Synthesis method of nickel protoxide precursor nickel carbonate

A nickel oxide and synthesis method technology, applied in the direction of nickel oxide/nickel hydroxide, nickel carbonate, etc., can solve the problems of difficulty in synthesizing high-quality nickel carbonate, high content of sodium and sulfate, and high water content of filter cake, to achieve It is convenient for industrialization, popularization and application, good effect, and the effect of improving labor productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

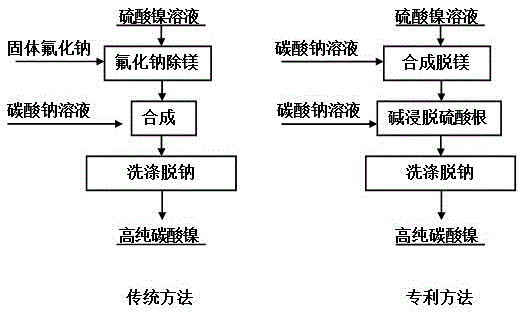

Method used

Image

Examples

example 1

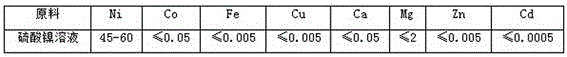

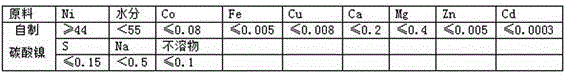

[0025] Put into 100m nickel sulfate solution containing nickel 54g / L 3 , output 20 tons of nickel carbonate with a water content of 50%, according to the above operation, synthesize mother liquor, synthesize nickel carbonate, alkali leached nickel carbonate, slurry washed nickel carbonate (high-purity nickel carbonate) and corresponding main metals and impurities of nickelous oxide products See the table below for changes.

[0026] Main metal and impurity variation of table 3 product example 1

[0027]

example 2

[0029] Put into 100m nickel sulfate solution containing nickel 55.35g / L 3 , output 20 tons of nickel carbonate with 50% water content, operate according to the specific implementation method, nickel sulfate solution, synthetic mother liquor, synthetic nickel carbonate, alkaline immersion nickel carbonate, nickel carbonate (high-purity nickel carbonate) after pulping and washing and corresponding oxidized The changes of main metals and impurities of nickel products are shown in the table below.

[0030] Main metal and impurity variation of table 4 product example 2

[0031]

example 3

[0033] Put into 100m nickel sulfate solution containing nickel 52.88g / L 3 , output 20 tons of nickel carbonate with 50% water content, operate according to the specific implementation method, nickel sulfate solution, synthetic mother liquor, synthetic nickel carbonate, alkaline immersion nickel carbonate, nickel carbonate (high-purity nickel carbonate) after pulping and washing and corresponding oxidized The changes of main metals and impurities of nickel products are shown in the table below.

[0034] Main metal and impurity variation of table 5 product example 3

[0035]

[0036] The above three examples yielded 60 tons of high-purity nickel carbonate. Compared with the traditional method for synthesizing high-purity nickel carbonate, the patented method has absolute advantages, processing costs and investment costs are greatly reduced, and labor productivity is improved. Magnesium removal by synthesis of nickel carbonate can remove 50% magnesium from the supernatant thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com