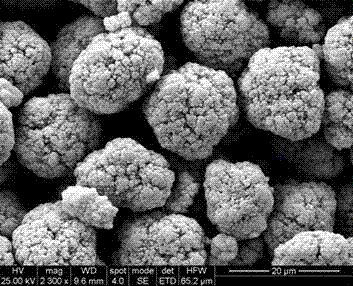

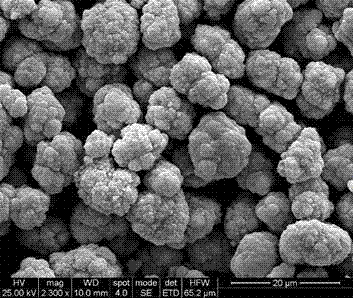

Spherical cobaltosic oxide and preparation method thereof

A technology of cobalt tetroxide and spherical shape, applied in the field of spherical cobalt tetroxide and its preparation, can solve the problems of difficult removal of cobalt hydroxide impurity content, small particles, poor particle size distribution, etc., and achieves low alkaline impurity content, uniform particle size distribution, and acceptable particle size. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare 4 mol / L cobalt sulfate solution, 8 mol / L sodium hydroxide solution and 8 mol / L hydrogen peroxide solution, and put the three solutions into the stirred reactor at the same time, and control the moles of salt: hydrogen peroxide: sodium hydroxide The ratio is 1:1:2, the liquid addition speed is controlled so that the pH value of the reaction is 8, the reaction temperature is controlled at 60°C, and the reacted slurry naturally overflows into another kettle for aging, centrifuged, washed and filtered, and then placed in Calcined at 500°C for 8h to obtain the diameter D 50 =15.51um, bulk density 1.64g / cm 3 of cobalt tetroxide.

Embodiment 2

[0024] Prepare 5mol / L cobalt chloride salt solution, 6mol / L sodium hydroxide solution and 7mol / L hydrogen peroxide solution, and add the three solutions into the stirred reactor at the same time, and control the salt: hydrogen peroxide: sodium hydroxide The molar ratio is 1:1:2, the liquid addition speed is controlled so that the pH value of the reaction is 9.5, the reaction temperature is controlled at 50°C, the reacted slurry naturally overflows into another kettle for aging, centrifuged, washed and filtered, and then Calcined at 600°C for 6h to obtain the diameter D 50 =12.50um, bulk density 1.57g / cm 3 of cobalt tetroxide.

Embodiment 3

[0026] Prepare 2mol / L cobalt sulfate solution, 5mol / L sodium hydroxide solution and 6mol / L sodium hypochlorite solution, and add the three solutions into the stirred reactor at the same time, and control the salt: hydrogen peroxide: the mole of sodium hydroxide The ratio is 1:1:2, the liquid addition speed is controlled so that the pH value of the reaction is 10.1, the reaction temperature is controlled at 65°C, the reacted slurry naturally overflows into another kettle for aging, centrifuged, washed and filtered, and then in Calcined at 500°C for 8h to obtain the diameter D 50 =10.89um, bulk density 1.57g / cm 3 of cobalt tetroxide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com