A kind of simncrnimo low-carbon martensitic steel, drilling rig suspension ring and manufacturing method thereof

A manufacturing method and martensitic steel technology, applied in the field of drilling rig rings and their manufacturing, SiMnCrNiMo low carbon martensitic steel, can solve the problem of low impact absorption energy, achieve excellent performance, reduce inclusions and harmful microstructures. The effect of forming and improving hardenability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

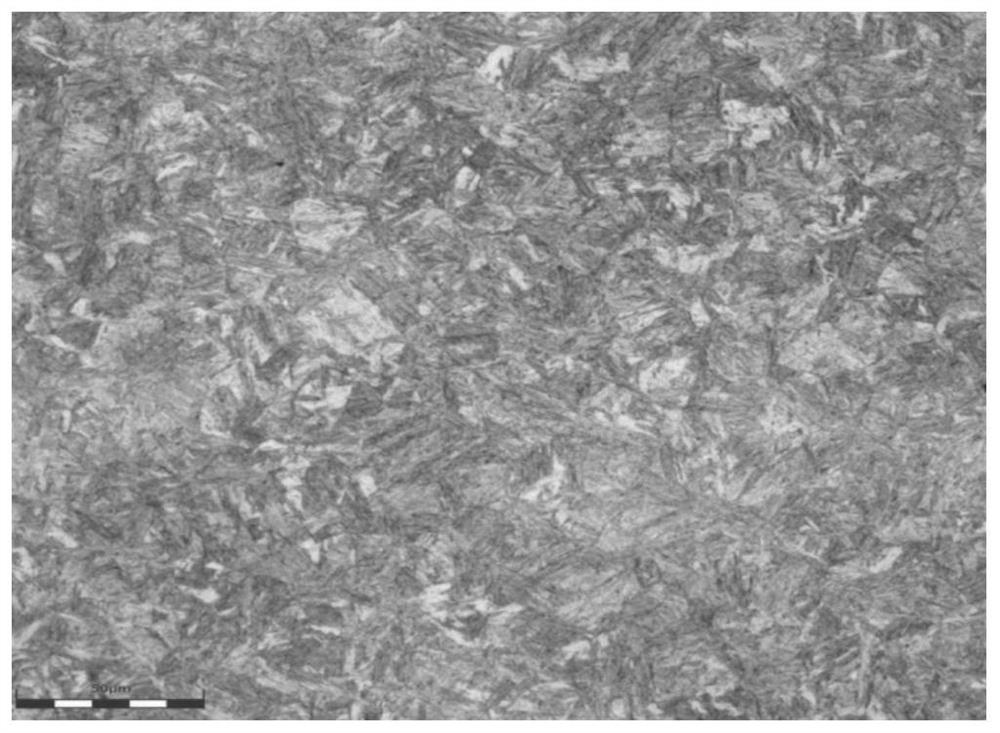

Image

Examples

Embodiment 1

[0036] A method of manufacturing a suspension ring, comprising the steps of:

[0037] (1) Refining the components of Example 1 in Table 1 to obtain a diameter of 600mm billet ingot, by mass percentage, including the following components:

[0038] C: 0.16%; Si: 0.30%; Mn: 1.5%; Cr: 0.4%; Mo: 0.50%; Ni: 3.5%; , [H]: 0.5ppm, the rest is iron and unavoidable impurities;

[0039] (2) Heating the billet ingot evenly, heating it to 1180°C for forging, controlling the forging termination temperature to 850°C, and obtaining a round steel with a diameter of 330-340mm, after forging, the surface temperature is lowered to 400°C for furnace cooling;

[0040] (4) Reheat the round steel to 1180°C for forging, the forging termination temperature is controlled at 850°C, and the forging ring sample is obtained with a diameter of 130-135mm;

[0041] (5) Heat the suspension ring sample to 910-920°C, keep it warm for 3 hours, air-cool to room temperature, then heat it to 880-890°C, keep it warm ...

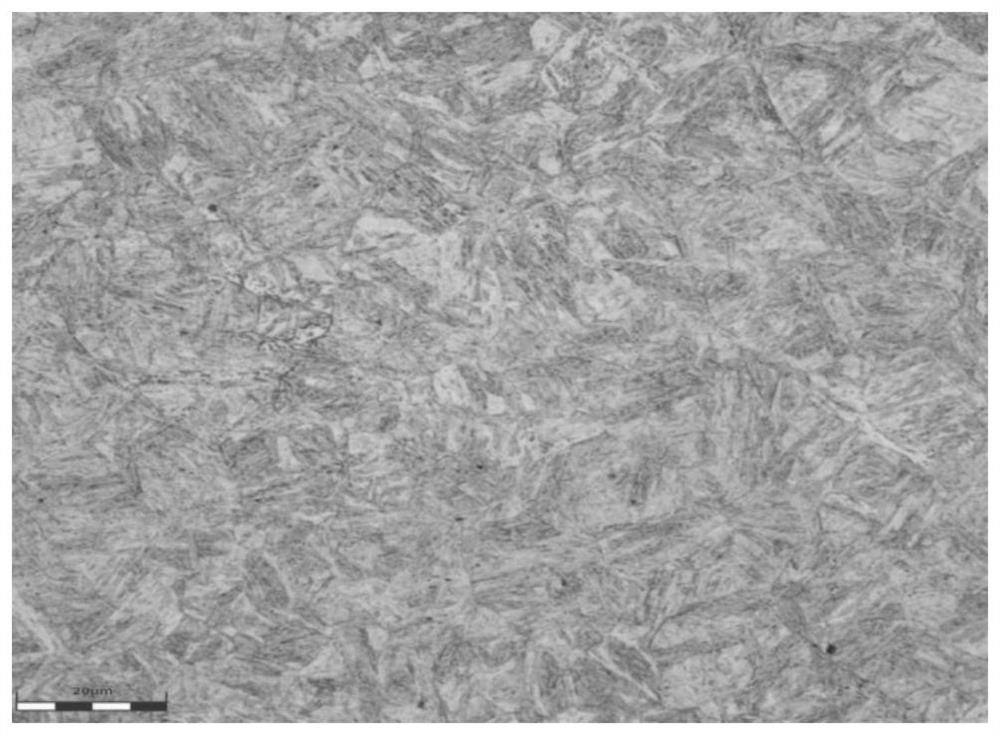

Embodiment 2

[0044] A method of manufacturing a suspension ring, comprising the steps of:

[0045] (1) Refining is carried out by the component of Table 1 Example 2, and the obtained diameter is the 620mm steel billet ingot, by mass percentage, comprising the following components:

[0046] C: 0.18%; Si: 0.45%; Mn: 1.4%; Cr: 0.5%; Mo: 0.45%; Ni: 3.8%; Al: 0.03%, V: 0.07%; [N]: 80ppm; S: 0.007% And P: 0.01%, [H]: 1ppm, the rest is iron and unavoidable impurities;

[0047] (2) Heating the billet casting ingot evenly, heating the temperature to 1170°C for forging, controlling the forging termination temperature to 850°C, forging to obtain a round steel with a diameter of 340-350mm, and reducing the surface temperature to 420°C for furnace cooling after forging;

[0048] (4) Reheat the round steel to 1170°C for forging, the forging termination temperature is controlled at 850°C, and the forging ring sample is obtained with a diameter of 136-140mm;

[0049] (5) Heat the suspension ring sample ...

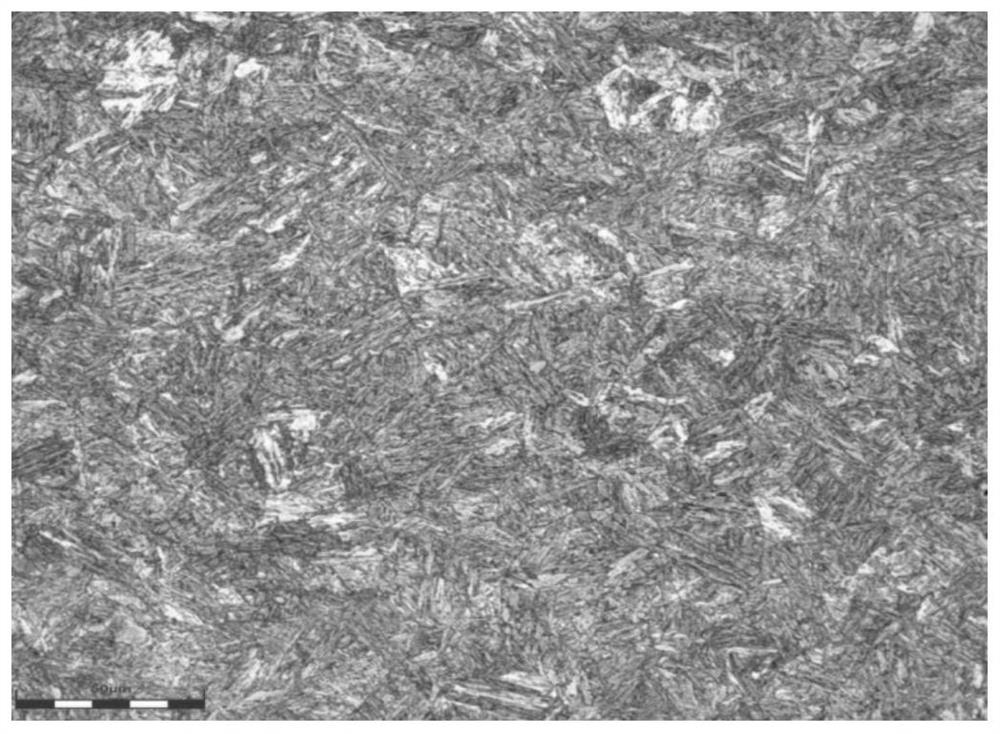

Embodiment 3

[0052] A method of manufacturing a suspension ring, comprising the steps of:

[0053] (1) Refining is carried out by the component of embodiment 3 in table 1, and obtaining diameter is 660mm billet ingot, and it comprises following component by mass percentage:

[0054] C: 0.20%; Si: 0.45%; Mn: 1.2%; Cr: 0.6%; Mo: 0.35%; Ni: 3.9%; Al: 0.02%, V: 0.08%; [N]: 50ppm; S: 0.008% And P: 0.007%, [H]: 0.3ppm, the rest is iron and unavoidable impurities;

[0055] (2) Heating the billet ingot evenly, heating it to 1190°C for forging, controlling the forging end temperature to 850°C, forging round steel with a diameter of 335-350 mm, and reducing the surface temperature to 450°C for furnace cooling after forging;

[0056] (4) Reheat the round steel to 1190°C for forging, the forging termination temperature is controlled at 850°C, and the forging ring sample is obtained with a diameter of 135-140mm;

[0057] (5) Heat the suspension ring sample to 915-930°C, keep it warm for 2.8h, air-coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com