Method for reducing embrittlement degree of amorphous strip

An amorphous strip, embrittlement technology, applied in the furnace type, furnace, heat treatment furnace and other directions, can solve the problem of the hardness of amorphous alloy materials, and achieve the effect of reducing the embrittlement degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

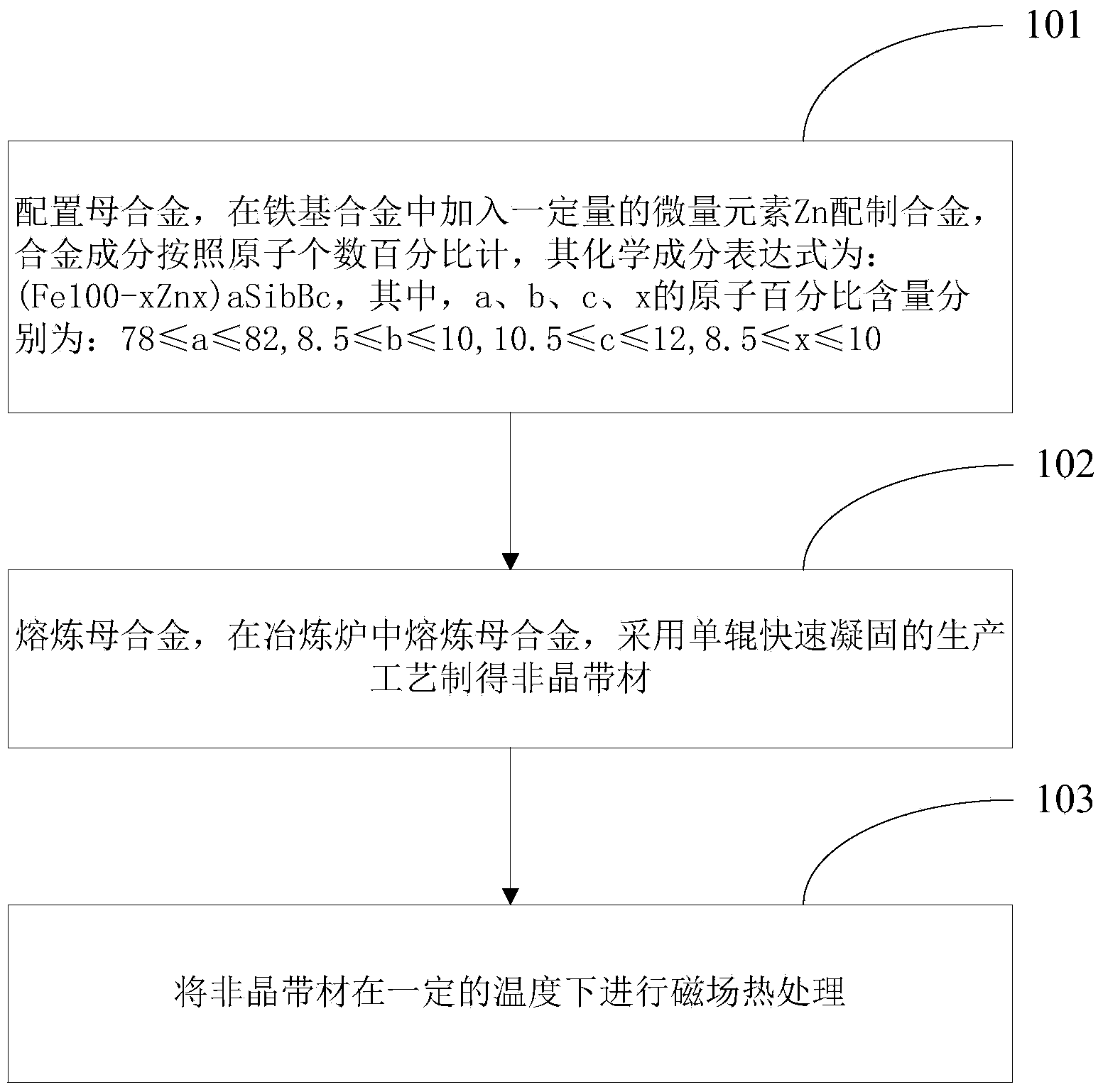

[0017] Such as figure 1 Shown is a flow chart of the method for reducing the embrittlement of amorphous strips in an embodiment of the present invention. As shown in the figure, the present invention specifically includes the following steps:

[0018] Step 101, configure the master alloy, add a certain amount of trace element Zn to the iron-based alloy to prepare the alloy, the alloy composition is calculated according to the atomic number percentage, and its chemical composition expression is: (Fe 100-x Zn x ) a Si b B c , wherein the atomic percent contents of a, b, c, and x are respectively: 78≤a≤82, 8.5≤b≤10, 10.5≤c≤12, 8.5≤x≤10.

[0019] A method for reducing the brittleness of the amorphous strip provided by the present invention is to add an appropriate amount of Zn in the smelting process of the strip mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com