Production method for submicron-grade high-purity nickel protoxide powder

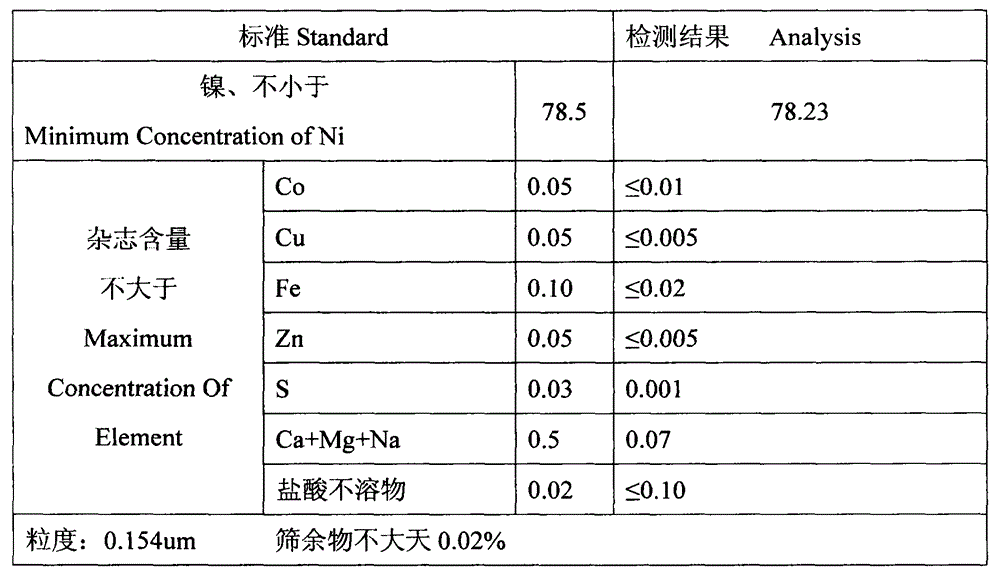

A nickel oxide powder, sub-micron-level technology, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of poor particle dispersion, unreachable fineness, and low purity of nickel oxide, and achieve particle dispersion Good, high-purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

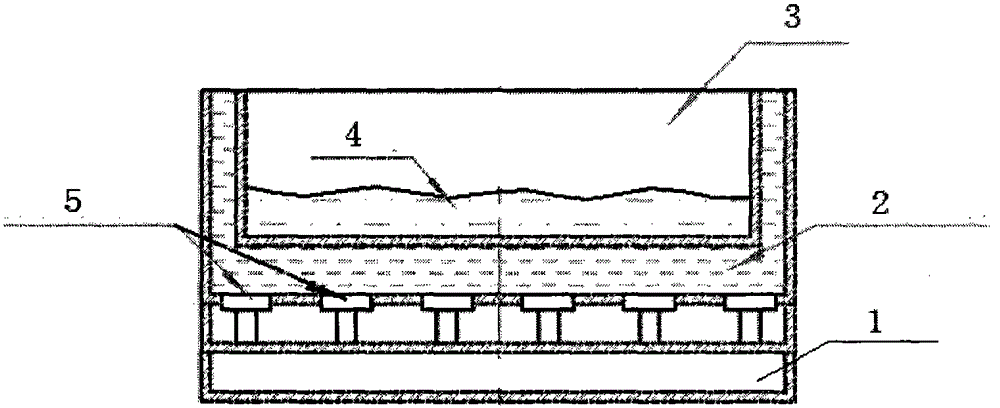

Image

Examples

Embodiment 1

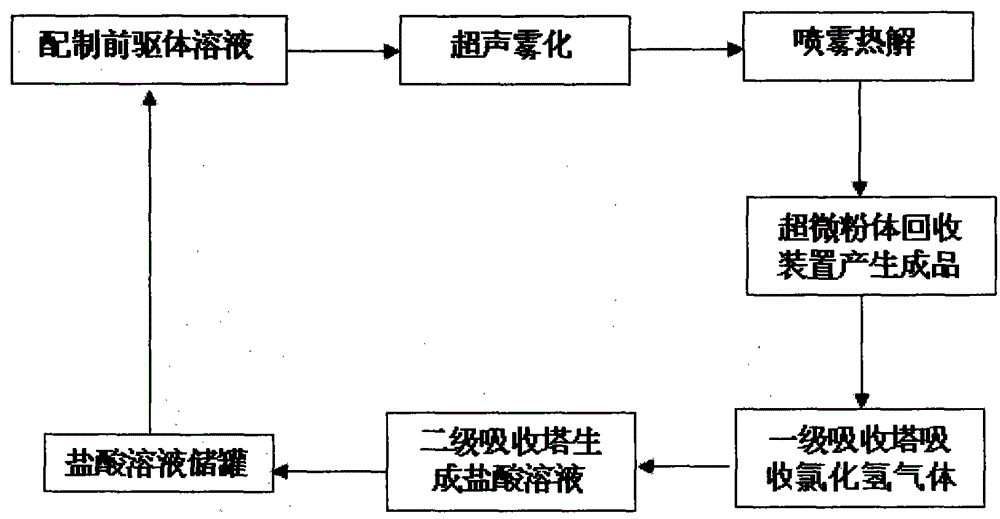

[0027] The concrete steps of the production method of submicron order high-purity nickelous oxide powder of the present invention are as follows:

[0028] (1) first prepare nickel chloride precursor solution;

[0029] (2) Add the precursor solution prepared in step (1) into an ultrasonic atomization device, and use the cavitation effect of ultrasonic waves to atomize the solution into a gaseous smoke state to form droplets of a submicron solution;

[0030] (3) The mist that step (2) produces is pumped into the high-temperature atmosphere with a blower fan to carry out spray pyrolysis to produce high-purity, sub-micron nickel oxide powder;

[0031] (4) Utilize the superfine powder recovery device to obtain the finished product by the nickelous oxide powder that step (3) produces;

[0032] (5) Utilize the absorption tower to absorb the hydrogen chloride gas to obtain a hydrochloric acid solution, which is used in step (1) to prepare the nickel chloride precursor.

[0033] In s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com