Wire rod for Cr-Mo steel submerged arc welding wire and manufacturing method thereof

A technology of submerged arc welding wire and manufacturing method, which is applied to the wire rod and manufacturing field of Cr-Mo steel submerged arc welding wire, can solve the problems of dependence on imports and difficult metallurgical manufacturing, and achieves high purity, improved toughness, and reduced embrittlement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

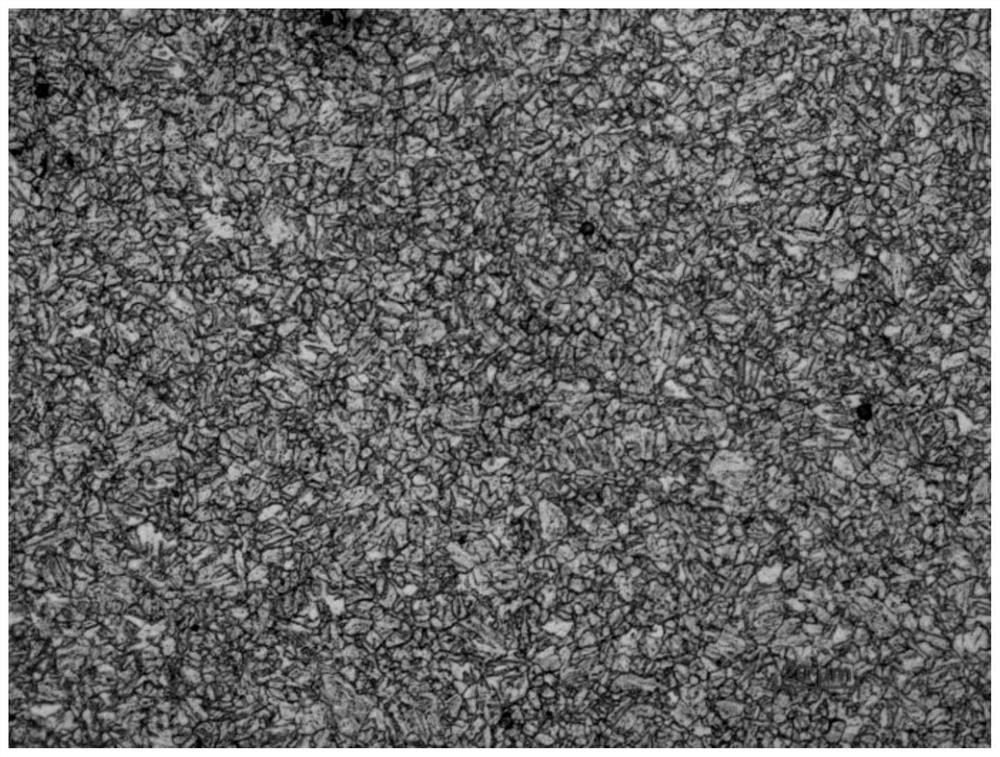

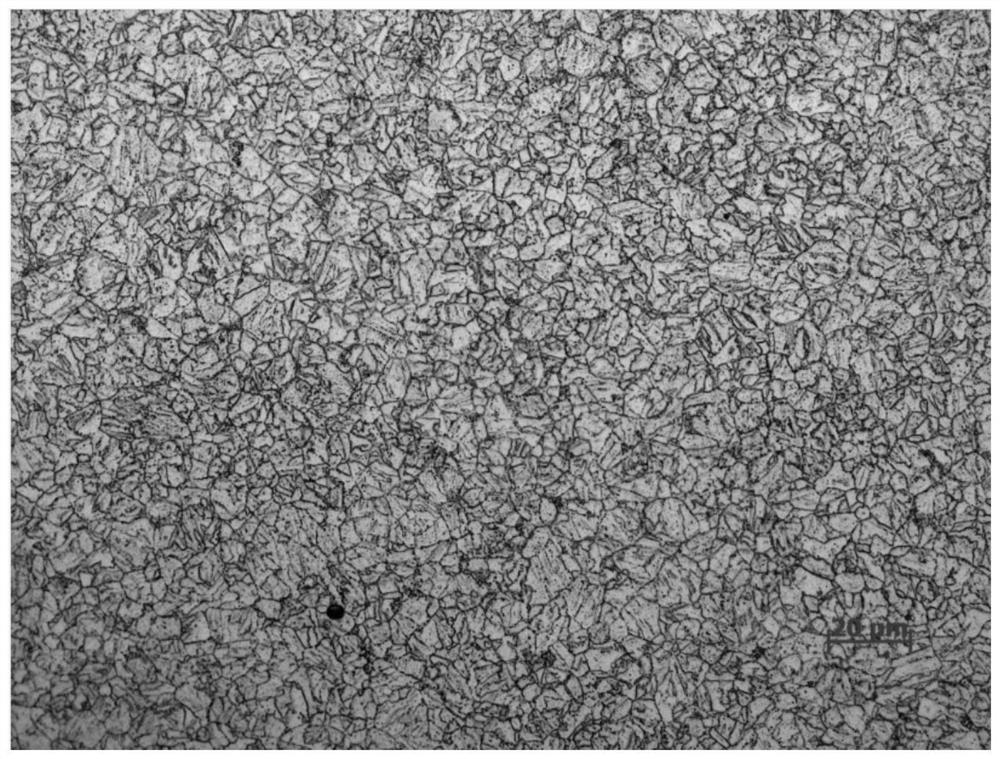

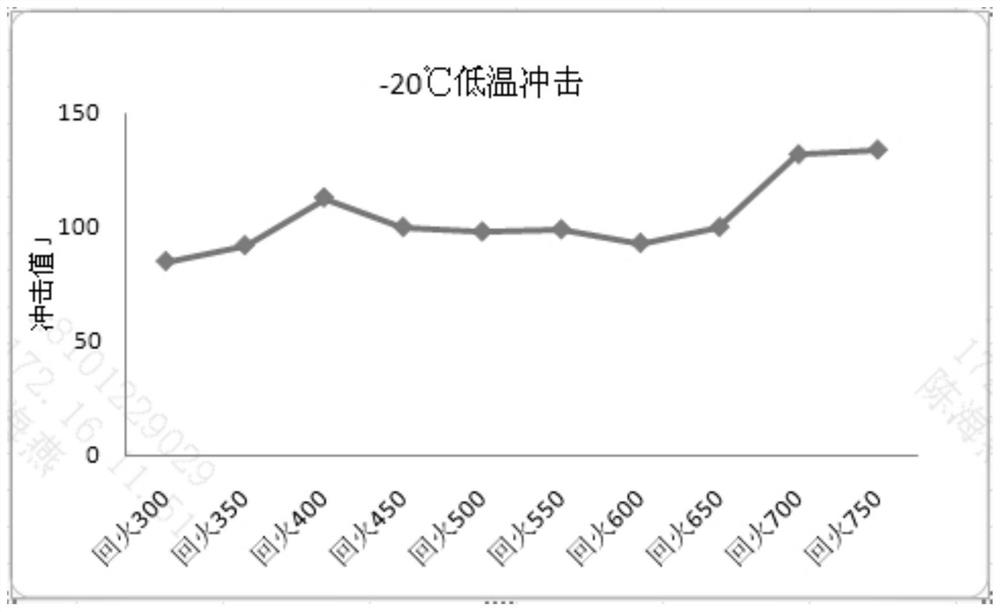

Image

Examples

Embodiment 1

[0045] C: 0.13%, Si: 0.18%, Mn: 1.2%, P: 0.003, S: 0.002%, Cr: 2.4%, Mo: 1.05%, V: 0.38%, Nb: 0.015%, Ni: 0.08%, Cu : 0.08%, Sb: 0.0012%, Sn: 0.0023%, As: 0.0062%, X=(10P+5Sb+4Sn+As)×10 2 =5.14, J=(Si+Mn)×(P+Sn)×10 4 =73.14, the balance is Fe and unavoidable impurity elements.

Embodiment 2

[0047] C: 0.12%, Si: 0.17%, Mn: 1.22%, P: 0.004, S: 0.002%, Cr: 2.4%, Mo: 1.05%, V: 0.38%, Nb: 0.015%, Ni: 0.08%, Cu : 0.08%, Sb: 0.0015%, Sn: 0.0020%, As: 0.0052%, X=(10P+5Sb+4Sn+As)×10 2 =6.07, J=(Si+Mn)×(P+Sn)×10 4 =83.4, the balance is Fe and unavoidable impurity elements.

[0048] The molten steel of the above two components is hoisted to the continuous casting respectively, and the continuous casting slab with the cross-sectional size of 200mm×200mm is produced, and the continuous casting ensures that the superheat of the tundish is 15-30°C. The mold adopts special low-carbon alloy steel mold slag, and adopts electromagnetic stirring of the mold and end electromagnetic stirring to ensure the uniformity of the billet structure. The billet is fully peeled before high-wire rolling, and the peeling depth is ≥1.0mm to ensure the surface quality of the billet.

[0049] Heat the continuous casting slab to above 1110°C, control the residual oxygen in the furnace below 4%, hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com