Nanao metal ceramic inert anode material for aluminium electrolysis and preparation method thereof

A nano-cermet and anode material technology, applied in the field of electrochemical electrolysis, can solve the problems of difficult processing and poor electrical conductivity, and achieve the effects of improved electrical conductivity, improved machinability, high bending strength and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

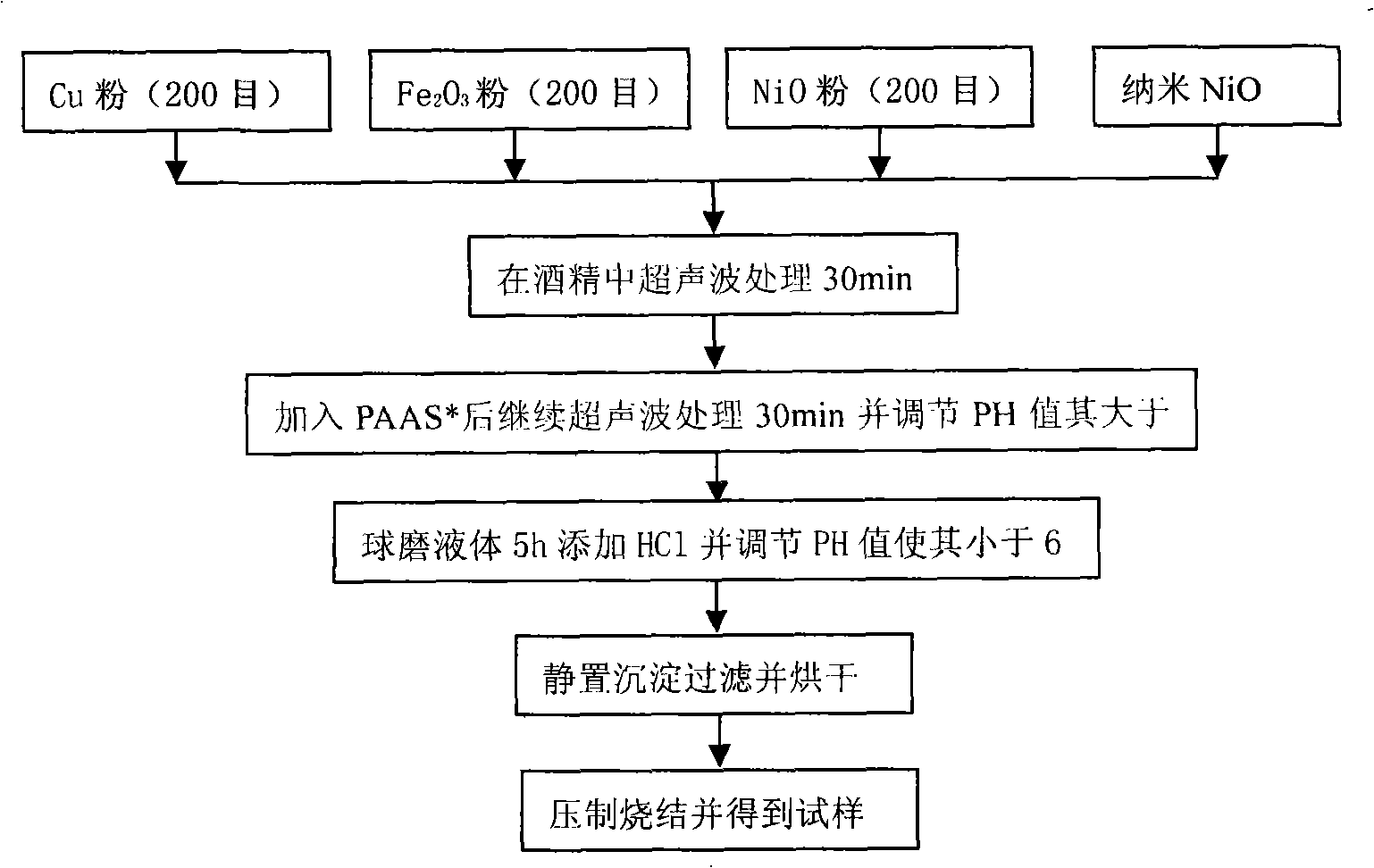

[0025] (1) 200 mesh copper powder, iron oxide powder, nickel oxide powder according to Cu 14.8% ~ 15.1%, Fe 2 o 3 35% to 36%, NiO 47% to 50% mixed in a ratio, add nickel oxide powder 4% to 14% nano-NiO powder, ultrasonic treatment in alcohol for 30min;

[0026] (2) Add sodium polyacrylate, continue ultrasonic treatment for 30 minutes and adjust the pH value to be greater than 8, and after ball milling the liquid for 5 hours, add HCl and adjust the pH value to be less than 6;

[0027] (3) Stand still for 1 hour, precipitate, filter, and dry at 100-150°C to obtain the mixed base material;

[0028] (4) Add paraffin wax of about 5% of the mass of the mixture to the mixed base material as a plasticizer, and mix evenly, at 1MPa / cm 2 pressed under pressure into a billet;

[0029] (5) The compact is sintered at 1100°C and cooled to room temperature to obtain nano-NiO-Cu-NiFe 2 o 4 Composed of nano-cermet anode materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com