Novel ferroelectric-ferromagnetic composite material and preparation method thereof

A composite material and ferroelectric technology, which is applied in the field of low temperature sintering to prepare composite materials and ferroelectric-ferromagnetic composite materials, can solve the problems of increased material defects, performance deterioration, and cost increase, and achieves a reduction in magnetic properties and dielectric properties. Losses, high permeability and permittivity, avoiding negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

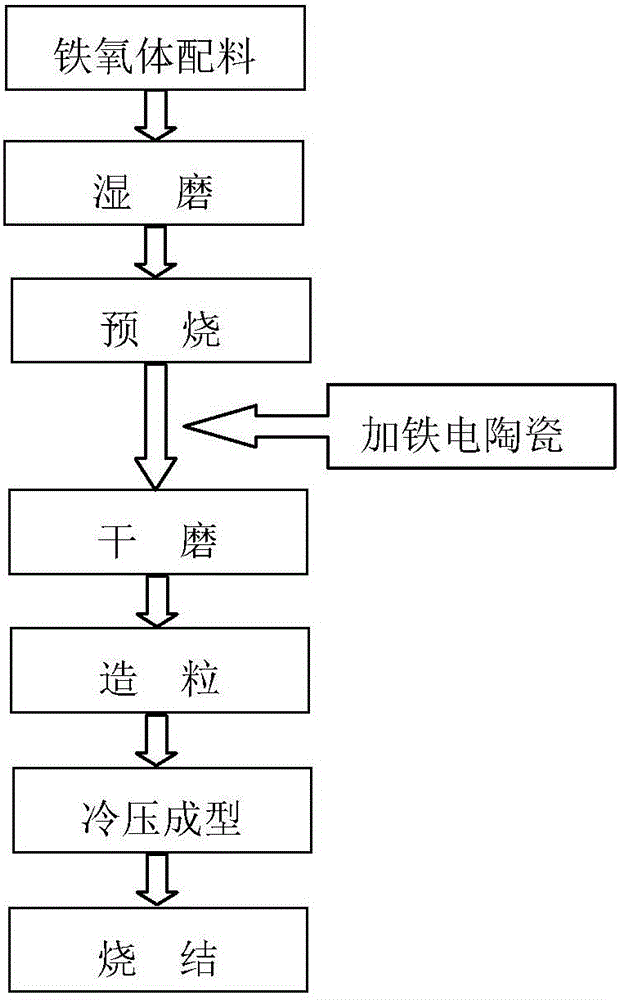

[0020] A preparation method of a novel ferroelectric-ferromagnetic composite material, comprising the following steps:

[0021] Step 1: According to the composition and content of the ferromagnetic phase: iron oxide 65-68wt%, nickelous oxide 7-10wt%, zinc oxide 17-19wt%, copper oxide 6-8wt%, lithium carbonate 0.5-1.5wt%, five The proportion of vanadium oxide is 2-4wt%, weighing and mixing, and then wet ball milling for 10-14 hours to fully mix the raw materials evenly, wherein the ball mill speed is 250-350 rpm, the ball milling medium is ethanol aqueous solution, the concentration 2~6mol / L;

[0022] Step 2: Dry the mixed powder obtained after ball milling in Step 1 at 80-120°C, and then put it into a sintering furnace for pre-firing at a temperature of 800-850°C for 2-4 hours. Cool to room temperature, obtain calcined material;

[0023] Step 3: Add ferroelectric phase ceramics to the calcined material obtained in step 2, mix them, and then place them in a ball mill for dry ...

Embodiment 1

[0027] A preparation method of a novel ferroelectric-ferromagnetic composite material, comprising the following steps:

[0028]Step 1: According to the composition and content of the ferromagnetic phase: 66.2wt% iron oxide, 7.2wt% nickel oxide, 18.1wt% zinc oxide, 6wt% copper oxide, 0.5wt% lithium carbonate, 2wt% vanadium pentoxide , weighing and mixing, and then wet ball milling each raw material in a planetary ball mill for 10 hours to fully mix the raw materials evenly, wherein the ball mill rotating speed is 250 rpm, the ball milling medium is ethanol aqueous solution, and the concentration is 3mol / L;

[0029] Step 2: Dry the mixed powder obtained after ball milling in Step 1 at 90°C, and then put it into a sintering furnace for pre-calcination at a temperature of 800°C for 3 hours. burning material;

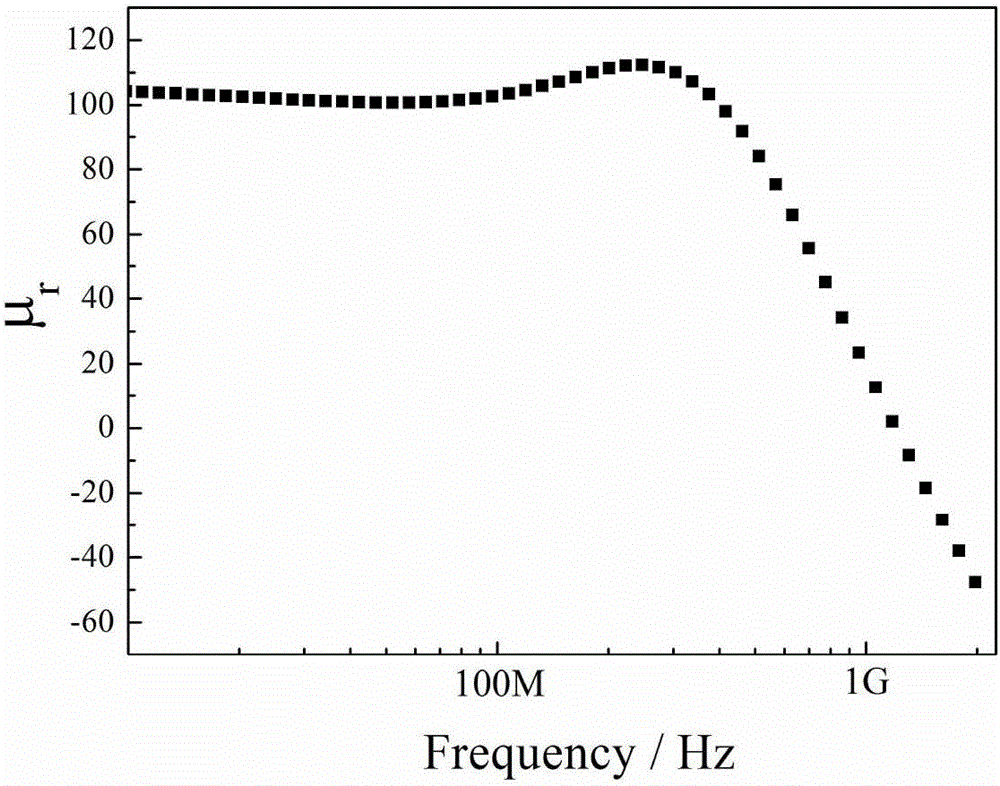

[0030] Step 3: Add Bi to the calcined material obtained in Step 2 2 TiO 6 Ferroelectric phase ceramics, mixed, and then placed in a vibrating ball mill for dry grinding f...

Embodiment 2

[0035] A preparation method of a novel ferroelectric-ferromagnetic composite material, comprising the following steps:

[0036] Step 1: According to the composition and content of the ferromagnetic phase: 66.2wt% iron oxide, 7.2wt% nickel oxide, 18.1wt% zinc oxide, 6wt% copper oxide, 0.5wt% lithium carbonate, 2wt% vanadium pentoxide , carrying out weighing and mixing, and then wet ball milling each raw material in a planetary ball mill for 12 hours to fully mix the raw materials evenly, wherein the ball mill rotating speed is 250 rpm, the ball milling medium is ethanol aqueous solution, and the concentration is 3mol / L;

[0037] Step 2: Dry the mixed powder obtained after ball milling in Step 1 at 100°C, and then put it into a sintering furnace for pre-calcination. burning material;

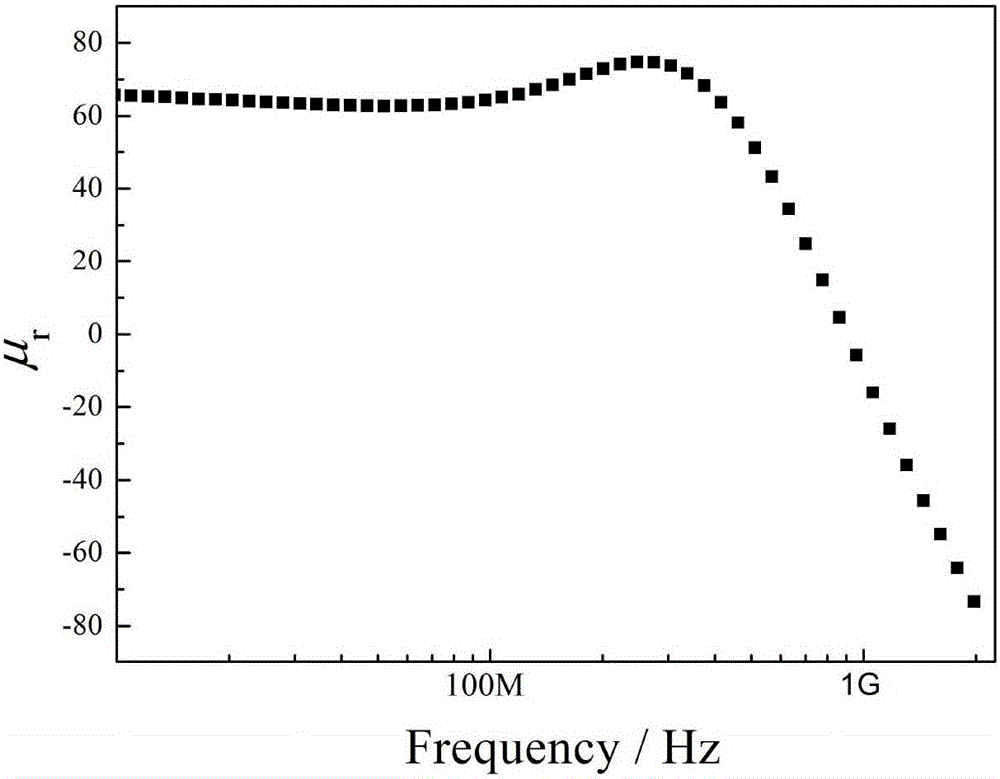

[0038] Step 3: Add Bi to the calcined material obtained in Step 2 2 TiO 6 Ferroelectric phase ceramics, mixed, and then placed in a vibrating ball mill for dry grinding for 0.5h, with an interv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com