A heat treatment process for improving temper brittleness of martensitic heat-resistant steel

A tempering brittle, martensite technology, applied in the field of heat-resistant steel, can solve the problems of scrapped workpieces and economic losses, and achieve the effect of improving strength and toughness, obvious benefits, and inhibiting crack nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Processing material: Cr12Ni2 martensitic heat-resistant steel, weight 10Kg;

[0026] After the steel ingot undergoes high-temperature solution treatment, high-temperature forging and quenching, the billet is tempered. Tempering temperature is 620 ℃, heat preservation 2 hours.

[0027] The impact energy was tested to be 65J, the toughness was significantly reduced, and a certain amount of M23C6 carbide particles were observed to be distributed on the boundaries of martensite laths, resulting in temper brittleness.

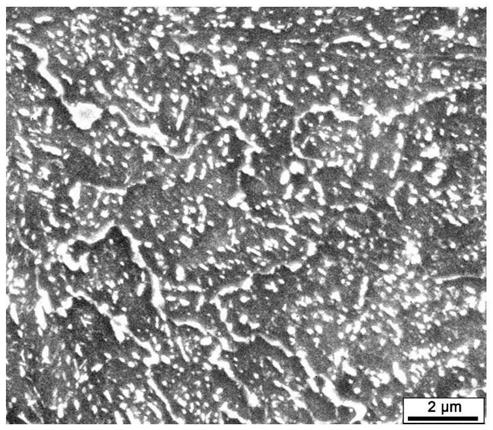

[0028] The brittle sample was tempered again, and the tempering temperature was raised to 650° C., and kept for 3 hours. The mechanical properties of the sample after secondary tempering were tested, and the impact energy was determined to be 115J, the hardness was 335HBW, and the tensile strength was 917Mpa. At the same time, the diffuse distribution of carbonitrides distributed in the matrix can be observed by SEM and TEM. The results show that after sec...

Embodiment 2

[0030] The processing material is Cr12Ni2 martensitic heat-resistant steel with a weight of 15Kg.

[0031] After the steel ingot undergoes high-temperature solution treatment, high-temperature forging and quenching, the billet is tempered. Tempering temperature is 630 ℃, heat preservation 5 hours. The mechanical properties of the workpiece in Example 2 were tested, and the impact energy was 102J, the hardness was 340HBW, and the tensile strength was 938Mpa. At the same time, it is observed that carbides such as M2X and M7C3 are distributed in the matrix. The results show that although the tempering is carried out in the brittle temperature region, due to the prolonged tempering time, the toughness of the sample is not significantly reduced, and the performance is improved to avoid temper brittleness.

Embodiment 3

[0033] The processing material is Cr12Ni2 martensitic heat-resistant steel with a weight of 18Kg.

[0034] After the steel ingot undergoes high-temperature solution treatment, high-temperature forging and quenching, the billet is tempered. Tempering temperature is 660°C, heat preservation for 1 hour, then lower the temperature to 625°C and heat preservation for 2 hours. The mechanical properties of the workpiece of Example 3 were tested, and the impact energy was 114J, the hardness was 337HBW, and the tensile strength was 925Mpa. It can be observed that carbides such as M2X and M7C3 are distributed in the matrix. The results show that after pre-tempering, even at T 脆 Tempering within the range will also not produce temper brittleness.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com