Weather-proof modified asphalt

A modified asphalt and weather-resistant technology, applied in building components, building insulation materials, buildings, etc., can solve the problem of unsatisfactory high-temperature stability of modified asphalt, insignificant modification performance of modified asphalt, and restrictions on the promotion and use of modified asphalt. and other problems, to achieve the effect of improving fluidity and weather resistance, avoiding embrittlement and cracking, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

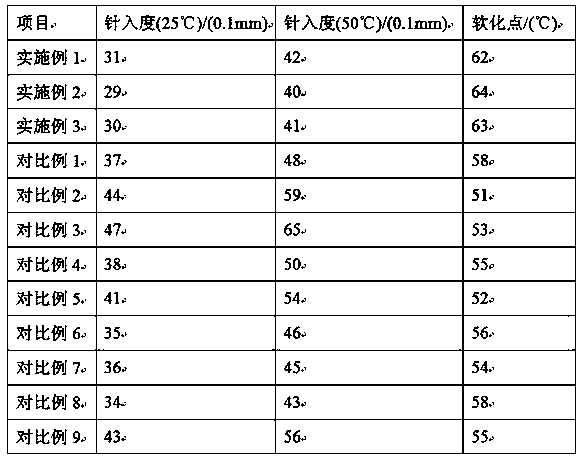

Examples

Embodiment 1

[0016] A weather-resistant modified asphalt, made of the following raw materials in parts by weight: base asphalt 95, water 2.2, nano-titanium dioxide 2.1, SBS asphalt modifier 1.7, fatty alcohol polyoxyethylene ether ammonium sulfate 1.1, asphalt stabilizer 0.3, graphite Alkene 0.5.

[0017] The asphalt stabilizer is made of the following raw materials in parts by weight: 4.1 zinc acetate, 2.4 methylcyclopentadiene, and 7 ethanol.

[0018] A preparation method of weather-resistant modified asphalt, comprising the following steps:

[0019] (1) Heat the base asphalt to 180°C, transfer it to the production tank, and keep it warm for 10 minutes to obtain heated asphalt;

[0020] (2) Add nano-titanium dioxide and SBS asphalt modifier into the heated asphalt, stir evenly, keep warm and swell for 20 minutes, which can improve the fluidity and weather resistance of the asphalt, reduce the difficulty of construction, and obtain swollen asphalt;

[0021] (3) Add graphene to swollen a...

Embodiment 2

[0024] A weather-resistant modified asphalt, made of the following raw materials in parts by weight: base asphalt 98, water 2.3, nano-titanium dioxide 2.2, SBS asphalt modifier 1.8, fatty alcohol polyoxyethylene ether ammonium sulfate 1.2, asphalt stabilizer 0.4, graphite Alkene 0.6.

[0025] The asphalt stabilizer is made of the following raw materials in parts by weight: 4.2 parts by weight of zinc acetate, 2.5 parts by methylcyclopentadiene, and 7.5 parts by weight.

[0026] A preparation method of weather-resistant modified asphalt, comprising the following steps:

[0027] (1) Heat the base asphalt to 185°C, transfer it to the production tank, and keep it warm for 13 minutes to obtain heated asphalt;

[0028] (2) Add nano-titanium dioxide and SBS asphalt modifier into the heated asphalt, stir evenly, keep warm and swell for 25 minutes, which can improve the fluidity and weather resistance of the asphalt, reduce the difficulty of construction, and obtain swollen asphalt; ...

Embodiment 3

[0032] A weather-resistant modified asphalt, made of the following raw materials in parts by weight: base asphalt 100, water 2.4, nano-titanium dioxide 2.3, SBS asphalt modifier 1.9, fatty alcohol polyoxyethylene ether ammonium sulfate 1.3, asphalt stabilizer 0.5, graphite Alkene 0.7.

[0033] The asphalt stabilizer is made of the following raw materials in parts by weight: 4.3 parts by weight of zinc acetate, 2.6 parts by methylcyclopentadiene, and 8 parts by weight.

[0034] A preparation method of weather-resistant modified asphalt, comprising the following steps:

[0035] (1) Heat the base asphalt to 190°C, transfer it to the production tank, and keep it warm for 15 minutes to obtain heated asphalt;

[0036] (2) Add nano-titanium dioxide and SBS asphalt modifier into the heated asphalt, stir evenly, and heat-preserve and swell for 30 minutes, which can improve the fluidity and weather resistance of the asphalt, reduce the difficulty of construction, and obtain swollen asp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com