Preparation method of nickel oxide powder

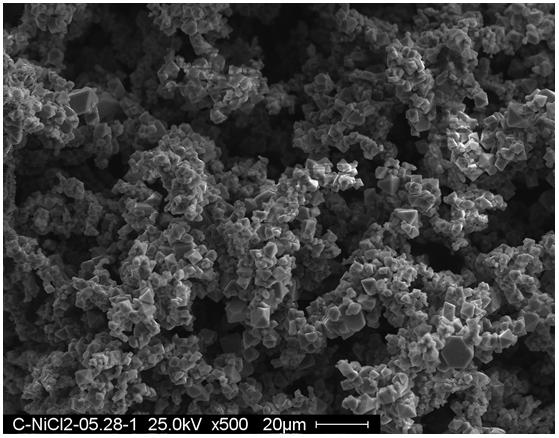

A technology of nickel oxide powder and nickel chloride, which is applied in the direction of nickel oxide/nickel hydroxide, etc., to achieve the effects of uniform powder particle size distribution, significant economic and social benefits, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

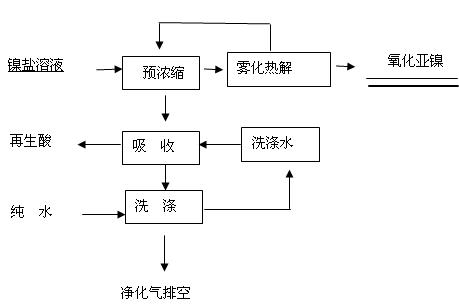

[0016] A method for preparing nickelous oxide powder. In the preparation process, nickel salt solution is atomized, and then thermally decomposed at high temperature to obtain nickelous oxide powder material; the steps of the preparation process include:

[0017] 1) Ingredients: Nickel salt solution (nickel chloride, nickel nitrate, nickel sulfate) is prepared according to the nickel concentration of 10-240g / L.

[0018] 2) Atomization: Atomize the solution in ingredient 1) into droplets of 0.5-100 μm.

[0019] 3) Pyrolysis: pyrolyze the liquid droplets obtained in 2) for 1-30 minutes at 300-1200°C and oxygen partial pressure of 1kPa-8kPa.

Embodiment 1

[0021] Add a nickel chloride solution with a nickel concentration of 10g / L into the liquid storage tank and atomize it through an atomizer; heat the atomized droplets for 10 minutes at a temperature of 650°C and an oxygen partial pressure of 2kPa. The resulting nickel oxide has a uniform particle size distribution, a D50 of 2 μm, and a bulk density of 0.9 g / cm 3 .

Embodiment 2

[0023] Add a nickel chloride solution with a nickel concentration of 100g / L into the liquid storage tank and atomize it through an atomizer; heat the atomized droplets for 10 minutes at a temperature of 650°C and an oxygen partial pressure of 3kPa. The resulting nickel oxide has a uniform particle size distribution, a D50 of 3 μm, and a bulk density of 1.0 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com