-be-welded sections of an aluminum block and a steel block are polished cleanly; a pre-polished steel sheet is placed to cling to the aluminum block between a gap of the to-be-welded sections of the aluminum block and the steel block; a bottom through hole of a graphite crucible is aligned to the center of the gap; a self-propagating welding flux is put into the graphite crucible; pyrophoric powder on the surface of the self-propagating welding flux is ignited; molten liquid generated by self-propagating welding flux reaction flows into the gap between the aluminum block and the steel block from the bottom small hole of the graphite crucible; the steel sheet is heated, molten, and cooled to a room temperature; and then aluminum-steel welding is accomplished. The adopted self-propagating welding flux comprises the following raw materials by mass percent: 22-28% of Al powder, 62-68% of Fe2O3 powder, 4-7% of Si powder and 3-6% of slag forming constituent. The method is simple to operate, simple in equipment, stable, safe and reliable in reaction, extensive in raw material, low in cost and less in joint slag inclusion, and has a great industrial popularization value; aluminum steel bonding adopts metallurgical bonding; and the quality is good.

Owner:WUHAN UNIV

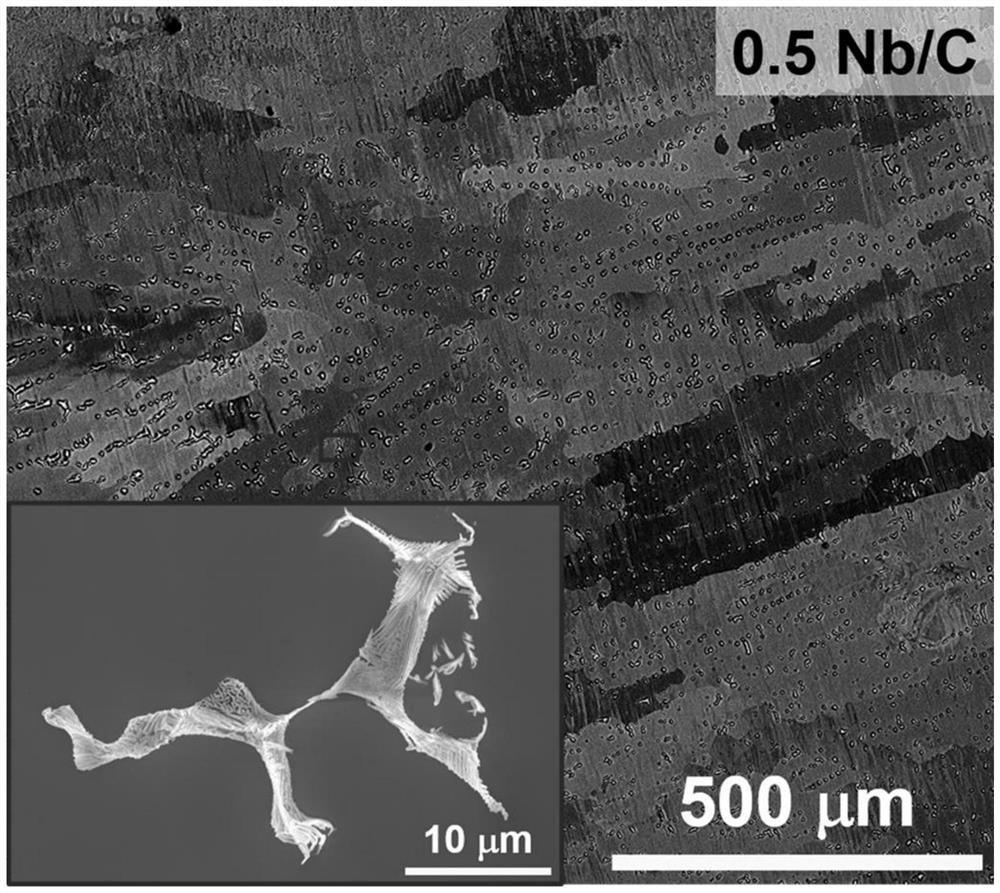

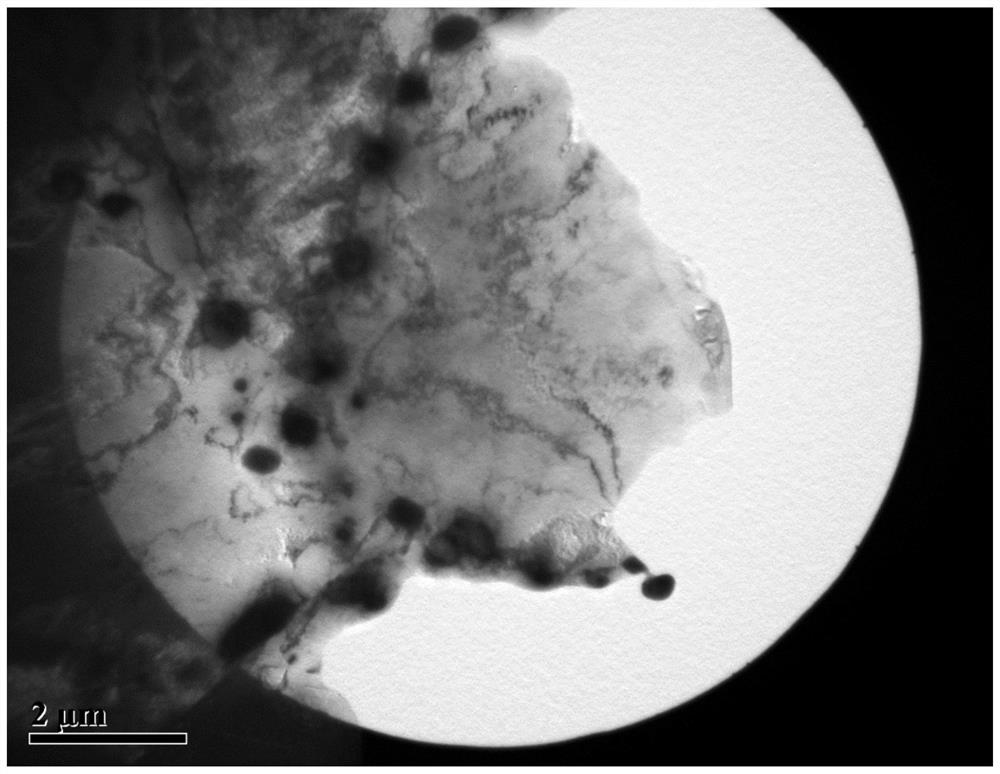

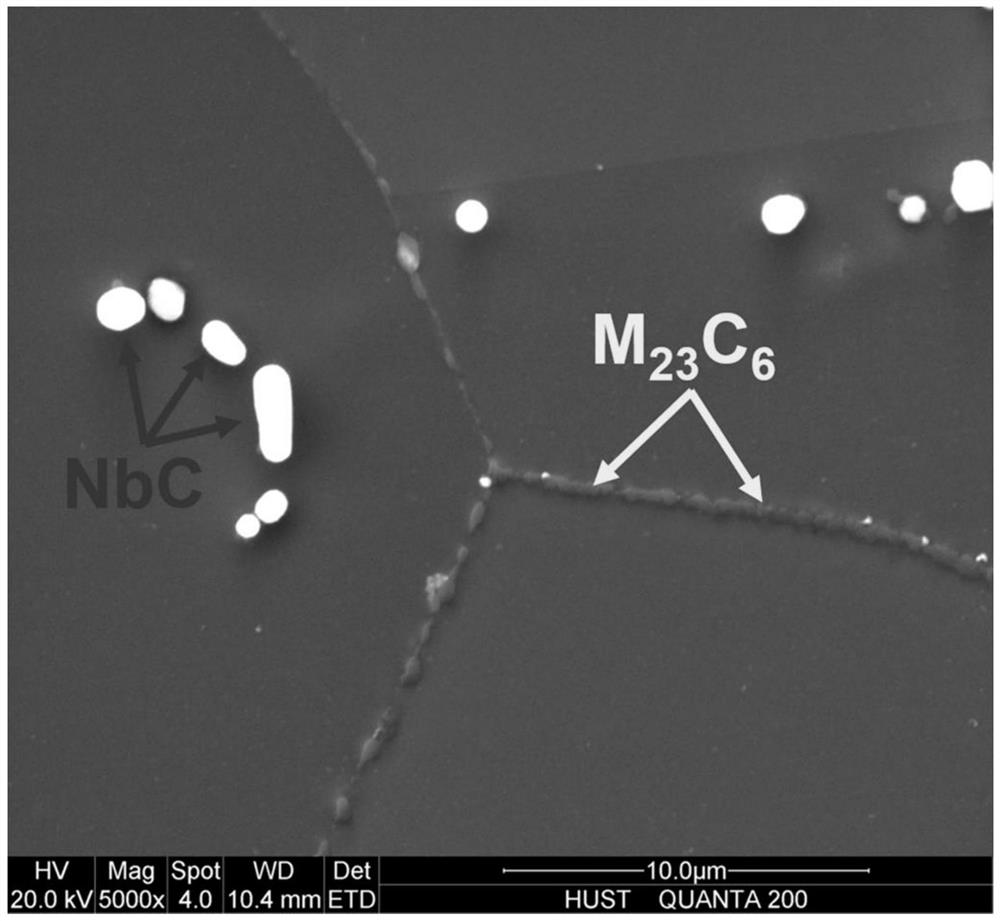

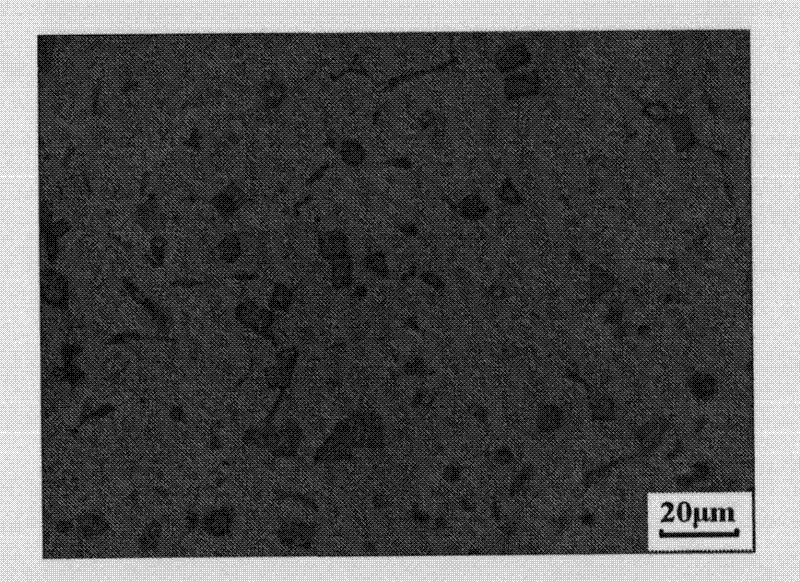

Precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and preparation method thereof

ActiveCN111621660AGood high temperature mechanical propertiesImprove mechanical propertiesHeat stabilityCarbide

The invention discloses a precipitation strengthening type high-temperature high-entropy alloy for in-situ precipitation of carbide and a preparation method thereof, and belongs to the field of high-entropy alloy preparation. According to the method, a raw material composed of Cr, Fe, Co, Ni, Nb and Cr3C2 is fully smelted and mixed in an inert atmosphere and then subjected to solid solution agingtreatment, and the atomic percent and the atomic number of all the elements meet the requirements of 24.5% to 24.75% of Cr, 24.5% to 24.75% of Fe, 24.5% to 24.75% of Co, 24.5% to 24.75% of Ni, 0.5% to1% of Nb and 0.5% to 1% of C, wherein the atomic numbers of Cr, Fe, Co and Ni satisfy Cr = Fe = Co = Ni, and the atomic numbers of Nb and C satisfy Nb = C. According to the prepared alloy, a large number of spherical NbC carbide particles are dispersedly distributed in crystal grains, and a small number of M23C6 carbides are distributed on a crystal boundary. The crystal grains and carbide precipitated phases of the alloy have high thermal stability at high temperature, and have good effects on high-temperature structure stability and high-temperature mechanical properties of the alloy.

Owner:HUAZHONG UNIV OF SCI & TECH

Orthopaedic bearing material

ActiveUS20070067044A1Improve wear resistanceImprove mechanical propertiesBone implantBearing componentsCrosslinked polymersMechanical property

Disclosed is a polymeric orthopaedic bearing material for use as an implant material or part thereof comprising one or more crosslinked regions and one or more non-crosslinked or substantially non-crosslinked regions at the surface. The bearing material can be prepared from a crosslinkable polymer, e.g., ultrahigh molecular weight polyethylene. The orthopaedic bearing material has an advantageous combination of at lest one wear property and at least one mechanical property. Also disclosed are processes for producing orthopaedic bearing materials, for example, by irradiating a raw material in consolidated form through a radiation mask having a perforated pattern for crosslinking selected regions of the raw material, and optionally shaping the raw material into a bearing material. Alternatively, a pulsed radiation beam can be used for crosslinking.

Owner:DEPUY PROD INC

Heat-resistant steel gas protection welding wire

InactiveCN101362262AReduce embrittlementImprove performanceArc welding apparatusWelding/cutting media/materialsChemical compositionUltimate tensile strength

The invention relates to a heat resisting steel gas-shielded welding wire, which comprises the following chemical compositions by mass percent: smaller than or equal to 0.12 percent of C, 0.40-0.60 percent of Si, 0.60-1.50 percent of Mn, smaller than or equal to 0.025 percent of S, smaller than or equal to 0.025 percent of P, 1.20-1.50 percent of Cr, smaller than or equal to 0.20 percent of Ni, 0.45-0.65 percent of Mo, smaller than or equal to 0.35 percent of Cu, and residue of Fe. The heat resisting steel gas-shielded welding wire is used for the welding of chrome molybdenum steel in the manufacture of steel structures in power plants, the embrtittlement phenomenon of the weld metal in long-term use can be reduced, the obtained deposit metal and welded joint can be ensured to have sufficient creep strength, endurance strength and lasting plasticity and good high temperature structure stability; for the all-round properties, the obtained deposit metal has good match between strength and toughness, the yield strength is larger than or equal to 440 MPa, the tensile strength is larger than or equal to 550 MPa, and the specific elongation is larger than or equal to 20 percent.

Owner:CHENGDU XINDAYANG WELDING MATERIAL

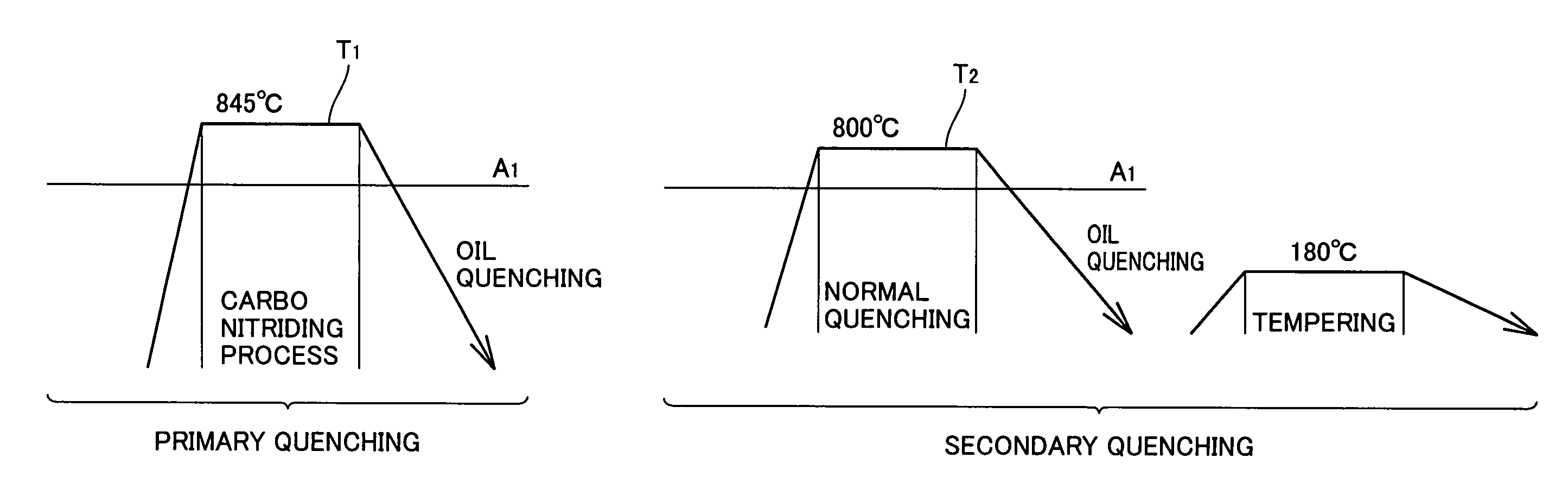

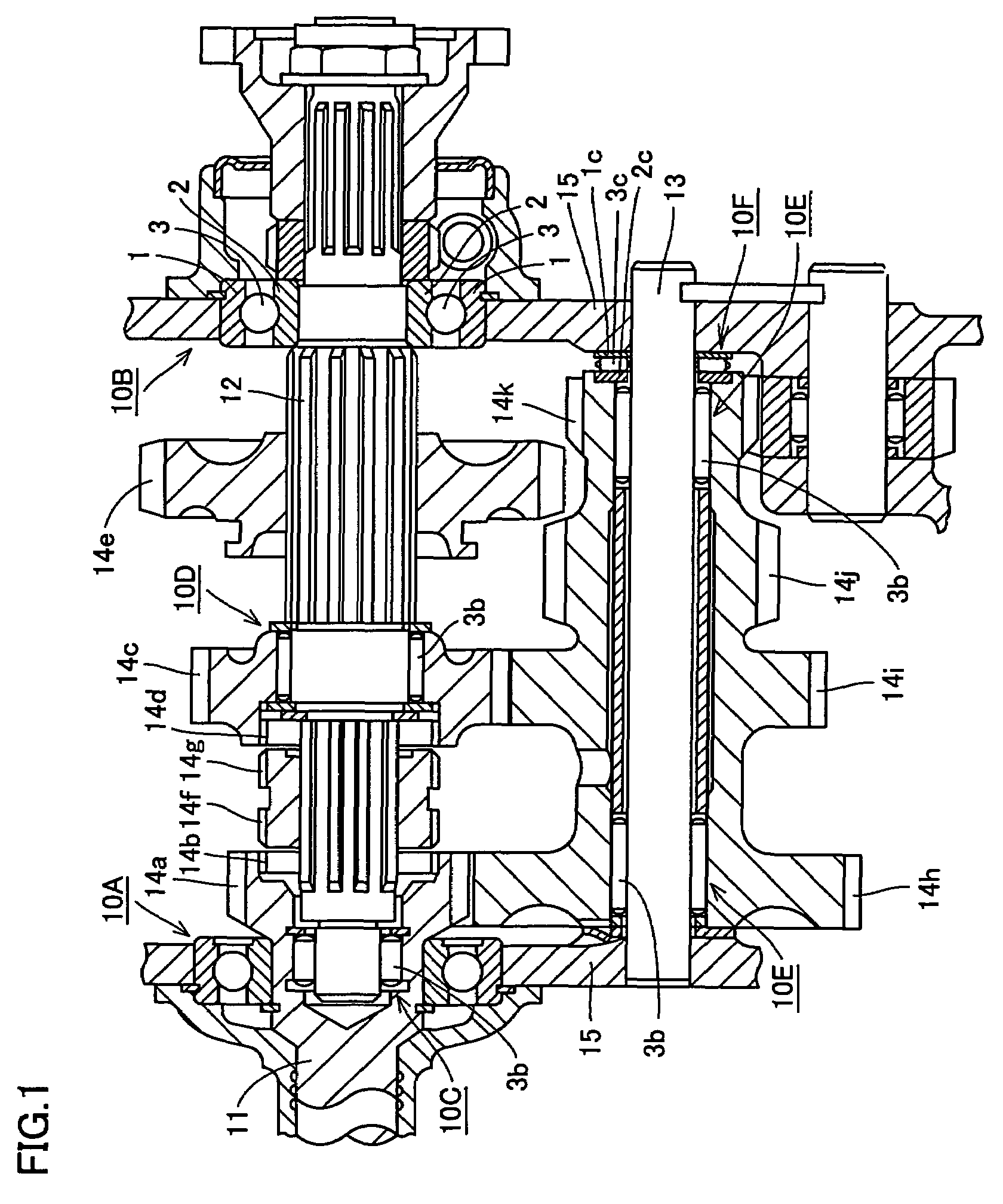

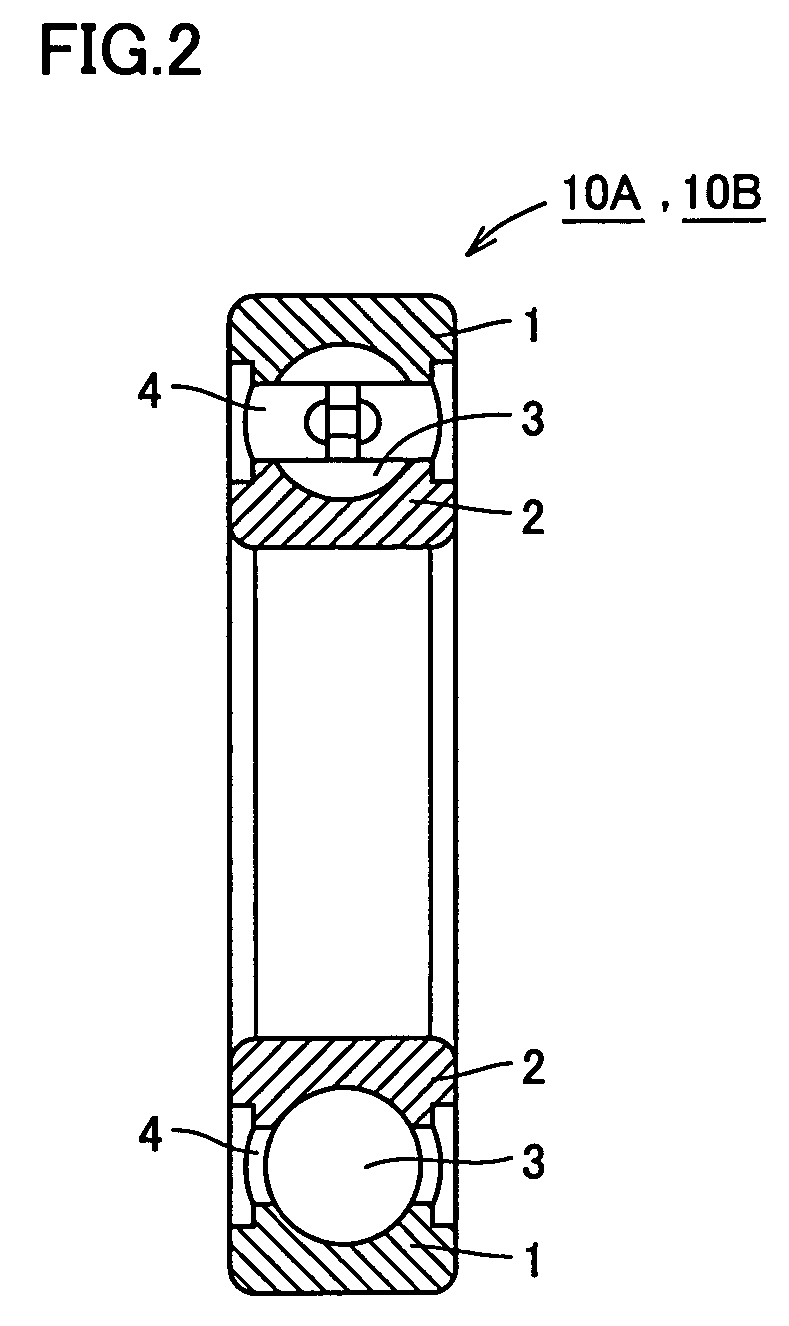

Transmission component, method of manufacturing the same, and tapered roller bearing

ActiveUS7682087B2Improve cracking strengthGood dimensional stabilityGearboxesPortable liftingAustenite grainSurface layer

A transmission component is incorporated into a transmission in which an input shaft, an output shaft, or a gear is rotatably supported by a rolling bearing. The component has a nitriding layer at a surface layer and an austenite grain with a grain size number falling within a range exceeding 10. This provides a transmission component having an increased anti-crack strength, enhanced dimensional stability, and a long fatigue life. A method of manufacturing such a transmission component and a tapered roller bearing are also provided.

Owner:NTN CORP

Phenolic foaming resin toughened with hydroxyl-terminated nitrile rubber

The invention provides phenolic foaming resin toughened with hydroxyl-terminated nitrile rubber and relates to phenolic foaming resin. The phenolic foaming resin is prepared from components a follows: phenolic compounds, aldehyde compounds, a modifier and a catalyst. The phenolic foaming resin is prepared through steps as follows: (1), the fused phenolic compounds and the basic catalyst are mixed, put in a water bath kettle and heated to 60 DEG C; (2), the aldehyde compounds are added in batches, and the addition is controlled to be finished within half an hour; (3), heat is preserved for half an hour after the aldehyde compounds are added completely, and the aldehyde compounds are enabled to react completely; (4), the modifier is added, a mixture is put in a magnetic stirrer, stirred for 10 min, heated, subjected to a reaction at the constant temperature for an hour and a half and cooled, PH is regulated to be 7-8 with a PH regulator, dehydration and cooling are performed for 24 h, and the modified target phenolic resin can be obtained. The modified phenolic resin has good mechanical properties and overall performance.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Stir friction welding method for dissimilar metal lap joint

InactiveCN111745286AImprove automationBeautiful shapeWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingLap joint

The invention provides a stir friction welding method for lap-joint welding of a first metal plate and a second metal plate. The hardness of the first metal plate is smaller than that of the second metal plate material, and a shaft shoulder and a stirring needle of a stirring head are pressed below the upper surface of the first metal plate and above the upper surface of the second metal plate. Pressure is applied to the stirring head, and the lower end face of the stirring needle is attached to and kept to the position above the upper surface of the second metal plate. Through stir friction welding, friction and heat generation are achieved on the surface of the upper-layer metal plate with the small hardness, the pressure is applied, an intermetallic compound is generated or diffusion happens or generation of the intermetallic compound and diffusion happen at the upper-lower junction face of the upper-layer plate and the lower-layer plate through control over the distance between thestirring needle and the upper surface of the lower-layer metal plate, and finally a dissimilar metal lap joint connector attractive in welding line forming and excellent in connector performance is obtained. The welding operation process is simple, and dissimilar metal lap-joint welding automation is easily achieved.

Owner:HARBIN WANZHOU WELDING TECH CO LTD

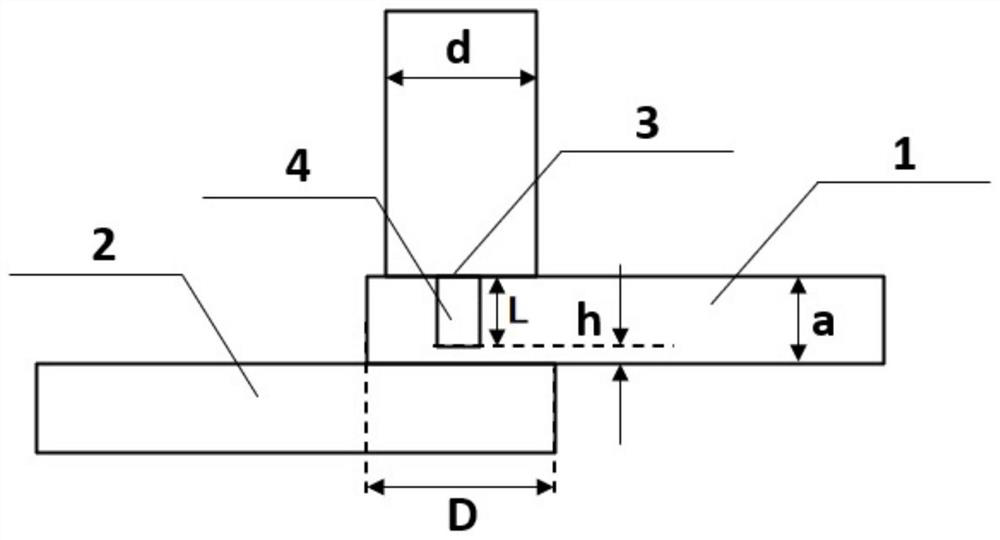

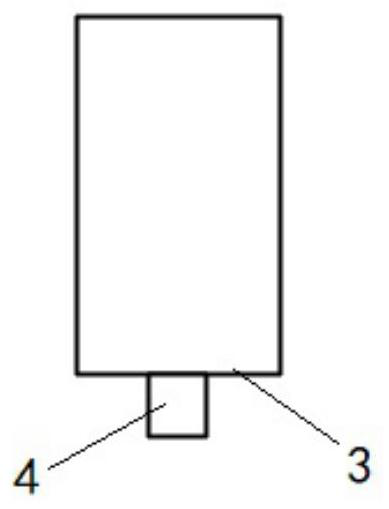

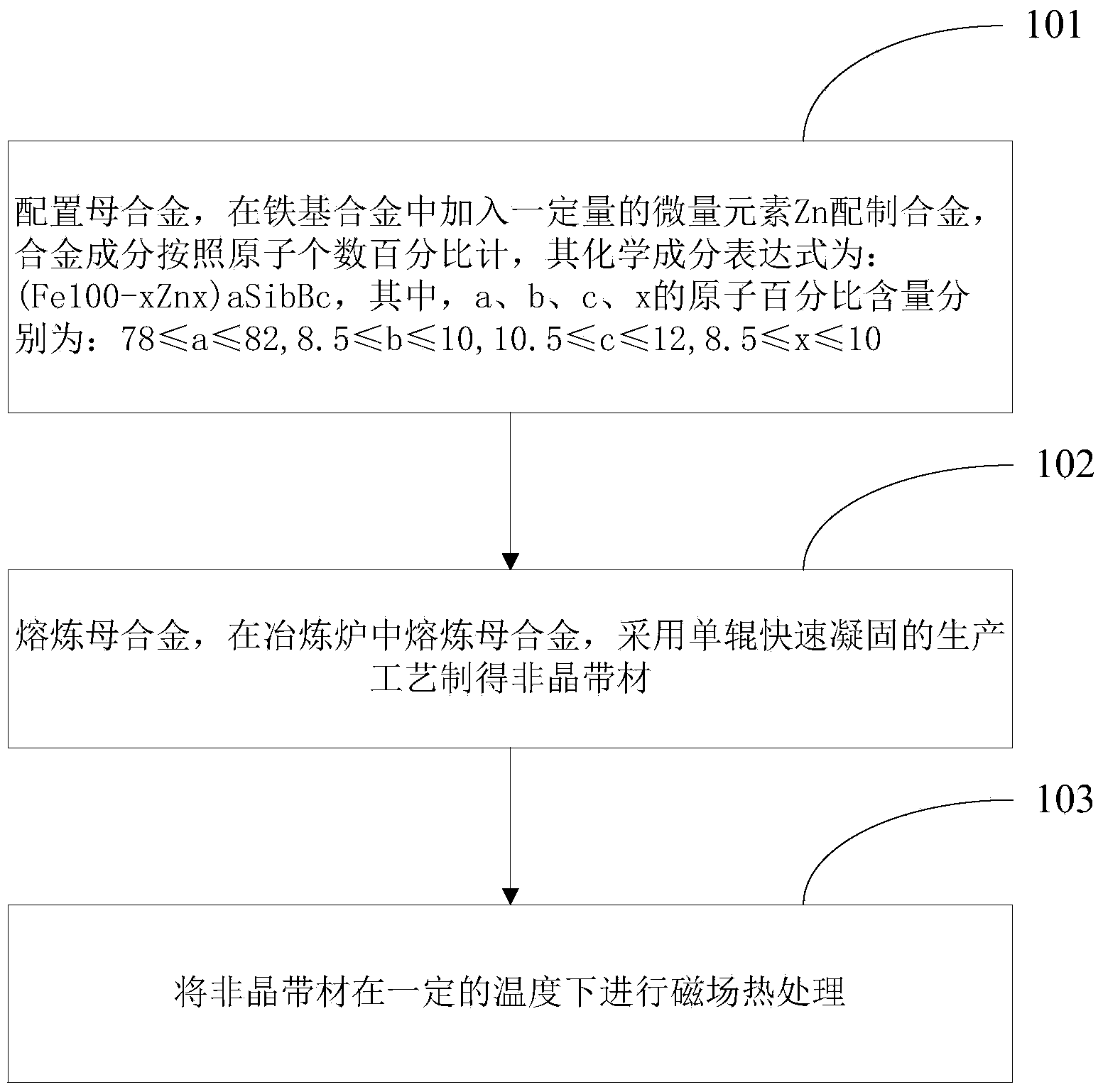

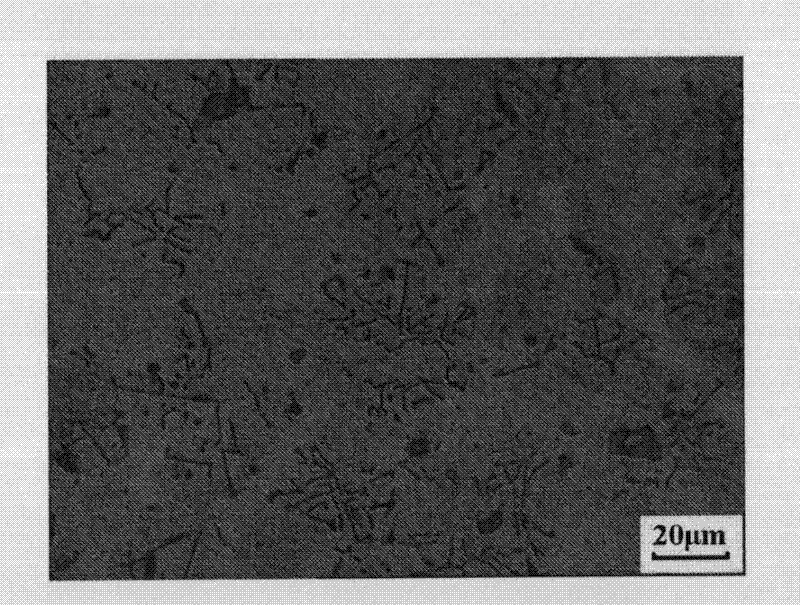

Method for reducing embrittlement degree of amorphous strip

ActiveCN103643179AStrong magnetismReduce embrittlementFurnace typesHeat treatment furnacesChemical compositionIron based alloy

The invention relates to a method for reducing the embrittlement degree of an amorphous strip. The method comprises the steps of configuring a master alloy, and adding a certain amount of microelement Zn into an iron-base alloy to prepare an alloy of which the chemical component expression is (Fe[100-x]Znx)aSibBc based on atom number percent, wherein the atom percentage contents of a, b, c and x are as follows: a is more than or equal to 78 and less than or equal to 82, b is more than or equal to 8.5 and less than or equal to 10, c is more than or equal to 10.5 and less than or equal to 12, and x is more than or equal to 8.5 and less than or equal to 10; smelting the master alloy in a smelting furnace, and preparing an amorphous strip by adopting a single-roller rapid solidification production process; performing magnetic-field heat treatment on the amorphous strip at a certain temperature. According to the method, by starting with component design and a smelting link during strip preparation, the component range of a main element alloy which ensures that the strip keeps excellent magnetic performance is determined at first, and then an appropriate amount of microelements are added on the basis of the component range, so that the embrittlement degree of the prepared amorphous strip is significantly reduced after the magnetic-field heat treatment.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

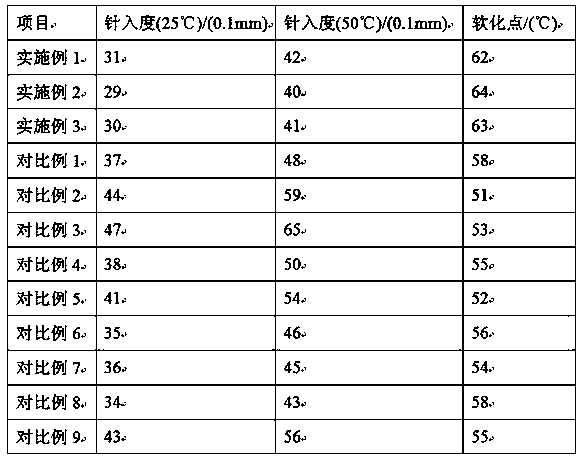

Preparation method of high-strength composite modified emulsified asphalt

PendingCN112375234AEasy to prepareEasy to operateBuilding insulationsBitumen emulsionMaterials science

The invention relates to the technical field of road asphalt materials, in particular to a preparation method of high-strength composite modified emulsified asphalt. The asphalt has the advantages that the stability is better, the bonding strength is high, and the problems of wheel sticking, infirm inter-layer bonding, long maintenance time, insufficient shearing property and durability and the like in the construction process are reduced. The process is simple, the production cost can be effectively reduced, the viscosity and bonding performance of the emulsified asphalt are enhanced, and thedemulsification speed of the emulsified asphalt is increased; the composite modified emulsified asphalt is composed of high-strength composite modified asphalt and an emulsifier aqueous solution, theoil-water mass ratio of a mixture of the high-strength composite modified asphalt and the emulsifier aqueous solution is 60: 40-65: 35, that is, the content of evaporation residues of the high-strength composite modified emulsified asphalt is 60%-65%, and the preparation method comprises the following steps: S1, carrying out asphalt heating treatment; S2, preparing high-strength SBS modified asphalt; S3, preparing high-strength composite modified asphalt; S4, preparing an emulsifier aqueous solution; and S5, preparing the high-strength composite modified emulsified asphalt.

Owner:HEBEI LUNTE PETROLEUM CHEM

Process for the coating of metallic surfaces, coating composition, and coatings produced in such a way

InactiveUS9695322B2Improve paint adhesionImprove adhesionLamination ancillary operationsLaminationOligomerPhotoinitiator

A process for coating a metallic surface of a metallic substrate comprising applying, an organic, anionically, cationically or radically curable anticorrosive composition, to the metallic surface, wherein said anticorrosive composition is a dispersion or solution containing at least two components that are at least partially anionically, cationically or radically curable, wherein at least one monofunctional monomer or monofunctional oligomer is present, a photoinitiator, and first organic corrosion inhibitor.

Owner:GROS GEORG +2

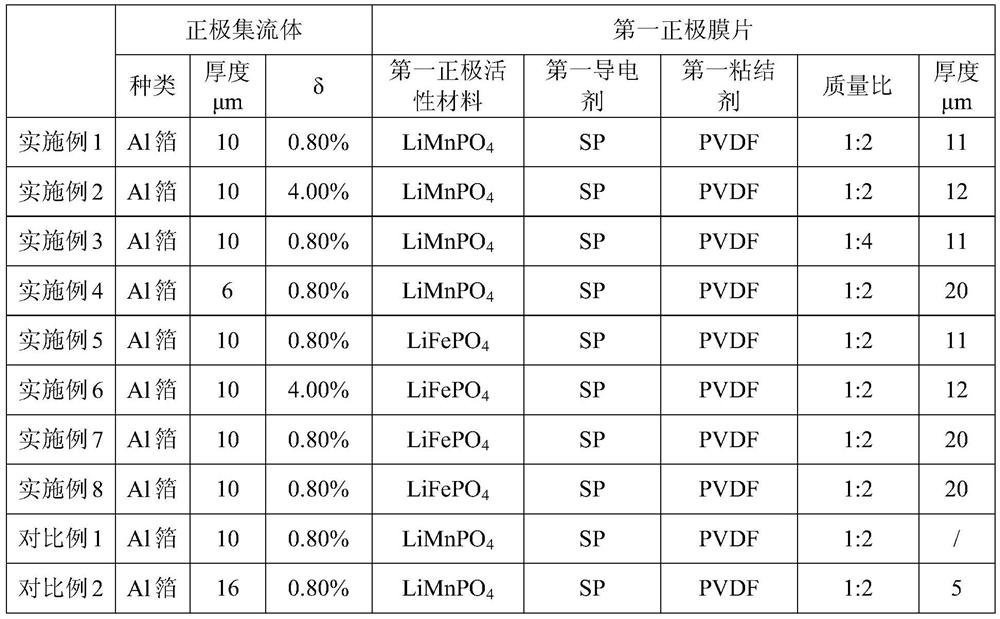

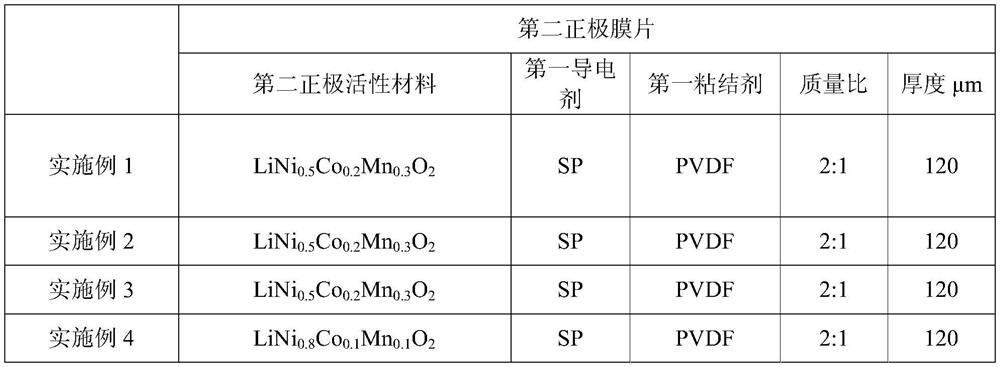

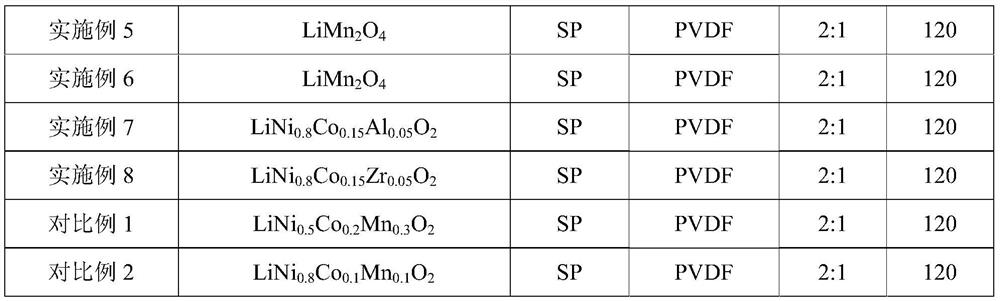

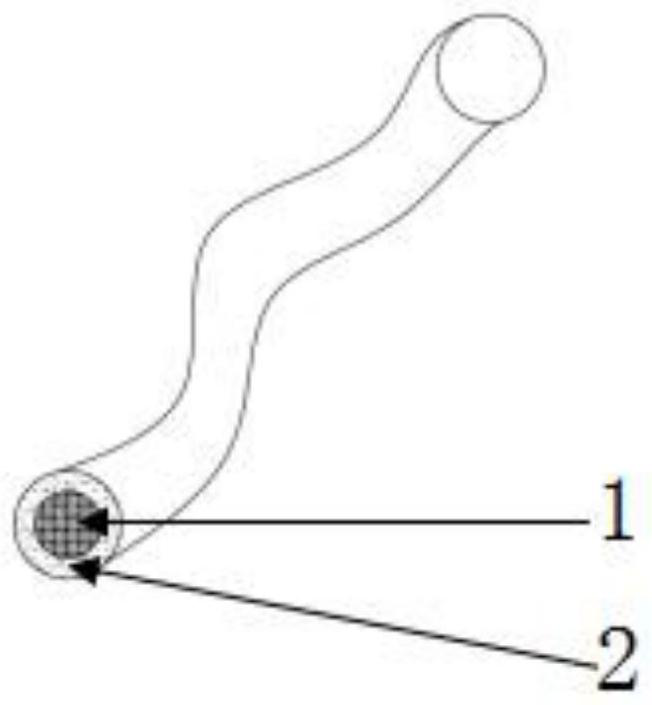

Positive pole piece and lithium ion battery

ActiveCN112349874AIncrease energy densityAvoid contactSecondary cellsPositive electrodesElectrical batteryHigh energy

The invention provides a positive pole piece and a lithium ion battery. The positive pole piece comprises a positive electrode current collector, a first positive electrode diaphragm and a second positive electrode diaphragm. The first positive electrode diaphragm is arranged on the positive electrode current collector and comprises a first positive electrode active material, wherein the first positive electrode active material is selected from one or more of phosphate materials LiFe1-x-yMnxMyPO4, x being greater than or equal to 0 and less than or equal to 1, y being greater than or equal to0 and less than or equal to 0.1, and x+y being greater than or equal to 0 and less than or equal to 1, and M being selected from one or more of Cr,Mg, Ti, Al, Zn, W, Nb and Zr; the second positive electrode diaphragm is arranged on the first positive electrode diaphragm and comprises a second positive electrode active material, wherein the gram volume of the second positive electrode active material is higher than that of the first positive electrode active material, and the second positive electrode active material is different from the first positive electrode active material; and the thickness D0 of the positive electrode current collector is less than or equal to the thickness D1 of the first positive electrode diaphragm. Based on the positive pole piece, the lithium ion battery has the characteristics of high energy density and good nail penetrating safety performance.

Owner:CONTEMPORARY AMPEREX TECH CO

Corrosion-resistant metal porous material and preparation method and application thereof

PendingCN111910166AGood filtration performanceLow reaction temperatureChemical vapor deposition coatingFluorhydric AcidComposite material

The invention provides a corrosion-resistant metal porous material and a preparation method and application thereof, and relates to the technical field of metal porous materials. The corrosion-resistant metal porous material comprises a metal porous material base material and a corrosion-resistant deposition layer metallurgically bonded on the surface of a porous framework of the metal porous material base material through chemical vapor deposition, wherein the corrosion-resistant deposition layer is a metal Ta layer or a metal Mo layer or an alternate composite layer of the metal Ta layer andthe metal Mo layer. The metal porous material can be bonded with Ta and Mo at a melting point far lower than that of Ta and Mo through chemical vapor deposition, and the chemical vapor deposition hashigh diffractivity, so that Ta and Mo can evenly and compactly surround the surface of the metal porous framework, and the corrosion resistance of the metal porous material is improved. The corrosion-resistant metal porous material has good corrosion resistance in sulfuric acid, hydrofluoric acid, hydrochloric acid, nitric acid and mixed acid of the sulfuric acid, the hydrofluoric acid, the hydrochloric acid and the nitric acid.

Owner:WESTERN METAL MATERIAL

Additive For A Silicone Encapsulant

ActiveUS20160168359A1Reduce embrittlementReduce yellowingSilicon organic compoundsGroup 3/13 organic compounds without C-metal linkagesArylMetal

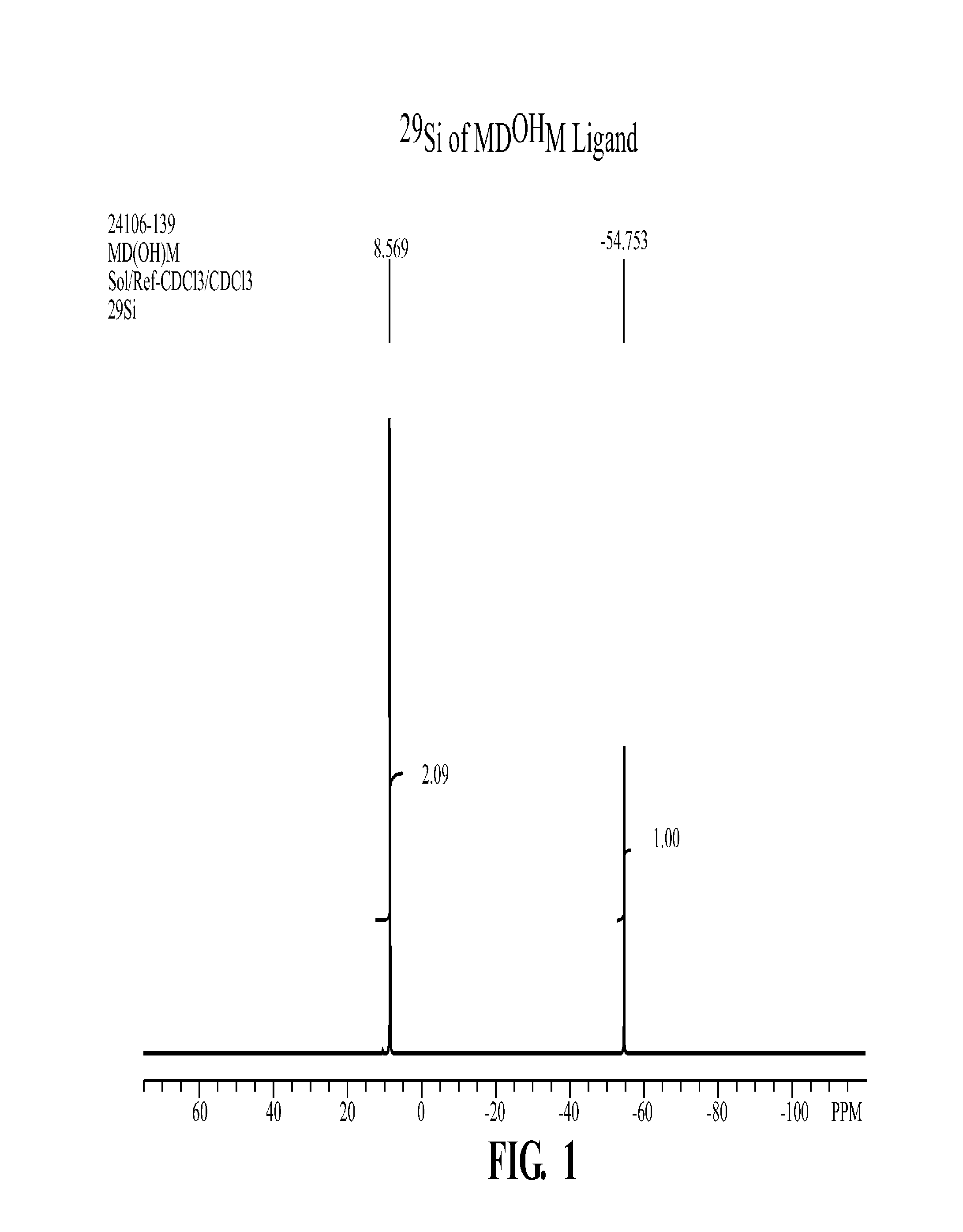

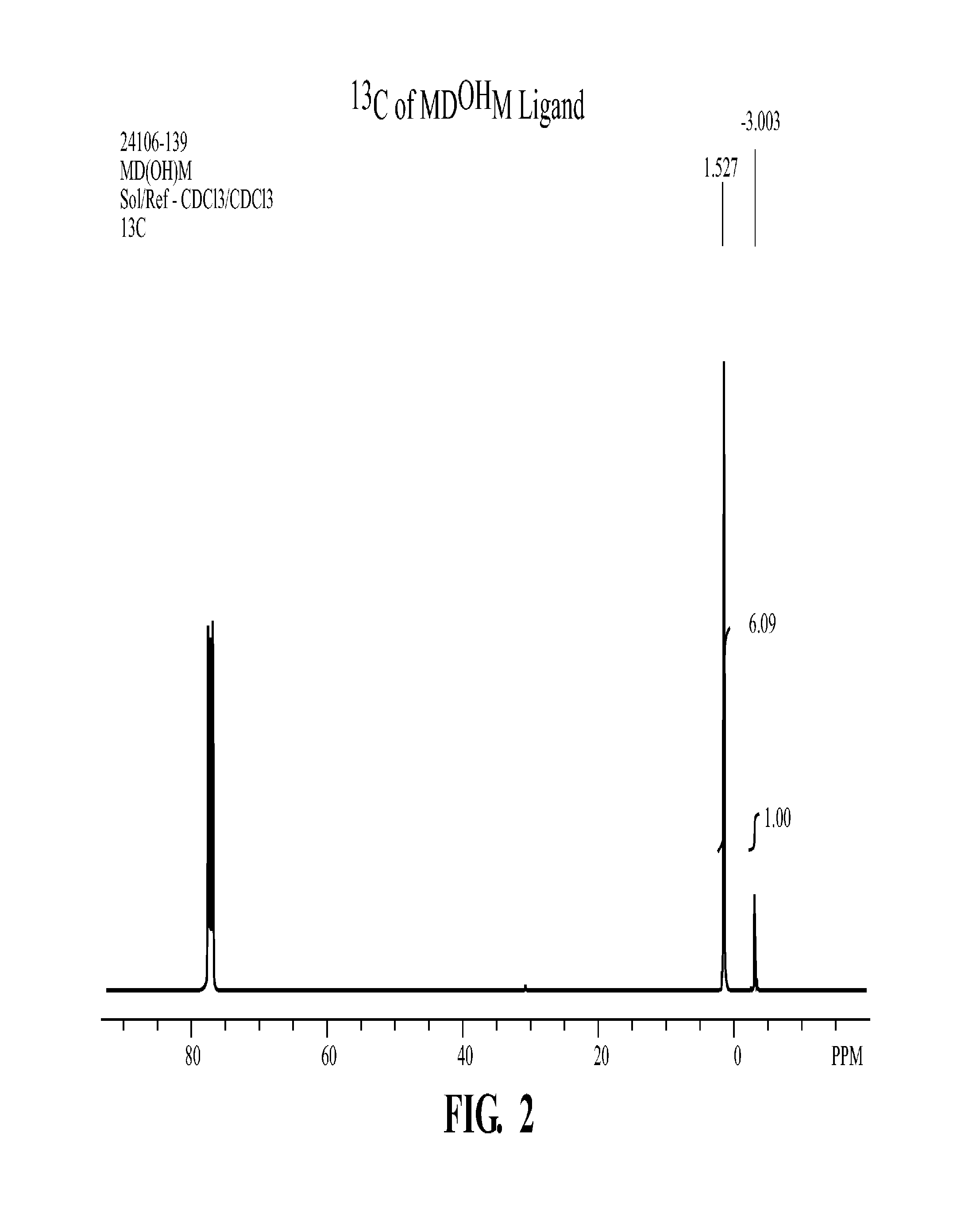

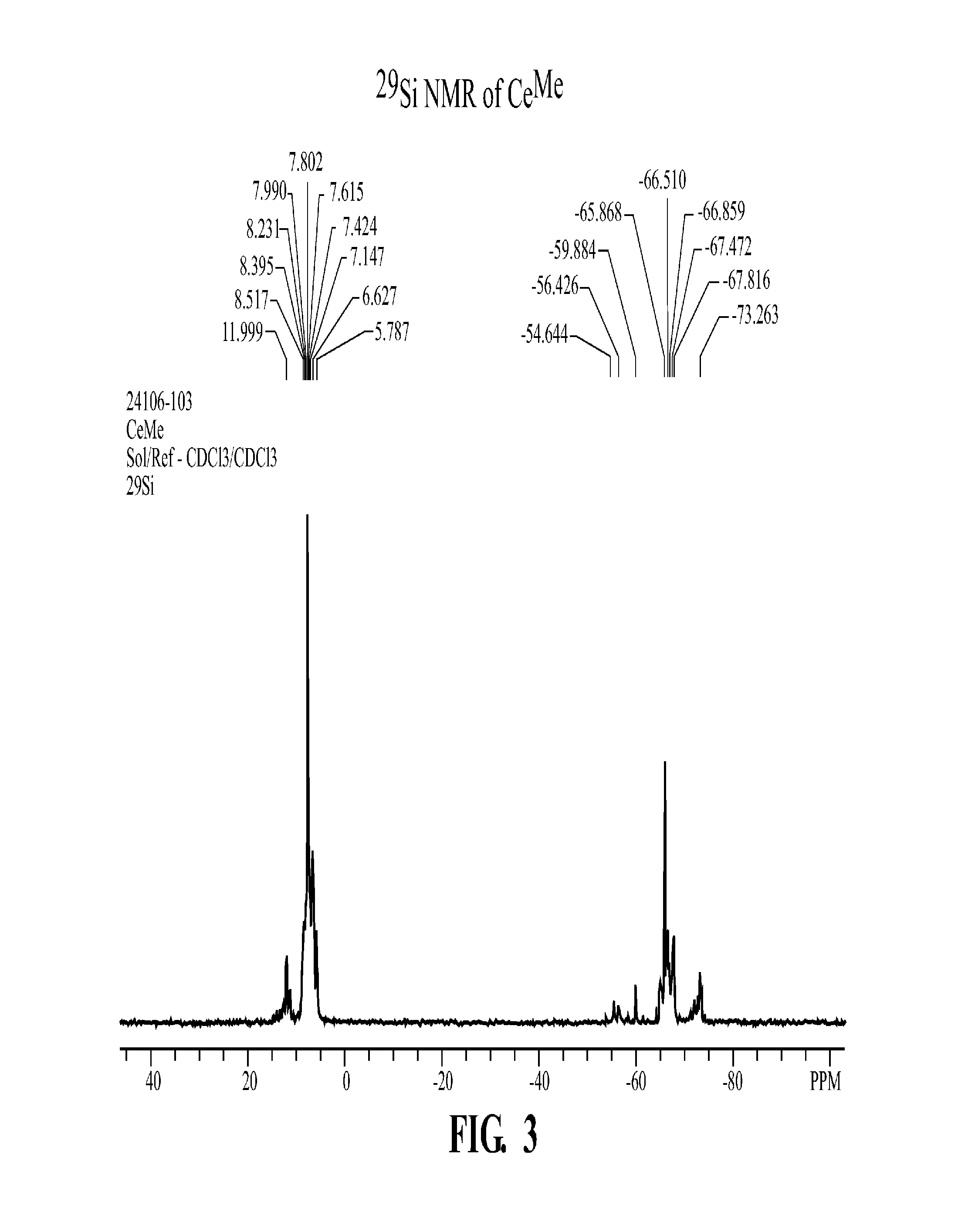

An additive for a silicone encapsulant has the structure: (I) R1Ce(OSi—R2) I I a R3 wherein a is 3 or 4, wherein R1 and R2 are each —O—Si(R4)(R5)(R6) and each of R4, R5, and R6 is independently chosen from C1-C10 hydrocarbyl groups, C1-C10 alkyl groups, C2-C10 alkenyl groups, and C6-C10 aryl groups, and wherein R3 is independently chosen from C1-C10 hydrocarbyl groups, C1-C10 alkyl groups, C2-C10 alkenyl groups, and C6-C10 aryl groups. More specifically, the cerium is cerium (III) or (IV). The additive is formed using a method that includes the step of reacting cerium metal or a cerium (III) or (IV) compound with a hydroxyl functional organosiloxane. An encapsulant includes the additive and a polyorganosiloxane. The encapsulant can be utilized to form a device that includes an optoelectronic component and the encapsulant disposed on the optoelectronic component. The device is formed using a method that includes the step of disposing the encapsulant on the optoelectronic device.

Owner:DOW SILICONES CORP

Formula of austenite heat-resisting alloy mesh belt wire for continuous mesh belt furnace and preparation method of mesh belt wire

The invention discloses a formula of an austenite heat-resisting alloy mesh belt wire for a continuous mesh belt furnace and a preparation method of the mesh belt wire. The austenite heat-resisting alloy mesh belt wire consists of the following components in percentage by weight: 0.01-0.20% of C, 0.005-3.5% of Si, 0.01-2.5% of Mn, less than or equal to 0.035% of P, less than or equal to 0.030% of S, 22-27% of Cr, 18-26.0% of Ni, 0.05-2.5% of Co, 0.05-1.0% of Nb, 0.05-0.25% of Mo, 0.02-0.50% of N, 0.05-1.0% of W, added mixed metal rare-earth alloy that contains 0.003-0.50% of rare earth, and the balance of Fe and inevitable impurities. The austenite heat-resisting alloy mesh belt wire is provided in order to overcome the problems of a mesh belt wire for an existing continuous heat treatment furnace which is short in service life and is easy to become deformed and to cause brittle fracture. The austenite heat-resisting alloy mesh belt wire can further improve the high-temperature strength of austenite heat-resisting alloy, prolong service life and significantly reduce an effect of embrittlement.

Owner:JIANGSU XINHUA ALLOY ELECTRIC

High-strength heat-resistant steel gas shielded solid welding wire

ActiveCN103056548BReduce embrittlementImprove performanceWelding/cutting media/materialsSoldering mediaHeat resistanceRoom temperature

Owner:CHENGDU XINDAYANG WELDING MATERIAL

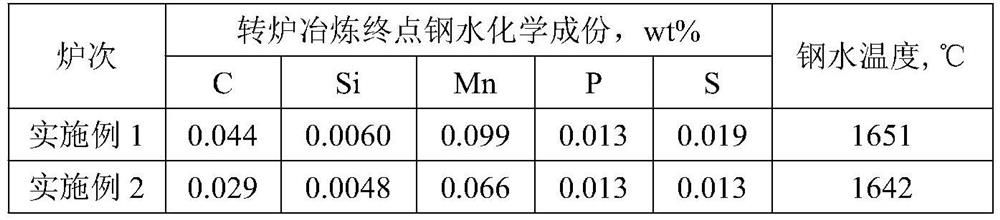

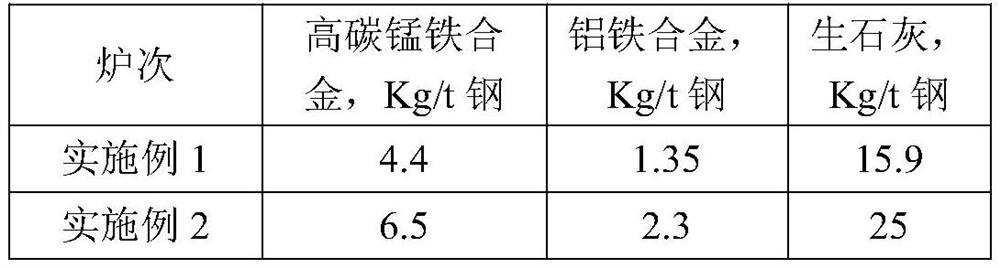

Method for reducing corner cracks of medium-carbon boron-containing steel continuous casting sheet billet

InactiveCN112921247ARealize hot charging and hot deliveryNegative slip time reductionNarrow faceTitanium

The invention discloses a method for reducing corner cracks of a medium-carbon boron-containing steel continuous casting sheet billet. The method mainly solves the technical problem that the corner crack defect of an existing medium-carbon boron-containing steel continuous casting sheet billet is difficult to control. The method for reducing the corner cracks of the medium-carbon boron-containing steel continuous casting sheet billet comprises the following steps of 1) adjusting the equipment precision of a straight arc-shaped continuous casting machine, and ensuring that the arc alignment precision of a crystallizer foot roller and a bent section is less than or equal to 0.15 mm; and (2) pouring the continuous casting sheet billet, specifically, adopting the straight arc-shaped continuous casting machine for pouring the sheet billet, enabling the superheat degree of tundish molten steel to be 15-25 DEG C, increasing the corner temperature in a weak cooling manner, enabling the water amount of the wide face of a crystallizer to be 3650-3850 L / min, enabling the water amount of the narrow face of the crystallizer to be 460-480 L / min, and controlling the temperature of the corners of the sheet billet before straightening to be 900 DEG C. By means of the method, titanium is adopted as an optimized alloy element, the equipment precision of the continuous casting machine is controlled, and the corner crack rate of the continuous casting sheet billet is smaller than or equal to 0.05%.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Weather-proof modified asphalt

InactiveCN109504108AImprove stress resistanceImprove wear resistanceBuilding insulationsFatigue damageGraphene

The invention mainly relates to the technical field of construction and discloses a weather-proof modified asphalt. The weather-proof modified asphalt is prepared from the following raw materials: 95-100 parts of matrix asphalt, 2.2-2.4 parts of water, 2.1-2.3 parts of nanometer titanium dioxide, 1.7-1.9 parts of SBS asphalt modifier, 1.1-1.3 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 0.3-0.5 part of asphalt stabilizer and 0.5-0.7 part of graphene. The weather-proof modified asphalt provided by the invention has the advantages of extensive source of raw materials, simple preparation, low cost, high weather fastness, ageing delaying effect, high fatigue damage resistance and anti-rutting performance under high-temperature and rainy conditions, capability of avoiding embrittlement and cracking under low temperature, high stability and capability of prolonging service life of road. Nanometer titanium dioxide and SBS asphalt modifier are added after matrix asphalt is heated and molten, so that fluidity and weather fastness of asphalt can be promoted and construction difficulty can be reduced.

Owner:魏林涛

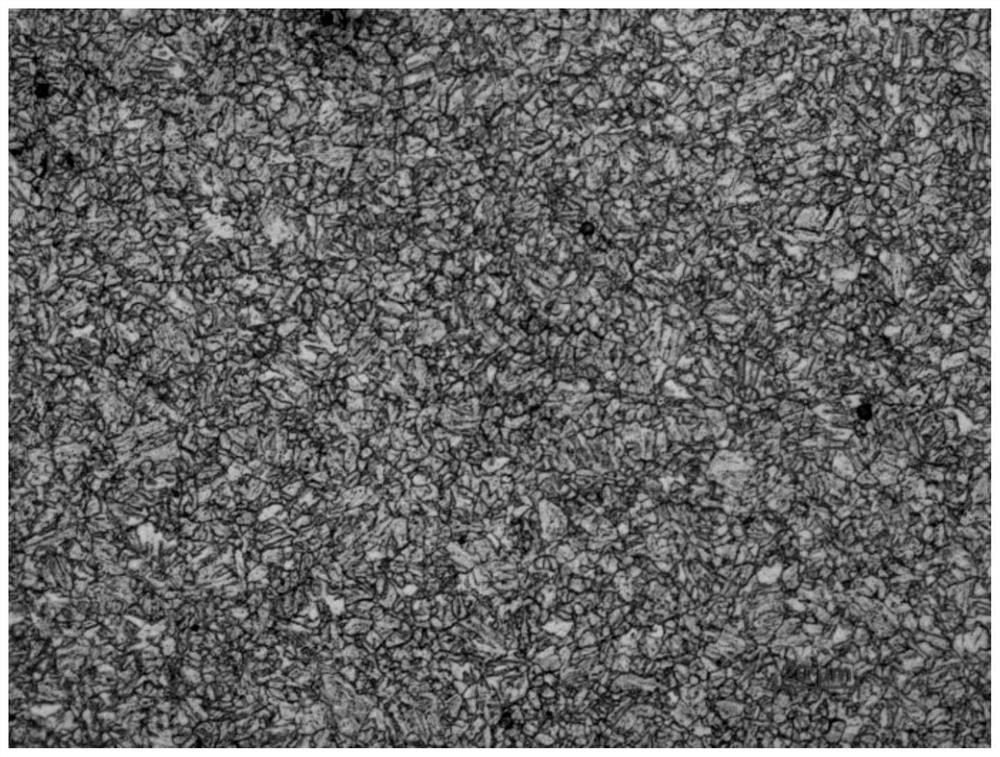

Wire rod for Cr-Mo steel submerged arc welding wire and manufacturing method thereof

PendingCN112091473AImproved temper brittlenessImprove toughnessWelding/cutting media/materialsSoldering mediaWire rodSteelmaking

The invention relates to a wire rod for a Cr-Mo steel submerged arc welding wire and a manufacturing method thereof. The wire rod is prepared from the following chemical components in percentage by mass: 0.10-0.20% of C, 0.10-0.60% of Si, 1.0-1.5% of Mn, 2.0-3.0% of Cr, 0.95-1.15% of Mo, 0.3-0.5% of V, 0.01-0.05% of Nb, 0.01-0.20% of Ni, 0.01-0.20% of Cu, and the balance of Fe and inevitable impurity elements. The wire rod produced through steelmaking, refining, continuous casting, controlled rolling and cooling and annealing can be used for welding during manufacture of high-strength Cr and Mo steel, and good temper brittleness resistance and good high-temperature endurance performance of welded metal are guaranteed through the component design and high-purity requirements of the wire rod.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

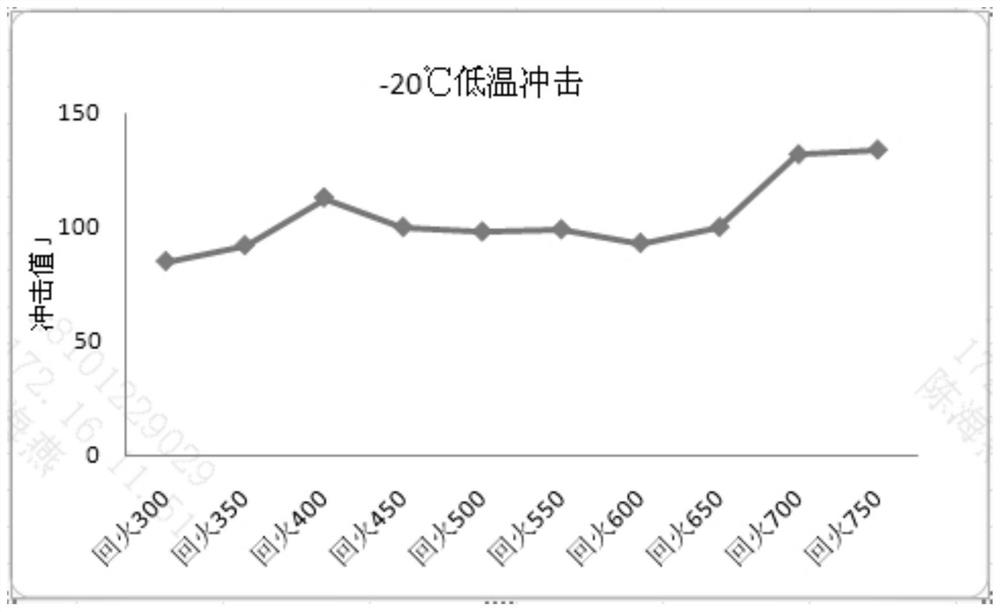

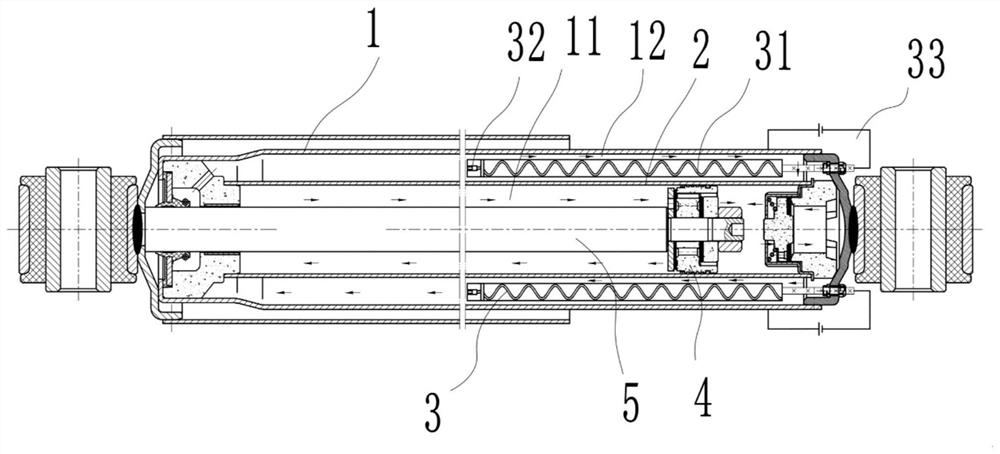

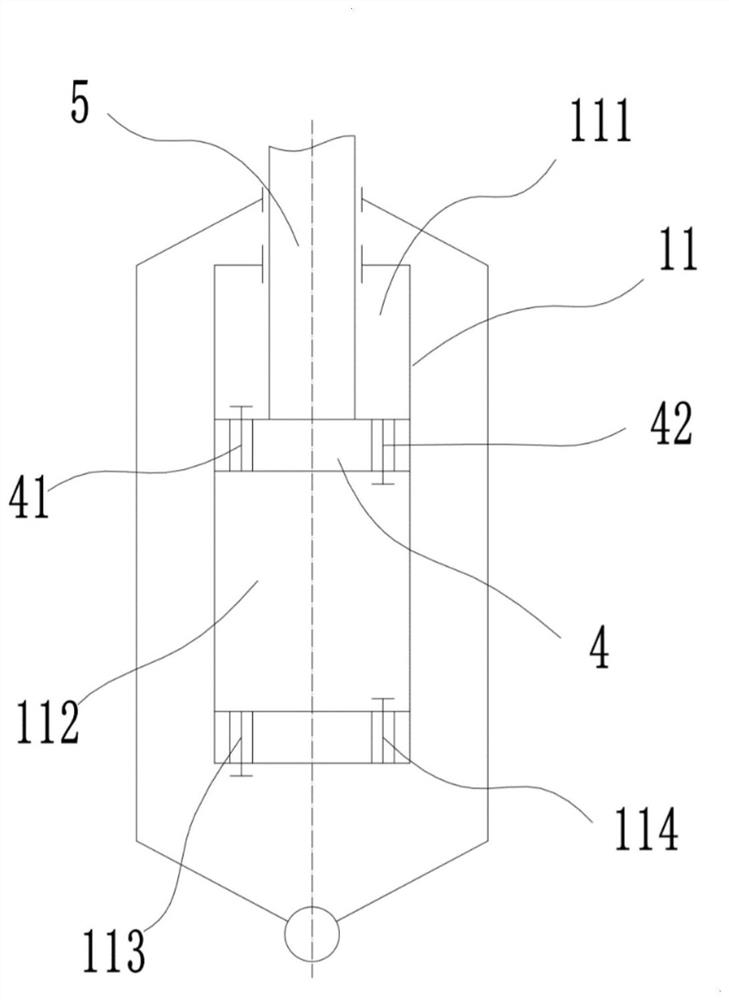

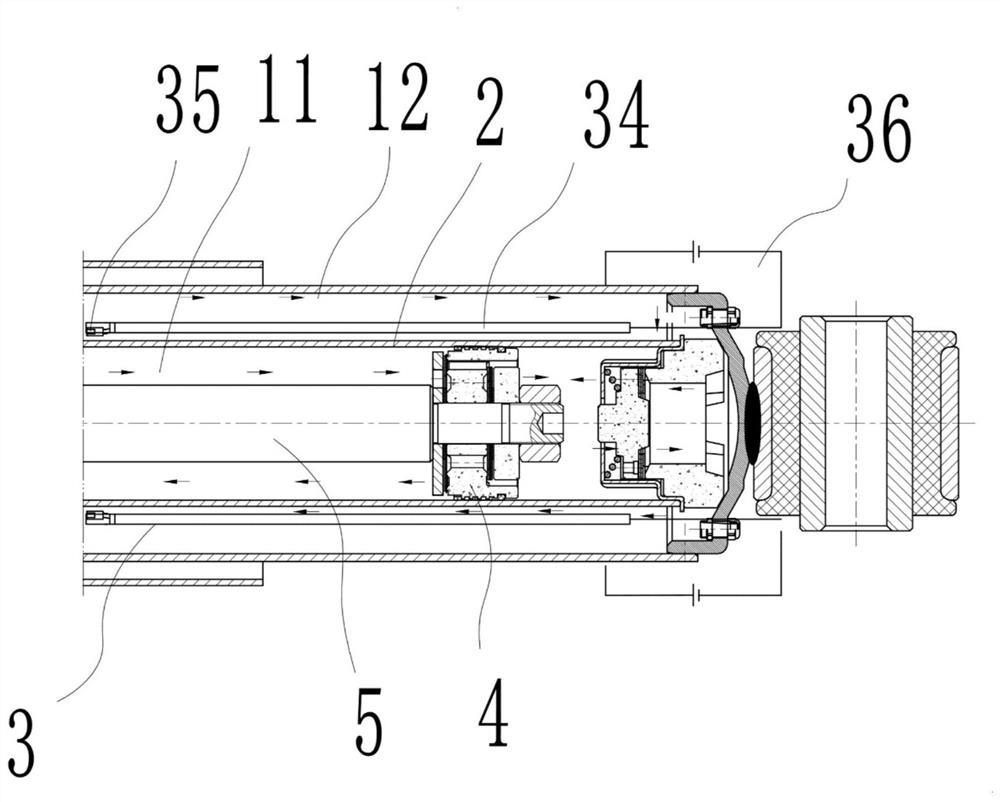

Temperature self-adaptive automobile shock absorber

ActiveCN113309808ASuitable temperatureAvoid failureSpringsImmersion heating arrangementsTemperature controlEngineering

In order to solve the problems of failure and abnormal sound caused by too low temperature of a shock absorber, a temperature self-adaptive automobile shock absorber is provided. The shock absorber comprises a shock absorption cylinder body, the shock absorption cylinder body comprises a working cavity and a liquid storage cavity which are separated by a working cylinder, and the working cavity and the liquid storage cavity are communicated through a valve. The working cavity and the liquid storage cavity are filled with oil, a piston is arranged in the working cavity, and a temperature control device is arranged in the liquid storage cavity. A temperature control device is additionally arranged in the liquid storage cavity, when the temperature of oil liquid is too low, the oil liquid in the liquid storage cavity is heated, the viscosity of the oil liquid is guaranteed, embrittlement of a sealing piece is reduced, and therefore a series of failure and noise problems caused by the too low temperature of the shock absorber can be avoided.

Owner:XGM CORP LTD

High chromium steel roller

InactiveCN103302100AHigh hardnessGood thermal crack resistanceRollsMetal rolling arrangementsMetallurgyMaterials science

The invention discloses a high chromium steel roller which comprises a jacket and a core, wherein the jacket comprises the following components by mass percentage: 1.1-1.3% of C, 0.9-1.1% of Si, 0.4-0.6% of Mn, less than or equal to 0.03% of P, less than or equal to 0.03% of S, 10.4-10.6% of Cr, 0.7-0.9% of Ni, 0.9-1.1% of Mo, 0.2-0.4% of V, 0.2-0.4% of Re, and the balance of Fe; and the core comprises the following components by mass percentage: 3.3-3.5% of C, 1.9-2.1% of Si, 0.4-0.6% of Mn, less than or equal to 0.1% of P, less than or equal to 0.03% of S, less than or equal to 0.03% of Cr, 0.4-0.8% of Ni, 0.2-0.4% of Mo, 0.04-0.06% of Re, and the balance of Fe. With the adoption of the mode, the rigidity of the high chromium steel roller can be improved; the roller has good abrasive resistance and hot tearing resistance; and the possibility of slipping during steel rolling is low.

Owner:WUXI CAIYUN MACHINERY & EQUIP

Heat resistant magnesium alloy

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Orthopaedic bearing material

ActiveUS8343230B2Improve wear resistanceImprove mechanical propertiesBone implantBearing componentsPulse radiationCrosslinked polymers

Disclosed is a polymeric orthopaedic bearing material for use as an implant material or part thereof comprising one or more crosslinked regions and one or more non-crosslinked or substantially non-crosslinked regions at the surface. The bearing material can be prepared from a crosslinkable polymer, e.g., ultrahigh molecular weight polyethylene. The orthopaedic bearing material has an advantageous combination of at least one wear property and at least one mechanical property. Also disclosed are processes for producing orthopaedic bearing materials, for example, by irradiating a raw material in consolidated form through a radiation mask having a perforated pattern for crosslinking selected regions of the raw material, and optionally shaping the raw material into a bearing material. Alternatively, a pulsed radiation beam can be used for crosslinking.

Owner:DEPUY PROD INC

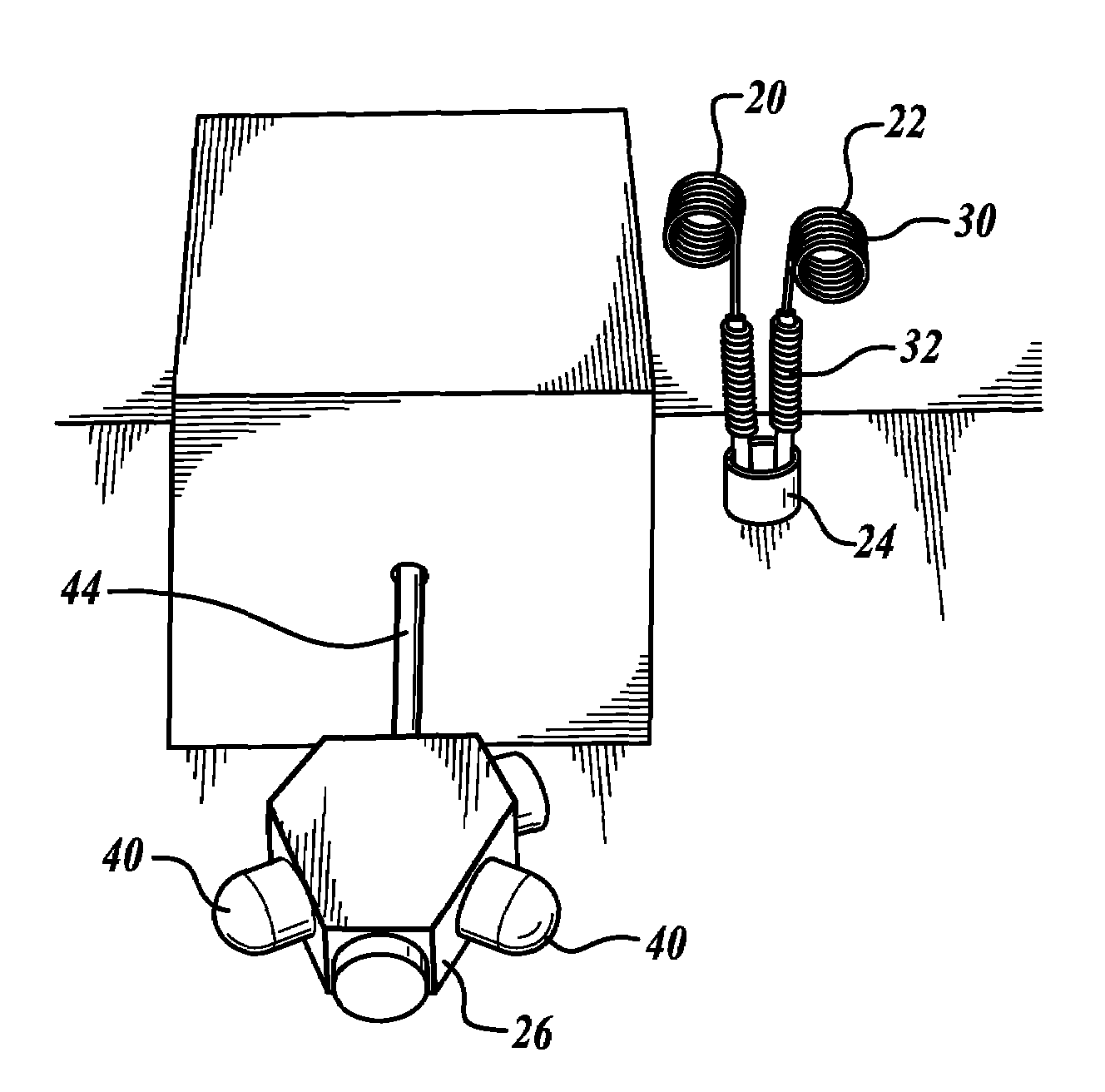

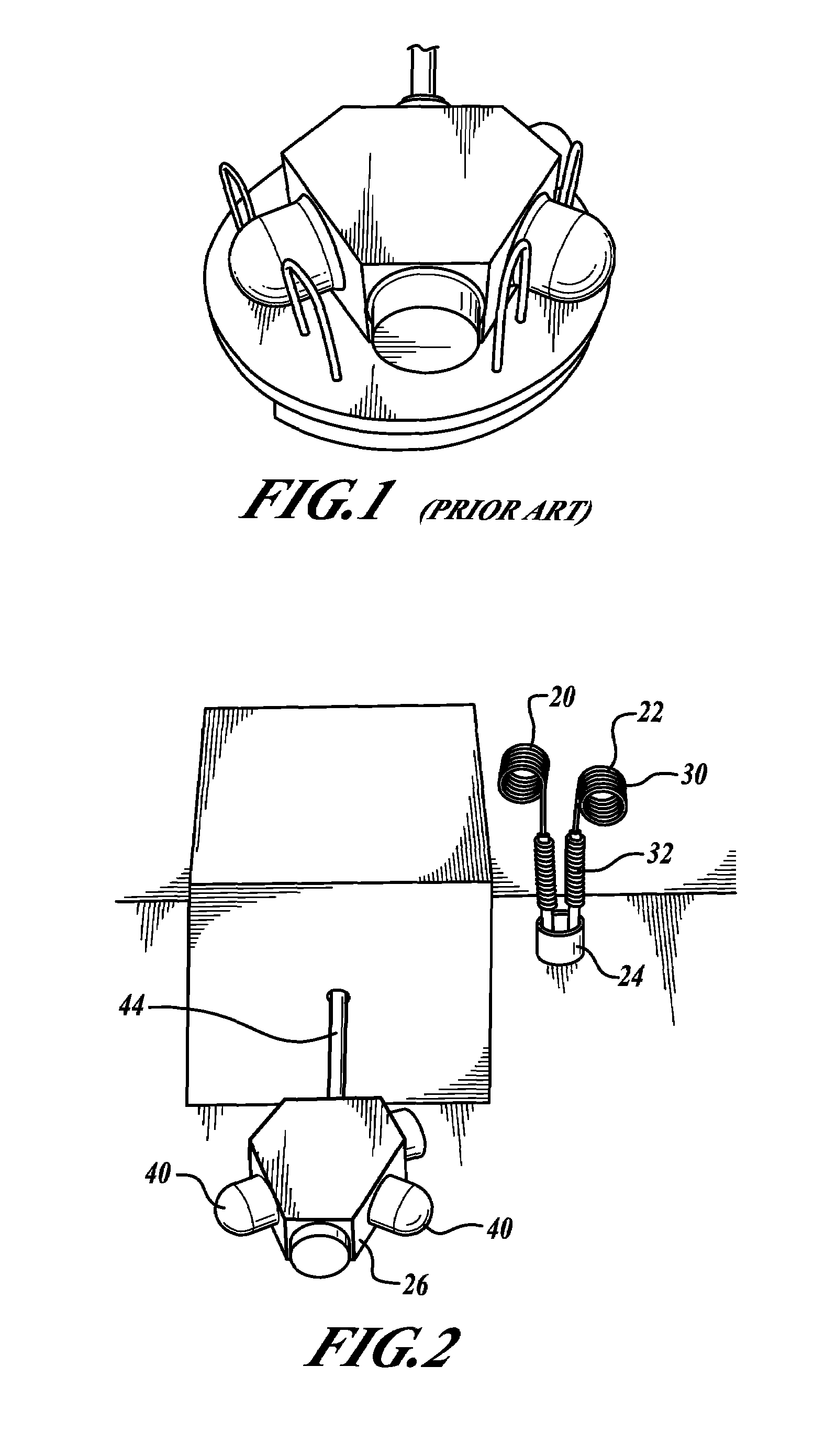

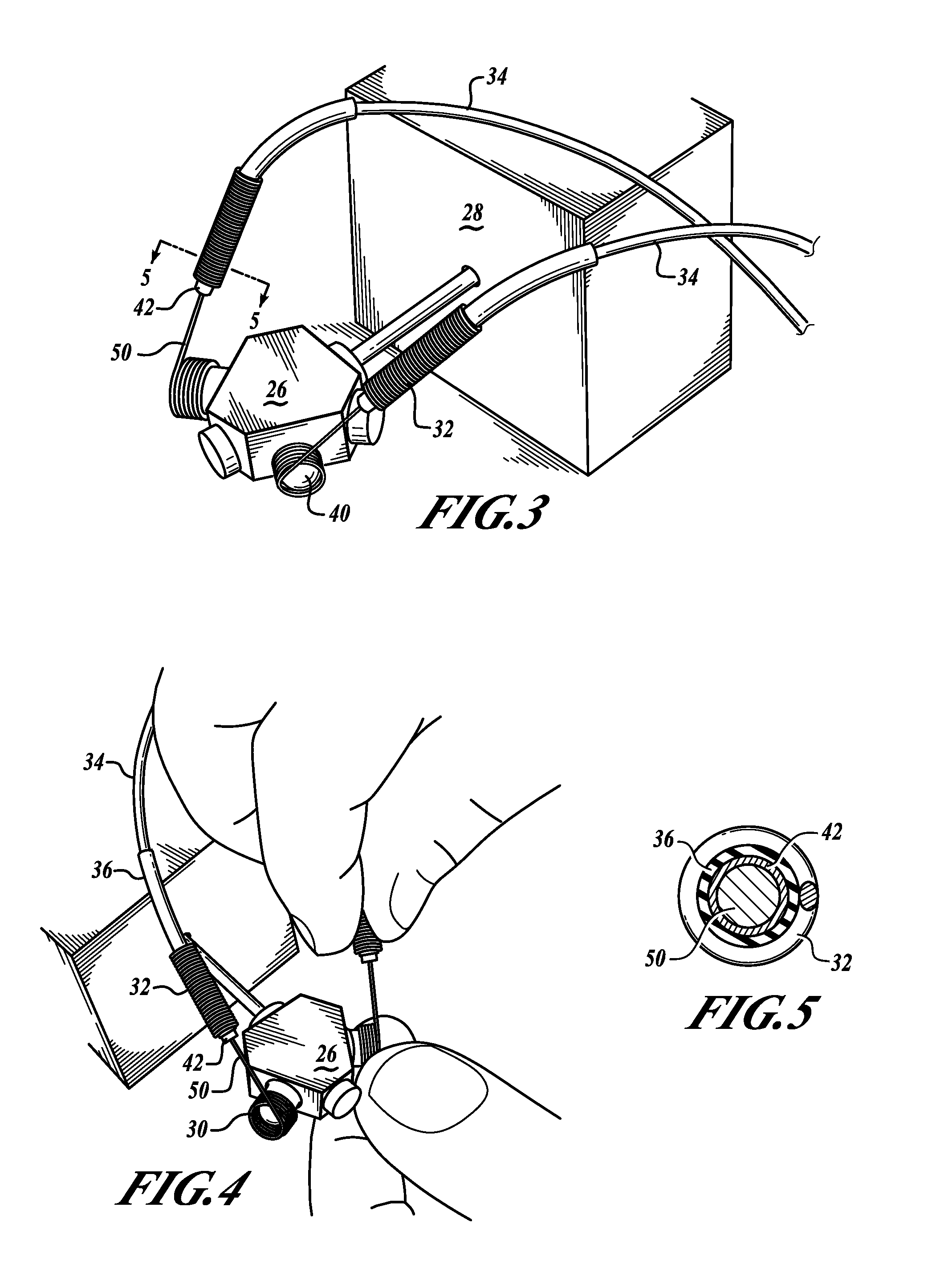

Electrode connector for ring laser gyros

InactiveUS7429198B1Reduce oxidationReduce electrical contact resistanceAir-treatment apparatus arrangementsCoupling contact membersGyroscopeEngineering

A laser block assembly (LBA) gas fill process device with improved cathode electrode connectors. An example device includes a gas fill component that attaches to an LBA under test and electrical connectors that receive a voltage bias from a voltage source and apply the voltage bias to cathodes of the LBA. The electrical connectors include an end having a torsion spring that is sized based on the cathodes of the LBA. Also, the electrical connectors may include a strain relief spring.

Owner:HONEYWELL INT INC

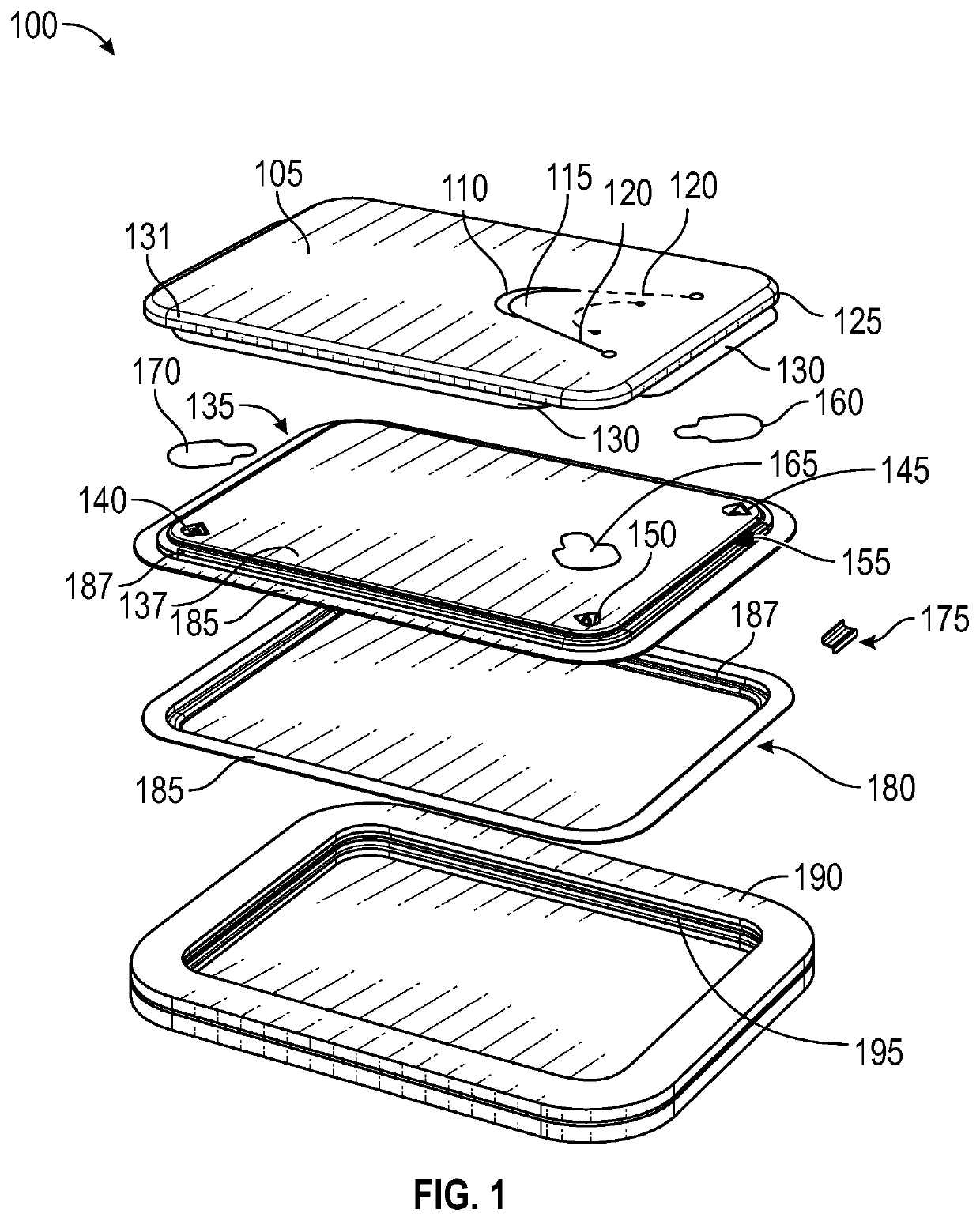

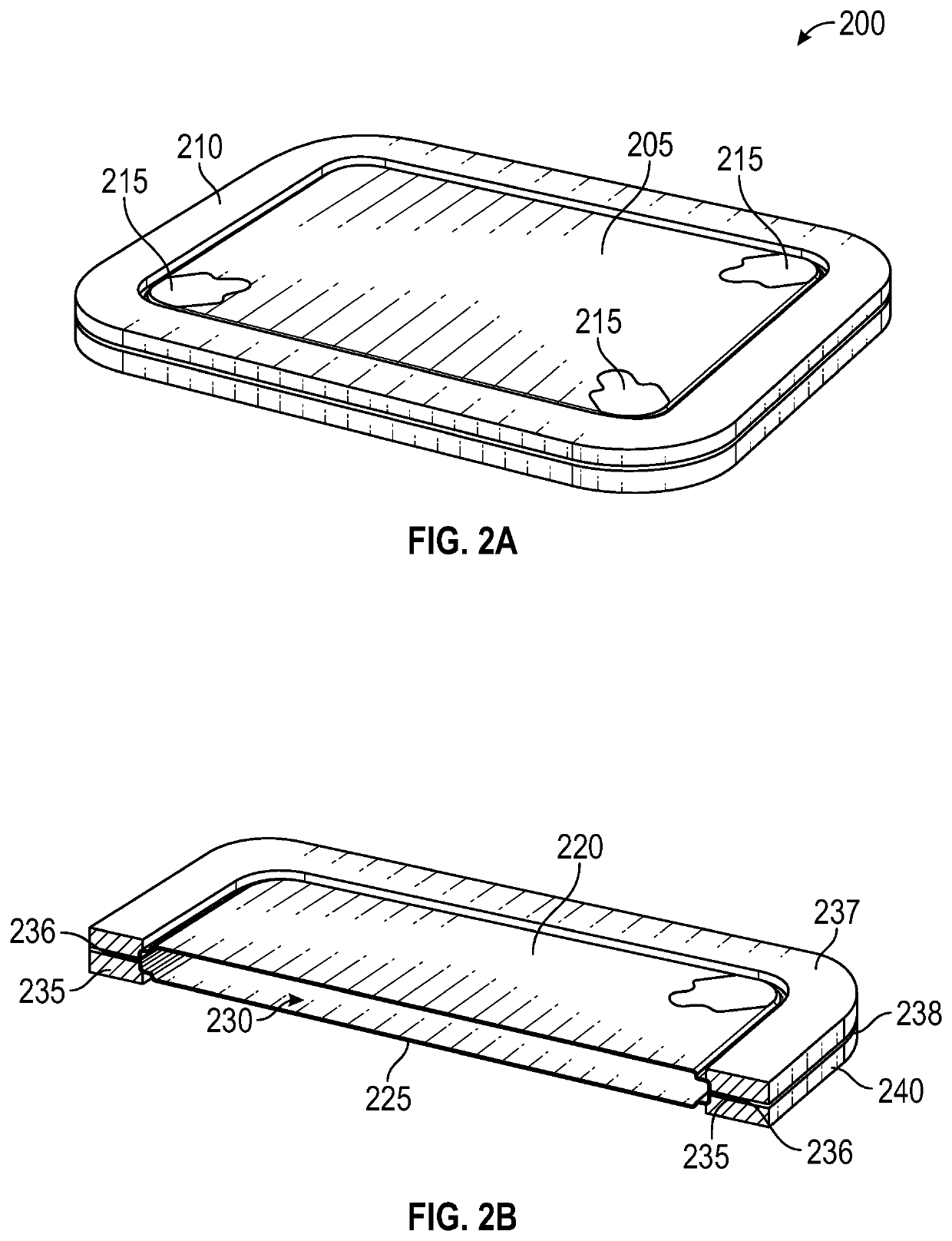

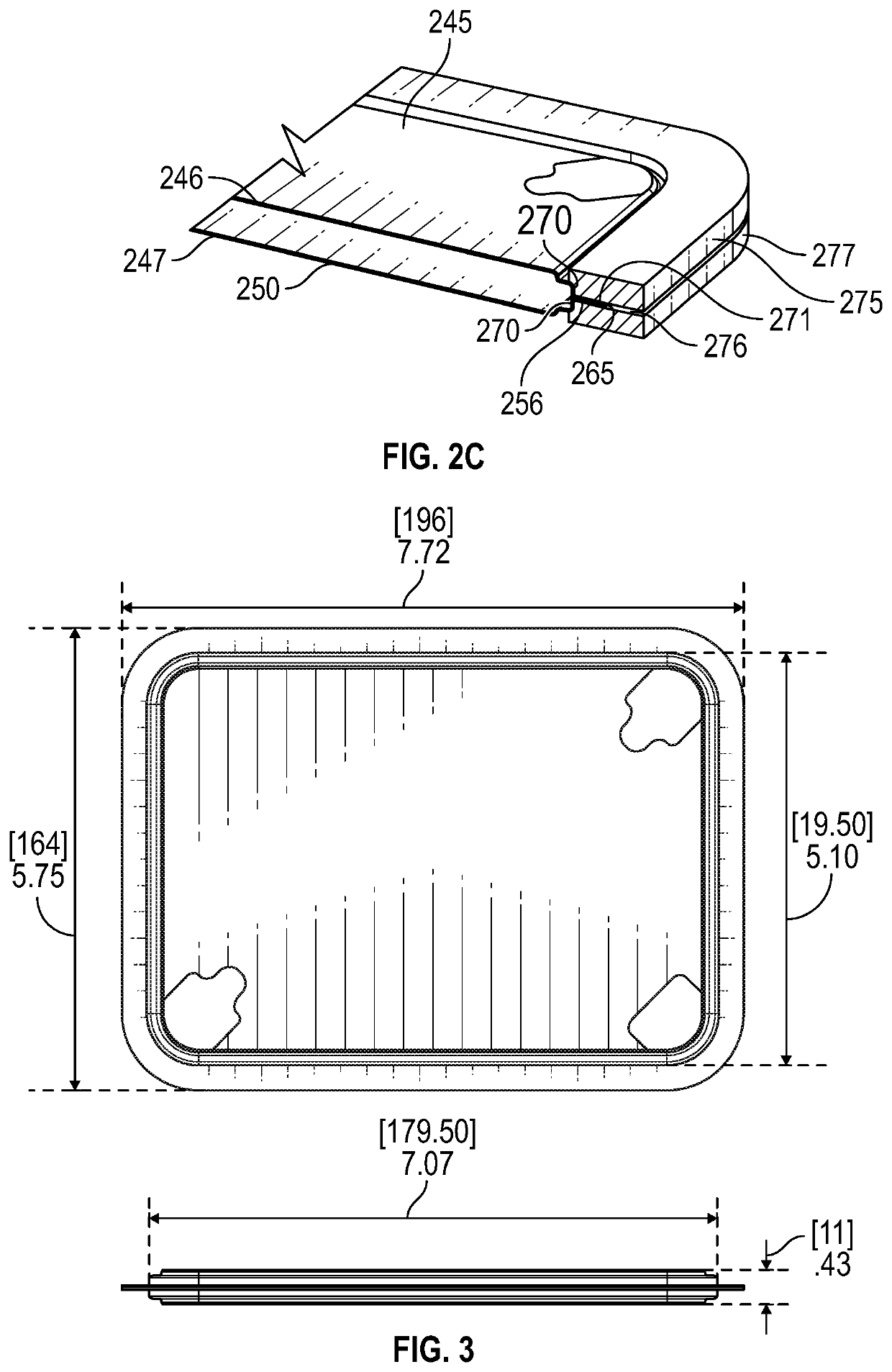

Multi-Functional Cryogenic Storage Vessel

PendingUS20210244019A1Reduce embrittlementMaximize flexibilityBottlesDead animal preservationEngineeringMechanical engineering

Systems and devices with enhanced stability to kinetic impact for the containment of cryogenically preserved material. A device comprising a vessel with increased surface to volume ratio when compared to cylindrical vessels of like capacity, and further comprising a material that remains resistant to shock and impact at cryogenic temperatures while providing a continuous barrier of a single material surrounding the vessel contents. The device further comprising a design that may be readily modified to include internalized sensors, enhanced interfacing to external instruments, provide optimized thaw rate, and post-thawing sample processing capabilities.

Owner:BIOLIFE SOLUTIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com