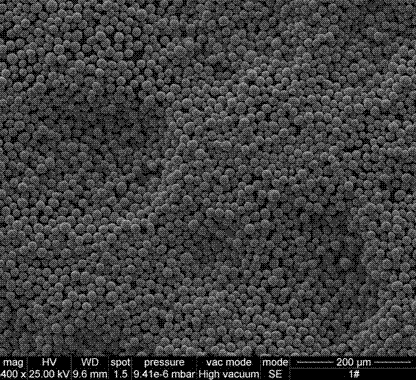

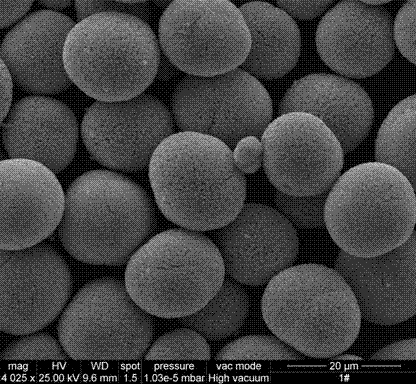

Porous spherical nickel protoxide and preparation method thereof

A nickel oxide, porous spherical technology, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of poor fluidity, difficulty in mixing uniformly, affecting product quality, etc., and achieve good fluidity, improve product quality, and uniform and stable color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Prepare nickel sulfate solution and ammonia water with a concentration of 2mol / L and 5mol / L respectively, prepare a sodium hydroxide solution with a pH value of 12.0 in the reaction kettle as the reaction bottom liquid; mix the nickel sulfate solution and ammonia water in a volume ratio of 1:0.2 After mixing evenly, add it to the reaction kettle for reaction, continuously stir the reaction solution, and control the pH value of the reaction solution at 12.0 by adding sodium hydroxide solution; control the reaction temperature at 55°C to obtain spherical nickel hydroxide; Ni(II) hydroxide was calcined at 800°C for 15 hours to obtain porous spherical Ni(II) oxide.

[0023] The prepared porous spherical NiO has a particle size distribution of D50=10um and a specific surface area of 15m 2 / g. Among them, D50=10um means that the particles with a particle size larger than 10um account for 50% of the nickel oxide particles, and the particles with a particle size smaller than...

Embodiment 2

[0025] Prepare the concentration of 1mol / L, 4mol / L nickel chloride solution and ammonia water respectively, and prepare a sodium hydroxide solution with a pH value of 12.5 in the reaction kettle as the reaction bottom liquid; After mixing evenly, add it to the reaction kettle for reaction, continuously stir the reaction solution, and add sodium hydroxide solution to control the pH value of the reaction solution at 12.5; control the reaction temperature at 58 ° C to obtain spherical nickel hydroxide; Spherical nickel hydroxide is calcined at 1000°C for 10 hours to obtain porous spherical nickel oxide.

[0026] The prepared porous spherical nickel oxide D50=3um, the specific surface area is 30m 2 / g.

Embodiment 3

[0028] Prepare nickel sulfate solution and ammonia water with concentrations of 2.5mol / L and 5mol / L respectively, and prepare potassium hydroxide solution with a pH value of 13 in the reaction kettle as the reaction bottom liquid; After mixing evenly, add it to the reactor for reaction, continuously stir the reaction solution, and add potassium hydroxide solution to control the pH value of the reaction solution at 13; control the reaction temperature at 50°C to obtain spherical nickel hydroxide; Spherical nickel hydroxide is calcined at 1400°C for 5 hours to obtain porous spherical nickel oxide.

[0029] The prepared porous spherical nickel oxide D50=7um, the specific surface area is 24m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com