Preparation method of solid oxide fuel cell two-layer anode

A solid oxide, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large, trapped in the anode body, expansion, deformation of the anode surface, and increased impact force of the anode body. , to achieve the effect of simple and easy preparation method, diverse structure design and reasonable anode structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

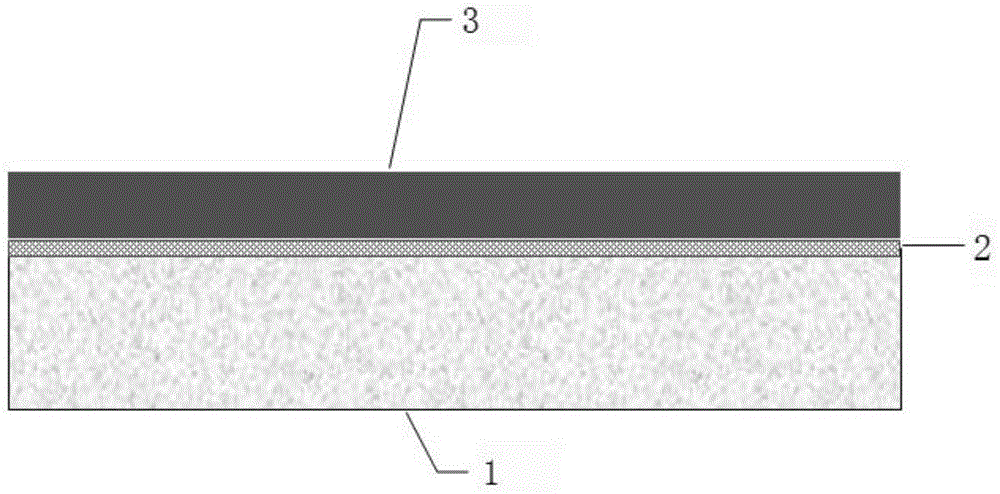

[0020] Specific implementation mode 1: The preparation method of the double-layer anode of the solid oxide fuel cell in this implementation mode is realized according to the following steps:

[0021] 1. Put the solid oxide electrolyte powder into the mold, press the electrolyte powder into a green body with a thickness of 0.05-3mm at room temperature, and then sinter at a high temperature of 1000-1400°C for 1-10 hours to obtain an electrolyte support ;

[0022] 2. Mix nickelous oxide and solid oxide electrolyte at a mass ratio of 0.25 to 9:1 and then grind, and the ground powder is divided into initial powder a and initial powder b;

[0023] 3. Add a pore-forming agent to the initial powder a, mix evenly to obtain a mixed powder, place the mixed powder in a steel mold, and press the mixed powder into an anode green body with a thickness of 0.05-3mm at room temperature, Sintering the anode body at 900-1500°C for 1-10 hours to obtain a dry-pressed porous anode block;

[0024] ...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment differs from Embodiment 1 in that the solid oxide electrolyte is zirconia doped with an alkaline earth oxide with a molar doping amount of 1% to 30%, and a molar doping amount of 1% to 20% rare earth Oxide-doped zirconia, a molar doping amount of 1% to 50% alkaline earth oxide doping ceria or a molar doping amount of 1% to 50% rare earth oxide doping ceria. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Specific embodiment three: the difference between this embodiment and specific embodiment two is that the rare earth oxides in the rare earth oxide doped zirconia are lanthanum oxide, cerium oxide, praseodymium oxide, neodymium oxide, europium oxide, gadolinium oxide, Holmium oxide, erbium oxide, dysprosium oxide, thulium oxide, ytterbium oxide, yttrium oxide or scandium oxide; the rare earth oxide in the rare earth oxide doped cerium oxide is lanthanum oxide, praseodymium oxide, neodymium oxide, europium oxide, gadolinium oxide , holmium oxide, erbium oxide, dysprosium oxide, thulium oxide, ytterbium oxide, yttrium oxide, or scandium oxide. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com