Nanometer metal ceramic inertia anode material for electrolytic aluminum and preparation method thereof

A nano-cermet and inert anode technology, applied in the field of electrochemical electrolysis, can solve the problems of increasing electrical conductivity, cracks in the electrode body, difficulty in processing and large-scale, etc., to achieve improved processing performance, high bending strength and fracture toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

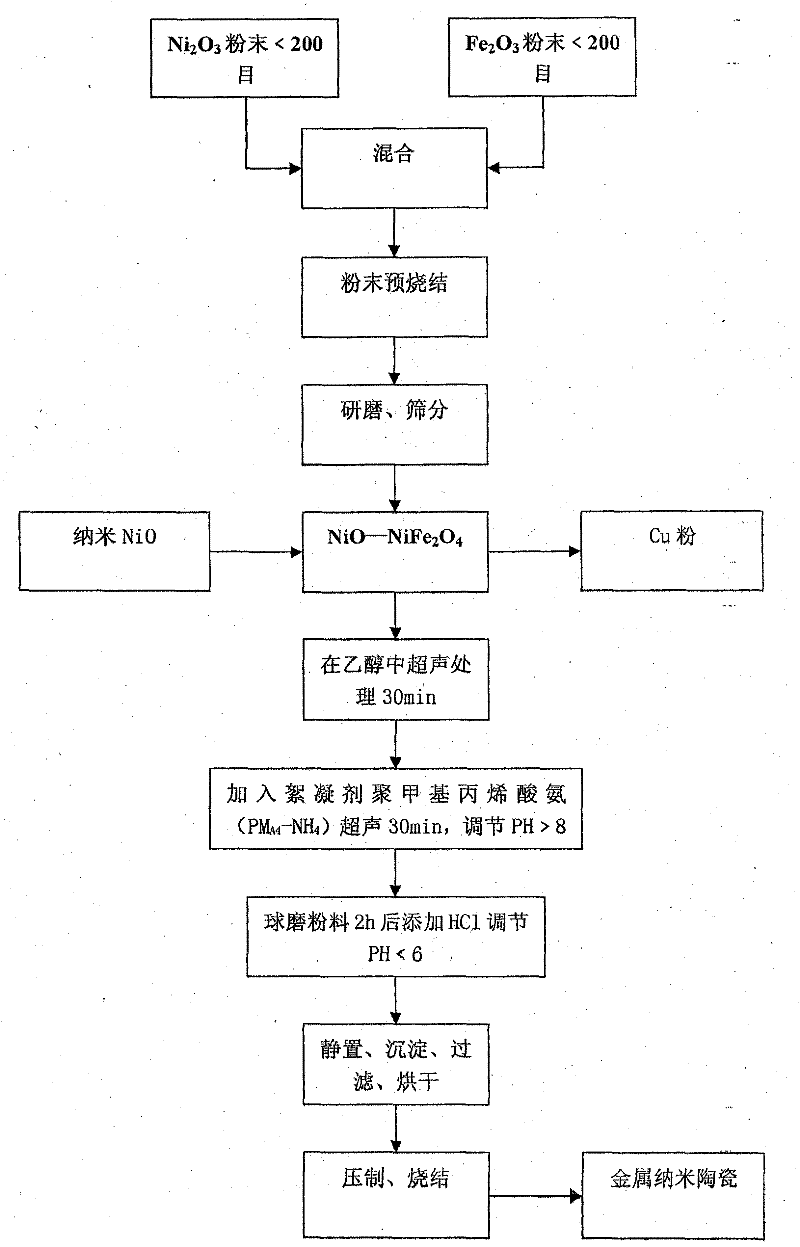

Method used

Image

Examples

Embodiment

[0032] (1) Mix 104g of 200-mesh nickel oxide with 62g of 200-mesh iron oxide powder, and sinter at 1150°C to obtain NiO-NiFe 2 o 4 Cermet matrix sintered material;

[0033] (2) After the sintered material is crushed, grind it with a QM-4H ball mill, and pass through a 200-mesh sieve to obtain the sintered powder;

[0034] (3) Add 34g of Cu powder to the sintered powder, and then add 7.2g of nano-NiO; after mixing, ultrasonically treat in alcohol with a mass fraction of 95% for 30min;

[0035] (4) Add sodium polyacrylate, continue the ultrasonic treatment for 30 minutes and adjust the pH value to be greater than 8 by adding sodium polyacrylate; then use a ball mill to grind the powder for 2 hours, add HCl to adjust the pH to be less than 6, and obtain a slurry;

[0036] (5) The slurry is left to settle for 1 hour, filtered, and dried at 140°C;

[0037] (6) Add paraffin wax of 5% of the total mass of the mixture in the mixture as a plasticizer, mix well, and use 30 tons of un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com