Hollow sphere anode material and preparation method thereof

A technology of positive electrode materials and hollow spheres, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of cycle performance, poor rate performance, restrictions on the industrial application of materials, and large irreversible capacity, and achieve small capacity decay and excellent cycle performance and rate performance, the effect of good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a hollow spherical positive electrode material, which includes preparing a nickel oxide precursor, preparing a second mixed solution and preparing a hollow spherical positive electrode material.

[0032] S1. Preparation of NiO precursor:

[0033] The first mixed solution containing glucose and nickel ammonium sulfate is hydrothermally reacted to obtain the first suspension; the first suspension is dried to obtain the first precipitate of solid spheres; the first precipitate is calcined to obtain nickel oxide of hollow spheres precursor;

[0034] Specifically, the step of preparing the nickelous oxide precursor includes the preparation of the first mixed liquid, the first suspension, the first precipitate and the nickelous oxide precursor.

[0035] S101, preparation of the first mixed solution:

[0036] Get glucose and ammonium nickel sulfate dissolved in deionized water to obtain the first mixed solution, and stir the firs...

Embodiment 1

[0065] This embodiment provides a method for preparing a hollow spherical positive electrode material, comprising the following steps:

[0066] S1. Preparation of NiO precursor:

[0067] Get 228mmol glucose and 45.6mmol nickel sulfate ammonium and dissolve in 360ml deionized water to obtain the first mixed solution, stir the first mixed solution evenly under magnetic stirring; At a stirring speed of 4°C / min, the temperature was raised to 180°C at a heating rate of 4°C / min, kept at 180°C for 24 hours, and then cooled to room temperature at a cooling rate of 3°C / min to obtain the first suspension; the first suspension was filtered To obtain a precipitate, wash the precipitate with deionized water 3 times, wash with ethanol 2 times, and vacuum dry it in a vacuum oven at 100°C for 10 hours to obtain the first precipitate; put the above first precipitate into a corundum magnetic boat in a tube furnace Pyrolysis under medium air atmosphere, the tube furnace is controlled to raise t...

Embodiment 2

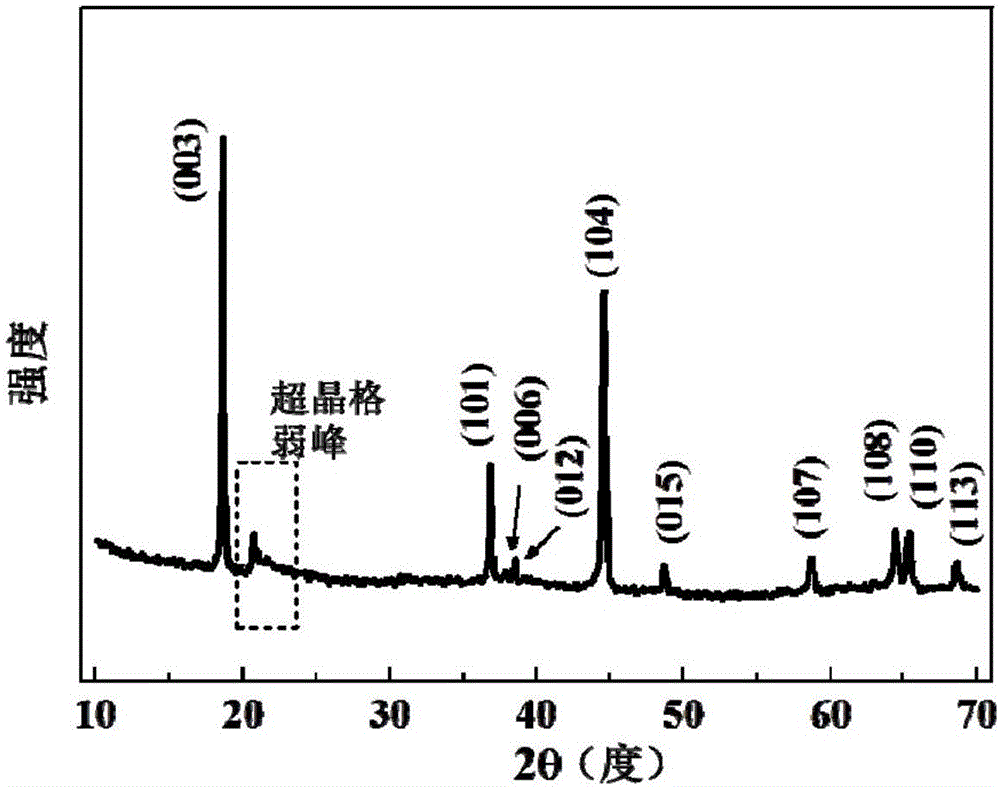

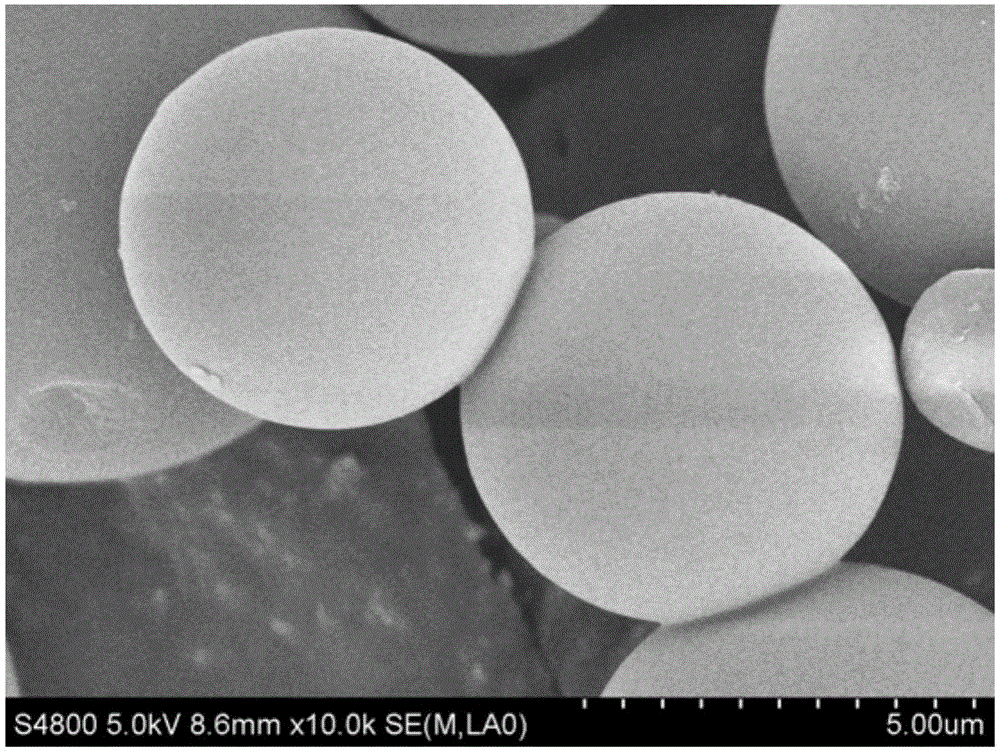

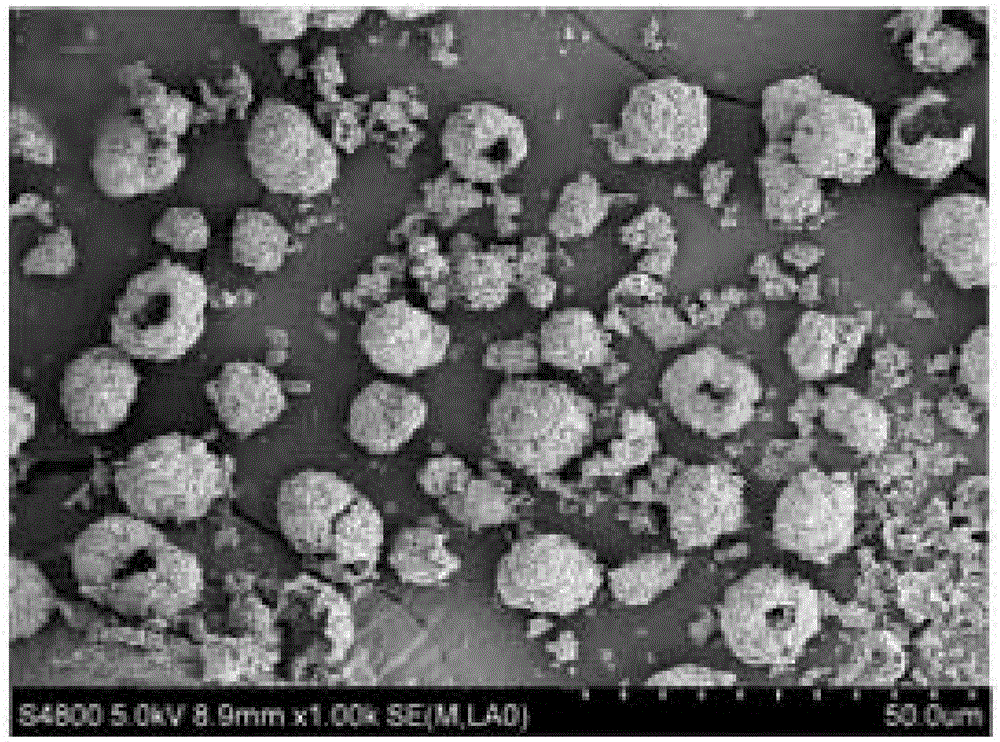

[0078] This embodiment provides a hollow sphere positive electrode material, which has nanometer-sized primary particles stacked into a micron-sized hollow sphere structure.

[0079] This embodiment provides a method for preparing a hollow spherical positive electrode material, comprising the following steps:

[0080] S1. Preparation of NiO precursor:

[0081] Get 220mmol glucose and 46mmol nickel sulfate ammonia and dissolve in 360ml deionized water to obtain the first mixed solution, stir the first mixed solution evenly under magnetic stirring; Under the stirring speed of 3°C / min, the temperature was raised to 190°C at a heating rate of 3°C / min, kept at 190°C for 20 hours, and then cooled to room temperature at a cooling rate of 5°C / min to obtain the first suspension; the first suspension was filtered To obtain a precipitate, wash the precipitate with deionized water 3 times, wash with ethanol 2 times, and vacuum dry it in a vacuum oven at 100°C for 10 hours to obtain the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average discharge specific capacity | aaaaa | aaaaa |

| Average discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com