Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

94 results about "Nickel Protoxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature type lithium manganate anode material for power lithium ion battery and preparation method of high-temperature type lithium manganate anode material

ActiveCN104485452AImprove high temperature resistanceExcellent discharge specific capacityCell electrodesCobalt(II,III) oxideManganate

The invention discloses a high-temperature type lithium manganate anode material for a power lithium ion battery. The high-temperature type lithium manganate anode material consists of a core material as shown in a formula Li1+xMn2-y-zAyQzO4, and a coating layer on the surface of the core material, wherein the coating layer is one or more of cobaltosic oxide, aluminum oxide and nickel protoxide. The anode material is excellent in high-temperature property, and is good in specific discharge capacity, capacity retention ratio and electrochemical circulation property at high temperature. In addition, the preparation method of the anode material disclosed by the invention is simple in production process, easy to achieve and low in cost, and can be applied to large-scale industrialization production.

Owner:北京盟固利新材料科技有限公司

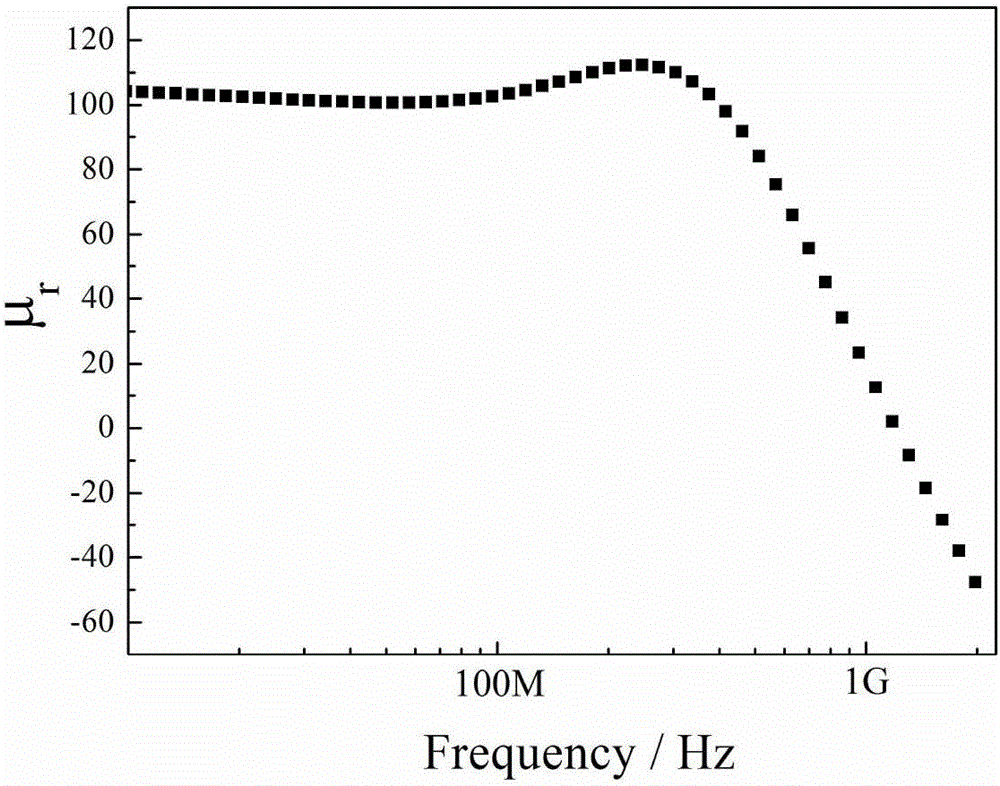

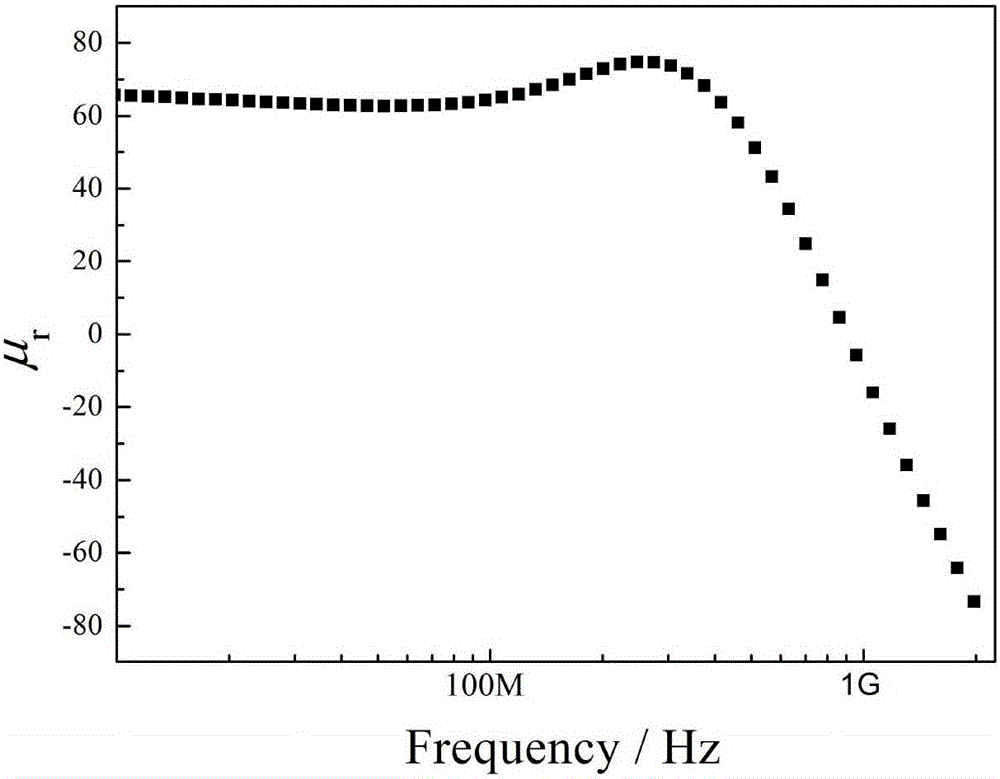

Ni-Zn soft magnetic ferrite material and preparation method thereof

The invention discloses a nickel-zinc soft magnetic ferrite material and a preparation method thereof. The material comprises the following compositions in mol percentage: 45 to 50 mol percent of ferric oxide Fe2O3, 20 to 26 mol percent of zinc oxide ZnO, 12 to 17 mol percent of nickel protoxide NiO, 5 to 10 mol percent of copper oxide CuO, and 3 to 10 mol percent of magnesium oxide MgO. The preparation method comprises the following steps: treating raw materials, proportioning, primary ball milling, drying, powdering or screening, preburning, secondary proportioning, secondary ball milling, secondary drying and secondary powdering or screening; the preburning condition is to carry out pre-synthesis in an air furnace at a temperature of between 900 and 980 DEG C, and the sintering temperature is between 1,050 and 1,100 DEG C. The nickel-zinc soft magnetic ferrite material has the characteristics of property of high Q, high frequency, high TC, high Bm and low cost.

Owner:广东肇庆微硕电子有限公司 +1

A nickel-copper-zinc ferrite and its making method

InactiveCN101236819AUniform grain sizeUniform sizeInorganic material magnetismCurie temperatureVanadium oxide

The invention relates to a nickel-copper-zinc ferrite and a manufacturing method thereof. The ferrite of the invention comprises principal constituents and auxiliary constituents, wherein, the principal constituents are respectively iron oxides, nickel protoxide, zinc oxides and cupric oxides; the contents of the principal constituents calculated by respective reference substances are that: 48 mol percent to 50 mol percent Fe2O3, 13 mol percent to 16 mol percent NiO, 29 mol percent to 31.5 mol percent ZnO and 4.5 mol percent to 6.5 mol percent CuO; the auxiliary constituents comprise vanadium oxides, molybdenum oxides and titanium oxides; compared with the gross of the principal constituents, the total content of the auxiliary constituents calculated by respective reference substances V2O5, MoO3 and TiO2 is 0.01 weight percent to 0.08 weight percent. The nickel-copper-zinc ferrite has higher Curie temperature and high initial permeability, high saturation magnetic flux density and low loss under the condition of wide-temperature range, thereby comprehensive performance requirements of development of electric equipment towards directions of miniaturization, mobilization, integration and multifunction can be better met.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

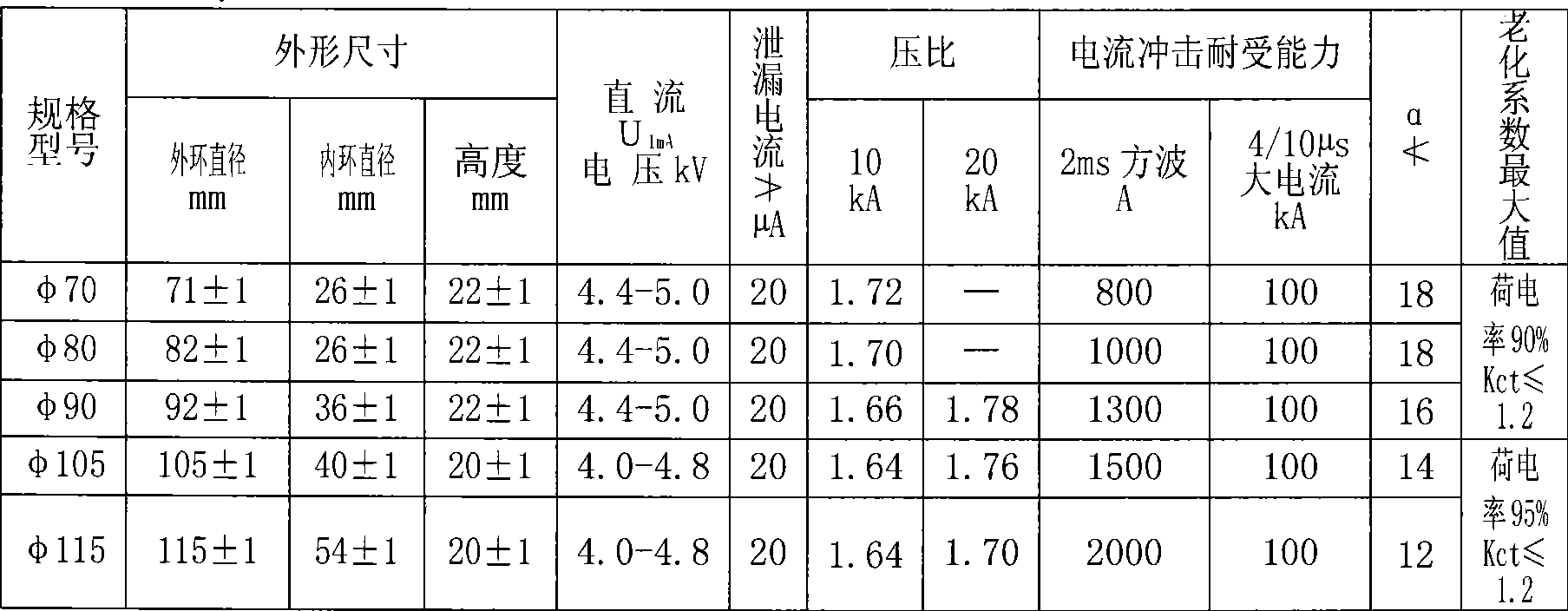

Formula of direct current zinc oxide resistance chip

ActiveCN101503292AUniform and stable structureReduce defect concentrationVaristor coresSesquioxideAntimony trioxide

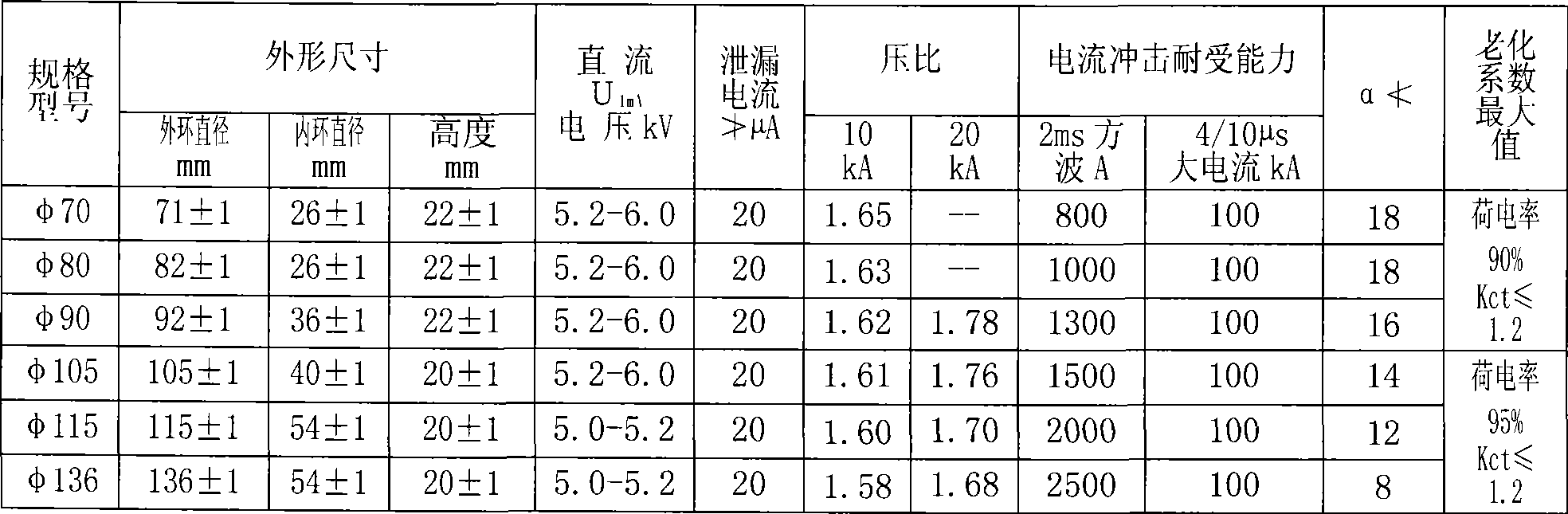

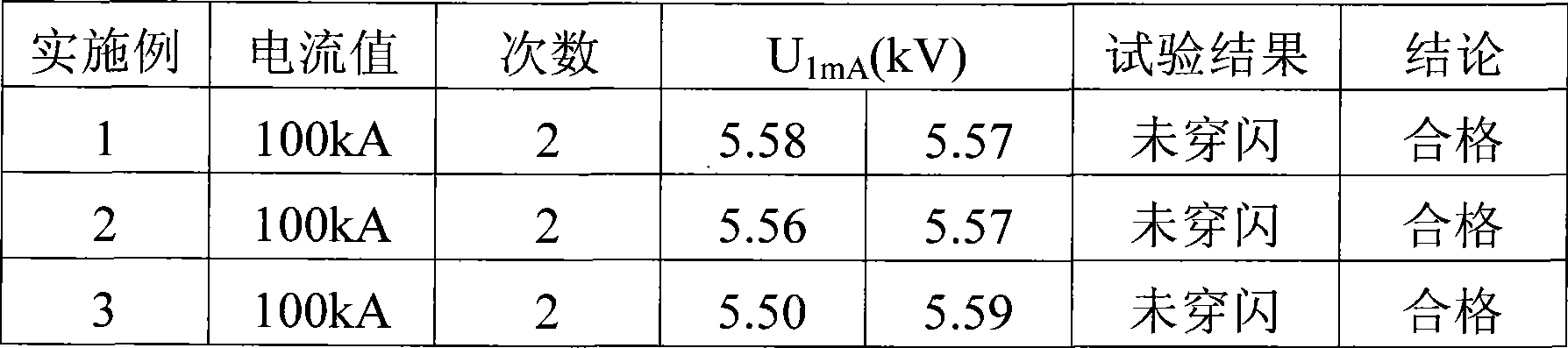

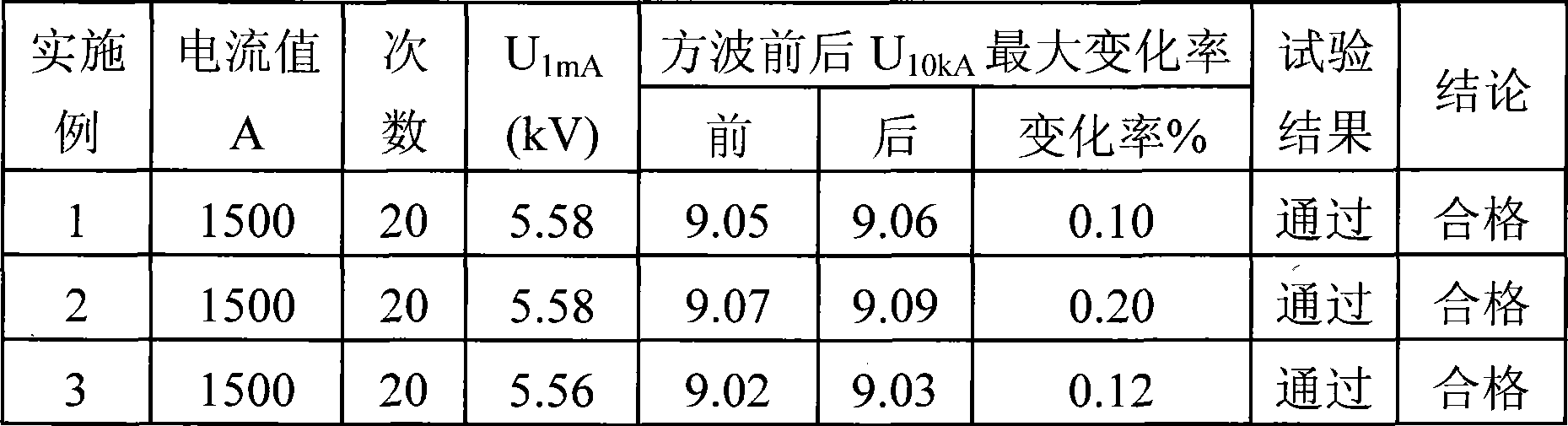

The invention discloses a formulation of an AC zinc oxide resistance chip. The formulation is characterized by comprising the following additives and a main material ZnO by weight percentage: 4.0 to 4.9 percent of Bi2O3, 3.0 to 4.0 percent of Sb2O3, 0.5 to 1.0 percent of SiO2, 2.0 to 3.0 percent of Co2O3, 0.50 to 0.80 percent of Cr2O3, 0.50 to 0.80 percent of MnCO3, 0.70 to 0.90 percent of NiO, 0.03 to 0.05 percent of aluminum nitrate, 0.10 to 0.20 percent of glass dust, 0.07 to 0.10 percent of B2O3 and 85.0 to 88.0 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the internal structure of the resistance chip is more excellent; and 2, dosage of cobalt sesquioxide, dibismuth trioxide and diantimony trioxide are added in the formulation, the mixture ratio of each composition is more reasonable, and the non-linearity coefficient of the resistance chip can be improved, the pressure ratio is reduced, the circulation capability is improved, and the comprehensive performance is excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

High-voltage resistant high-stability piezoelectric ceramic

The invention discloses high-voltage resistant high-stability piezoelectric ceramic, comprising the following raw materials in parts by weight: 100 parts of lead tetroxide, 14-17 parts of barium carbonate, 3.5-6.5 parts of strontium carbonate, 28-30 parts of zirconium dioxide, 15-17 parts of titanium dioxide, 9.6 parts of niobium pentoxide, 2.8 parts of nickel protoxide, 0.05-0.07 part of cerium oxide, 0.03-0.05 part of chromium sesquioxide, 0.04-0.06 part of silicon dioxide and 0.02-0.04 part of lithium carbonate. The piezoelectric ceramic is prepared through mixing, pre-sintering, crushing, baking, pulping, cast film forming, isostatic pressing, sintering, electric shock treatment and polarization. A micro unit cell of the piezoelectric ceramic is square unit cell, the included angle between crystal axes is 90 degrees, the unit cell structure is relatively stable, and the electric domain is changed little by high voltage and high temperature shock. A device manufactured by adopting the piezoelectric ceramic is low in performance drift and low in failure rate, the stability and consistency of products are improved, and large-scale application of piezoelectric high-power products is promoted.

Owner:HUNAN JIAYEDA ELECTRONICS

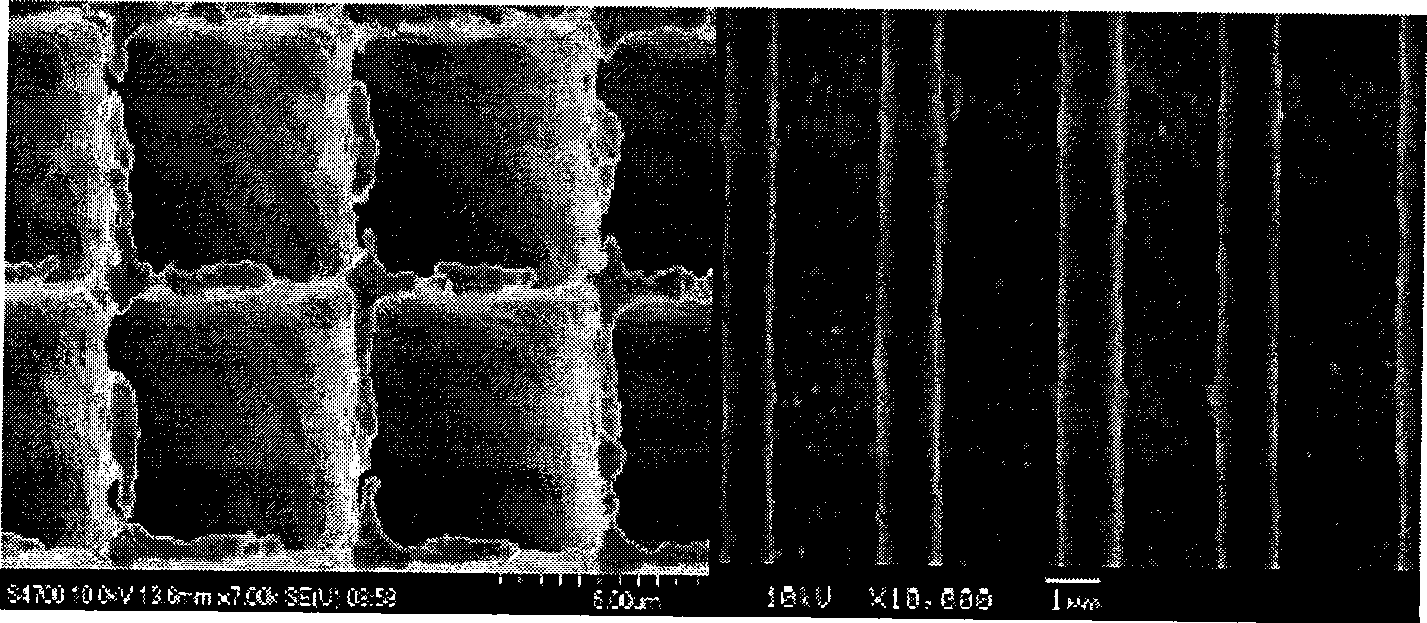

Nanometer metal ceramic inertia anode material for electrolytic aluminum and preparation method thereof

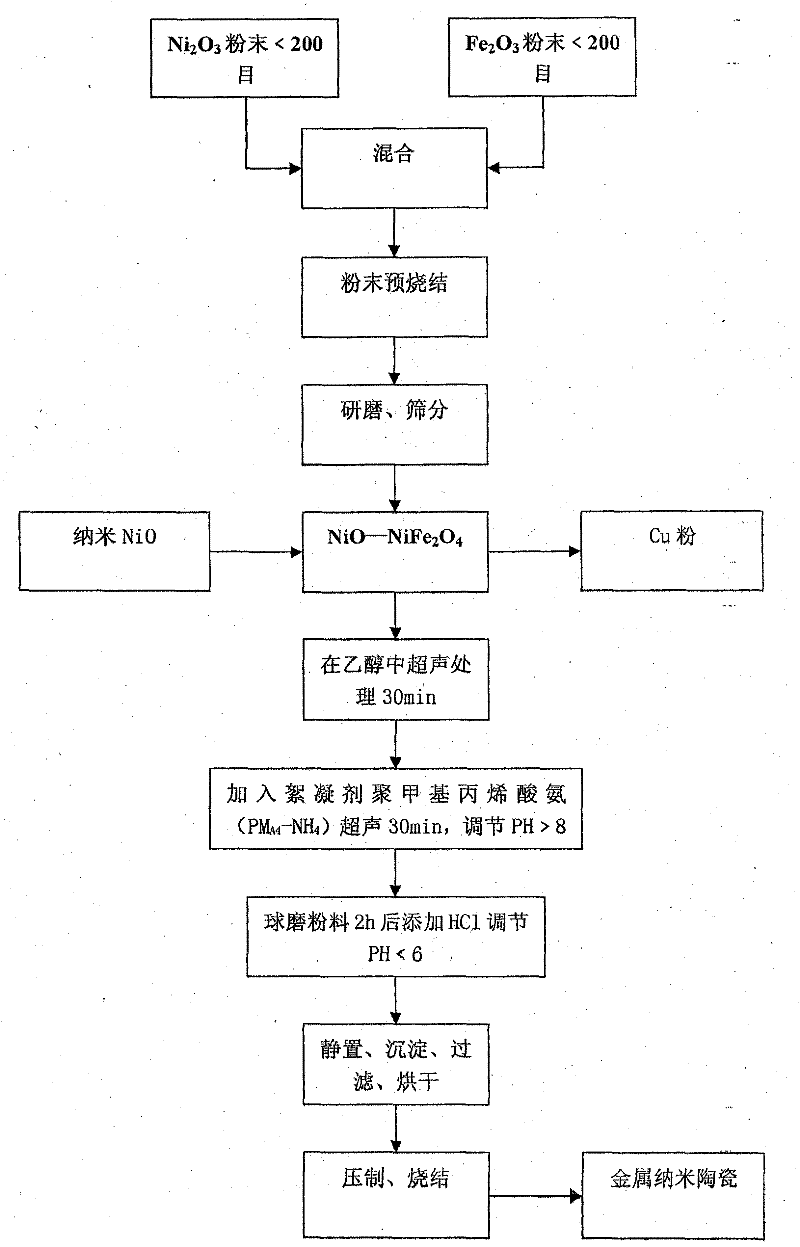

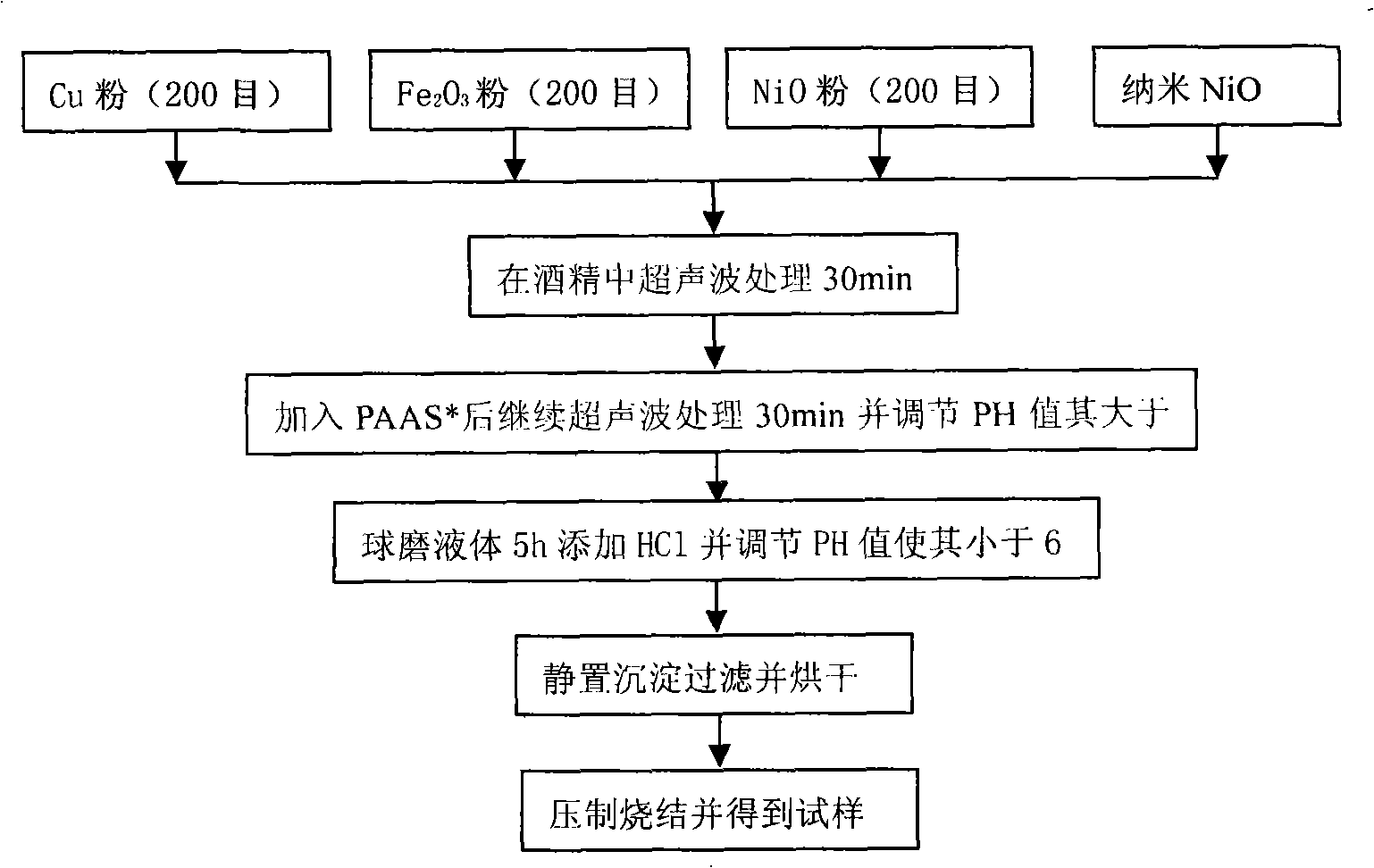

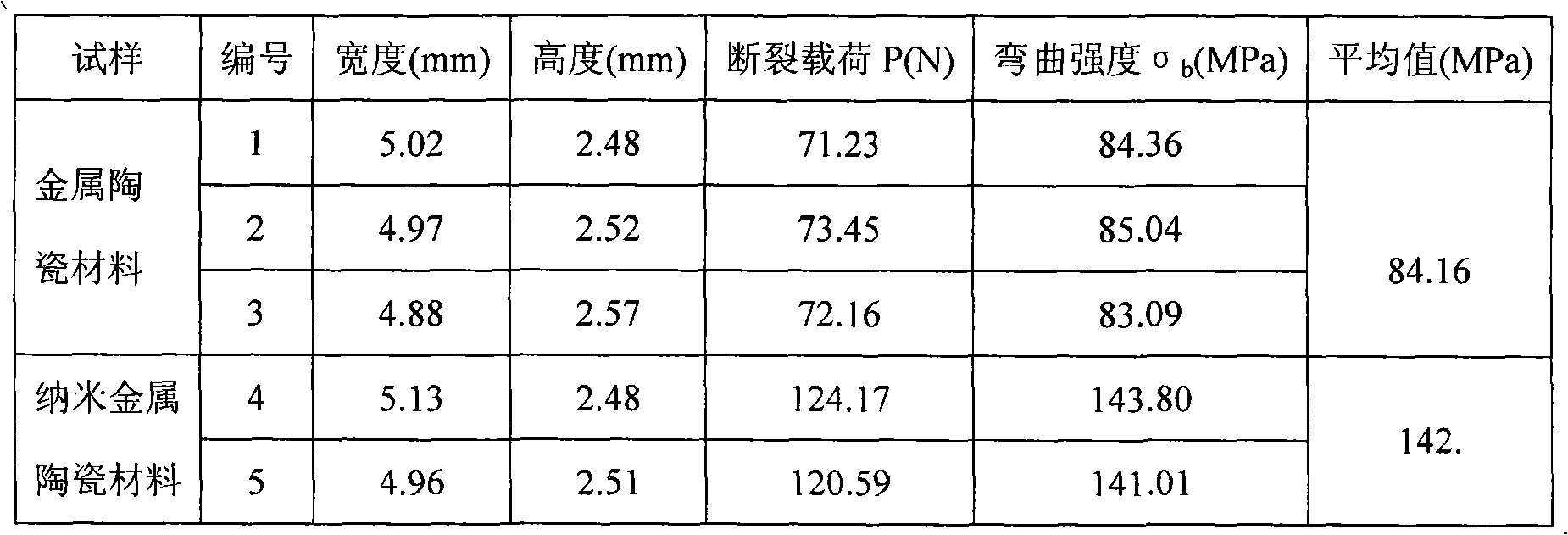

The invention relates to a nanometer metal ceramic inertia anode material for electrolytic aluminum and a preparation method thereof. The anode material is prepared by adding metal Cu powder and nanometer NiO into a metal ceramic matrix NiO-NiFe2O4 prepared from Ni2O3 and Fe2O3 which serve as raw materials, wherein the anode material comprises the following raw materials in percentage by mass: 52 to 54 percent of Ni2O3, 31 to 33 percent of Fe2O3 and 15 to 20 percent of Cu powder; and the addition amount of the nanometer NiO is 3 to 6 percent of the total mass of the raw materials. The preparation method comprises the following steps of: mixing nickel protoxide powder and iron oxide powder, and sintering to obtain a ground mass NiO-NiFe2O4; (2) grinding and sieving the ground mass; (3) adding copper powder and the nanometer NiO in the powder, and performing ultrasonic processing in industrial ethanol; (4) adding a dispersing agent and regulating a pH value, performing ball milling, and regulating the pH value again; (5) standing, precipitating, filtering and drying to obtain powder; (6) adding a plasticizing agent, mixing uniformly and compacting; and (7) sintering and cooling compacted blanks to obtain the nanometer metal ceramic inertia anode material. In the nanometer metal ceramic inertia anode material, the conductivity can reach 102 <-1>cm<-1> at the temperature of 1,000 DEG C, so the anode material can be used for aluminum electrolysis industry.

Owner:GUIZHOU UNIV

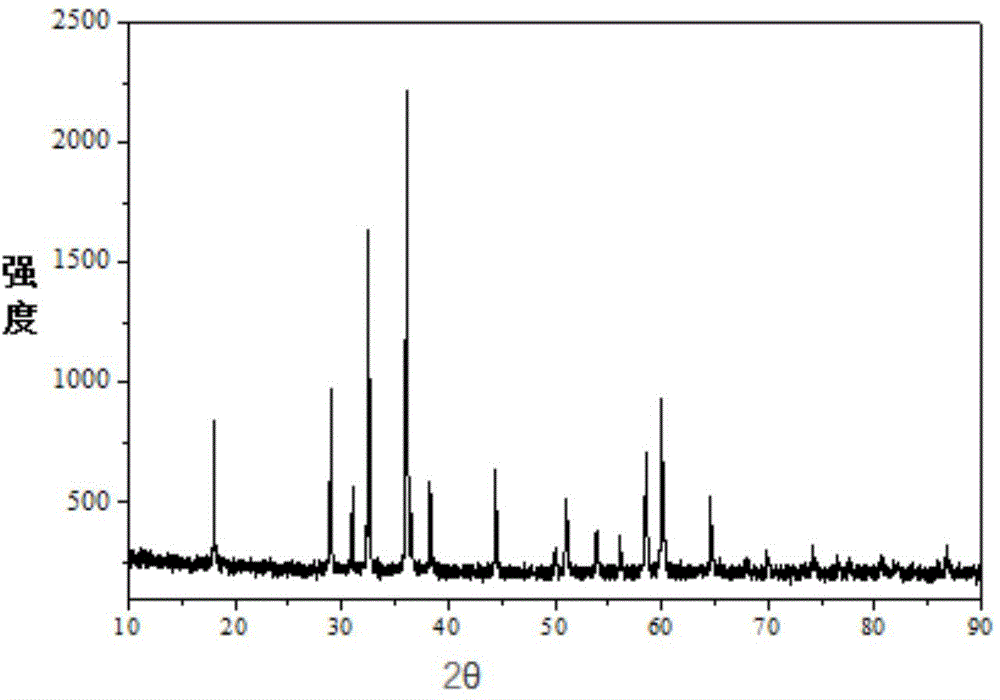

Technique for firing spinel-type black ceramic material with tunnel kiln

The invention discloses a technique for firing a spinel-type black ceramic material with a tunnel kiln, which comprises the following steps: 1) uniformly mixing 25-40 wt% of chrome oxide green, 30-45 wt% of iron oxide red, 2-25 wt% of cobalt oxide, 10-20 wt% of nickel protoxide and 0-20 wt% of dopant; 2) filling the mixture obtained in the step 1) into a saggar by 70-80% full, calcining in a tunnel kiln, and naturally cooling the calcining product, wherein the technological conditions for calcination are as follows: the temperature of the preheating region is 1170-1250 DEG C, the temperature of the high-temperature region is 1200-1300 DEG C, and the transmission speed is 12-20 hours from charging to discharging; 3) pulverizing and grinding the cooled calcining product; and 4) adding concentrated hydrochloric acid to wash the calcining substance powder obtained in the step 3), stirring to sufficiently react, stirring, washing with water until the pH value is 7, drying and screening. The ceramic pigment has the advantages of high color development capacity and low cost.

Owner:佛山市南海万兴材料科技有限公司

Preparation method and application of interface modification layer based on nickel protoxide hole transport layer

InactiveCN107221601AChanging the surface contact angleIncrease the open circuit voltageSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellHole transport layer

The invention discloses a preparation method and application of an interface modification layer based on a nickel protoxide hole transport layer. The preparation method comprises the following steps: (1) immersing the nickel protoxide hole transport layer in the aqueous solution of an interface modification agent; and (2) adsorbing the interface modification agent to a side of the nickel protoxide hole transport layer and forming the interface modification layer, wherein the interface modification agent is an organic molecule with an amino group at one end and a carboxyl group at the other end. By using the characteristics of the organic molecule with an amino group at one end and a carboxyl group at the other end, the organic molecule can be adsorbed to the nickel protoxide hole transport layer to form the interface modification layer to change the surface contact angle of the nickel protoxide hole transport layer, passivate the interface defect of the nickel protoxide hole transport layer and a perovskite film, improve the open-circuit voltage and the stability of a perovskite solar cell prepared subsequently, and further improve the overall performance of the perovskite solar cell.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

Formula of high pressure AC zinc oxide resistance chip

ActiveCN101503291AUniform and stable structureImproved energy toleranceVaristor coresSesquioxideCarbide

The invention discloses a formulation of a high-voltage AC zinc oxide resistance chip. The formulation comprises the following additives and a main material ZnO by weight percentage: 4.5 to 5.5 percent of Bi2O3, 5.0 to 6.0 percent of Sb2O3, 0.8 to 1.2 percent of Co2O3, 0.9 to 1.1 percent of MnCO3, 1.0 to 1.5 percent of NiO, 0.02 to 0.04 percent of aluminum nitrate, 0.010 to 0.050 percent of glass dust and 85.0 to 87.5 percent of ZnO. The formulation of the resistance chip has the following characteristics and advantages: 1, the formulation is a new formulation system using the zinc oxide, dibismuth trioxide, diantimony trioxide, nickel protoxide, cobalt sesquioxide and manganous carbide as main compositions, so that the internal structure of the resistance chip is more uniform and stable, and the energy endurance capability is greatly improved; and 2, the nickel protoxide and the glass dust are introduced into the formulation, so that the stability and the aging performance of the resistance chip is more excellent.

Owner:FUSHUN ELECTRIC PORCELAIN MFG CO LTD

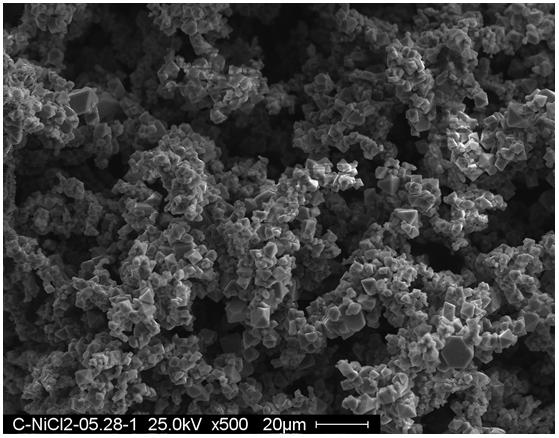

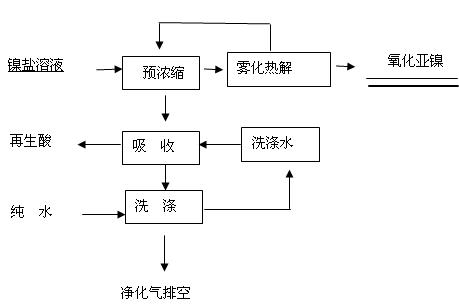

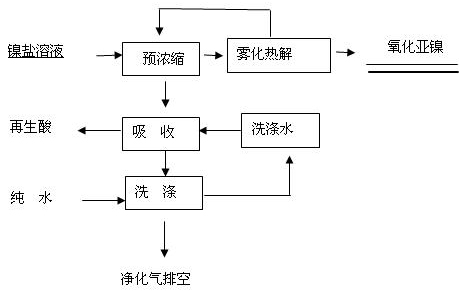

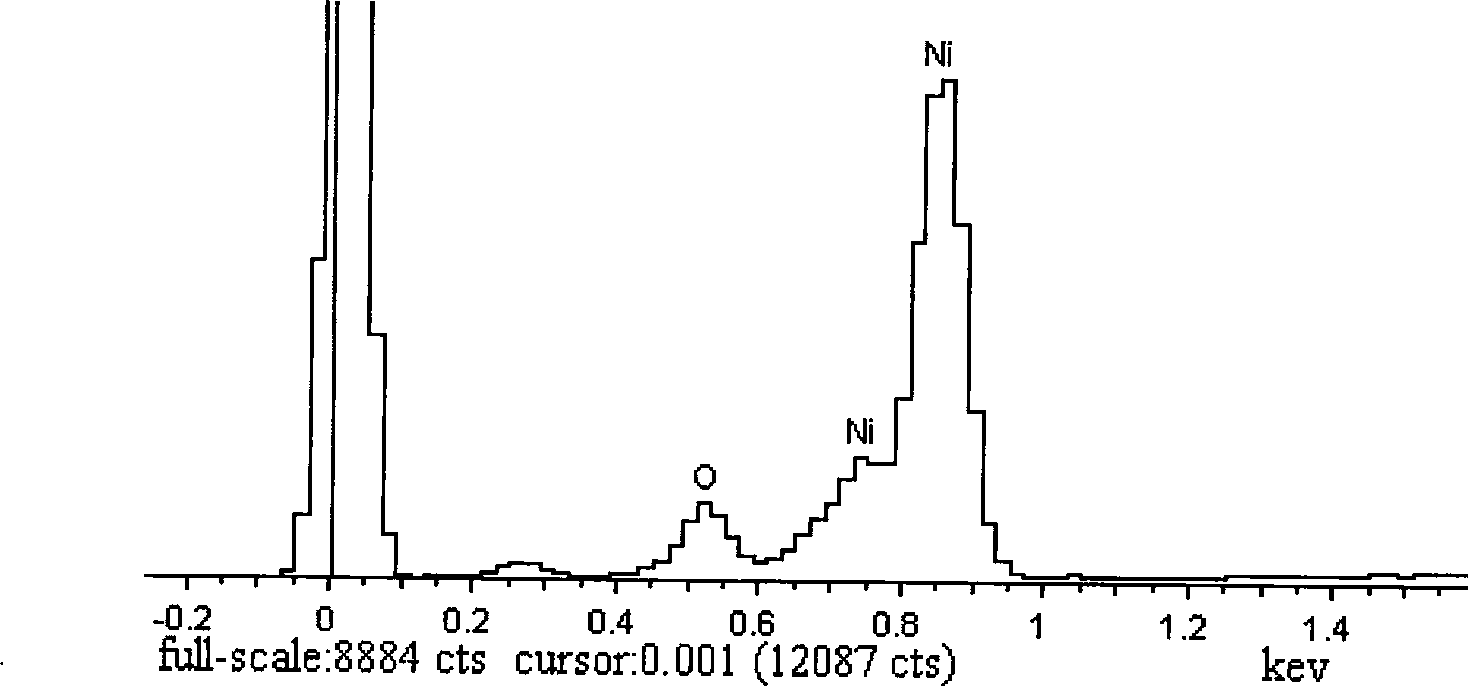

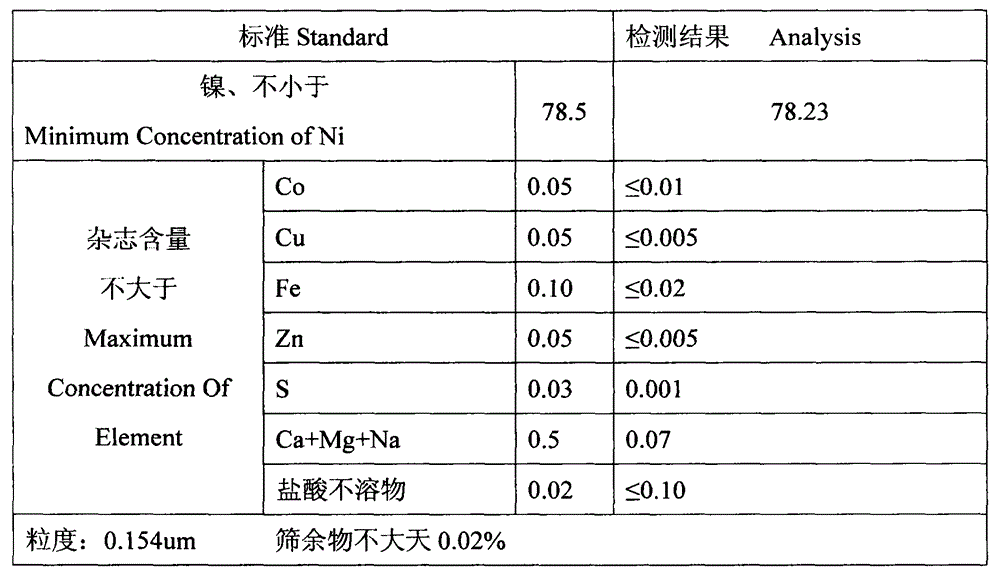

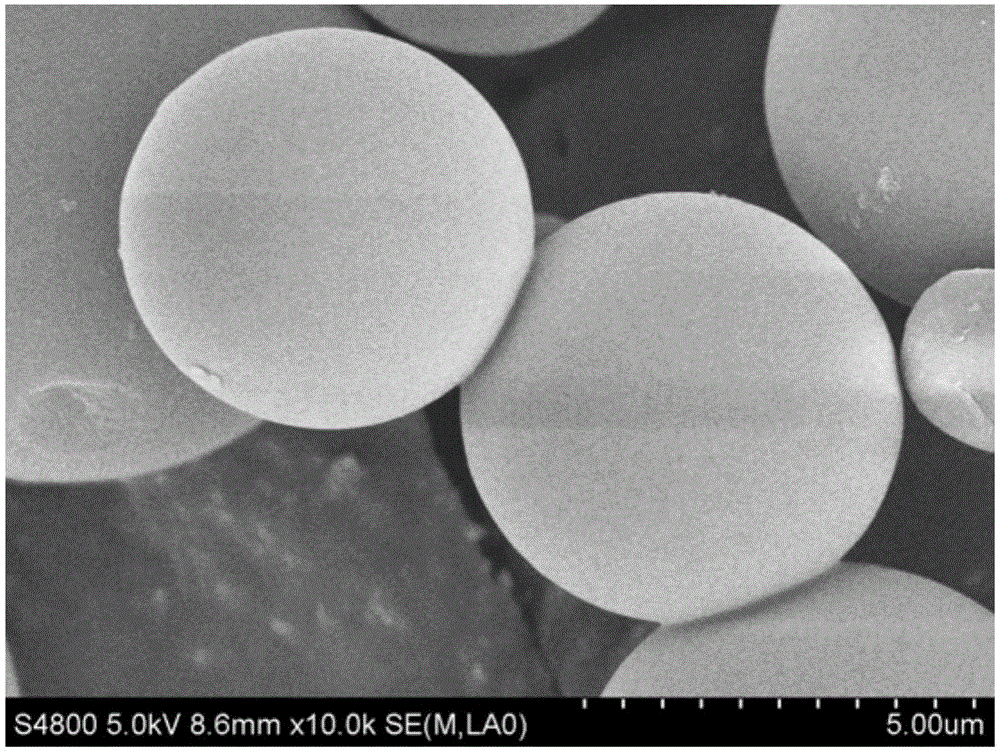

Preparation method of nickel oxide powder

InactiveCN102115215AGranularity controllableUniform particle size distributionNickel oxides/hydroxidesSocial benefitsNickel salt

The invention provides a preparation method of nickel oxide powder, and relates to a preparation method of nickel oxide powder in the fields of battery material, catalyst, magnetic material, electronic material, ceramic and the like. The preparation method is characterized by atomizing nickel salt solution, and thermally decomposing the atomized nickel salt solution under high temperate to obtain the nickel oxide powder. The preparation method comprises the steps of: taking the nickel salt solution as a raw material, atomizing the nickel salt solution under high temperate, thermally decomposing the atomized raw material to generate NiO under controllable atmosphere, and absorbing the generated tail gas to generate regenerated acid. The method can further continuously realize the preparation process from the solution to the NiO, the granularity of the NiO powder obtained by the method is controlled within the range from 0.2 to 20 micrometers, the granularity of the powder is even in distribution, and the performance of the powder is good. The preparation method is energy-saving, environment-friendly, low in preparation cost, and good in economic benefit and social benefit.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

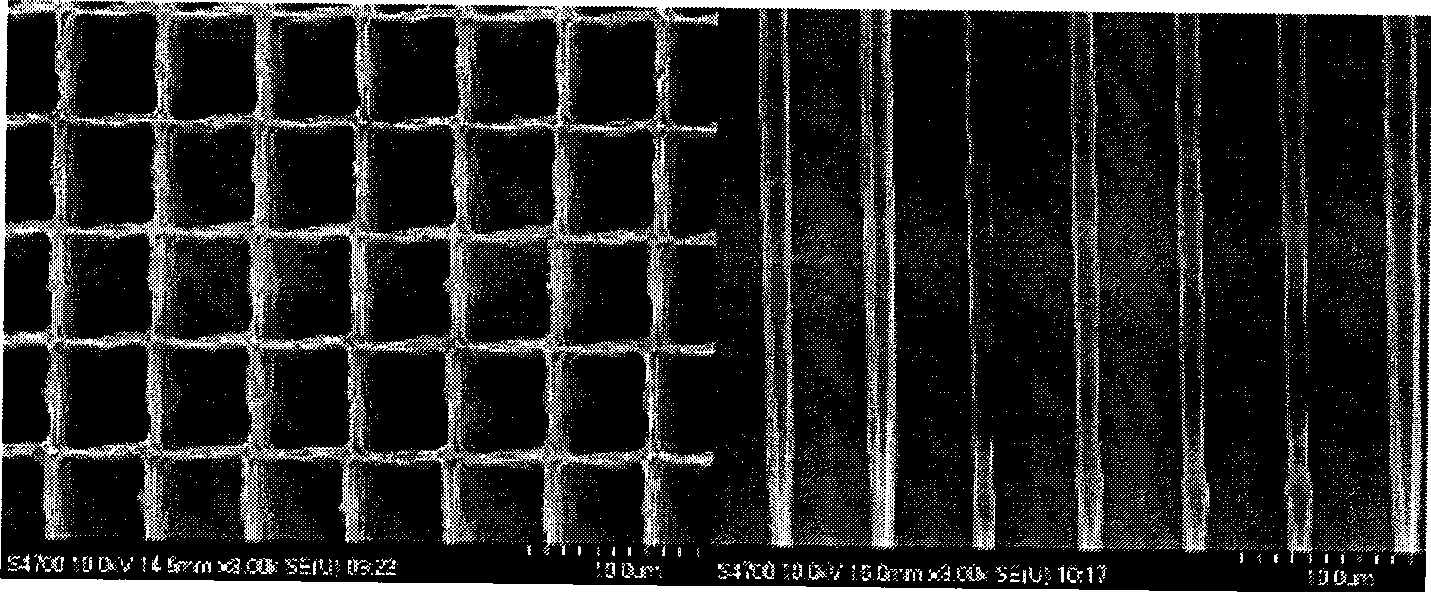

Super capacitor plate material and preparation method thereof

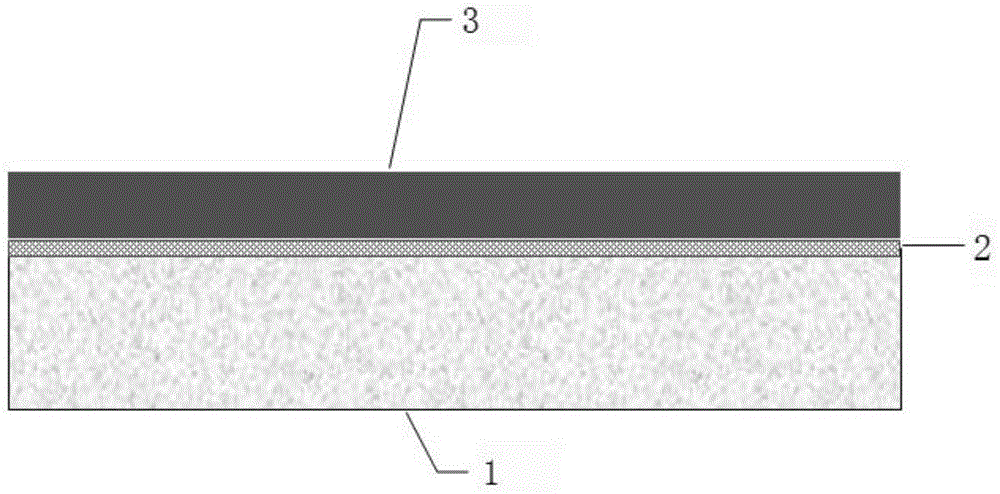

InactiveCN101510467AGood channel connectivityLarge specific surface areaDecorative surface effectsCapacitor electrodesComposite constructionCapacitance

The invention relates to a pole plate material of a super-capacitor, and a preparation method thereof, which are based on the micro-electro-mechanical-system silicon process and belong to the filed of capacitor manufacturing. In the pole plate material of the super-capacitor, a nickel protoxide thin film is wrapped on a silicon micro-channel substrate layer. The preparation method of the material comprises the following steps: an electrochemistry method is used for making a silicon micro-channel which is then taken as a substrate; after surface pretreatment is finished, a nickel layer is deposited in an electroless nickel plating solution; finally, fast thermal annealing is carried out in the atmosphere of oxygen; and nickel protoxide / silicon micro-channel compound material is formed. The pole plate material of the super-capacitor has large specific area and high chemical activity, is beneficial for electrolyte to be in better contact with active materials and can obtain relatively high charge storage capability and better capacitance characteristic; in addition, the combination of the pole plate material with the current micro-electronic processing technique can cause the super-capacitor to be easier for miniaturization and integration.

Owner:EAST CHINA NORMAL UNIV

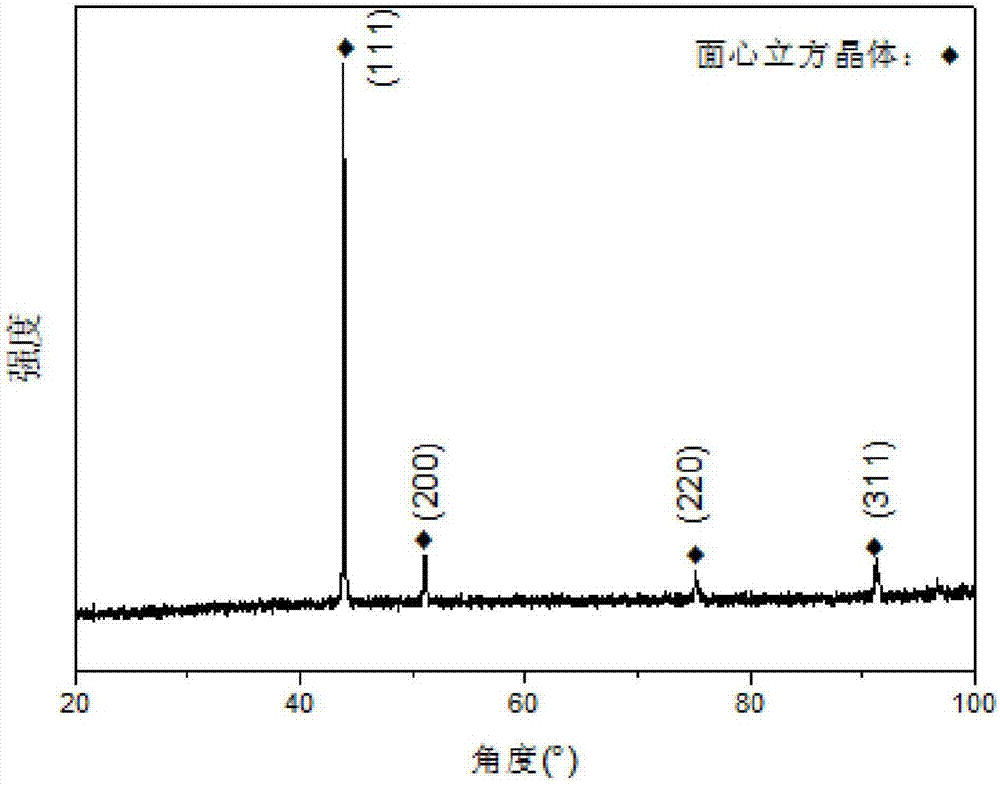

Process and device for preparing superfine nickel powder

The invention relates to a process and a device for preparing superfine nickel powder. According to the process, the two-stage process of low-temperature prereduction prilling and high-temperature deep reduction is conducted on superfine nickel protoxide to prepare the nickel powder. The device comprises a first fluidized bed reactor and a second fluidized bed reactor which is connected with the first fluidized bed reactor in sequence. According to the process and the device, for the core, the two processes of low-temperature prereduction prilling and high-temperature deep reduction and a doble-fluidized bed reactor system adapting to prereduction and deep reduction are adopted, uniform and rapid fluidization of particles can be achieved, purity of the prepared nickel powder can achieve more than 99%.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

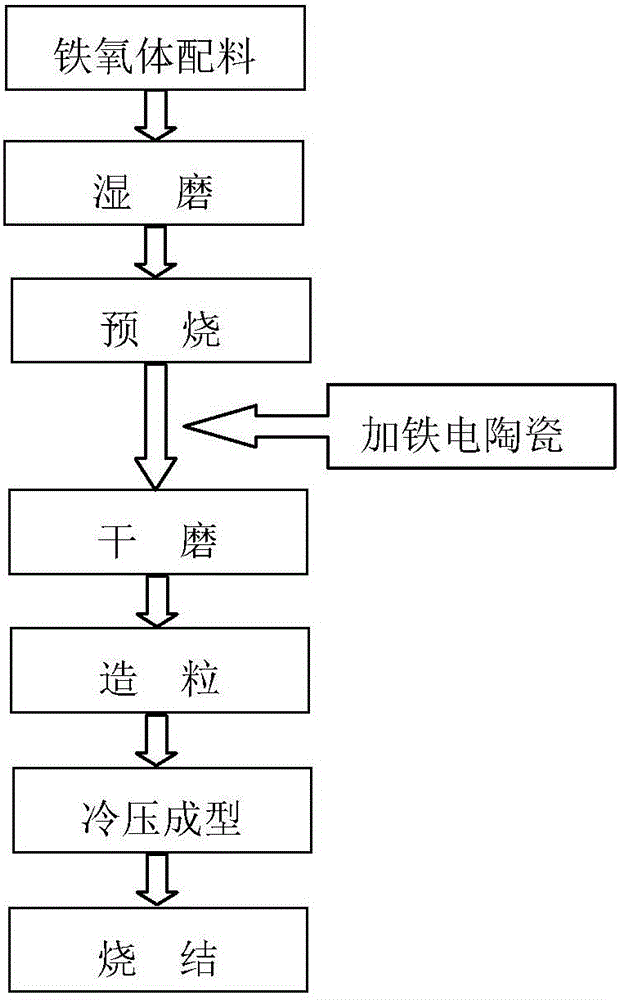

Novel ferroelectric-ferromagnetic composite material and preparation method thereof

The invention discloses a novel ferroelectric-ferromagnetic composite material and a preparation method thereof and belongs to the technical field of electronic materials. The novel ferroelectric-ferromagnetic composite material comprises a ferromagnetic phase and a ferroelectric phase, wherein the content of the ferromagnetic phase is 30-99 wt%, and the content of the ferroelectric phase is 1-70 wt%; the ferromagnetic phase is modified NiCuZn ferrite, and the main ingredients and the content of each ingredient comprise 65-68 wt% of ferric oxide, 7-10 wt% of nickel protoxide, 17-19 wt% of zinc oxide, 6-8 wt% of copper oxide, 0.5-1.5 parts of lithium carbonate and 2-4 wt% of vanadium pentoxide; the ferroelectric phase is bismuth-based perovskite ferroelectric ceramics, and the general formula is An-1Bi2BnO3n+3, wherein A is one or two of Bi, Nd, Sm and W, B is one or two of Ti and V, and n is in the range of from one to five. By means of the novel ferroelectric-ferromagnetic composite material and the preparation method thereof, under the condition that no sintering aid is needed to be added, the high densification of the material at a low temperature is achieved, the LTCC technology can be well adapted, and the loss of magnetic property and dielectric property can also be reduced to some extent.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

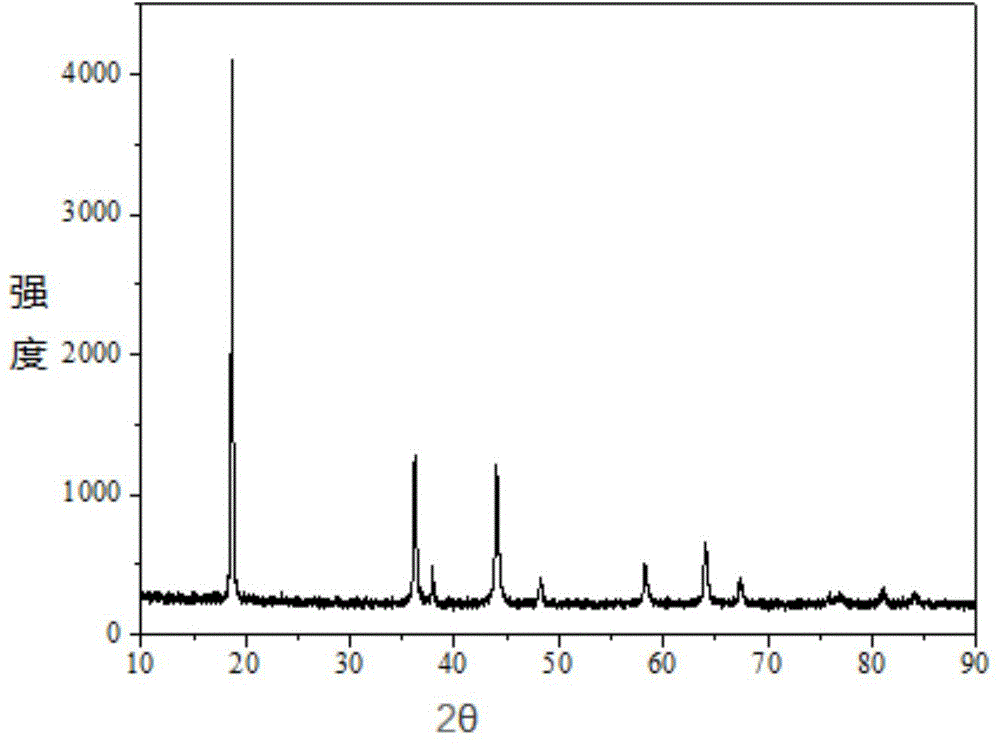

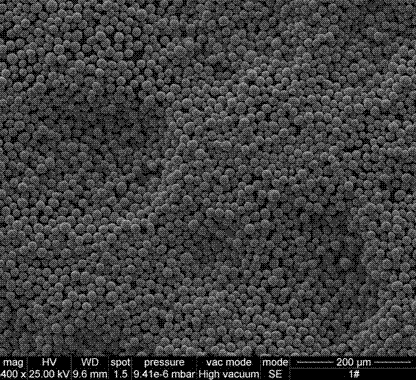

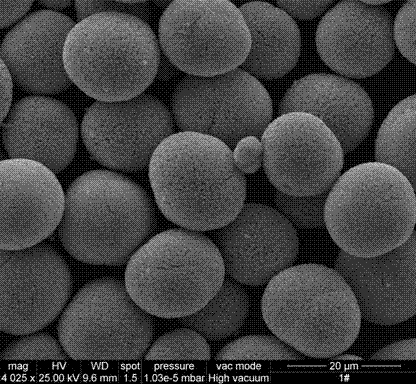

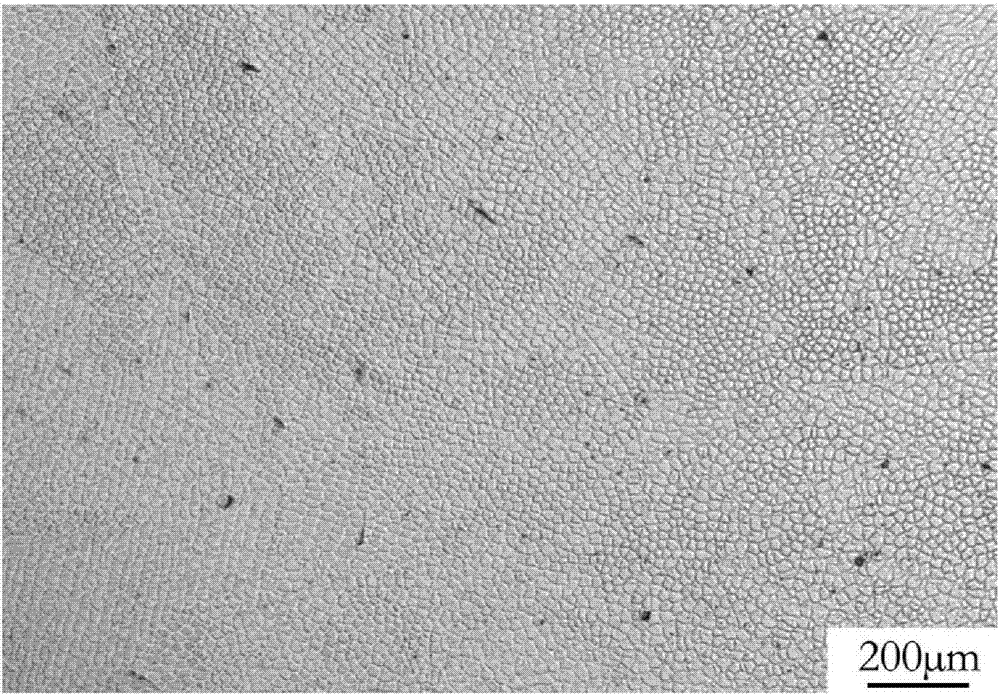

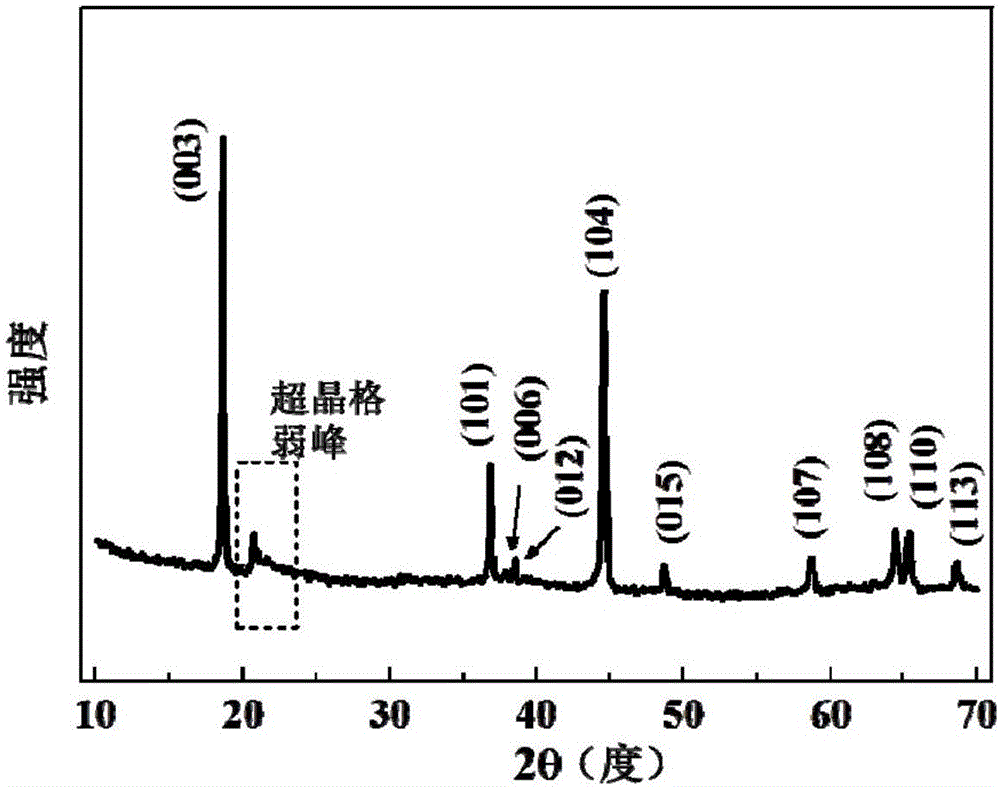

Porous spherical nickel protoxide and preparation method thereof

InactiveCN102887551ALarge specific surface areaUniform particle sizeNickel oxides/hydroxidesNickel saltReaction temperature

The invention provides a porous spherical nickel protoxide of which the particle size distribution is 1um<=D50<=10um and the specific area is 15-30 m<2> / g. The preparation method of the porous spherical nickel protoxide comprises the following steps: respectively preparing a nickel salt solution and ammonia water according to the solute mol ratio of 1:(0.5-1), and preparing an alkali solution with the pH value of 12.0-13.0 in a reaction kettle as a reaction bottom solution; evenly mixing the nickel salt solution and ammonia water, and adding the mixture into the reaction kettle to react while continuously stirring the reaction solution, wherein the alkali solution is supplemented to control the pH value of the reaction solution at 12.0-13.0; controlling the reaction temperature at 50-60 DEG C to obtain spherical nickel hydroxide; and calcining the spherical nickel hydroxide at 800-1400 DEG C for 5-15 hours to obtain the porous spherical nickel protoxide. The nickel protoxide product provided by the invention appears porous spherical shape, and has the advantages of large specific area, uniform particle size and favorable flowability.

Owner:JINCHUAN GROUP LIMITED

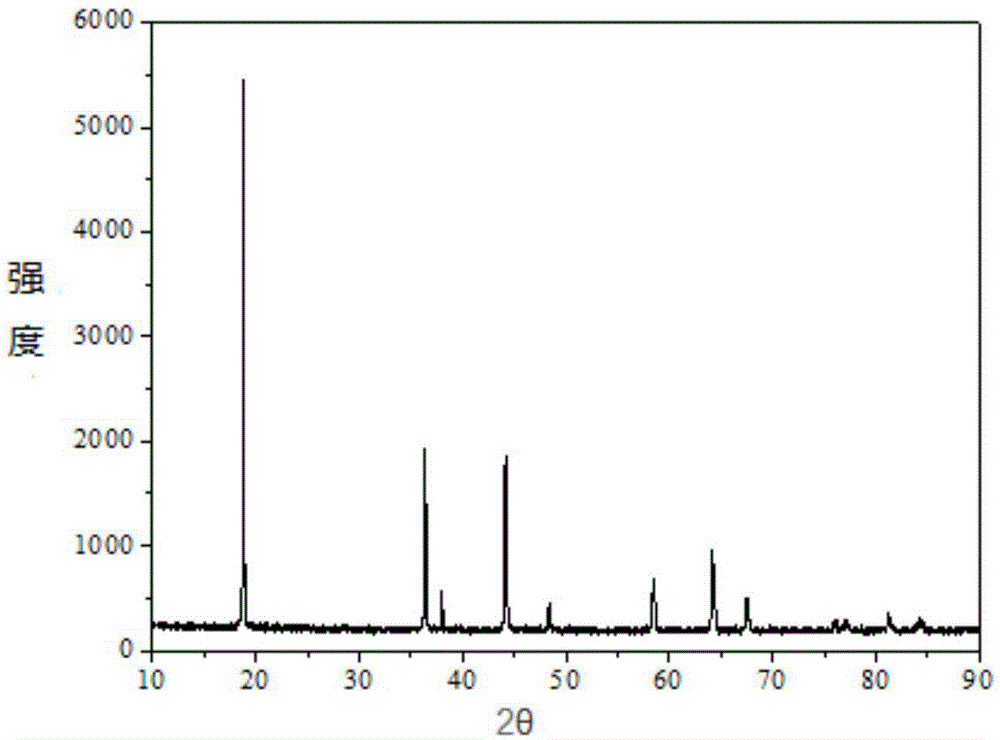

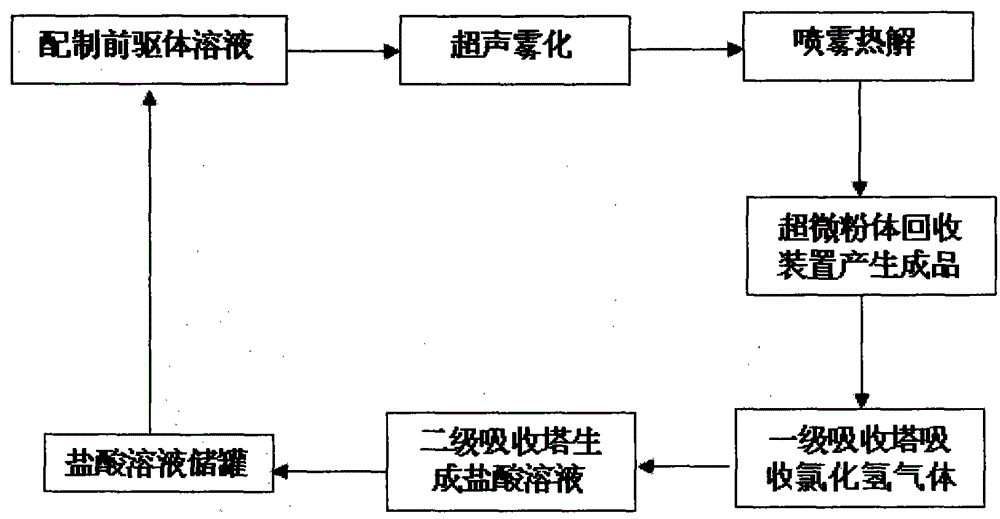

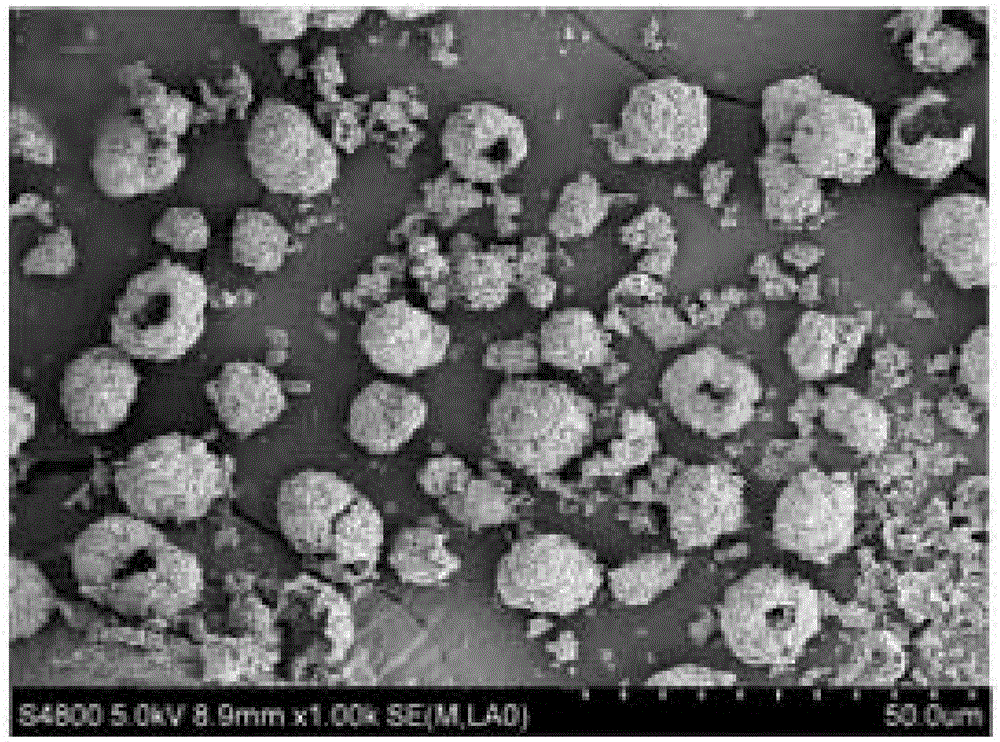

Production method for submicron-grade high-purity nickel protoxide powder

InactiveCN105000601AEfficient disseminationStrong energyNickel oxides/hydroxidesDispersityUltrasonic cavitation

The invention discloses a production method for submicron-grade high-purity nickel protoxide powder. The production method comprises the following steps of: (1) firstly preparing a nickel chloride precursor solution; (2) adding the precursor solution prepared in the step (1) into an ultrasonic atomization apparatus, atomizing the solution into smoke by utilizing an ultrasonic cavitation effect, and forming submicron-grade solution fogdrops; (3) sucking the fogdrops generated in the step (2) into a high-temperature atmosphere by using a fan for spray pyrolysis, and generating the submicron-grade high-purity nickel protoxide powder; (4) recovering the nickel protoxide powder generated in the step (3) by utilizing an ultrafine powder recovery apparatus, and obtaining a finished product; and (5) absorbing hydrogen chloride by utilizing an absorption tower, and obtaining a hydrochloric acid solution for preparing a nickel chloride precursor in the step (1). Nickel protoxide produced with the method is high in purity and good in particle dispersity, and the product fineness meets the submicron-grade requirement.

Owner:安鹏九

Nickel-zinc magnetic material formula applicable in wide frequency range

The invention discloses a nickel-zinc magnetic material formula applicable in a wide frequency range; the formula is composed of the following raw materials by mass: 65.0-67.0% of ferric oxide, 10.5-13.0% of nickel protoxide, 18.0-20.3% of zinc oxide, and 4.0-5.0% of copper oxide. According to the nickel-zinc magnetic material formula applicable in the wide frequency range, the ratios of various main element atoms in ferrite crystals are changed, a produced nickel-zinc magnetic material is superior to a conventional nickel-zinc magnetic material, has relatively high impedance in the range of 1 MHZ to 100 MHZ, expands the use frequency range of devices, and reduces the cost; and the nickel-zinc material is small in size, light in weight and wide in application.

Owner:ZHONGSHAN DONGCHEN MAGNETIC ELECTRONICS PROD CO LTD

Preparing method for synthesizing and fusion casting of high-entropy alloy through self-propagating combustion

ActiveCN107012380AHigh cost of preparationRealize short process preparationHigh entropy alloysManganese oxide

The invention discloses a preparing method for synthesizing and fusion casting of a high-entropy alloy through self-propagating combustion. The method comprises the following steps that firstly, aluminum powder, iron oxide, cobalt oxide, nickel protoxide, chromic oxide and manganese oxide serve as raw materials, meanwhile, aluminum oxide is added to serve as a reaction dilution agent, and a prefabricated block with the corresponding density is obtained; secondly, a graphite crucible and a graphite cast mold are assembled, casting gypsum is poured, and after being subjected to vacuum pumping and air removal, a gypsum mold is placed in a muffle furnace, and mold baking is conducted; thirdly, the prefabricated block obtained in the first step is placed in the gypsum mold obtained in the second step, a heating coil is placed on the surface of the prefabricated block, so that the surface of the prefabricated block is rapidly heated, the prefabricated block is ignited, and high-entropy alloy liquid is obtained in the combustion heat releasing process; and fourthly, vacuum pumping is conducted on the bottom of the gypsum mold, the alloy liquid is cooled in the graphite cast mold, and the high-entropy alloy is obtained. According to the method, needed raw materials are cheap, the equipment and the technology are simple, the process can be conducted at the normal pressure, protective atmosphere is not needed, a high-entropy alloy interphase boundary is clean, and the structure is fine.

Owner:SOUTHEAST UNIV

Method for producing nickel protoxide

InactiveCN109775768AReduce pollutionImprove qualityNickel oxides/hydroxidesGranularitySpray pyrolysis

The invention discloses a method for producing nickel protoxide. In the method, a nickel plate is dissolved with hydrochloric acid to prepare a nickel chloride solution, the prepared nickel chloride solution reacts through a spray pyrolysis process to produce a high-quality nickel protoxide semi-finished product, the high-quality nickel protoxide semi-finished product is then subjected to calcinating and washing to reduce impurities in nickel protoxide, and the granularity of the high-quality nickel protoxide is reduced through the drying and grinding process to obtain the finished product. The method is specially used for overcoming the defects that nickel protoxide production cost is high, the environmental pollution is high and the product quality is low, the high-quality nickel protoxide is produced through the spray pyrolysis method, and the method is simple in technological operation, low in production cost, small in environmental pollution and remarkable in effect and has quitehigh actual application value.

Owner:JINCHUAN GROUP LIMITED +1

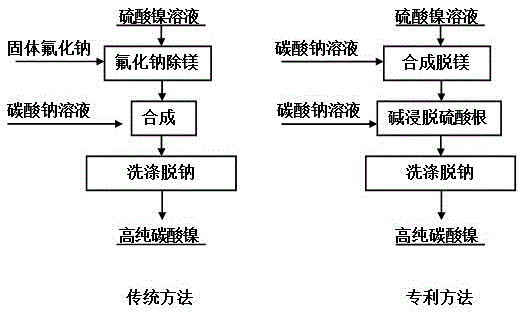

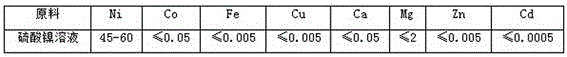

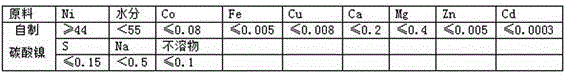

Synthesis method of nickel protoxide precursor nickel carbonate

ActiveCN105645482AHigh recovery rateIncrease profitNickel oxides/hydroxidesNickel carbonatesSulfate radicalsImpurity

The invention discloses a synthesis method of nickel protoxide precursor nickel carbonate. According to the method, parallel-flow and low-pH-value semi-synthesis for magnesium removal, pulpifying and high-pH-value alkaline leaching for sulfur removal as well as pulpifying and washing for sodium removal are performed, through precise control on the pH value, fractional precipitation, filtering and washing, impurities including magnesium, sodium and sulfate radicals are removed from a supernatant, and high-quality nickel protoxide precursor nickel carbonate is prepared. The method is low in processing cost, high in metal recovery rate, low in requirement for equipment materials, low in investment cost, low in technical threshold, simple, convenient, good in effect, good in nickel carbonate quality, stable and reliable in product quality, good in economy, high in profit, convenient to popularize and apply industrially and capable of recycling water resources, and is a green industrial project which is worthy of popularization, low in cost, low in energy consumption and high in benefit.

Owner:JINCHUAN GROUP LIMITED

Preparation method of solid oxide fuel cell two-layer anode

The invention relates to a preparation method of a solid oxide fuel cell two-layer anode, and relates to a preparation method of a solid oxide fuel cell anode, which aims at solving the problems of the traditional slurry coating method for preparing a SOFC thick anode that the anode is fractured and separated. The preparation method comprises the following steps: I, pressing electrolyte powder to form a green body, and sintering the green body to obtain an electrolyte supporting body; II, mixing nickel protoxide with electrolyte to obtain a mixture I, grinding the mixture I, and dividing the ground powder into initial powder a and initial powder b; III, adding a pore-forming agent into the initial powder a, mixing the pore-forming agent and the initial powder a to obtain a mixture II, pressing the mixture II to form an anode blank, and sintering the anode blank to obtain a porous anode block; IV, adding a binder into the initial powder b to obtain a mixture III, and smearing the mixture III onto the electrolyte supporting body; V, arranging the porous anode block on the anode blank which is coated with the slurry, and sintering to prepare the two-layer anode. According to the preparation method, a slurry coating method and a dry pressure method are combined to prepare the two-layer anode, the thickness of the anode can reach 0.1 to 3mm, and the deformation, fracturing and separation of the thick anode in the high temperature sintering process can be avoided.

Owner:HARBIN INST OF TECH

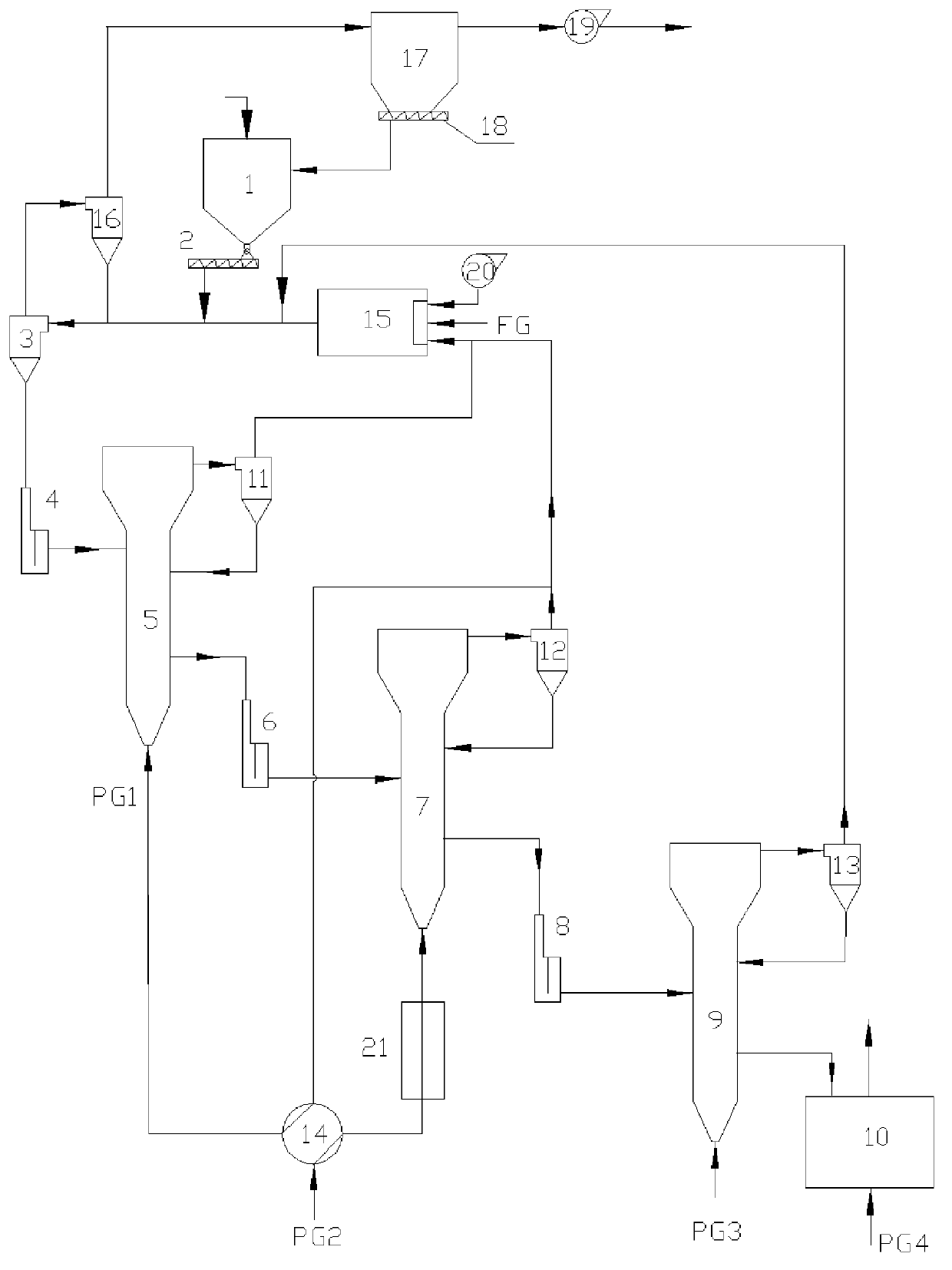

Treatment system for purifying industrial waste gas

ActiveCN106693640AStrong selective purification propertiesAchieve reuseCombination devicesGas treatmentEnvironmental engineeringOxygen

The invention discloses a treatment system for purifying industrial waste gas. The system is mainly used for removing metal nickel from waste gas of metallurgical industry. The system comprises an anti-shock protector, a multi-parameter gas tester, an alkali washing and deacidification device, a front-end induced draft fan, a double-magnetic-moment alternating catalytic-nickel oxygen cluster synthesis separation and purification device, an electrostatic dust remover, a wet gas purifier and a tail-end induced draft fan. The system transforms various forms of nickel elements in the waste gas are transformed into nickel protoxide (NiO) by creatively utilizing the chemical characteristic that metal oxide can be chemically combined into metal oxygen cluster under the catalytic action of a multi-magnetic-moment alternating magnetic field, the nickel protoxide is a double-magnetic-moment alternating magnetic field which is generated by oppositely rotating and superposing two sets of U-shaped electromagnet, the nickel protoxide in the waste gas is converged under the catalytic action of the alternating magnetic field to produce the nickel oxygen cluster at the moment, and specific metal oxide is used for capturing hydrazine to capture and remove the nickel oxygen cluster from the waste, so that the purpose of performing purification treatment on the nickel-containing waste gas is achieved.

Owner:JIANGSU HENGBO PNEUMATIC CONVEYING EQUIP MFG CO LTD

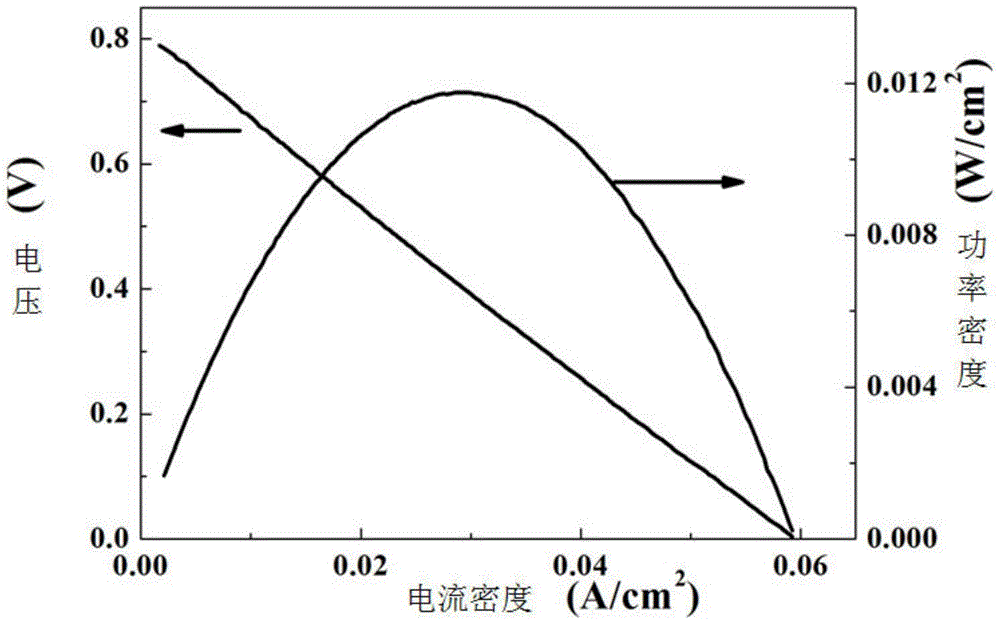

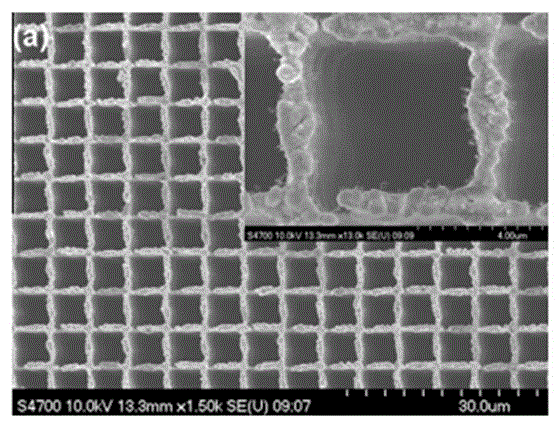

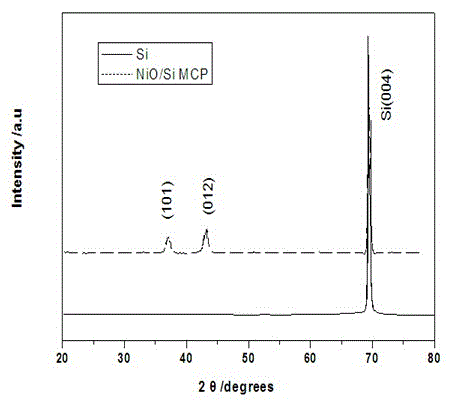

Preparation method of nanometer nickel protoxide-nickel-silicon alloy lithium ion battery negative electrode material

InactiveCN105047872AObvious advantagesImprove connectivityMaterial nanotechnologyCell electrodesMicro nanoIntegrated circuit manufacturing

The invention discloses a preparation method of a nanometer nickel protoxide-nickel-silicon alloy lithium ion battery negative electrode material and belongs to the technical field of preparing lithium ion battery electrode material. The feature of the lithium battery negative electrode material is that the lithium battery negative electrode material has a highly-ordered micro-nano silicon micro-channel substrate, and an excellent conductive NiSi layer electric charge collecting layer, and a NiO nanometer active layer has large specific surface area and an electrode orderly porous channel is suitable for an electrolyte solution to immerge. The preparation method of the battery cathode material is highly compatible with a traditional integrated circuit manufacturing process, and mainly comprises three main processes of etching to form the highly-ordered micro-nano silicon micro-channel substrate by using a photoinduced low temperature electrochemical pulse voltage wet method, depositing metallic nickel via an electroless plating process and rapid thermal annealing and oxidizing. The highly-ordered three-dimensional micro-nano porous NiO / Si-MCP (nickel protoxide / silicon microchannel) negative electrode material has excellent physical and electrochemical support for immerging the electrolyte, transporting charges and embedding and de-embedding lithium ions, and could be used for preparing the integratable lithium ion battery electrode material.

Owner:QIQIHAR UNIVERSITY

Nanao metal ceramic inert anode material for aluminium electrolysis and preparation method thereof

InactiveCN101255569AImprove conductivityImprove bending strengthMechanical propertyAluminum electrolysis

A nanometer cermet inert anode material for aluminum electrolysis and preparation method thereof, the anode material is composed of copper powder, ferric oxide powder and nickel protoxide. Mass fraction of each component is: Cu 14.8% to 15.1%, Fe2O3 35% to 36%, NiO 47% to 50%; adding amount of nanometer NiO is 4% to 14% of NiO mass. The preparation method comprises five steps: (1) mixing the copper powder, ferric oxide powder and nickel protoxide, adding the nanometer NiO powder, processing ultrasonic treatment in alcohol; (2) adding sodium polyacrylate, continuous processing ultrasonic treatment, adding HCl to regulate pH value after milling the liquid; (3) standing, depositing, filtering, drying to obtain mixed base material; (4) adding paraffin in mixed base material as plasticizer, mixing evenly to press as unburnt earthenware; (5) crushing sintering, cooling to obtain the anode material of the invention. The electrical conductivity of the anode material of the invention at 1000 deg.C reaches 100ohm / cm above, and the mechanical property is improved and machining property as well, which enables the cermet anode to machine and industrialize for aluminum electrolysis industry.

Owner:GUIZHOU UNIV

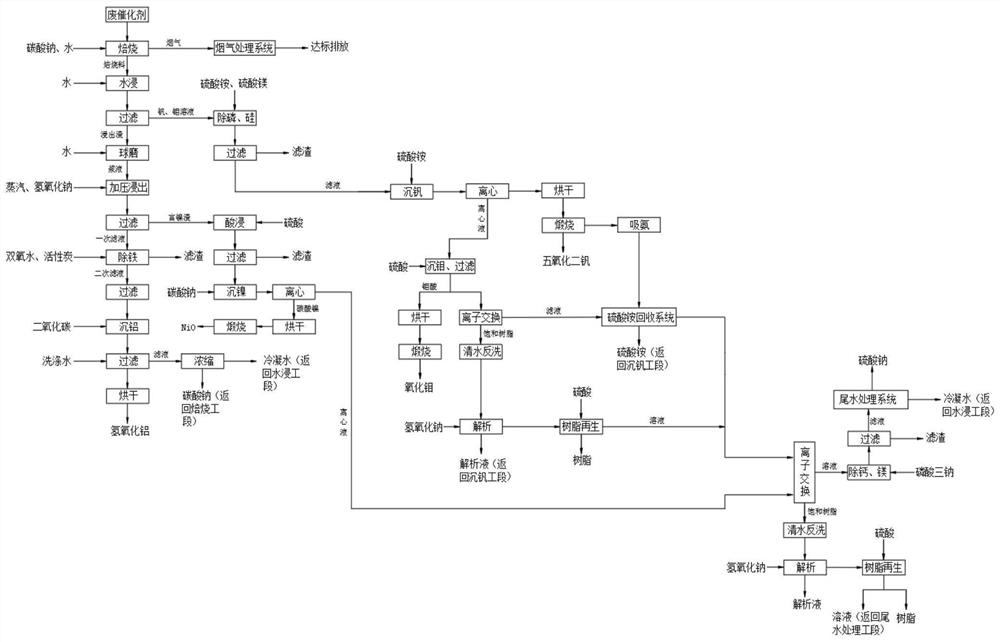

Multi-element recycling of residual oil hydrogenation waste catalyst

PendingCN113293297AReduce consumptionLess investmentVanadium oxidesChemical recyclingPtru catalystAluminium hydroxide

Owner:江苏瑞孚再生资源有限公司

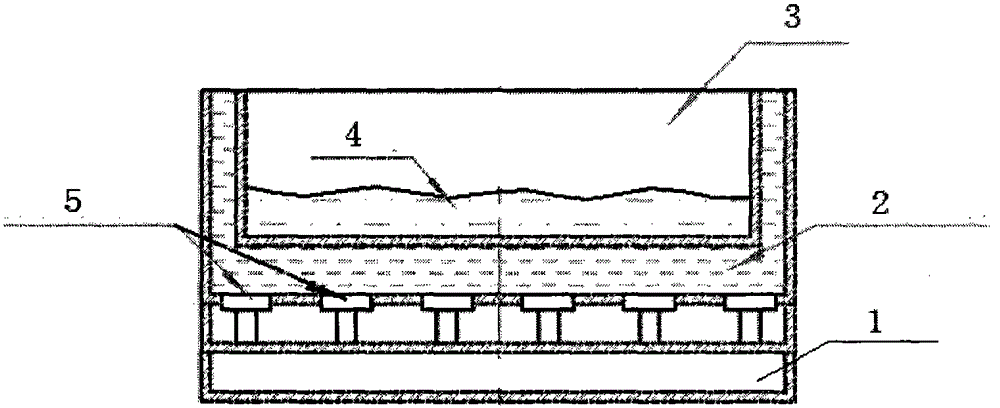

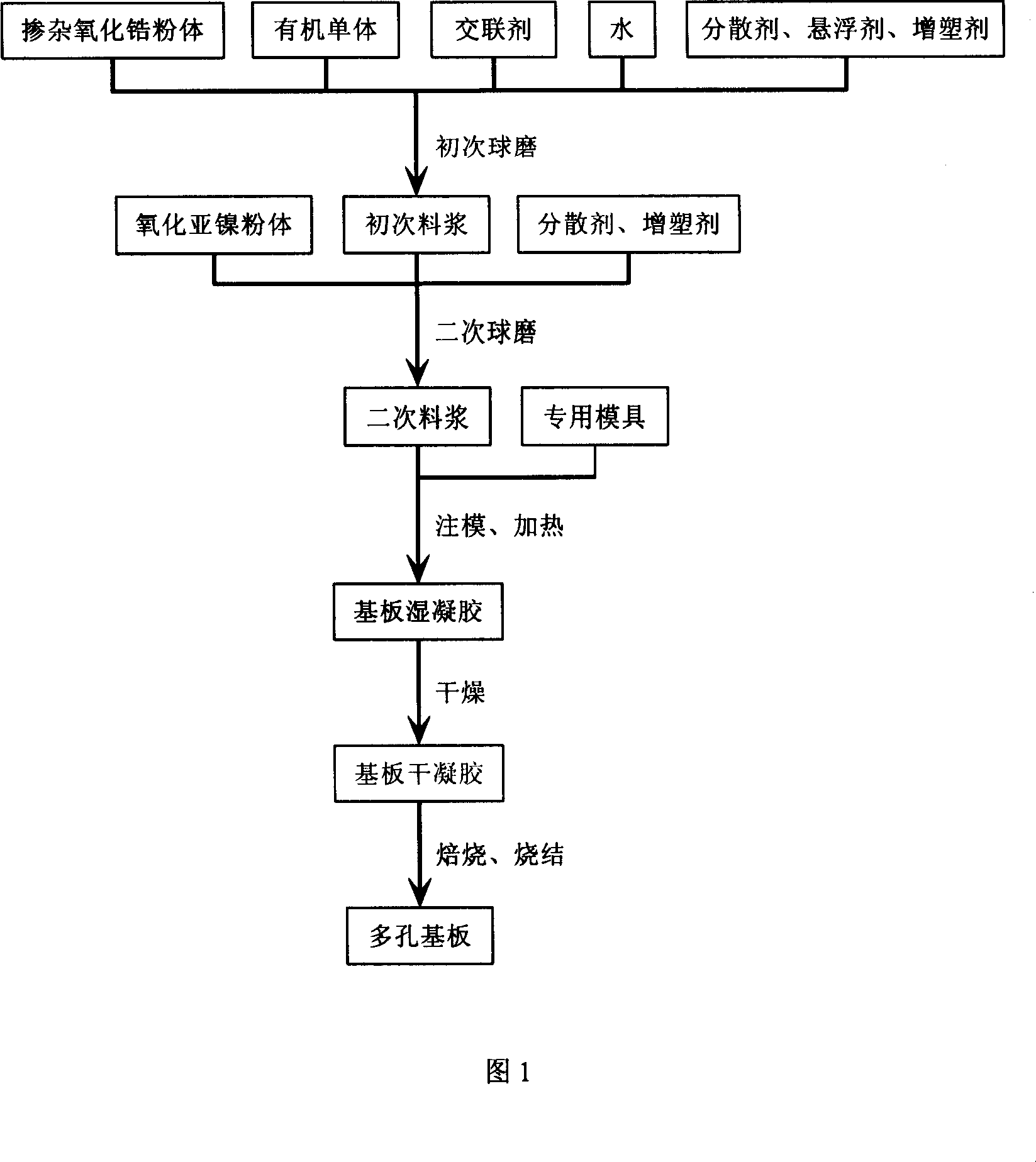

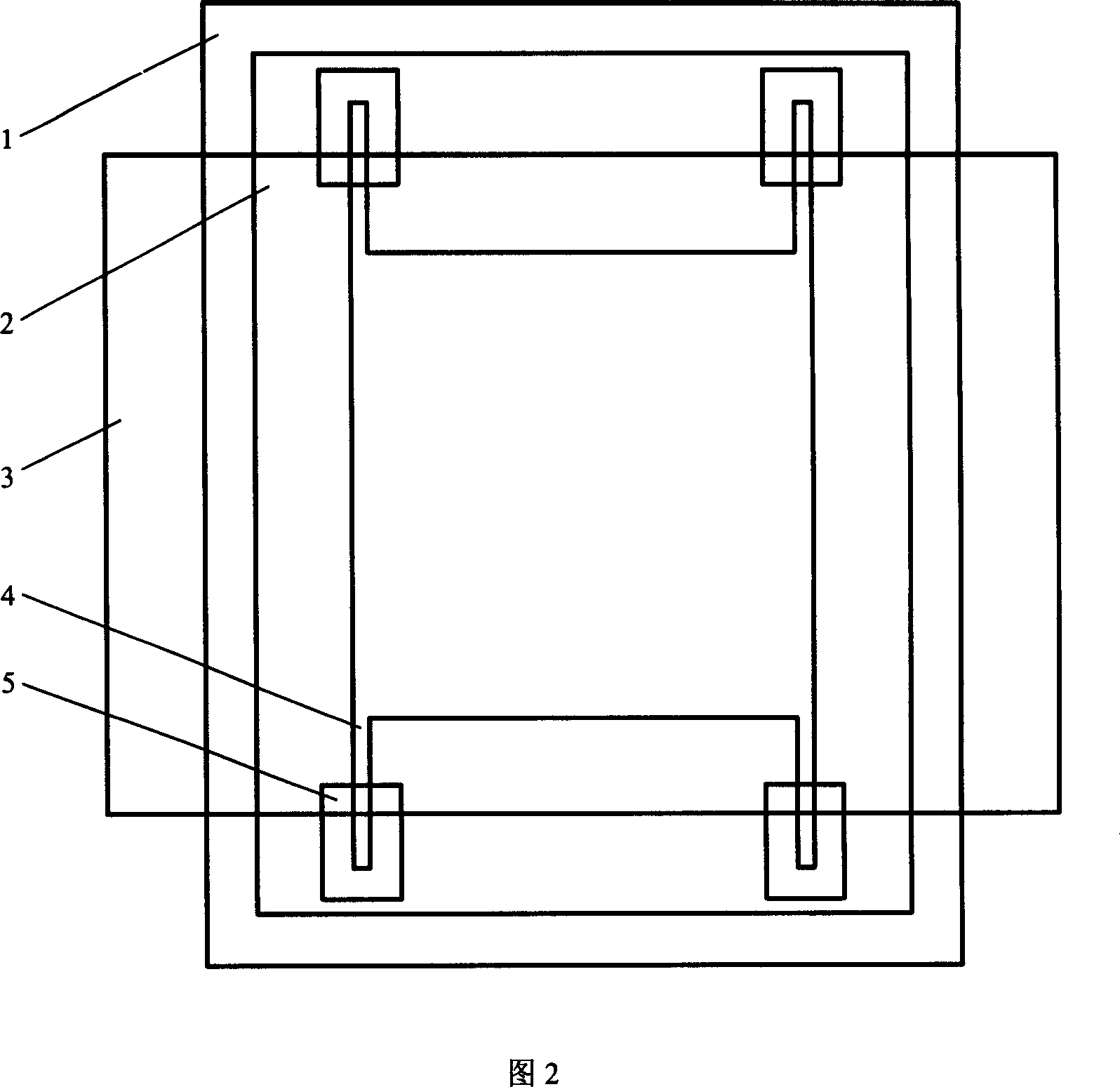

Method for producing solid oxide fuel cell anode substrate and die

InactiveCN1933223AReduce pollutionImprove uniformityCell electrodesFuel cell detailsCooking & bakingFuel cells

This invention relates to a method for preparing porous anode base plates of solid oxide fuel batteries and moulds, in which, the process flow is as follows: preliminary batching, preliminary ball mill, secondary batch, secondary ball mill, injection mould, heating of gel, taking off the mould, drying, baking and sintering, which utilizes the self-initiation character of nickelous oxide and applies two steps of ball mill procedures without adding initiators or eliminating air bubbles so as to simplify the operation and reduce cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Hollow sphere anode material and preparation method thereof

ActiveCN106784740AImprove structural stabilityReduce capacityCell electrodesMANGANESE ACETATECyclic process

The invention relates to the synthesis of an anode material for a lithium ion battery, and provides a hollow sphere anode material and a preparation method thereof. The preparation method comprises the following steps of enabling first mixed liquor containing glucose and nickel ammonium sulfate to subject to hydrothermal reaction to obtain first suspension liquid; drying the first suspension liquid to obtain first sediment of solid spheres; roasting the first sediment to obtain hollow spheres and a nickel protoxide precursor; mixing manganese acetate, lithium acetate and a solvent to obtain second mixed liquor; mixing and evaporating the second mixed liquor and the nickel protoxide precursor to obtain second sediment, and roasting the second sediment to obtain the hollow sphere anode material; the anode material is formed by packing nano-sized primary particles into micron-sized hollow sphere secondary particles. A hollow sphere micron-sized matrix structure can slow down the dissolution of the primary particles in electrolyte in a continuous cyclic process, so that the hollow sphere anode material cannot easily collapse in the cyclic process, showing excellent electrochemical performance.

Owner:上海鎏明科技有限公司

NTC thermistor

ActiveCN111499355AImprove sintering performanceImprove stabilityNegative temperature coefficient thermistorsManganous-manganic oxideEngineering

The invention belongs to the field of thermistors. According to a technical scheme in the invention, the NTC thermistor comprises the following components in percentage by weight: 60 to 65% of manganous manganic oxide (Mn3O4), 1.4 to 1.9% of cobaltosic oxide (Co3O4), 5 to 5.5% of nickel protoxide (NiO), 15 to 25% of copper oxide (CuO), 2 to 3% of zirconium oxide (ZrO2), 2 to 3% of lanthanum oxide(La2O3) and 1 to 2% of iron oxide (Fe2O3). The NTC thermistor of the invention has the following beneficial effects: sintering temperature is reduced; the obtained low-resistance NTC thermistor is uniform in resistance value and density and good in stability;e energy consumption is saved; the bending strength of the NTC thermistor is improved by adding zirconium oxide and lanthanum oxide; the problem of low bending strength of the NTC thermistor is solved while a low-resistance product is obtained; the electrical performance characteristics of the NTC thermistor product are improved; and the NTC thermistor can be applied to industrial mass production.

Owner:NANJING SHAGON ELECTRONICS

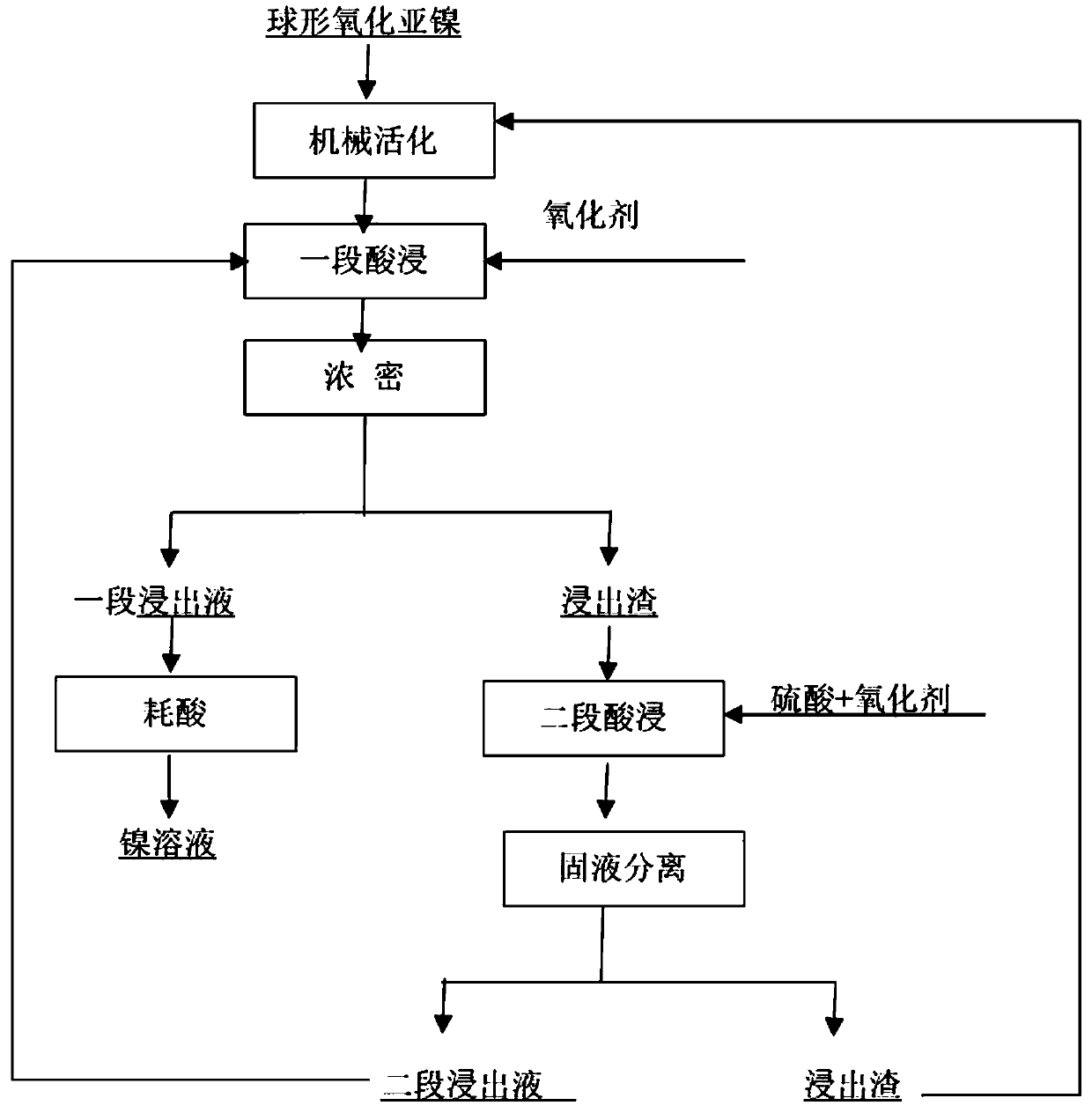

Method for synthesizing lithium battery anode material precursor raw material through nickel protoxide reclaimed materials

The invention relates to the field of waste recycling, and discloses a method for synthesizing a lithium battery anode material precursor raw material through nickel protoxide reclaimed materials. Themethod comprises the following steps that (1) the nickel protoxide reclaimed materials are mechanically activated; (2) the mechanically activated nickel protoxide reclaimed materials are leached withsulfuric acid; (3) nickel, cobalt and manganese containing materials easy to dissolve in water are added to the leachate to consume sulfuric acid in step 2, hydrogen peroxide is added until the pH value is above 4, and after solid and liquid are separated, the nickel leachate is obtained; and 4, sulfate crystals are added to the nickel leachate with acid consumed according to the proportion requirement of a nickel, cobalt and manganese lithium battery anode material, and a lithium battery anode material precursor solution is prepared. The method is short in process, simple, feasible, low in cost and low in investment, the nickel protoxide recycling rate is high, industrialization is easy to achieve, and the economic and social benefits are obvious.

Owner:LANZHOU JINCHUAN NEW MATERIAL SCI & TECH

Nickel protoxide / silicon nano-wire and use thereof for preparing integrated super capacitor electrode material

InactiveCN101481085AProcess compatibleLow costElectrolytic capacitorsIndividual molecule manipulationCapacitanceSilicon nanowires

The invention discloses a NiO / SiN wire and a method for preparing an integrated supercapacitor electrode material with high performance by adopting the material. The preparation method comprises the following steps: (1) the SiN wire is taken as a framework, a nickel membrane is sedimented on the SiN wire by the electroless plating technique to produce a nickel-silicon nanometer wire composite; and (2) the produced nickel-silicon nanometer wire composite is subject to rapid thermal annealing oxidation treatment. The invention adopts the advantages of the SiN wire that the scale is small, the specific surface is large, the surface atom has a large amount of nonsaturated bonds, and the tensiometric property is great, and takes the SiN wire as the framework for loading the NiO nanometer structure. The NiO / SiN wire has high specific capacitance, low equivalent essential resistance and good charging and discharging properties, is compatible with the integrated circuit technique and can be used for preparing the integrated supercapacitor electrode material with high performance.

Owner:EAST CHINA NORMAL UNIV

Spherical nickel protoxide segmented oxidation acid leaching treatment method

InactiveCN110607439AGuaranteed leaching ratePrevent crystallizationProcess efficiency improvementManganeseBiological activation

Owner:JINCHUAN GROUP LIMITED +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com