Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

305 results about "Carbocatalysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbocatalysis is a form of catalysis that uses heterogeneous carbon materials for the transformation or synthesis of organic or inorganic substrates. The catalysts are characterized by their high surface areas, surface functionality, and large, aromatic basal planes. Carbocatalysis can be distinguishable from supported catalysis (such as palladium on carbon) in that no metal is present, or if metals are present they are not the active species.

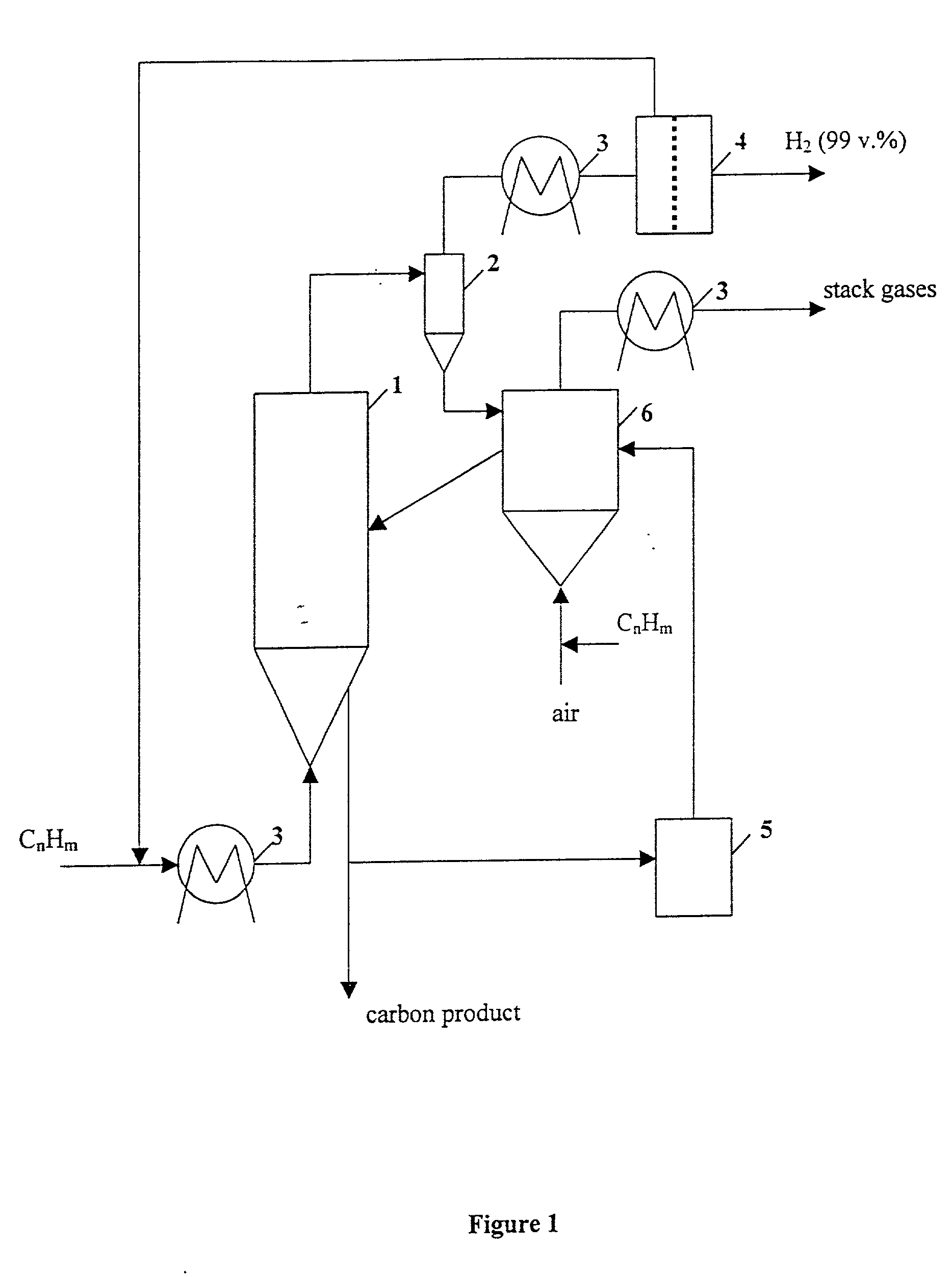

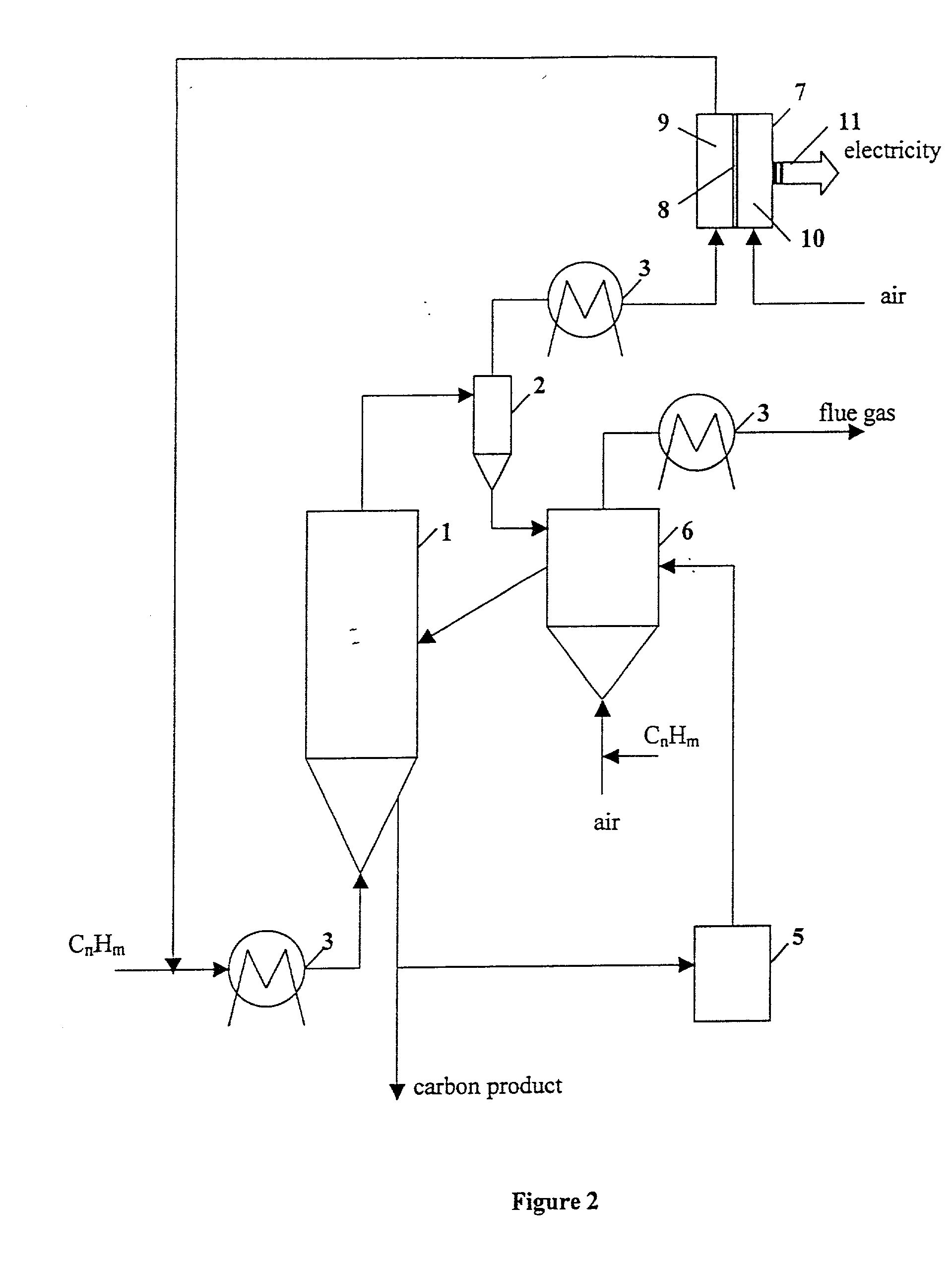

Thermocatalytic process for CO2-free production of hydrogen and carbon from hydrocarbons

InactiveUS20020007594A1Pigmenting treatmentPressurized chemical processDecompositionBiological activation

This invention relates to a novel process for sustainable CO2-free production of hydrogen and carbon by thermocatalytic decomposition (or dissociation, pyrolysis, cracking) of hydrocarbon fuels over carbon-based catalysts in the absence of air and / or water. The process is applicable to any hydrocarbon fuel, including sulfurous fuels. Combination of a catalytic reactor with a gas separation unit allows to produce high purity hydrogen (at least, 99.0 v %) completely free of carbon oxides. In a preferred embodiment, sustainable continuous production of hydrogen and carbon is achieved by both internal and external activation of carbon catalysts. Internal activation of carbon catalyst is accomplished by recycling of hydrogen-depleted gas containing unsaturated and aromatic hydrocarbons back to the reactor. External activation can be achieved via surface gasification of carbon catalysts by hot combustion gases during catalyst heating. The process can conveniently be integrated with any type of fuel cell.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

Nitrogen and phosphorus co-doped porous carbon catalyst and preparation method thereof

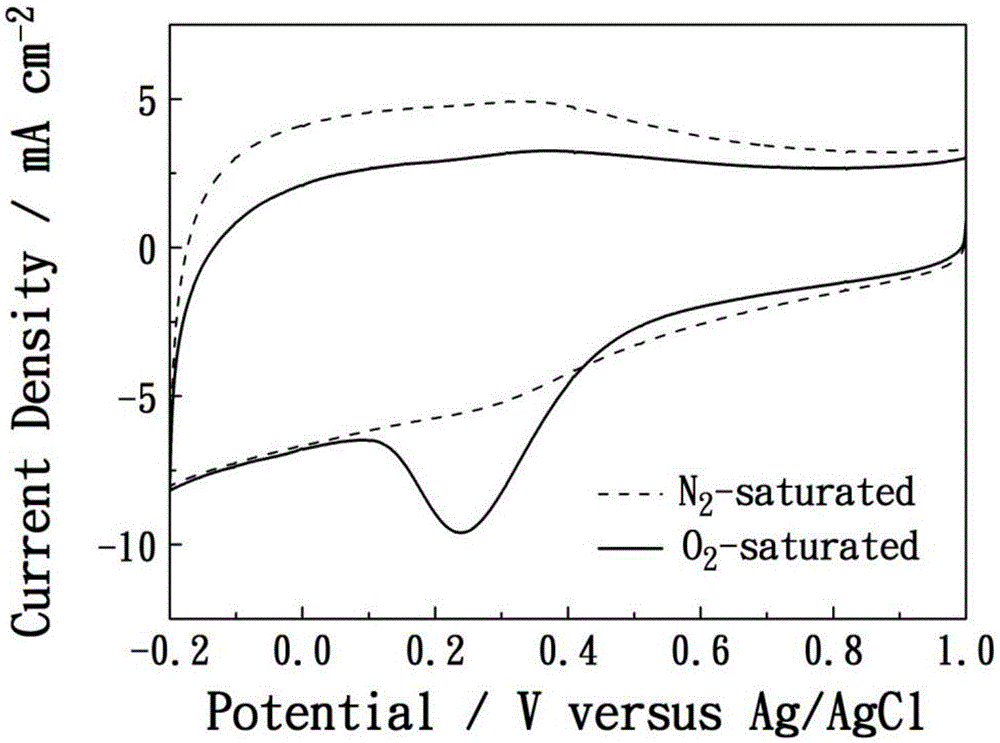

InactiveCN105457666AAperture controllableImprove adsorption capacityPhysical/chemical process catalystsCell electrodesPorous carbonAniline

The invention provides a preparation method and an application of a nitrogen and phosphorus co-doped porous carbon catalyst and belongs to the field of oxygen reduction catalysts for a fuel cell cathode. Nitrogen and phosphorus are introduced with an in-situ doping method, and the nitrogen and phosphorus doping amount is changed by adjusting the content of a nitrogen and phosphorus precursor. Besides, nitrogen and phosphorus co-doped porous carbon is prepared with a hard template method, and controllability of pore diameters of the porous carbon is realized by adjusting a hard template. The method comprises steps as follows: an earlier polymer of aniline monomers, a phosphorus precursor, a silica-based hard template and non-precious metal salt is prepared; the earlier polymer is calcined, and solids are obtained; the solids are etched, cleaned and dried, and the carbon material is obtained. More importantly, the prepared nitrogen and phosphorus co-doped porous carbon material has an excellent oxygen reduction electro-catalytic property under the acid condition and has huge application potential.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

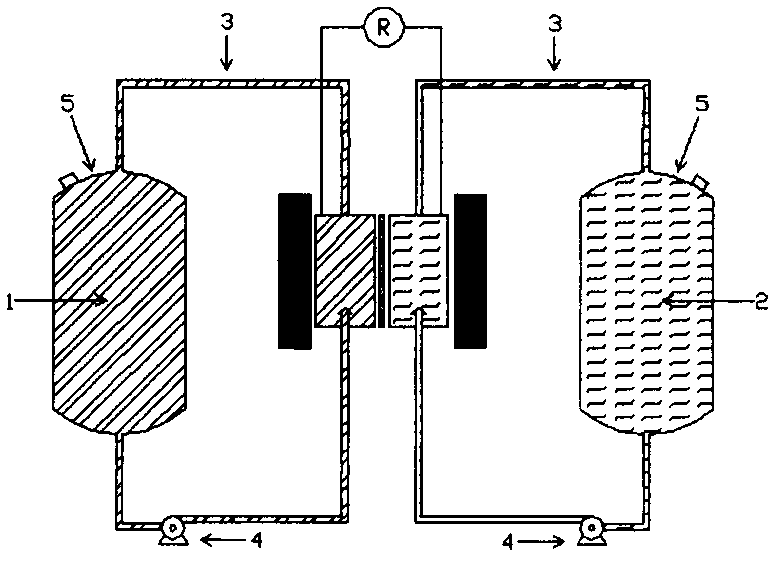

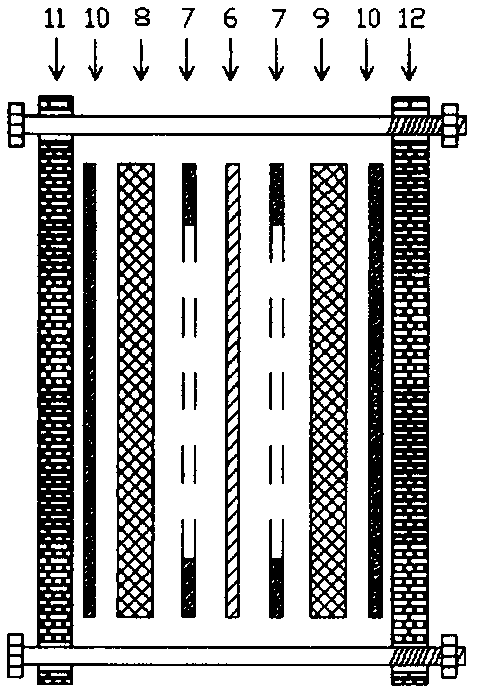

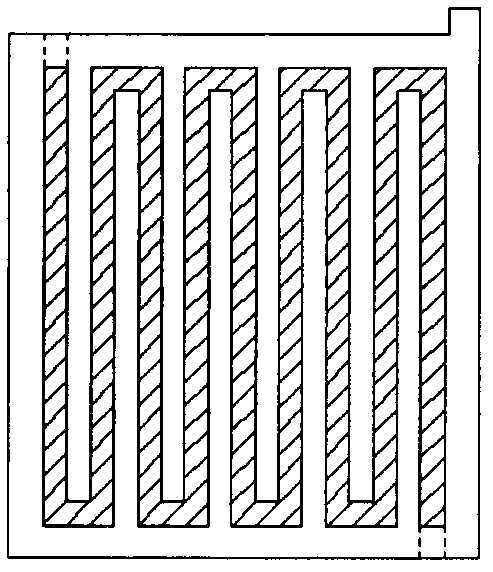

Lithium metal flow battery system and preparation method for same

InactiveCN102637890AIncrease capacityContinuous operationRegenerative fuel cellsMetallic lithiumPtru catalyst

A lithium metal flow battery system and a preparation method for the same belong to the field of electrochemical power sources. A cathode of a lithium metal flow battery is made of slurry formed by mixing lithium metal powder or lithium alloyed powder with organic liquid electrolyte containing lithium salt, an anode of the lithium metal flow battery is made of mixed slurry formed by the same organic liquid electrolyte and carbon catalyst or carbon-loaded catalyst, high-purity oxygen saturated in the slurry serves as oxidizer, a polymer composite membrane for separating the anode from the cathode is arranged in the middle, a lithium ion migrates between the two electrodes by means of the organic liquid electrolyte and the membrane, and an electron flows on an external lead connected with the anode and the cathode and a load to generate current. The novel lithium metal flow battery can be continuously used only by means of circulating feeding, and lithium metal can be regenerated by recovering discharge products in anode slurry and reused as cathode materials. The lithium metal flow battery system has the advantages of high energy density, continuous and stable operation, simple structure, long cycle life, high safety, high power density, and capability of realizing quick charge and discharge.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

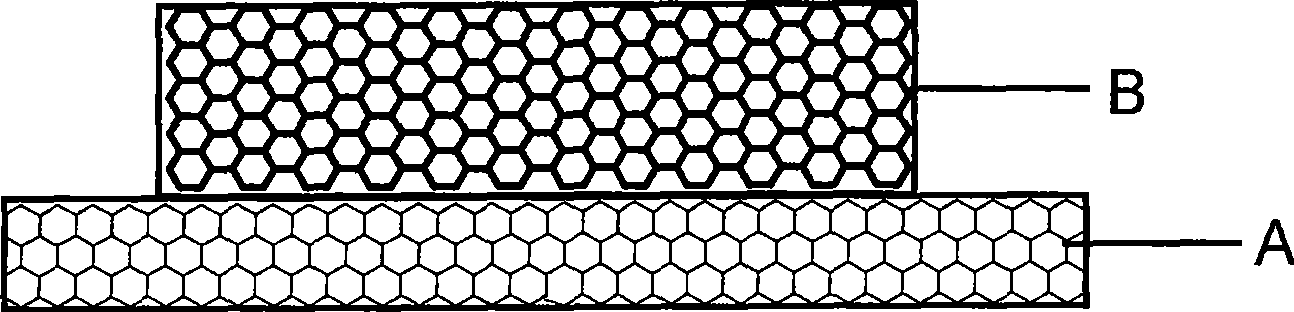

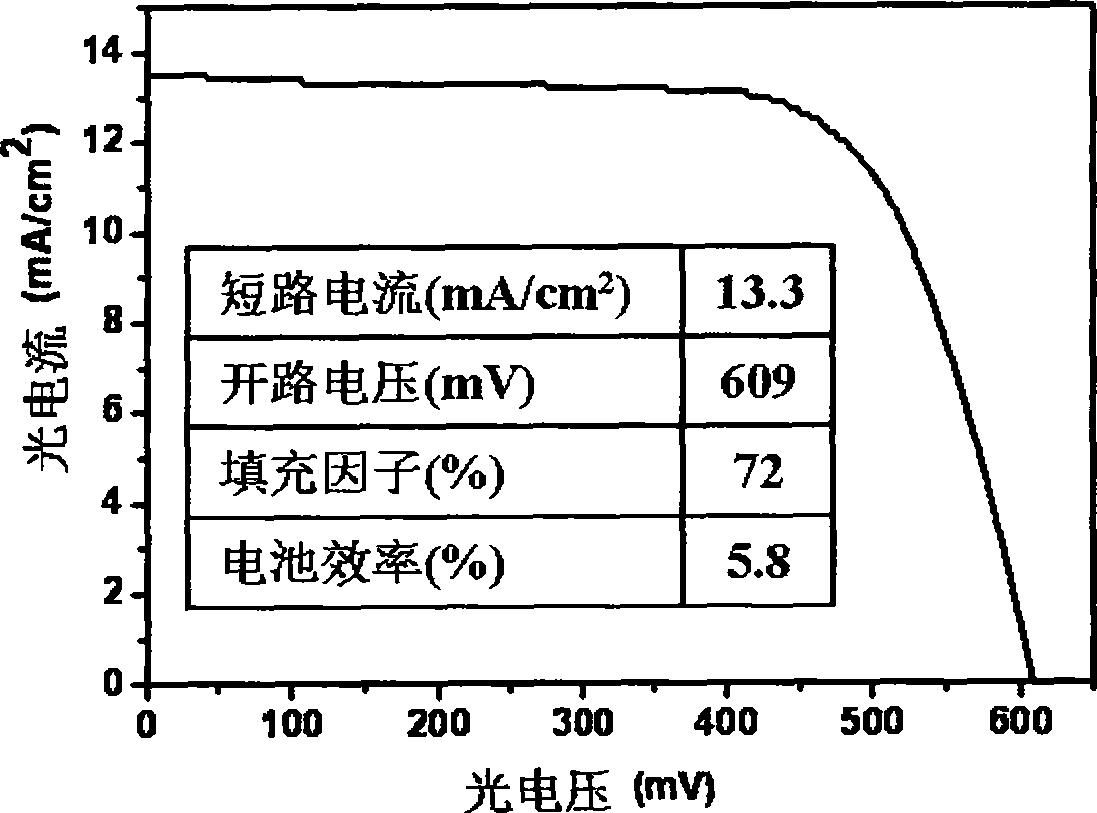

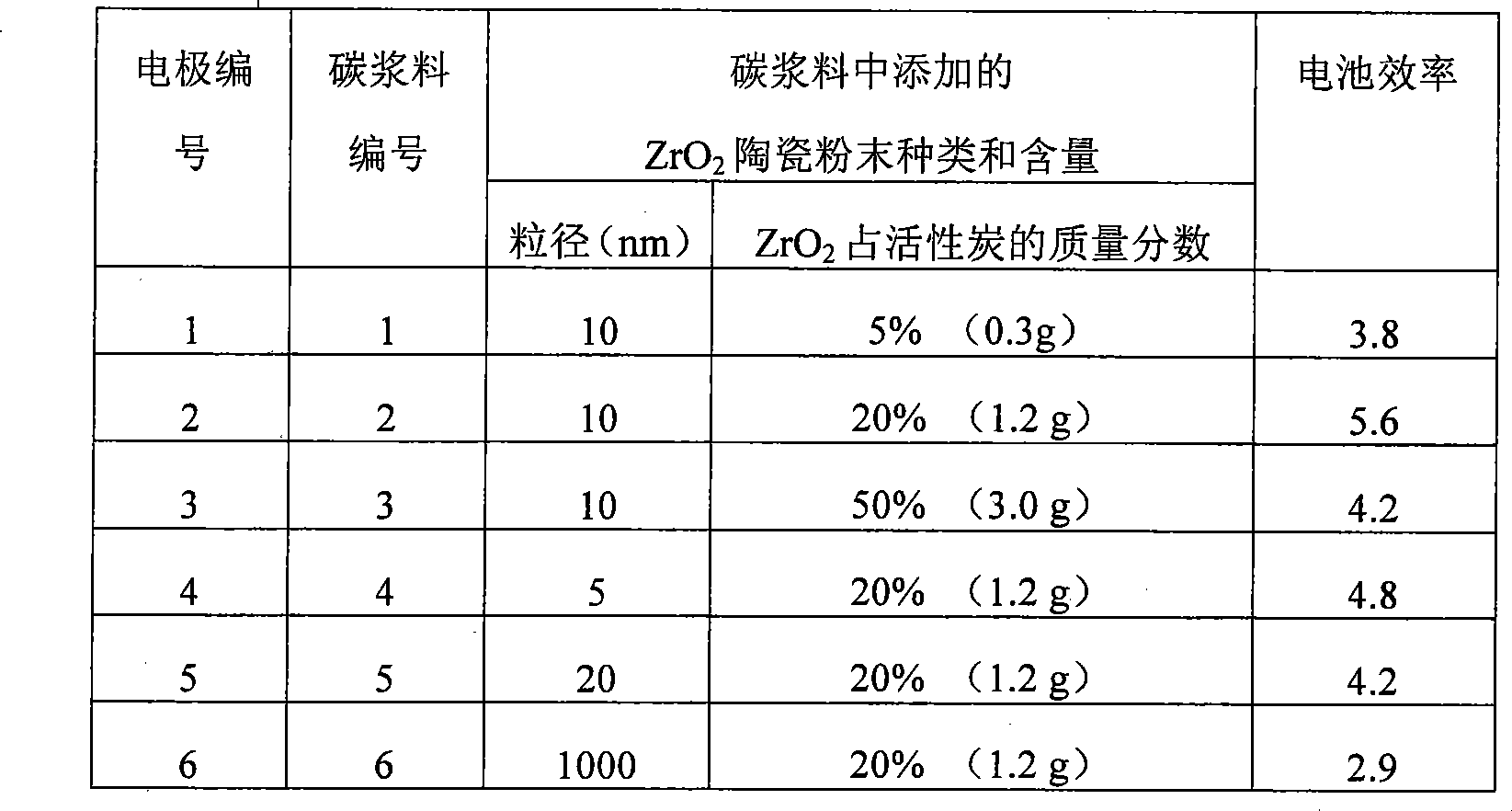

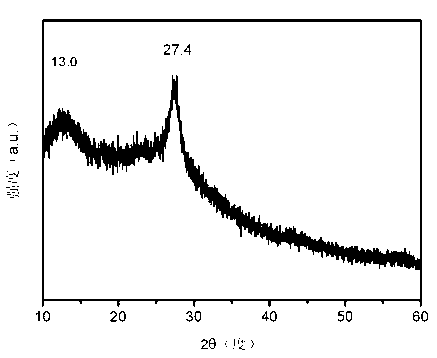

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

Polymer photocatalyst, and method of water-phase photo-catalytic selective alcohol oxidation

InactiveCN103127948AImprove conversion rateGood choicePhysical/chemical process catalystsOrganic compound preparationPtru catalystUltraviolet

The invention discloses a polymer photocatalyst and a method of water-phase photo-catalytic selective alcohol oxidation. According to the invention, an organic polymer carbon nitride catalyst is prepared, and is applied in a water-phase photo-catalytic selective alcohol oxidation system. Compared with common ultraviolet catalyst TiO2, visible light catalyst TiO2-xNx, metal sulfide, metal nitride, metal nitrogen oxides, and the like, when alcohol is oxidized in water phase with a green oxidant air / oxygen under mild conditions, the carbon nitride catalyst is more stable and shows higher efficiency. The preparation method of the carbon nitride catalyst is simple and feasible, and the catalyst comprises no metal element, such that the catalyst is cheap. With the catalyst, alcohol oxidation aldehyde synthesis or ketone synthesis processes are simple and feasible, such that industrialized large-batch productions of aldehyde and ketone compounds can be facilitated.

Owner:FUZHOU UNIV

Platinum-nickel-cobalt alloy@carbon nanotube composite material, preparation and application thereof

ActiveCN110783577AEasy to prepareLow costMaterial nanotechnologyCell electrodesPtru catalystMetal-organic framework

The invention belongs to the field of preparation of electro-catalytic materials, and more particularly relates to a nickel-cobalt alloy@carbon nanotube composite material and preparation and application thereof. A precursor solution containing platinum, nickel and cobalt is mixed with a metal organic ligand solution, coordination reaction is carried out, solid-liquid separation is carried out after the reaction is finished to obtain a metal organic framework containing platinum, nickel and cobalt, washing and drying are carried out to obtain a dried metal organic framework; and the obtained metal organic framework is annealed in a reducing atmosphere, cleaning with dilute acid is carried out, separating and drying are carried out to obtain the platinum-nickel-cobalt alloy@carbon nanotubecomposite material. The composite material is used as a catalyst for an electrocatalytic oxygen reduction test, and is prepared into a full cell for a fuel cell test system, and the obtained catalyticperformance and stability are superior to those of the current commercial platinum-carbon catalyst. The preparation method of the material is simple, reaction conditions are mild, cost is low, the concept of green chemistry is met, and large-scale industrial production can be carried out through synthesis of the adopted in-situ organic framework.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing ticagrelor key intermediate

InactiveCN106279095AReduce pressure on environmental protectionSuitable for large-scale industrial productionOrganic chemistryBulk chemical productionChemical synthesisPalladium on carbon

The invention relates to a chemical synthesis method of ticagrelor key intermediate 2-[[(3aR, 4S, 6R, 6aS)-6-aminotetrahydro-2,2-dimethyl-4H-cyclopenta-1,3-dioxolane-4-yl] oxy]ethanol (a key intermediate A). The method comprises the following steps: taking D-ribose as a raw material, and carrying out ten chemical reaction steps of 1-locus methylation and 2,3-loci isopropylidene protection, 4-locus derivatization, iodination, furan ring-opening, hydroxylamine reaction, palladium on carbon catalytic hydrogenation, amino Cbz protection, hydroxy protection, sodium borohydride reduction ester, Cbz removal protection and the like, thereby obtaining the key intermediate A. The raw materials are cheap and readily available, the preparation process is high in operability, steps of optical resolution, chiral induction and the like are avoided, the total yield is relatively high, and the product quality is better; particularly due to the use of sodium borohydride reduction ester, the preparation cost of ticagrelor is greatly reduced; and the method is suitable for large-scale industrial production.

Owner:CHONGQING SHENGHUAXI PHARMA CO LTD +1

Bifunctional electrode design and method of forming same

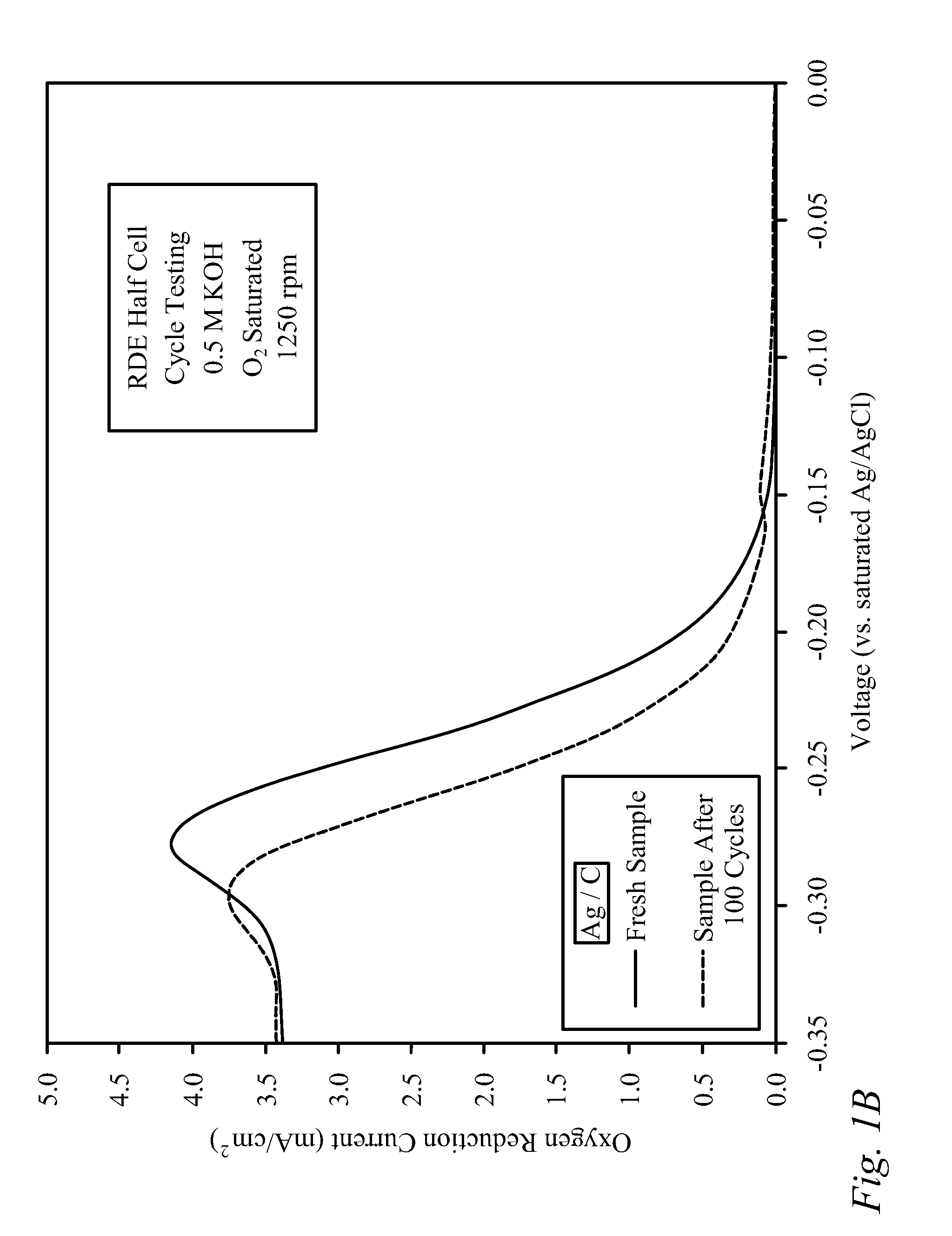

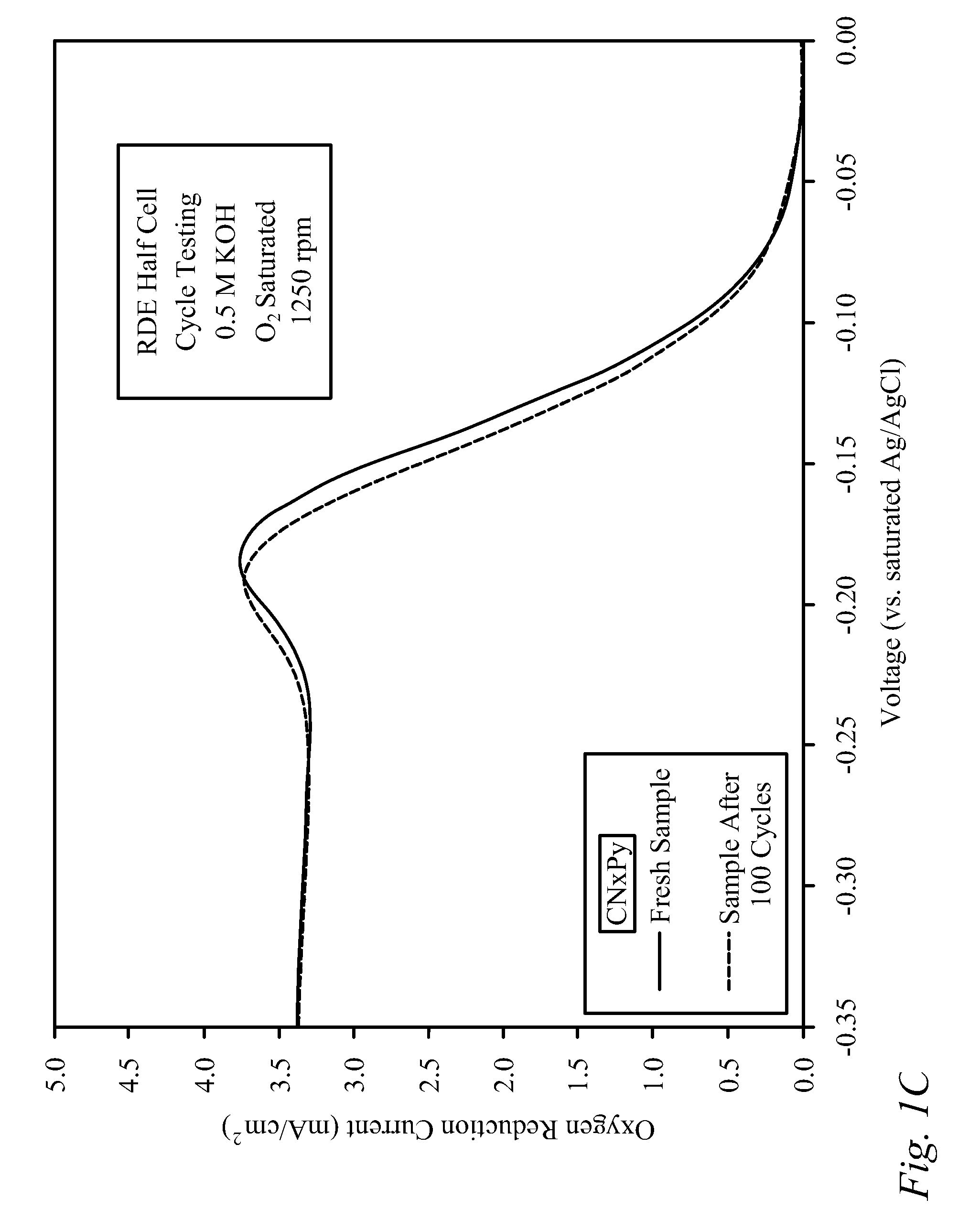

InactiveUS20140045081A1Without significant loss of performanceHigh surface area supportCell electrodesFuel cellsCelluloseFiber

A method for making a doped carbon bifunctional electrode capable of facilitating the oxygen reduction reaction and the oxygen evolution reaction that is not susceptible to performance degradation when operated bi-functionally for oxygen reduction and evolution.In one embodiment, a doped carbon catalyst is prepared by mixing a metal precursor with a high surface area support, impregnated with at least one organic phosphorus and / or organic nitrogen compound, and then pyrolyzed at high temperature under an inert or reducing atmosphere containing volatile carbon and / or nitrogen species. The doped-carbon catalyst may be coated on a conductive porous support and dispersed as an ink infiltrated into a porous conductive support.In another embodiment, a catalyst precursor, such as an iron salt and / or cobalt salt solution mixed with a binder, such as cellulosic binder, is infiltrated into a porous support, and pyrolized such that carbon catalyst fibers are anchored directly on the support.

Owner:PH MATTER

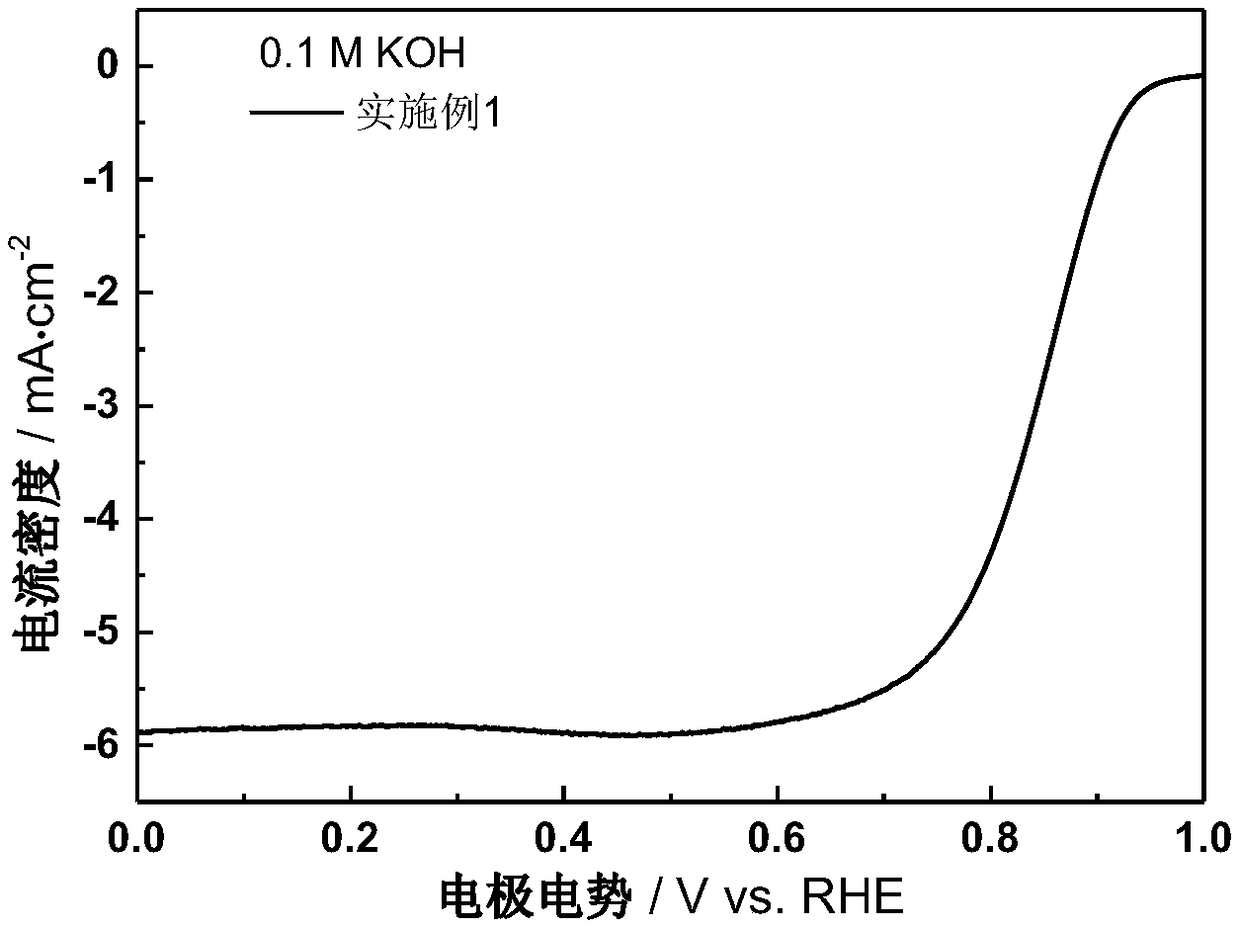

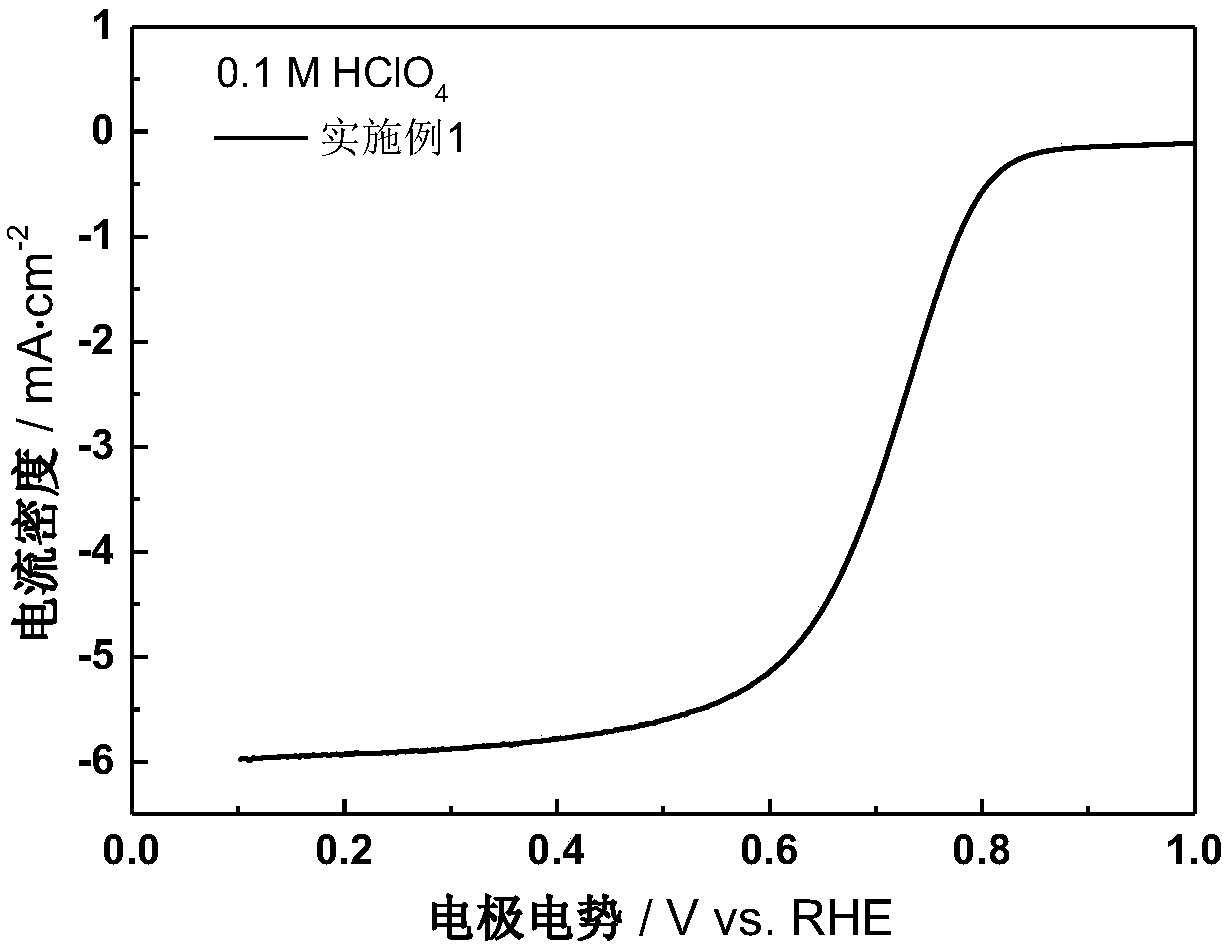

Catalyst for fuel cell and preparation method thereof

The invention discloses a catalyst for a fuel cell and a preparation method of the catalyst. The catalyst is a nitrogen-hybridized carbon-based catalytic material containing one or more metals. The catalyst is an M-NC single-metal nitrogen-carbon catalyst, a double-metal nitrogen-carbon catalyst or a multi-metal nitrogen-carbon catalyst, wherein M is one or more of metal elements. The catalyst isof a large-volume pore structure, has excellent gas and electron conductivity, high graphitization degree and nitrogen content, large specific surface area, multiple active sites, uniform distribution, high activity and strong stability, has the advantages of high catalytic activity, long service life and low comprehensive cost, and can be used for proton exchange membrane fuel cells and direct alcohol fuel cells. In addition, the preparation method is simple in process, controllable in operation, mild in condition, environmentally friendly and high in universality, no solvent is used in the synthesis process, various raw materials are subjected to a solid-phase thermal reaction to directly form a precursor and then are carbonized, the raw material cost is low, and the utilization rate ishigh.

Owner:CHINA-SINGAPORE INT JOINT RES INST

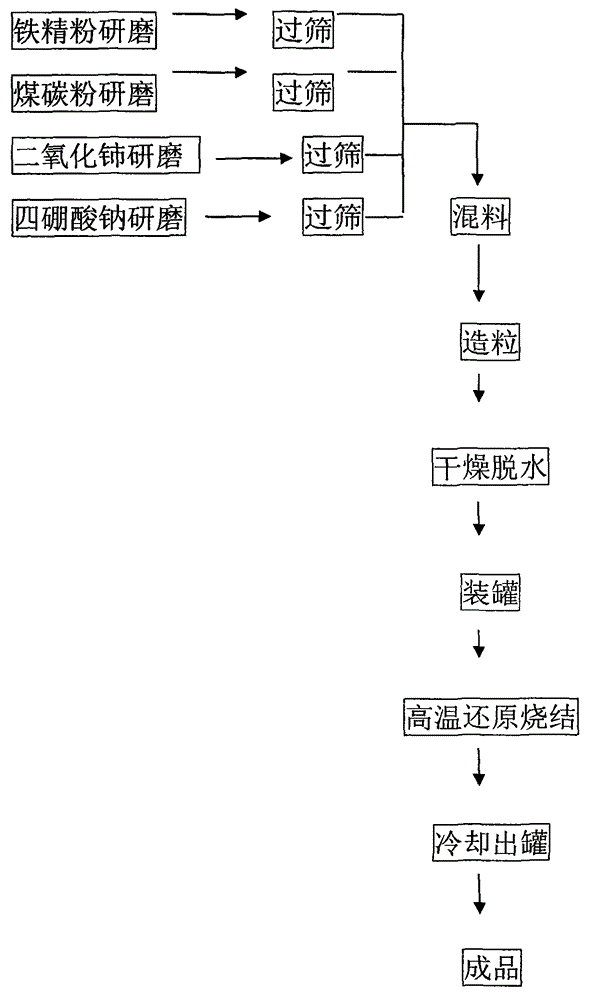

Spherical catalytic microelectrolytic environment-friendly material and preparation method therefor

InactiveCN105084470AImprove reaction speedGood removal effectWater/sewage treatmentHigh concentrationChemical oxygen demand

The invention relates to a spherical catalytic microelectrolytic environment-friendly material and a preparation method therefor. Aiming at the defects such as low reaction speed, low COD (Chemical Oxygen Demand) removal ratio, easiness in passivating and the like of the existing iron-carbon microelectrolytic materials, a special catalyst is added during the production of the spherical catalytic microelectrolytic environment-friendly material disclosed by the invention, the spherical catalytic microelectrolytic environment-friendly material is mainly prepared from 78-88wt.% of zero-valence active iron, 10-14wt.% of carbon, 1-5wt.% of catalyst and 1-3wt.% of auxiliary materials, is an iron, carbon and catalyst integrated composite spherical material and is prepared from fine iron powder, coal, the catalyst and a sintering agent through carrying out grinding and sieving, carrying out mixing and pelletizing, carrying out drying and canning, carrying out high-temperature reduction sintering and carrying out cooling and can discharging, wherein the catalyst is special compounded ceria, and the sintering agent is sodium tetraborate. During the treatment of a variety of high-concentration and toxic wastewater such as pharmaceutical wastewater, coking wastewater, petrochemical wastewater and the like, the reaction speed and COD removal ratio of the spherical catalytic microelectrolytic environment-friendly material are increased by 20-30% through the catalyst compared with those of the ordinary iron-carbon microelectrolytic materials.

Owner:GUANGZHOU S SUNNY ENVIRONMENTAL PROTECTION TECH CO LTD

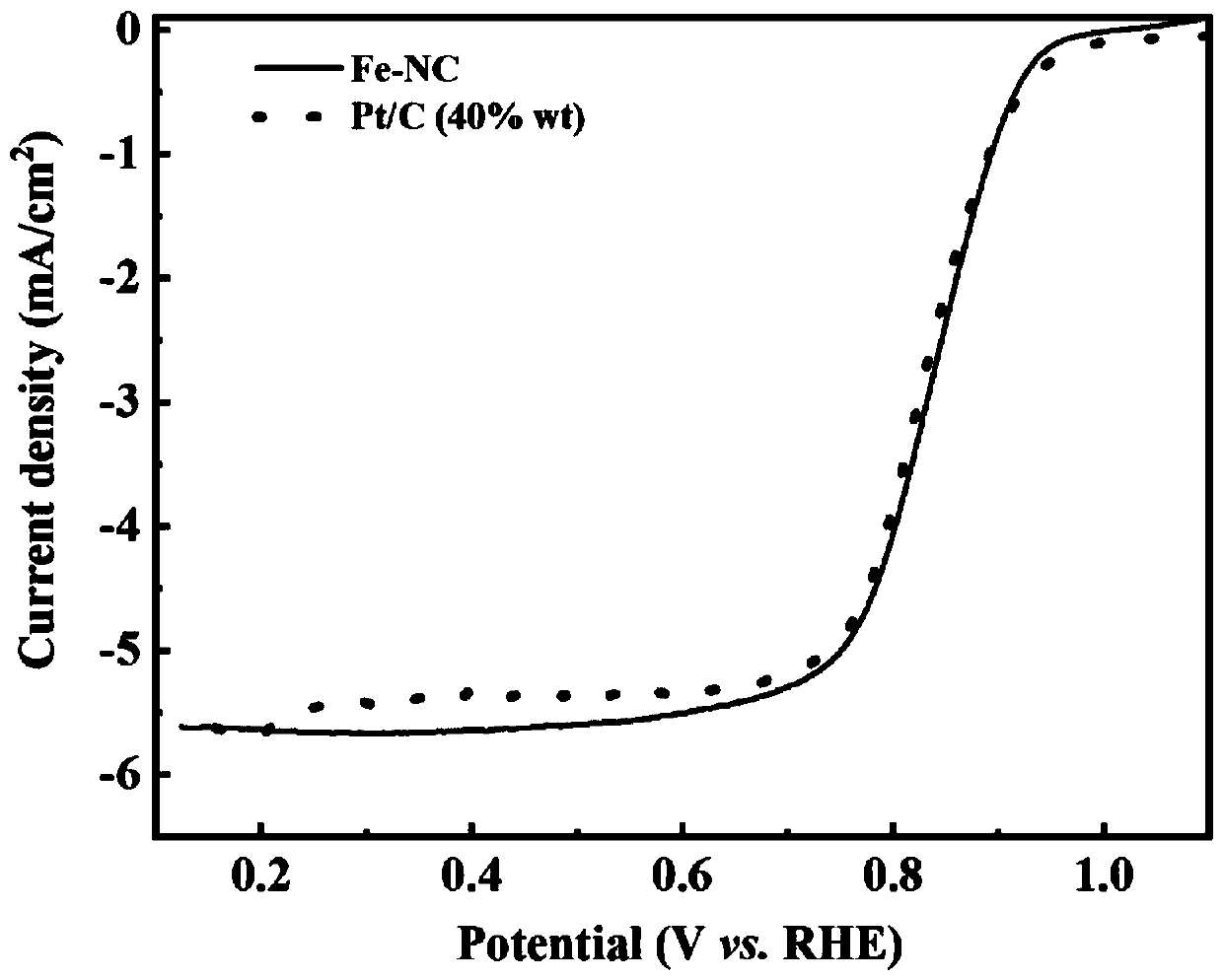

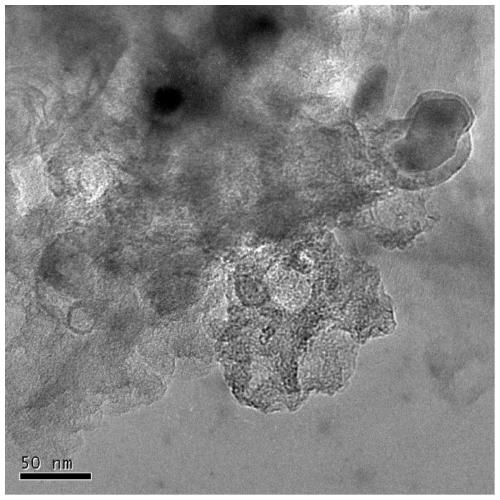

Iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical holes and preparation method of iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical holes

ActiveCN109433238AThe synthesis method is simpleCatalytic performance for efficient oxygen reduction reactionPhysical/chemical process catalystsMetal-organic frameworkPyrolysis

The invention belongs to the technical field of catalysts and discloses an iron-nitrogen doped oxygen reduction carbon catalyst with ordered hierarchical holes and a preparation method of the iron-nitrogen doped oxygen reduction carbon catalyst with the ordered hierarchical holes. A hierarchical-hole three-dimensional ordered iron doped metal organic framework is formed by a 3D skeleton template,then a high-temperature calcining pyrolysis method is adopted to obtain the iron-nitrogen doped carbon catalyst with ordered hierarchical holes and an oxygen reduction function, and a promising application prospect in the field of metal-air cells, regenerative fuel cells and the like is achieved.

Owner:宁波华储能源有限责任公司

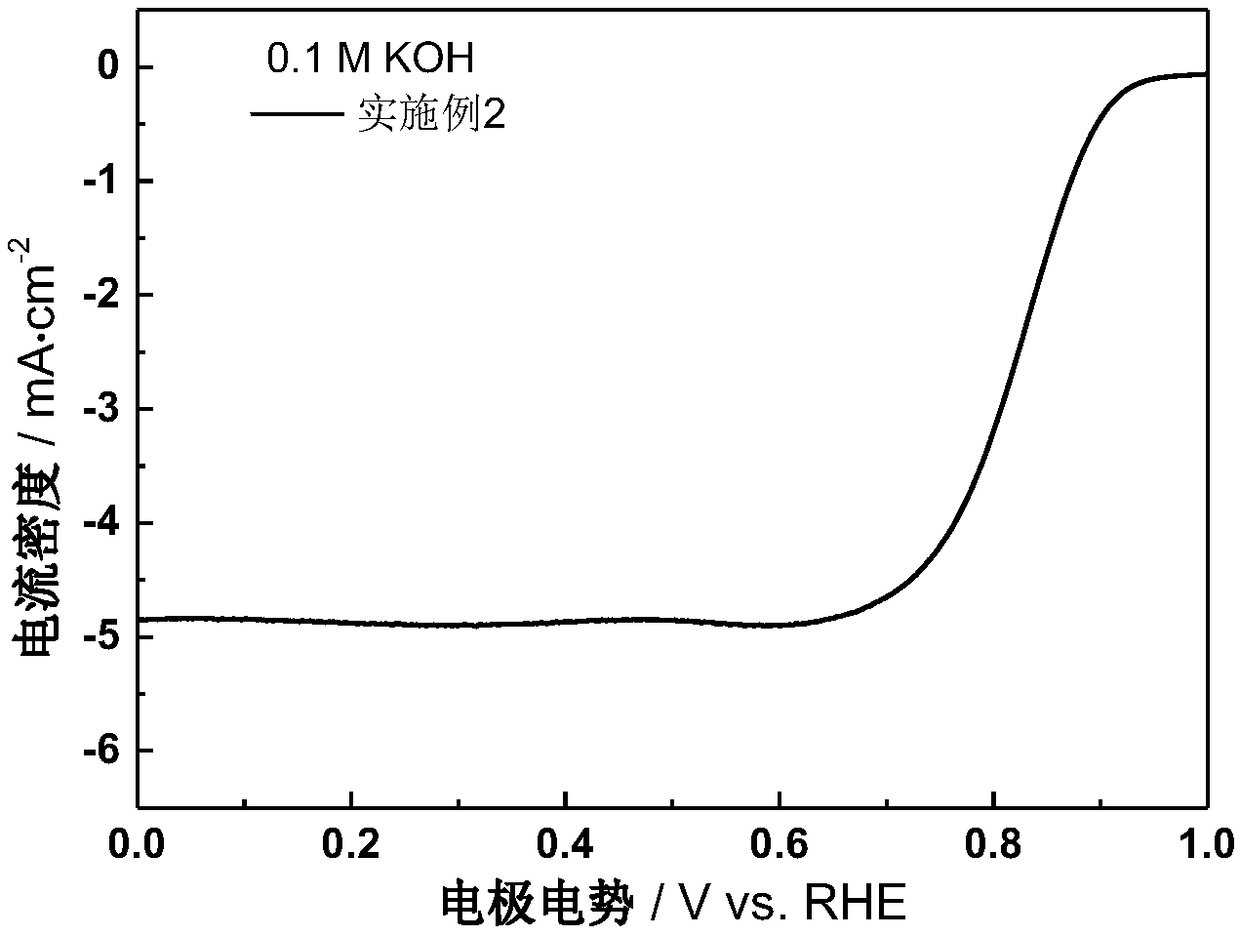

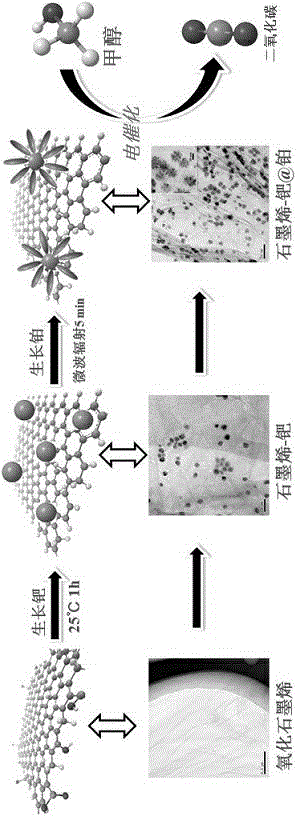

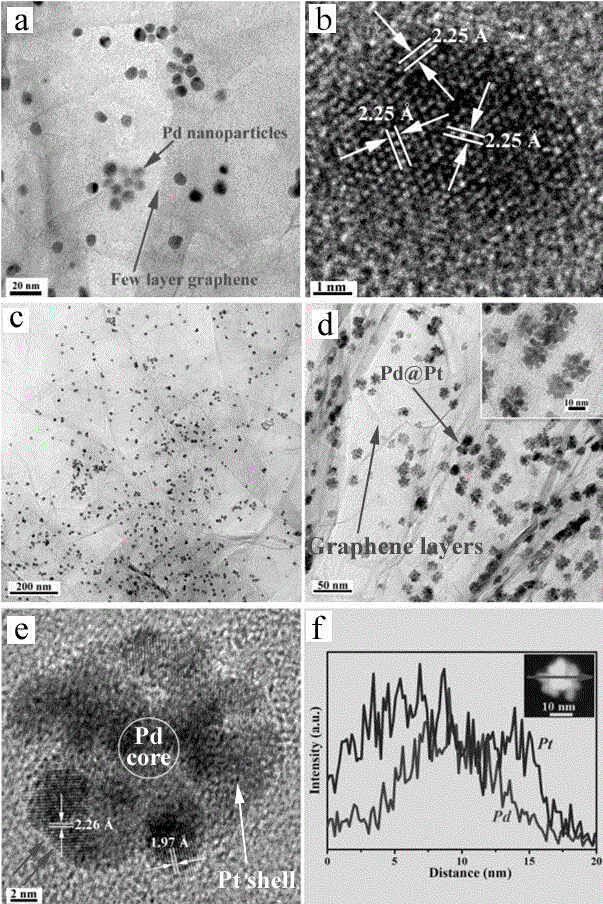

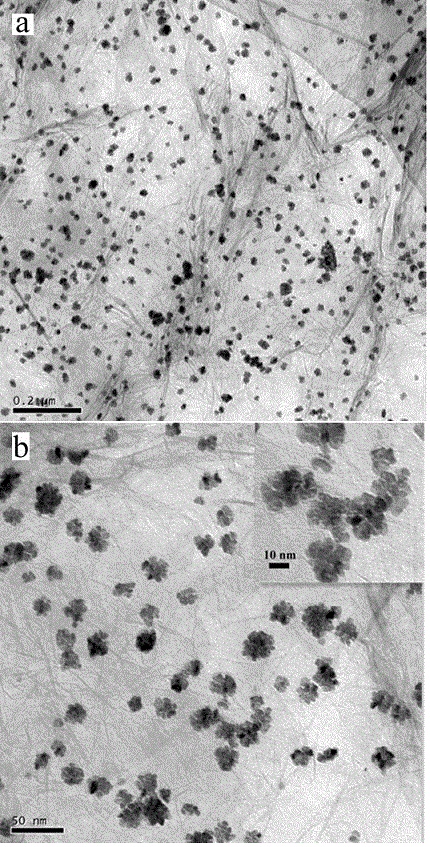

High catalytic activity graphene-Pd @ Pt core-shell structure nanoflower compound and preparation method thereof

InactiveCN104959137AImprove utilization efficiencyReduce usageMaterial nanotechnologyCell electrodesPtru catalystActive agent

The present invention relates to a high catalytic activity graphene-Pd @ Pt core-shell structure nanoflower compound and a preparation method thereof. First, at room temperature, ascorbic acid is used for reducing an aqueous solution of graphene oxide and palladium chloride to obtain palladium nanoparticles with regular morphology and assemble the palladium nanoparticles in situ onto the chemically-reduced graphene, then the resulting graphene-palladium is used as a seed crystal, seed growth method is used, chloroplatinic acid is added into the reaction solution, and the microwave-assisted rapid reduction of the chloroplatinic acid is perforemed to obtain graphene supported Pd @ Pt core-shell structure nanoflower. The electrochemical data shows that under alkaline conditions, the catalytic oxidation activity of the graphene-Pd @ Pt core-shell structure nanoflower compound is much higher than that of a graphene-platinum-palladium alloy compound, and the graphene-platinum compound and a commercial platinum carbon catalyst show great potential as fuel cell electrode material. The preparation process is simple, materials are non-toxic and harmless, and Pd @ Pt core-shell structure nanoparticles monodispersed on the graphene can be obtained without adding of any additional surfactant.

Owner:HUBEI UNIV

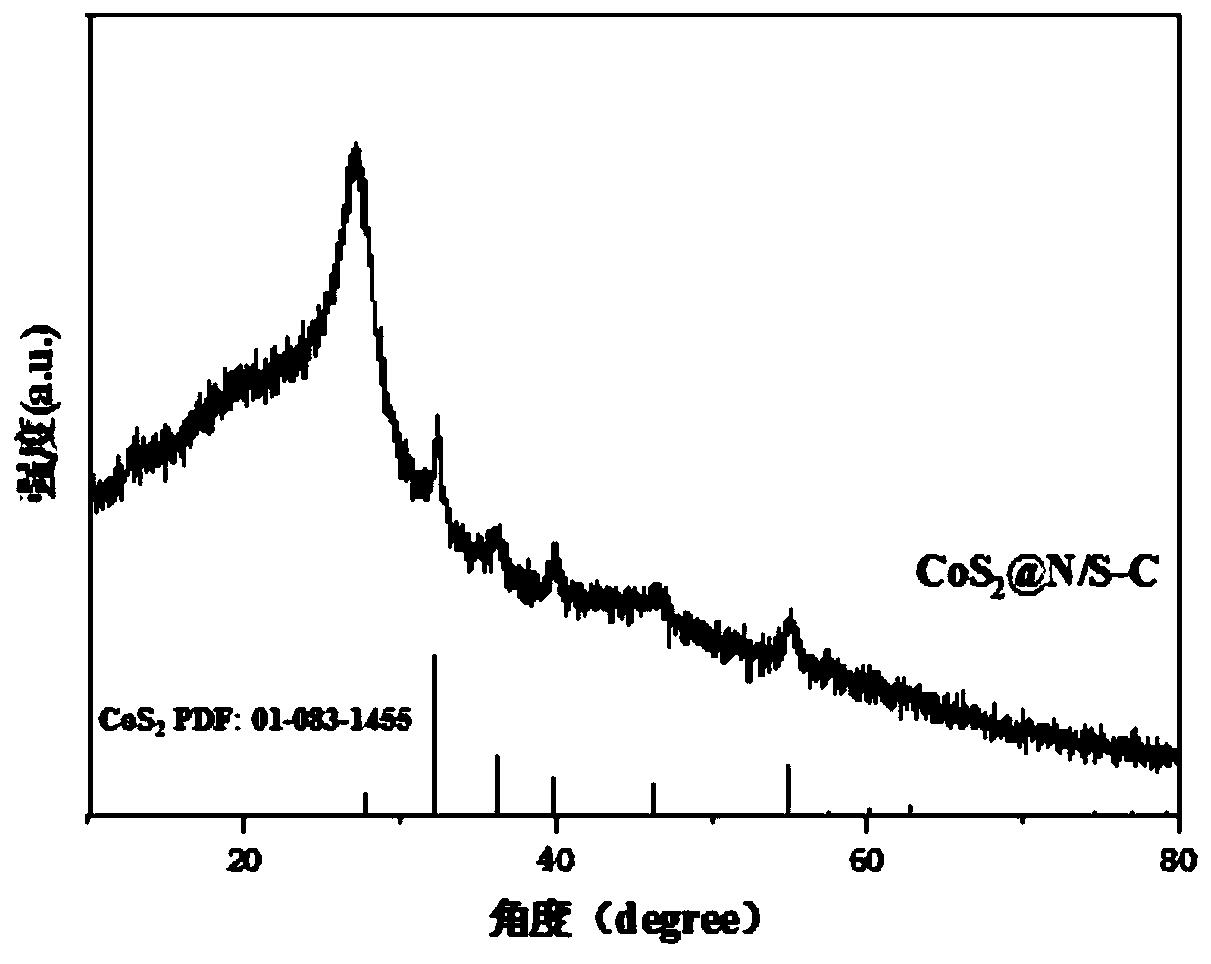

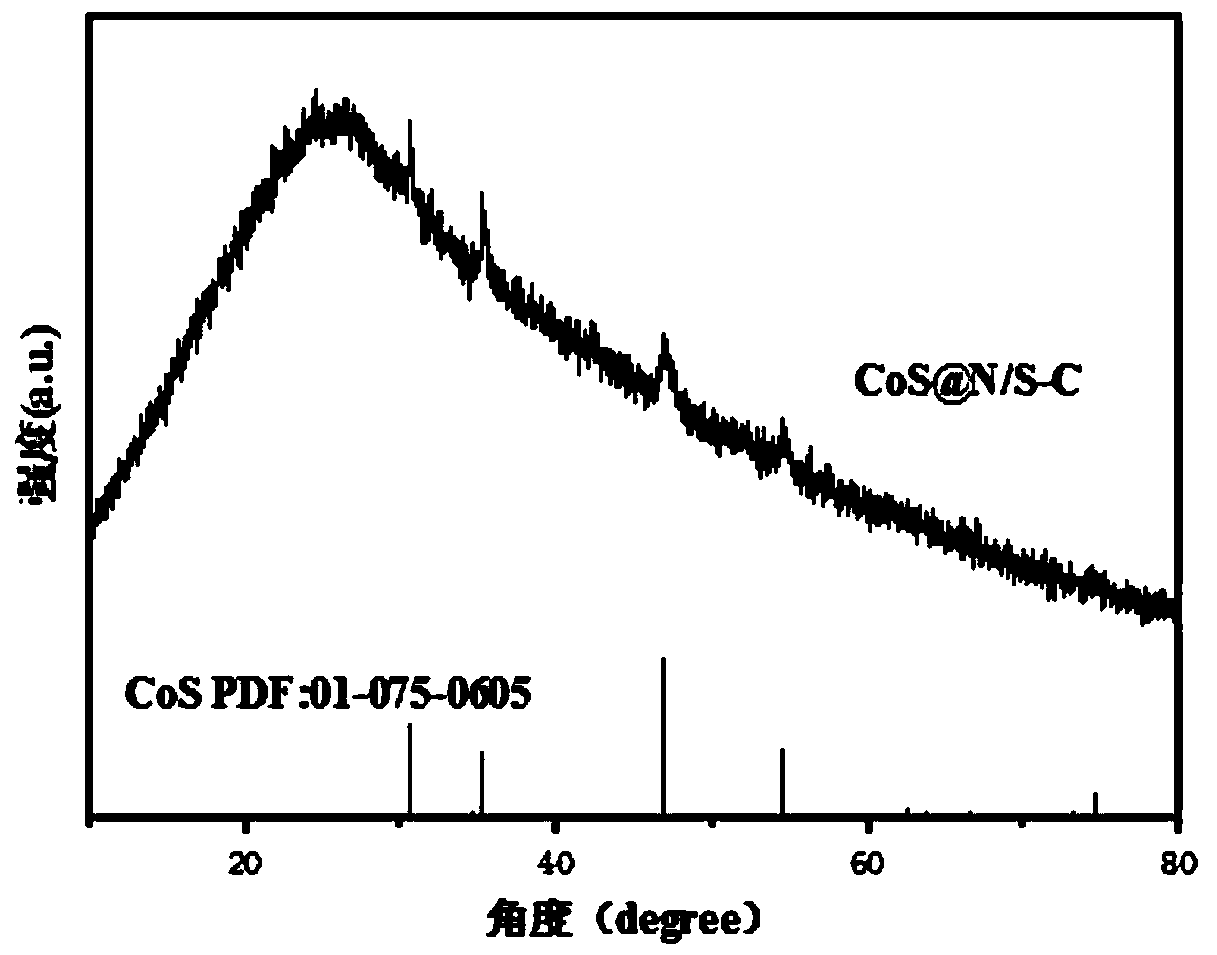

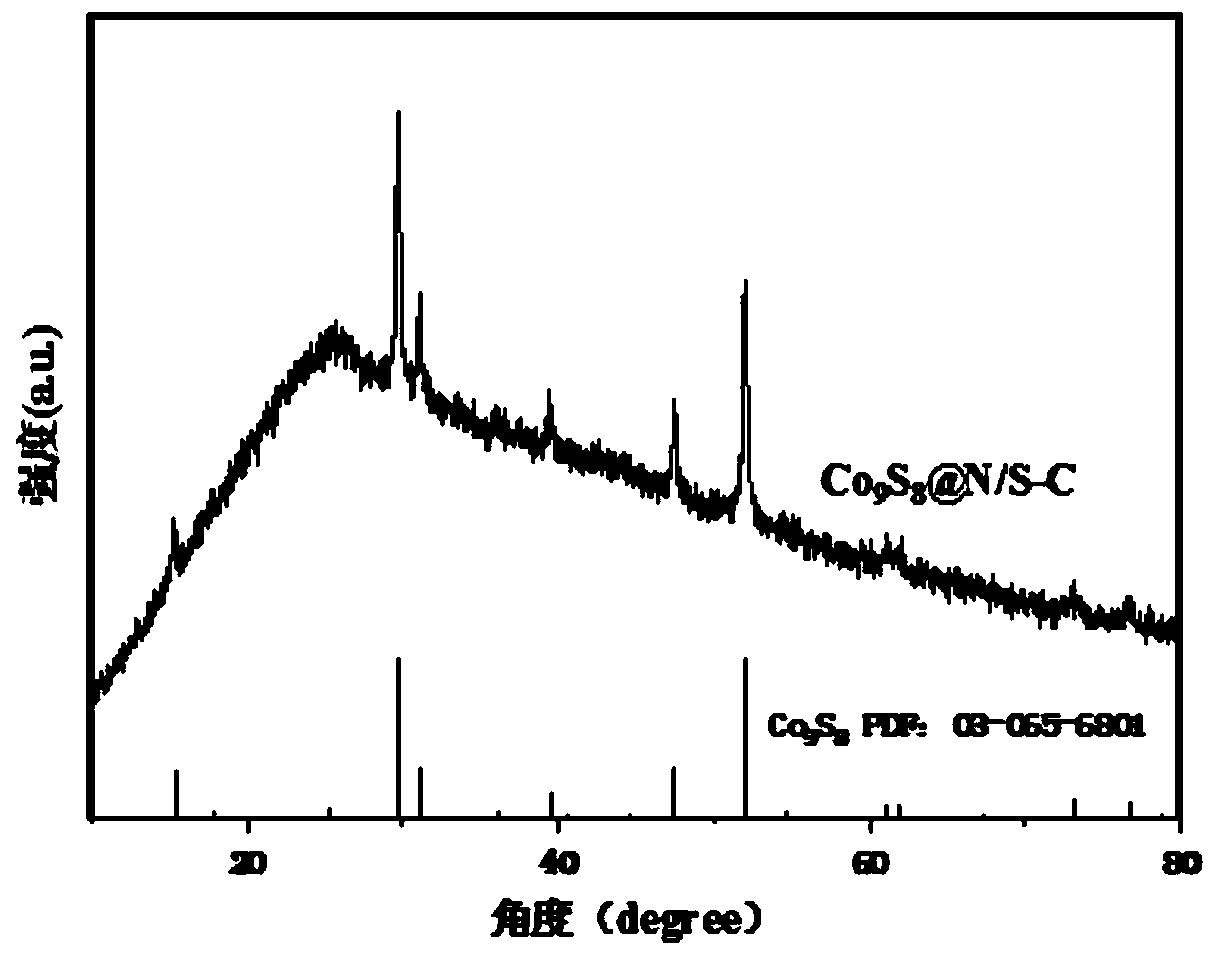

Cobalt-sulfur compound/nitrogen-sulfur-doped carbon composite catalyst and preparation method thereof

The invention belongs to the field of electrocatalysis materials, and particularly discloses a cobalt-sulfur compound / nitrogen-sulfur-doped carbon composite catalyst and a preparation method thereof.According to the invention, cobalt salt, thiourea and an organic carbon source are used as main raw materials, and heat treatment is carried out in an inert atmosphere by adopting a one-step solid-phase reaction method to obtain the cobalt-sulfur compound / nitrogen-sulfur-doped carbon catalyst material; the obtained cobalt-sulfur compound / nitrogen-sulfur-doped carbon composite catalyst material isstable in structure and high in electrical conductivity, and can show excellent catalytic performance and high stability; and the preparation method is simple, mild in the reaction conditions and environment-friendly, and the composition of the product is controllable, so that the method is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

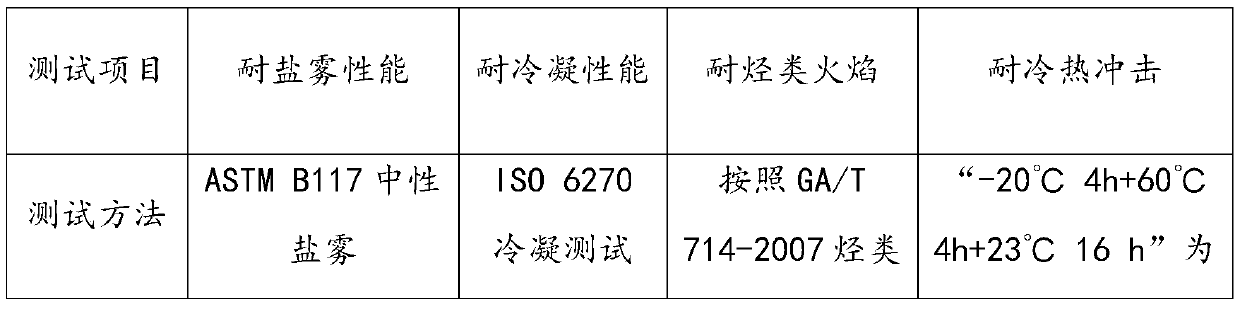

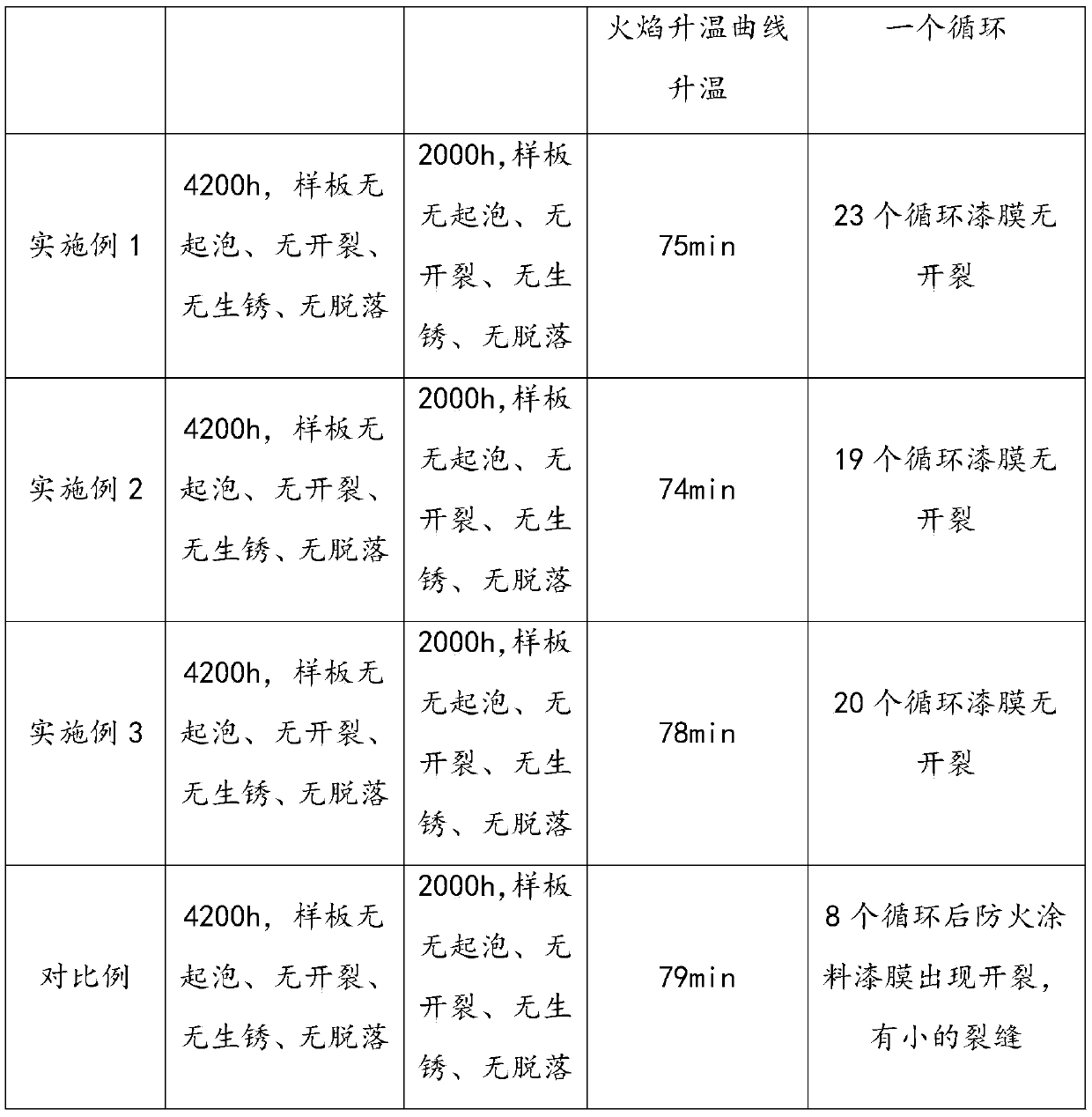

Flexible solvent-free epoxy fireproof paint and preparation method thereof

ActiveCN110903738AStrong adhesionStrong cohesionFireproof paintsAnti-corrosive paintsFiberPolymer science

The invention relates to the technical field of fireproof paint, in particular to a flexible solvent-free epoxy fireproof paint and a preparation method thereof. The flexible solvent-free epoxy fireproof paint provided by the invention comprises a component A and a component B, wherein the component A is composed of the following components by weight: 20-25 parts of epoxy resin, 5-10 parts of modified resin, 5-10 parts of a flame retardant, 15-25 parts of a carbon-forming catalyst, 10-15 parts of a foaming agent A, 8-15 parts of a pigment A, 10-15 parts of refractory filler A, 2-4 parts of anassistant A and 2-5 parts of refractory fiber A, wherein the epoxy resin is bisphenol A type liquid epoxy resin; and the component B is composed of the following components by weight: 50-60 parts of acuring agent, 2-4 parts of a curing agent accelerant, 10-15 parts of a foaming agent B, 10-15 parts of refractory filler B, 10-15 parts of a pigment B, 3-4 parts of an assistant B and 2-5 parts of refractory fiber B.

Owner:CHINA NAT OFFSHORE OIL CORP +3

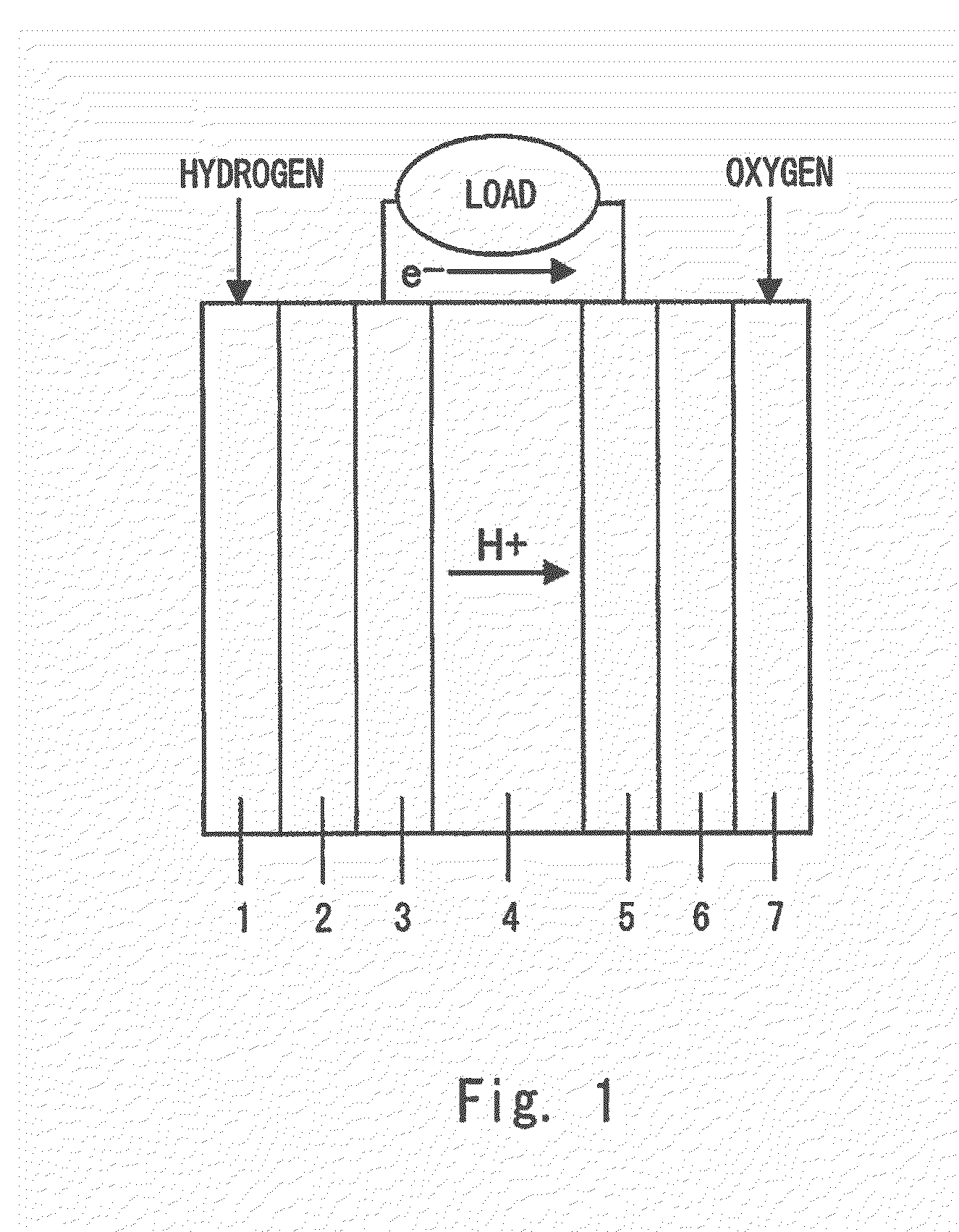

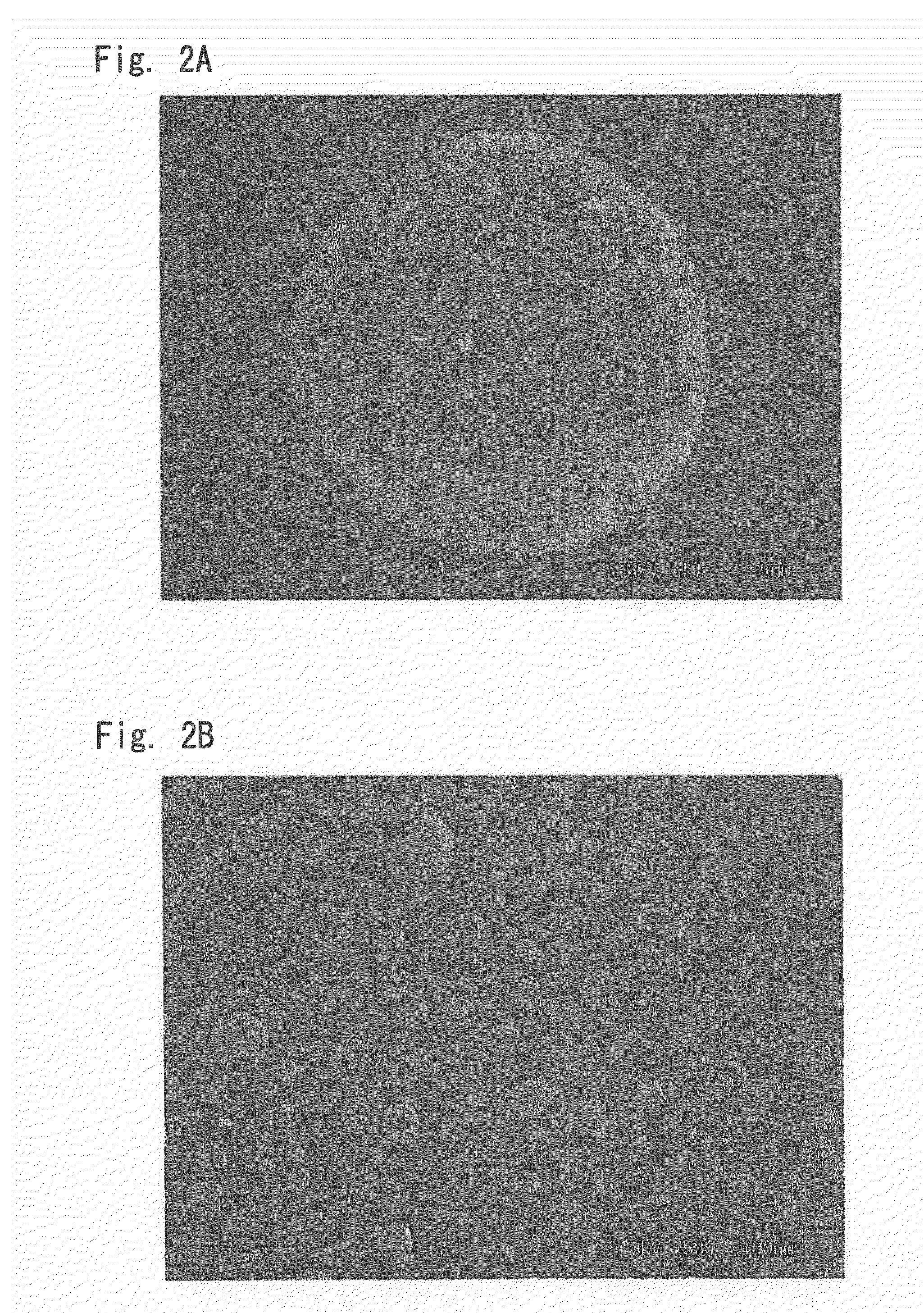

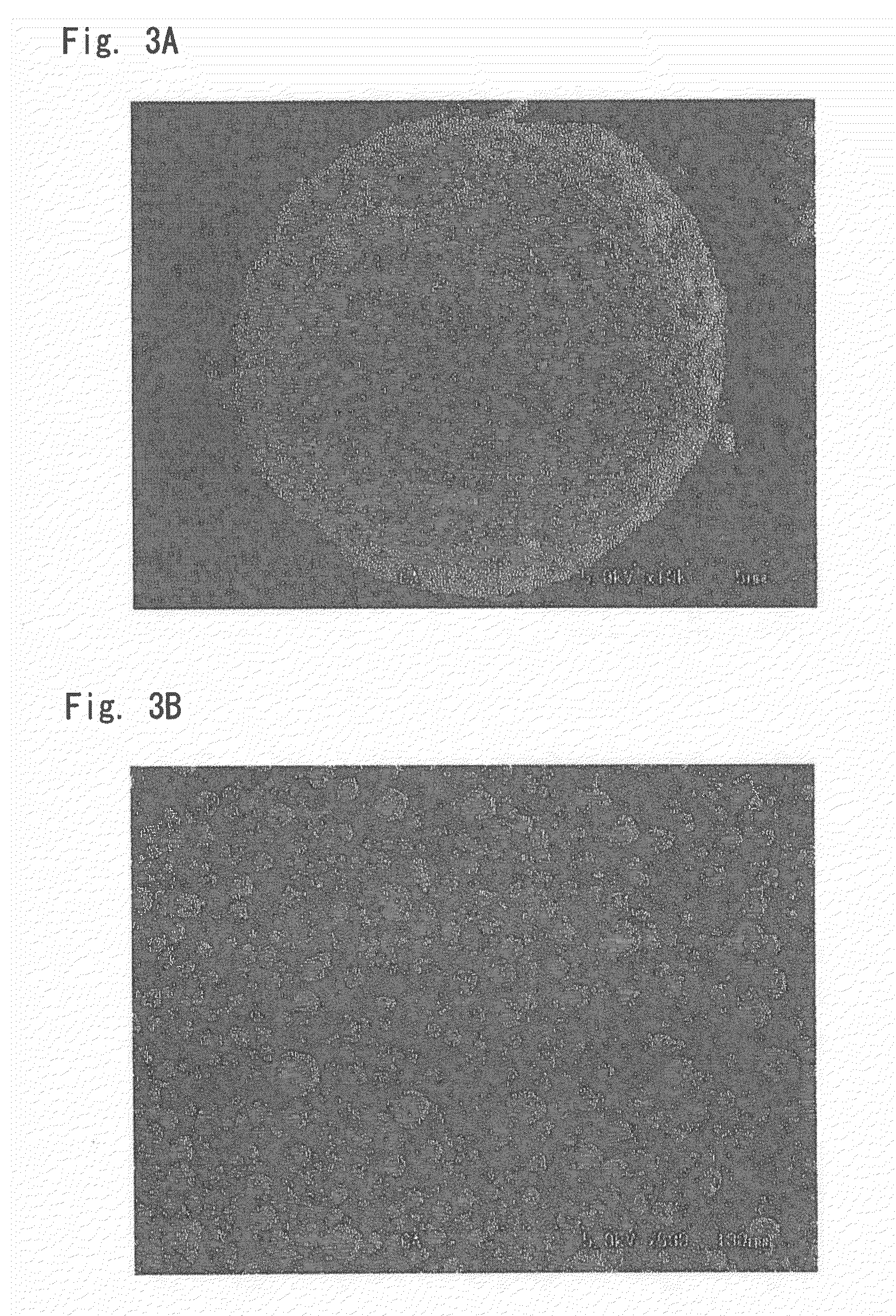

Cell catalyst composition andmanufacturing method thereof, electrode material, and fuel cell

InactiveUS20150214554A1Reduce production efficiencyReduce power generation efficiencyOrganic-compounds/hydrides/coordination-complexes catalystsActive material electrodesPtru catalystFuel cells

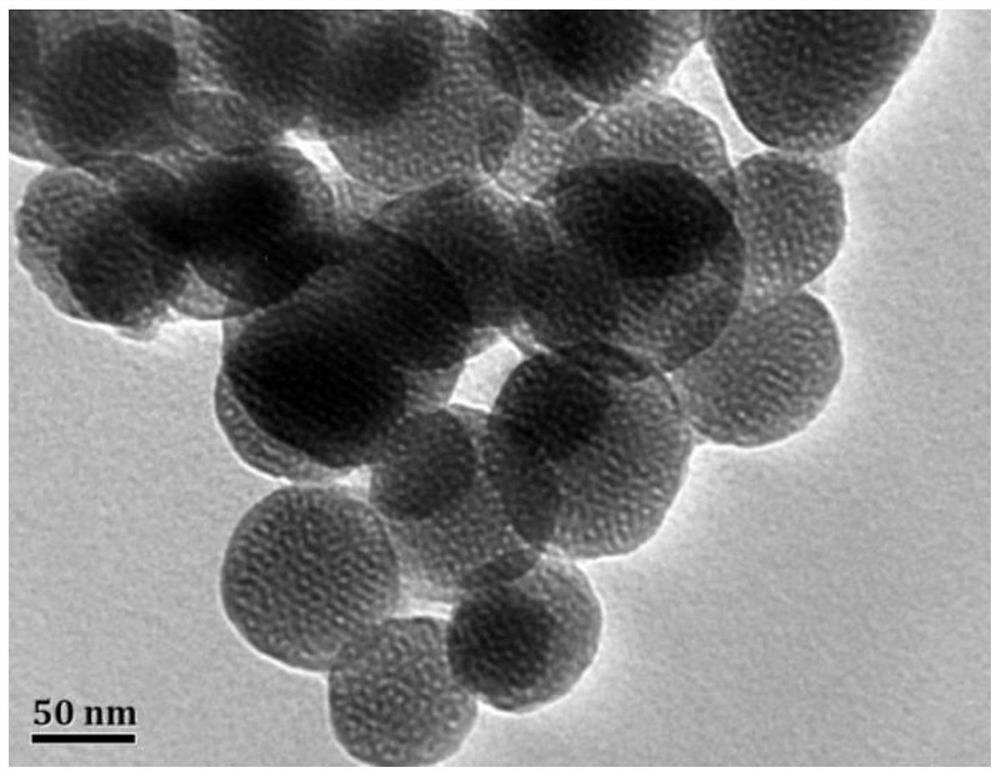

A cell catalyst composition according to the present invention includes a carbon catalyst granule and a binder resin, and at least a part of the binder resin includes a resin (B) including a hydrophilic functional group. The carbon catalyst granule is (i) a carbon catalyst granule wherein carbon catalyst (A) particles are bound to each other by using at least the resin (B), or / and (ii) a carbon catalyst granule wherein carbon catalyst (A) particles form a sintered body and are thereby bound to each other. The carbon catalyst (A) includes a carbon element, a nitrogen element, and a base metal element as constituent elements. Further, an average particle diameter of the carbon catalyst granule is 0.5 to 100 μm, and a sphericity of the carbon catalyst granule is equal to or greater than 0.5.

Owner:TOYO INK SC HOLD CO LTD

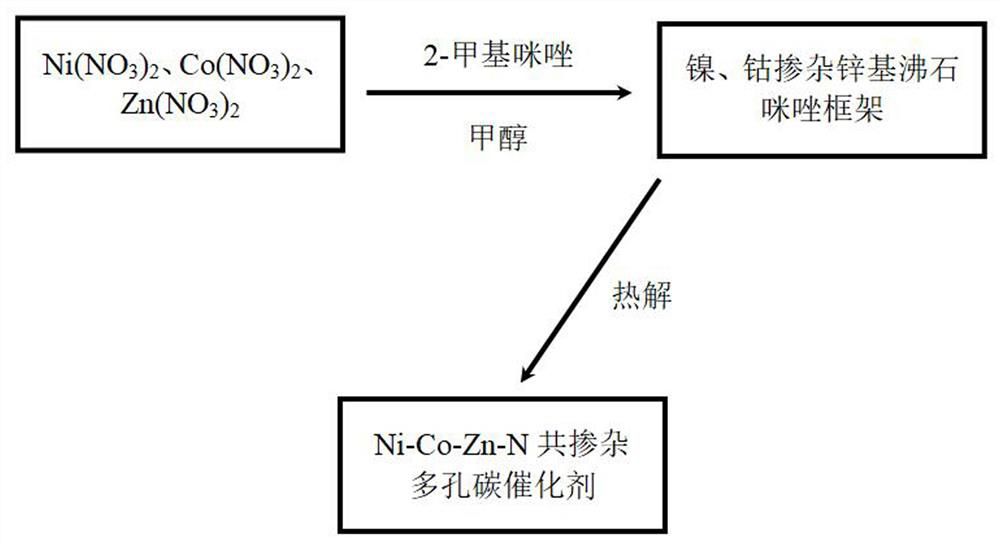

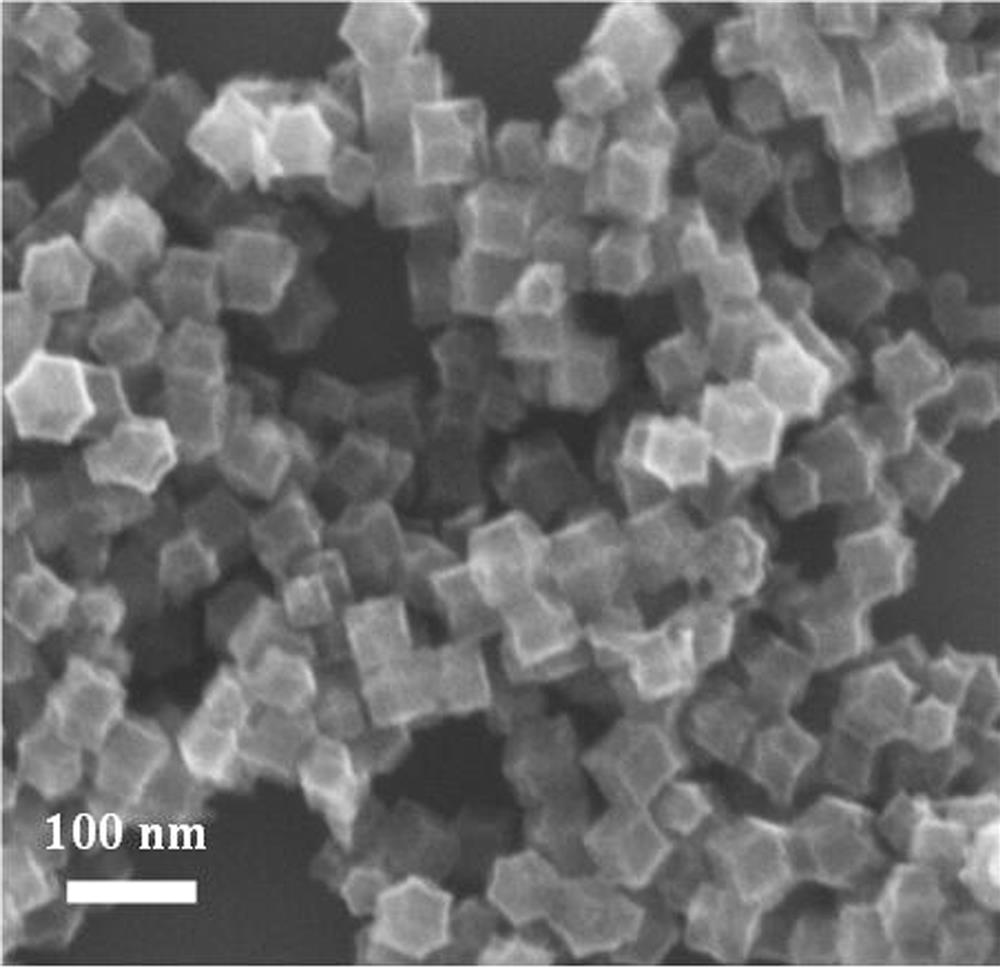

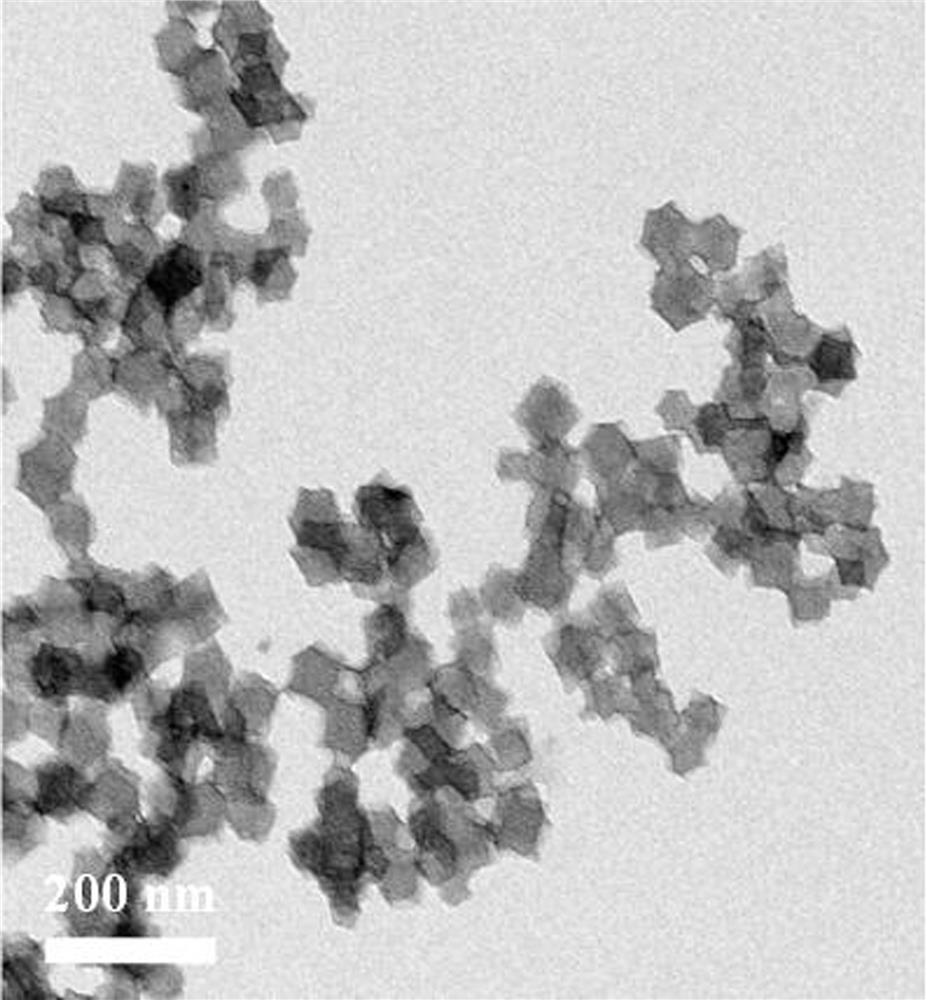

Trimetal-based Ni-Co-Zn-N co-doped porous carbon catalyst as well as preparation method and application thereof

The invention discloses a trimetal-based Ni-Co-Zn-N co-doped porous carbon catalyst as well as a preparation method and application thereof. According to the method, nickel nitrate, cobalt nitrate andzinc nitrate are used as transition metal sources and coordinated with 2-methylimidazole to synthesize a nickel-and-cobalt-doped zinc-based zeolite imidazole framework (Ni-Co-ZIF-8) precursor, and then the trimetal-based Ni-Co-Zn-N co-doped porous carbon catalyst can be prepared through pyrolysis. The method is simple in technological process, rich in raw material source and low in cost, and theprepared catalyst shows oxygen reduction reaction activity comparable to commercial Pt / C and better electrochemical stability and methanol resistance, and has a good application prospect in cathode oxygen reduction reaction of fuel cells and metal-air cells.

Owner:GUANGXI NORMAL UNIV

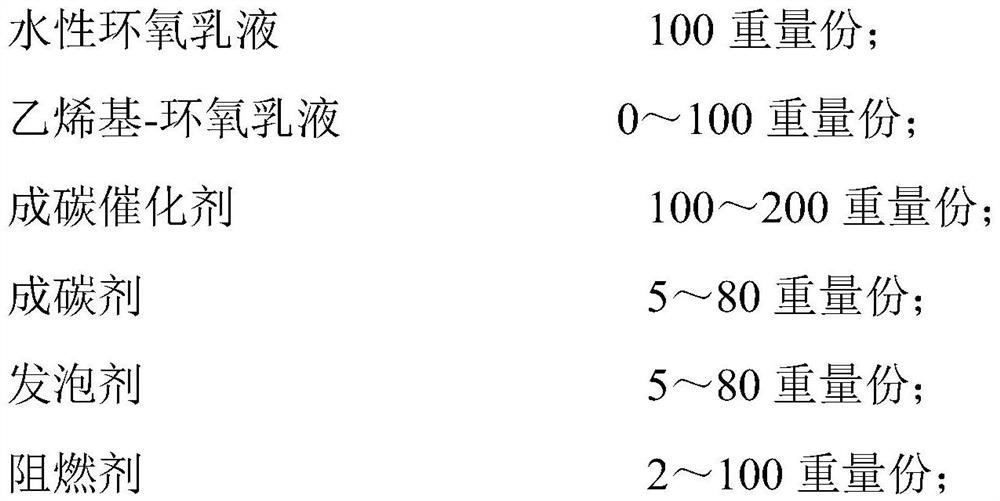

Waterborne epoxy fireproof coating as well as preparation method and application thereof

ActiveCN113444425ANo pollution in the processEasy to operateFireproof paintsAnti-corrosive paintsFiberPolymer science

The invention discloses a waterborne epoxy fireproof coating as well as a preparation method and application thereof. The waterborne epoxy fireproof coating is composed of a component A and a component B. The component A comprises a waterborne epoxy emulsion, a vinyl-epoxy emulsion, a carbon forming catalyst, a carbon forming agent, a foaming agent and a flame retardant; and the component B comprises a curing agent and refractory fibers. The water-based epoxy fireproof coating disclosed by the invention has the same excellent sealing performance as a solvent-free epoxy fireproof coating and a high-solid-content epoxy fireproof coating, has excellent corrosion resistance, UV irradiation resistance, water resistance and organic solvent resistance, and can be used in a severe outdoor environment. According to the fireproof coating, self-made emulsions are preferably selected, the structure of a film forming matter is optimized and adjusted, and fireproof efficiency is high. Meanwhile, water is selected as a diluent, so coating problems of an original epoxy fireproof coating are fundamentally solved, a water-based system is more environmentally friendly, and the coating belongs to a new-generation fireproof coating technology.

Owner:MARINE CHEM RES INST

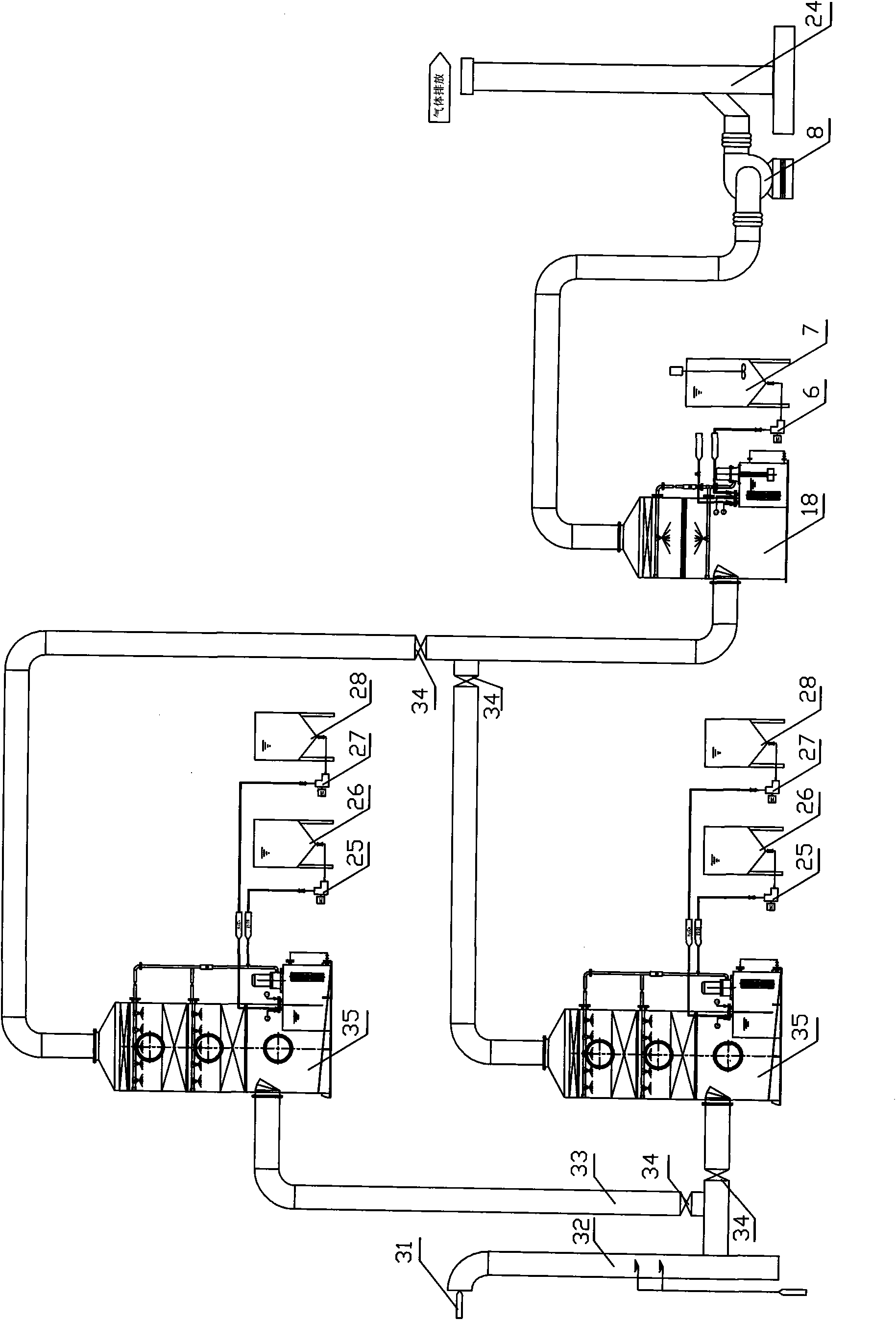

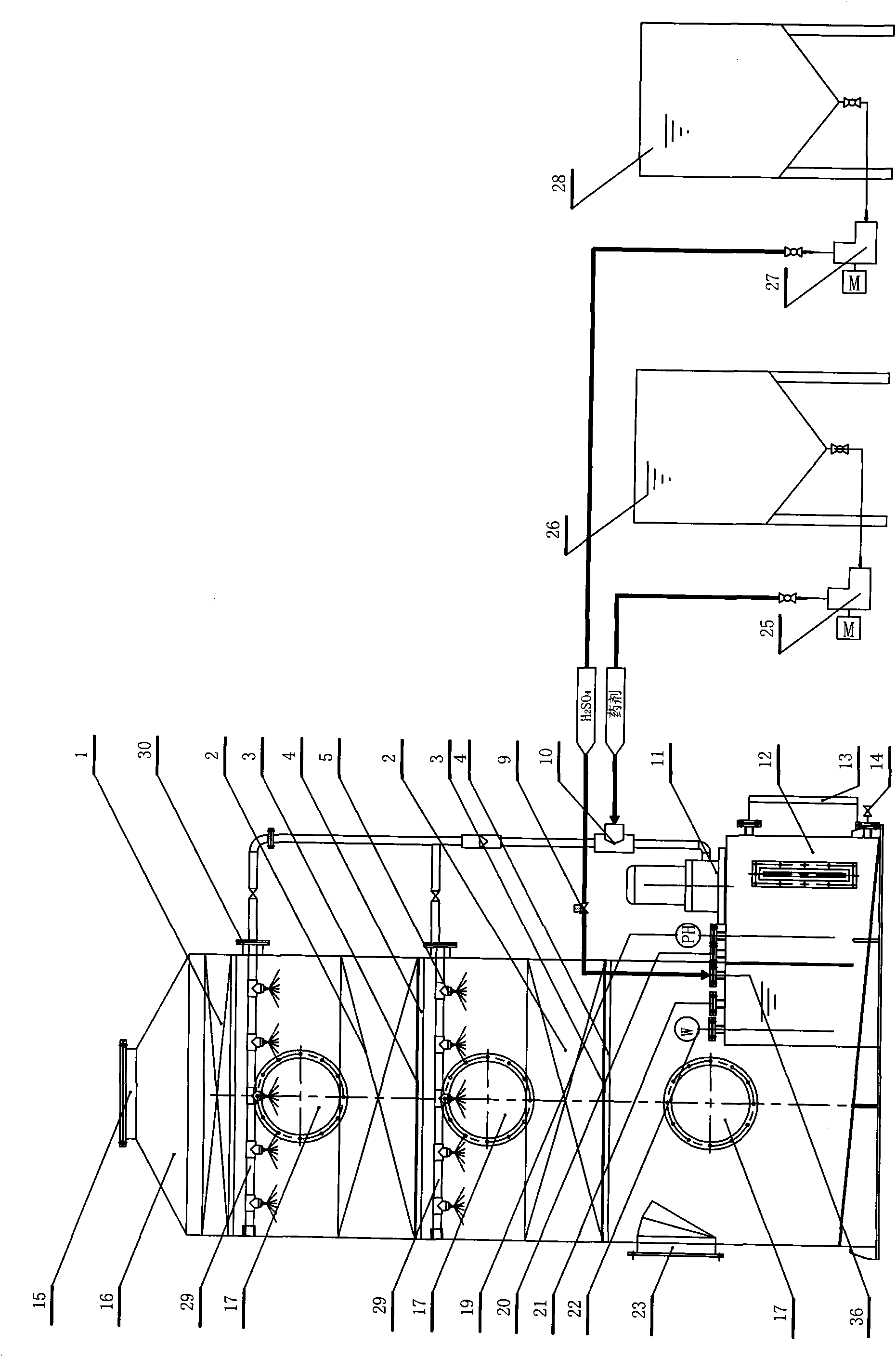

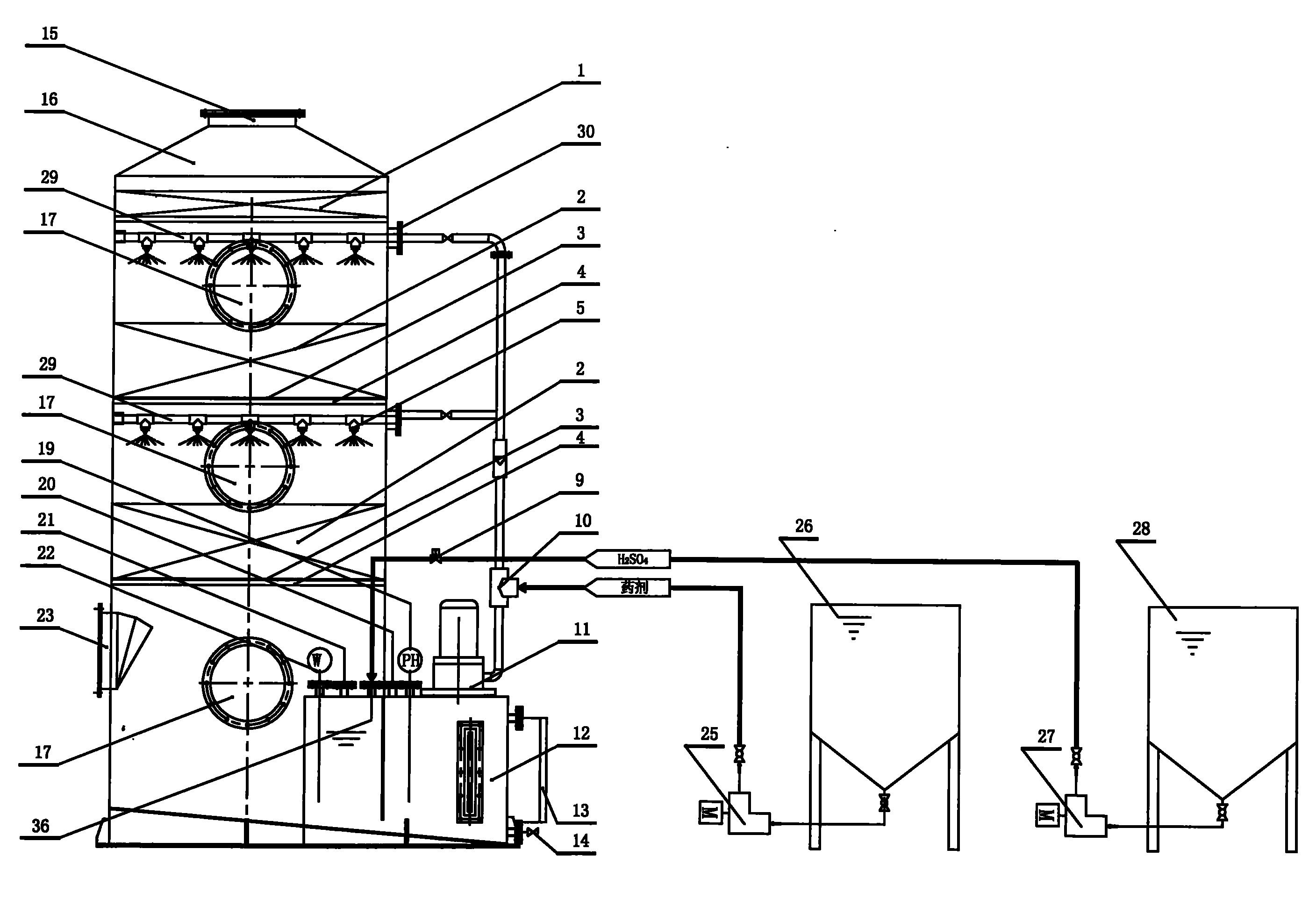

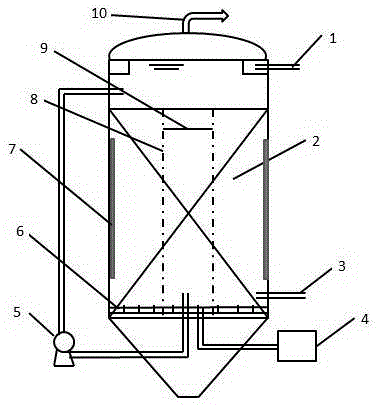

Method for treating obnoxious gas by active bamboo charcoal-H2O2 composite catalytic oxidation

InactiveCN102059048AExtended stayExtended reaction timePhysical/chemical process catalystsOther chemical processesCatalytic oxidationProduct gas

The invention relates to the technology of obnoxious gas treatment, and discloses a method for treating obnoxious gas by active bamboo charcoal-H2O2 composite catalytic oxidation. The method comprises the following steps of: adsorbing the obnoxious gas through a composite bamboo charcoal catalyst to remove obnoxious substance molecules, spraying aqueous solution of hydrogen peroxide to the composite bamboo charcoal catalyst to decompose the adsorbed obnoxious substance molecules and achieve recycle of the composite bamboo charcoal catalyst, performing water-gas separation by using a demister,introducing the gas into spraying alkali solution in an alkali spraying tower to neutralize acid substances in the gas, and discharging the neutralized gas. The obnoxious gas treatment method has high treatment efficiency, and is particularly suitable for treating high quantity of obnoxious gas.

Owner:SHANGHAI SHUITIAN ENVIRONMENTAL PROTECTION

Oxidation and reduction double-effect micro electrolysis combined reactor and application thereof

InactiveCN105417643AAchieve oxidationAchieve restorationWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment apparatusElectrolysisPhysical chemistry

The invention provides a double-effect micro electrolysis combined reactor which comprises a cylinder body and special iron carbon catalytic packing. The center of the cylinder is provided with a channel baffle, the channel baffle is a cylindrical baffle provided with sieve holes, and the special iron carbon catalytic packing is arranged in a packing area formed between the channel baffle and the cylinder body in a filled mode; the channel baffle is internally provided with a circulating pipe, and the circulating pipe is connected with the upper end of the cylinder body through a pump; the bottom of the packing area is provided with a microporous aeration plate, and the microporous aeration plate is connected with an aeration generator; the bottom end of the cylinder body is provided with a water inlet, and the top of the cylinder body is provided with a water outlet; the water inlet is higher than the bottom of the packing area, and the water outlet is higher than the whole circulating pipe. By means of the oxidation and reduction double-effect micro electrolysis combined reactor, an oxidation and reduction integrated reaction can be achieved.

Owner:NANJING GW ENVIRONMENT ENG

Fire-resistant decorative wall face coating material with dual-core structure

InactiveCN102492348AAdd lessPut an end to smokeFireproof paintsAntifouling/underwater paintsDual coreEngineering

The invention relates to a fire-resistant decorative wall face coating material with a dual-core structure. The fire-resistant decorative wall face coating material is characterized by comprising two parts, i.e. a fire-resistant priming coat and a fire-resistant decorative finishing coat; the fire-resistant priming coat includes an expandable flame retardant and priming coat film-forming substances; and the decorative finishing coat includes finishing coat film-forming substances and an incarbonization catalyst, wherein the finishing coat film-forming substances can be subjected to crosslinking reaction with the priming coat film-forming substances so as to form meshed crosslinked ultra-high molecules. The priming coat and the finishing coat are formed by compounding organic and inorganic materials; and meanwhile, the priming coat and the finishing coat exert synergistic reaction when a fire occurs, and thus, an effect that the priming coat carries out fire resisting and heat insulation and the finishing coat carries out inflame retarding and smoke purifying is achieved.

Owner:精碳伟业(北京)科技有限公司

Production method and application of iron-nitrogen co-doped carbon catalyst used for electrocatalytic reduction of CO2

ActiveCN110538673ARaise the defect levelPhysical/chemical process catalystsElectrodesAnilineMetal salts

The invention discloses a production method and application of a doped carbon catalyst used for electrocatalytic reduction of CO2. The carbon-based catalyst is doped with iron and nitrogen atoms, andcontains intrinsic carbon defects. Production of the doped carbon-based catalyst used for electrocatalytic reduction of the CO2 comprises the following steps: (1) dissolving an iron salt and urea in deionized water under stirring; (2) adding aniline into a metal salt solution, and conducting stirring for 1 h; (3) adding ammonium persulfate, and then conducting stirring for 0.5 h; (4) transferringan obtained mixed solution into a hydrothermal reactor, and carrying out a reaction; (5) conducting centrifugation on obtained suspension, cleaning the suspension subjected to centrifugation until thesuspension is neutral, and conducting drying to obtain a FeOOH / PANI precursor; and (6) calcining the obtained precursor in an inert gas atmosphere, then conducting acid pickling, and conducting calcining again to obtain the carbon-based catalyst. The production method is low in cost, simple and easy to control, and the catalyst is high in selectivity and good in catalytic activity in an electrocatalytic reduction process of the CO2.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Metal-nitrogen-carbon catalyst for carbon dioxide electroreduction and preparation method of metal-nitrogen-carbon catalyst

PendingCN111686780AImprove performanceGood dispersionCatalyst activation/preparationElectrodesPtru catalystFaraday efficiency

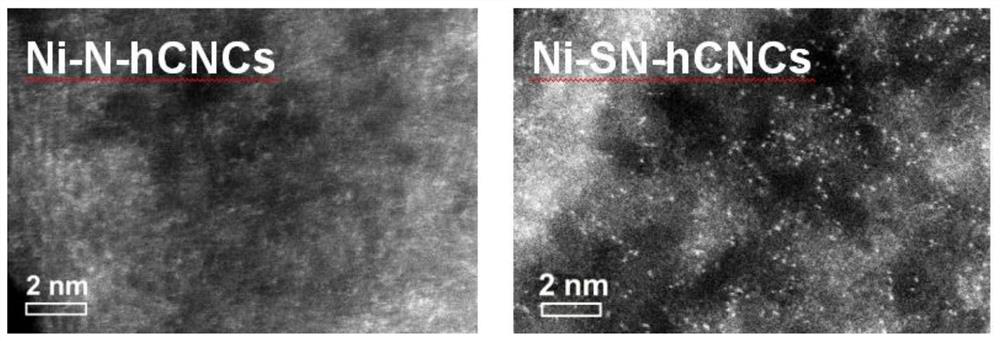

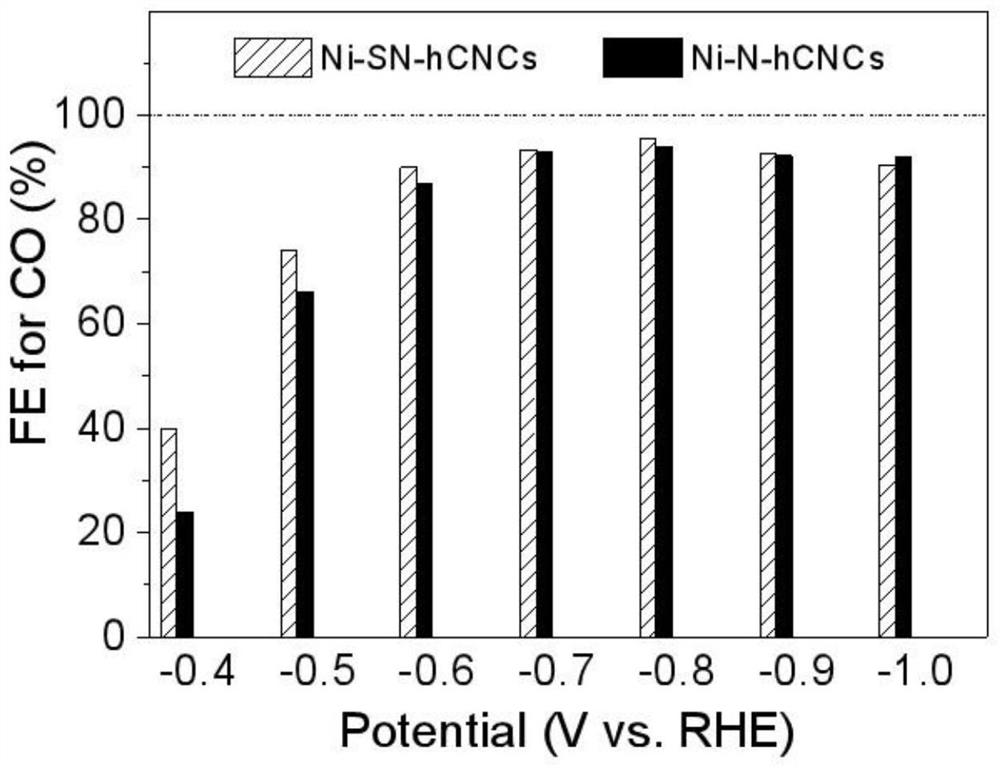

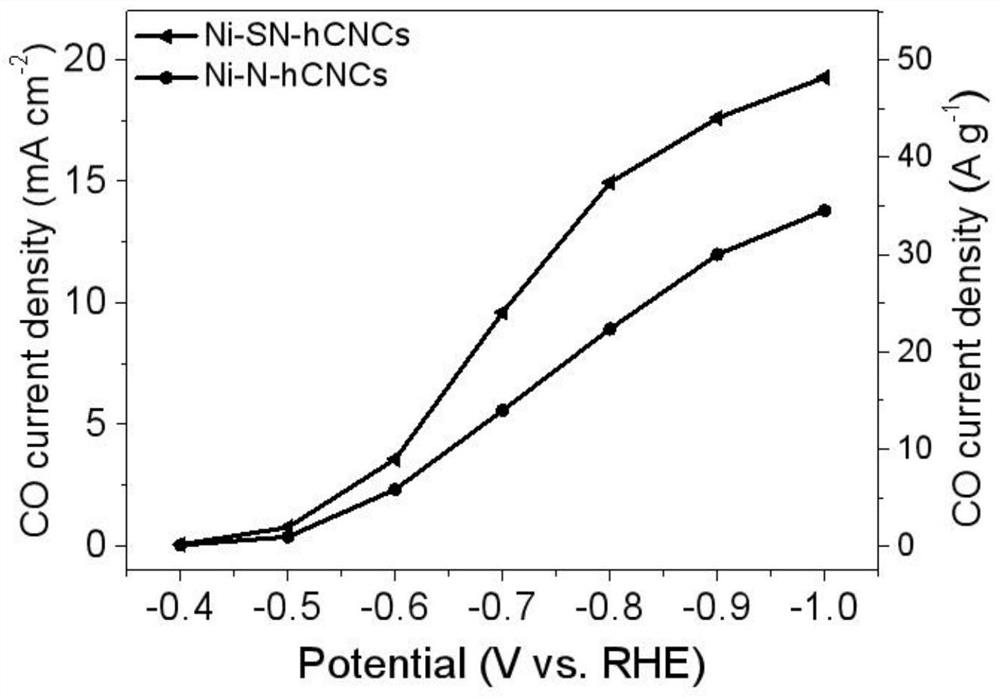

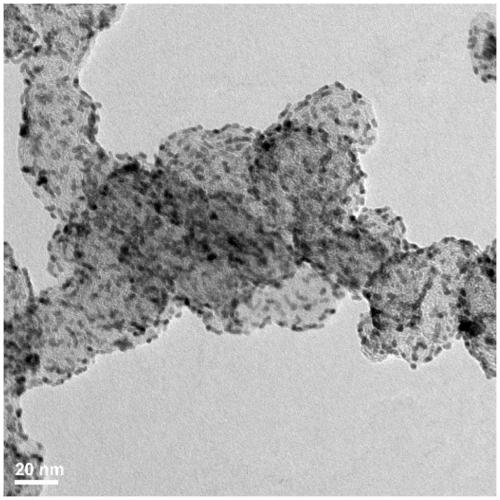

The invention provides a metal-nitrogen-carbon catalyst for carbon dioxide electroreduction. The metal-nitrogen-carbon catalyst comprises a carrier and an active component. Metal-nitrogen-carbon unitpoints are loaded on the surface of carbon-based nanocages, and the dispersity and the loading capacity of the unit points are greatly improved by utilizing the three-dimensional hierarchical structure and the high specific surface area of the nanocages. The nickel-nitrogen-carbon single-site catalyst is used for carbon dioxide electroreduction, and the Faraday efficiency of a carbon monoxide product reaches 87-94% at a wide voltage window of -0.6 V to -1.0 V; through sulfur doping, the specific current density of carbon monoxide is increased from 22.3 Ag<-1> to 37.5 Ag<-1>, and the Faraday efficiency of carbon monoxide reaches 90-95% in the same voltage window.

Owner:NANJING UNIV

Platinum-cobalt alloy catalyst and preparation method thereof

ActiveCN111092235AGood pre-freezing effectReduce energy consumptionFinal product manufactureCell electrodesPtru catalystFreeze-drying

The invention relates to the field of materials and particularly relates to platinum-cobalt alloy catalyst and a preparation method thereof. The preparation method comprises steps of uniformly mixingcobalt salt, platinum-carbon catalyst and volatile solvent, reducing the temperature to -70 DEG C to -20 DEG C within 2 hours for pre-freezing, and then performing vacuum freeze-drying within the range of -50 DEG C to 80 DEG C to obtain a platinum-cobalt precursor; reducing the platinum-cobalt precursor for 1-6 h at the low temperature of 200-400 DEG C and under the reducing atmosphere, and then performing high-temperature heat treatment for 1-3 h at the temperature of 500-900 DEG C and under the reducing atmosphere. The method is advantaged in that the size of platinum particles in the platinum-cobalt alloy catalyst can be well controlled, so the platinum-cobalt alloy particles are uniformly settled on an outer surface of a carbon carrier; when the obtained platinum-cobalt alloy catalystis utilized for a film electrode, the high power density of the film electrode can be realized, the use amount of platinum in the film electrode is greatly reduced, and cost of the film electrode is effectively reduced.

Owner:SUZHOU HYDROGINE POWER TECH CO LTD

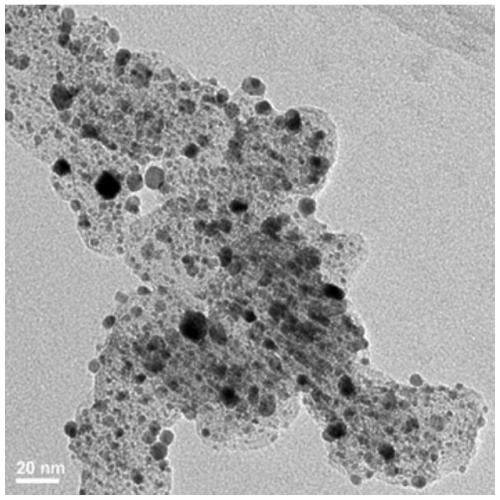

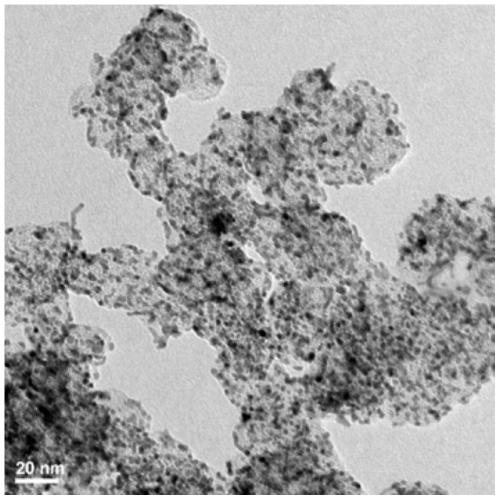

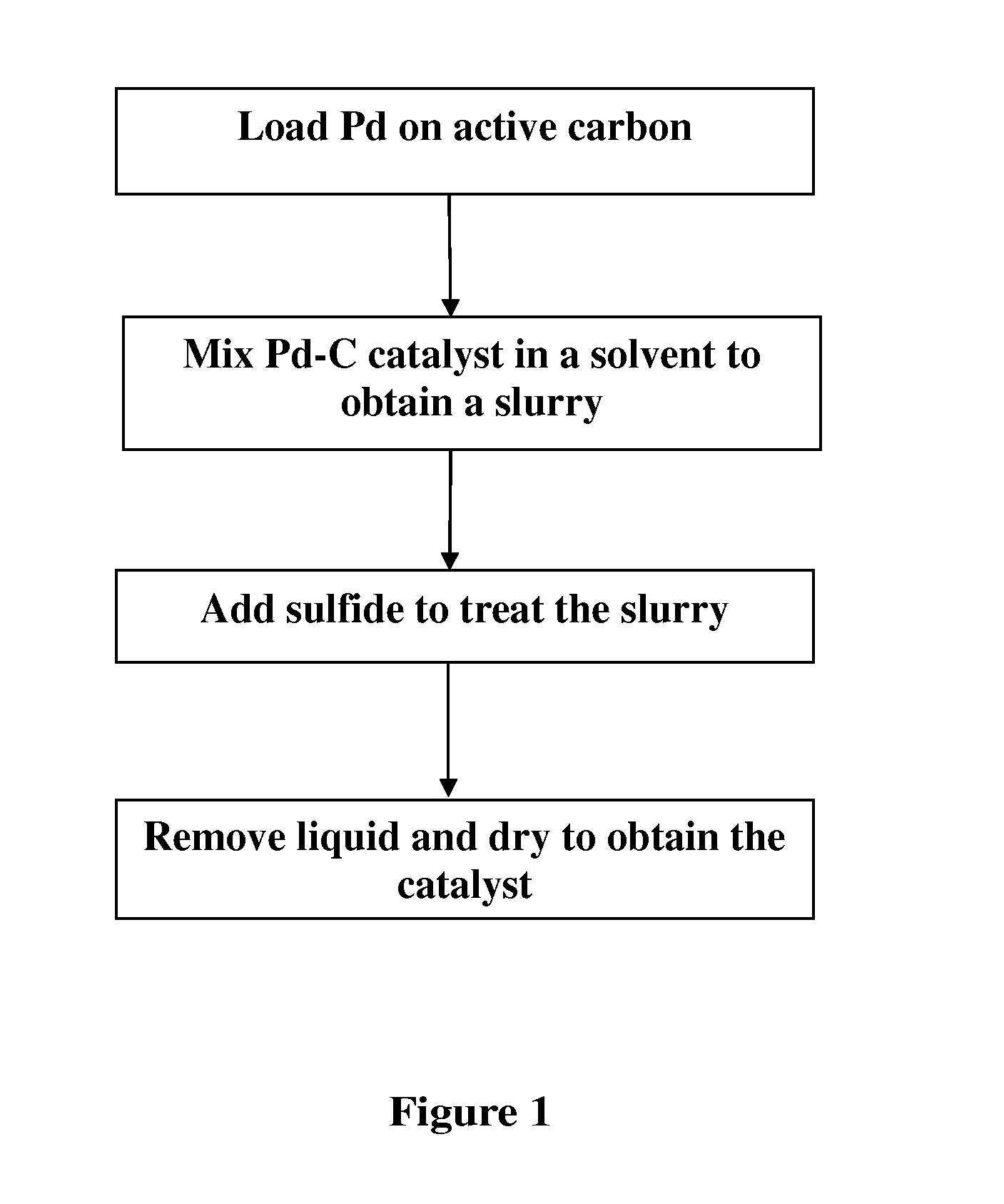

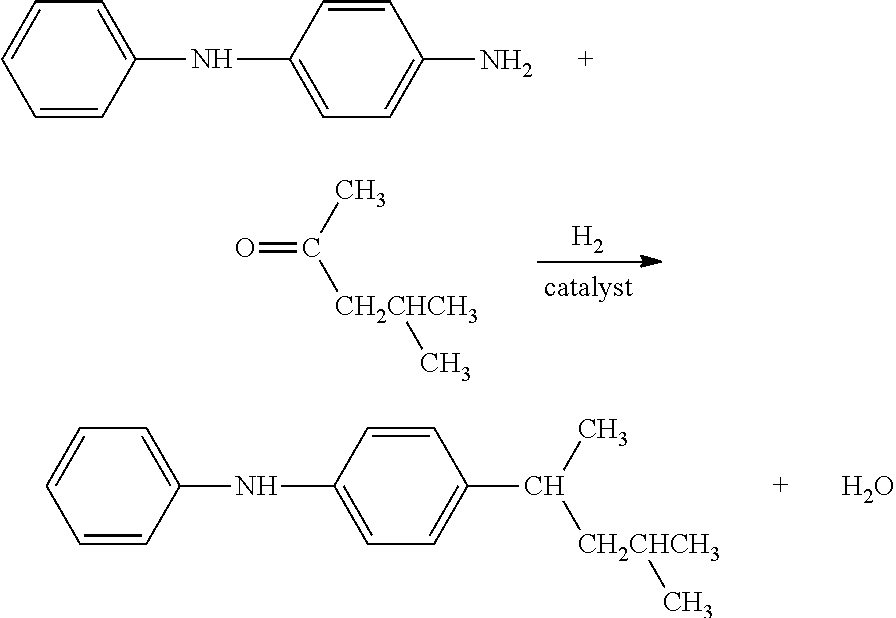

Sulfur-containing palladium-carbon catalyst and method for preparing and using the same

ActiveUS20130079559A1High activityImprove reusabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsProduction ratePolymer science

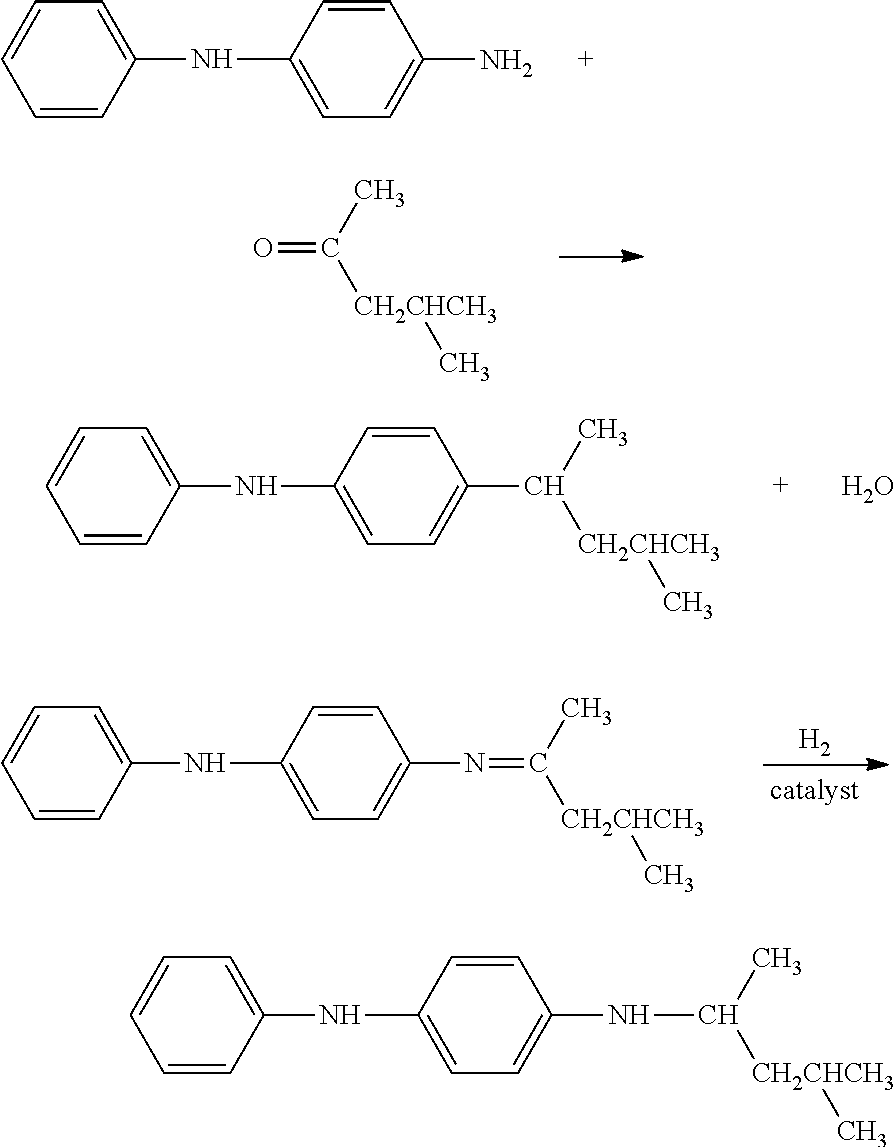

A sulfur-containing palladium-carbon catalyst prepared by loading palladium on an active carbon, mixing the palladium-carbon catalyst with a solvent to form a slurry, adding a sulfide to the slurry to treat the loaded palladium under a predetermined temperature, and removing liquid and drying to obtain the catalyst. The sulfur-containing palladium-carbon catalyst is suitable for making phenylene diamine rubber antioxidant with improved productivity and selectivity.

Owner:SENNICS CO LTD

Carbon catalyst for hydrogen production, method for producing catalyst, and method for producing hydrogen using catalyst

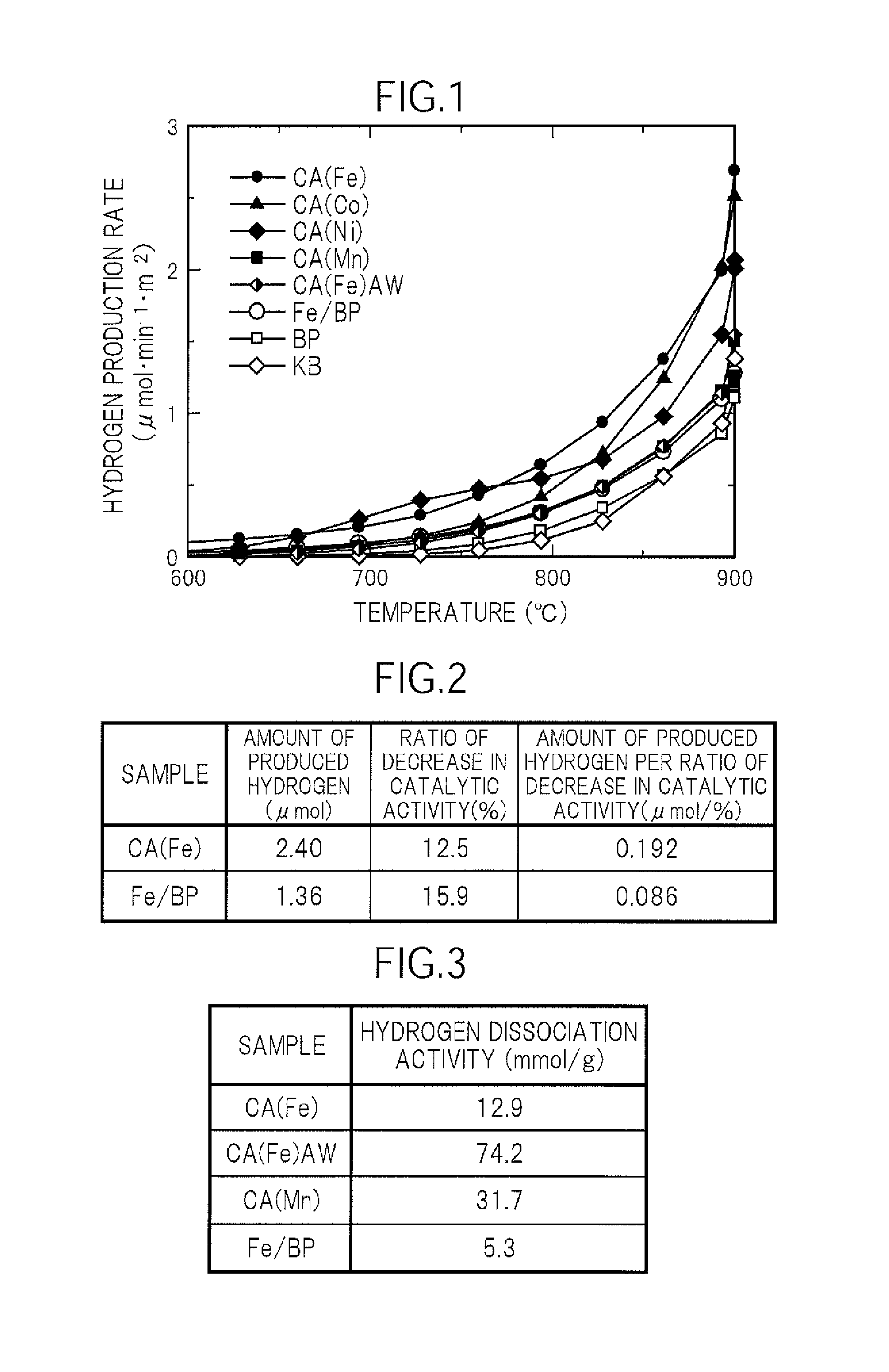

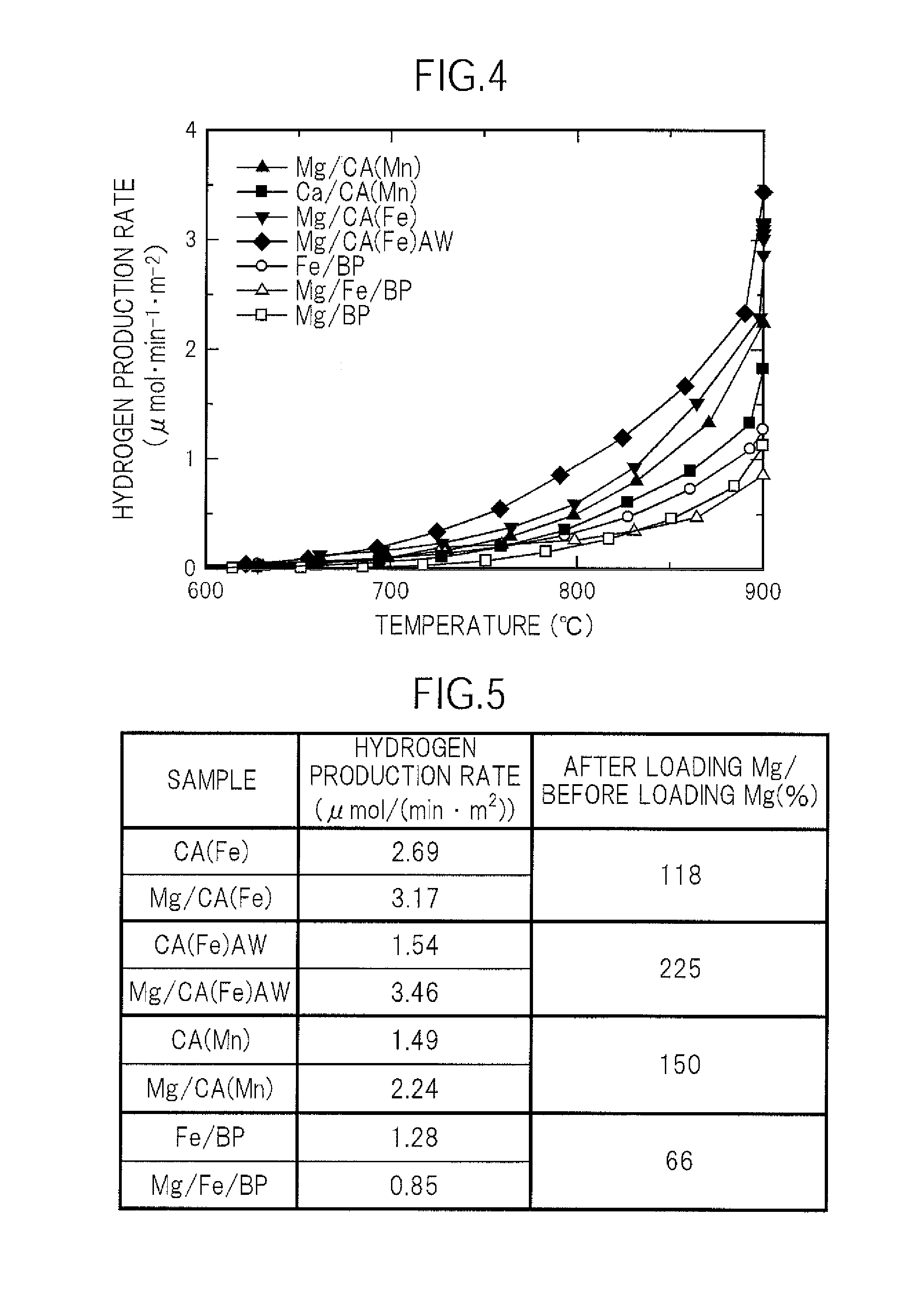

ActiveUS20130243687A1Excellent catalytic activityHigh catalytic activityHydrogenCatalyst activation/preparationHydrogen productionOrganic compound

Provided are a carbon catalyst for hydrogen production having an excellent catalytic activity, a production method therefor, and a method of producing hydrogen using the catalyst. The carbon catalyst for hydrogen production is a carbon catalyst, which is obtained by carbonizing a raw material including an organic substance and a transition metal, the catalyst being used for hydrogen production by thermal decomposition of a hydrocarbon compound and / or an oxygen-containing organic compound. Further, the carbon catalyst for hydrogen production may be obtained by loading an alkaline earth metal on a carbonized material produced by the carbonization.

Owner:GUNMA UNIVERSITY +1

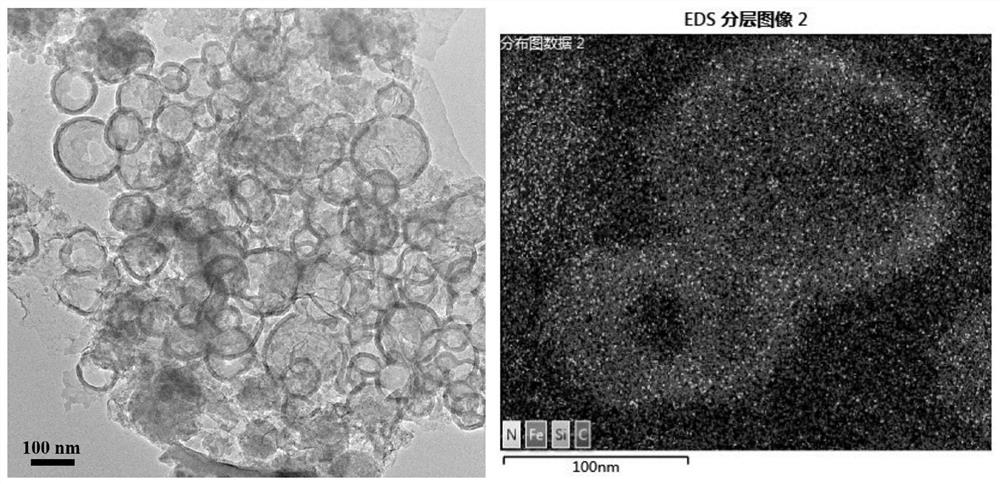

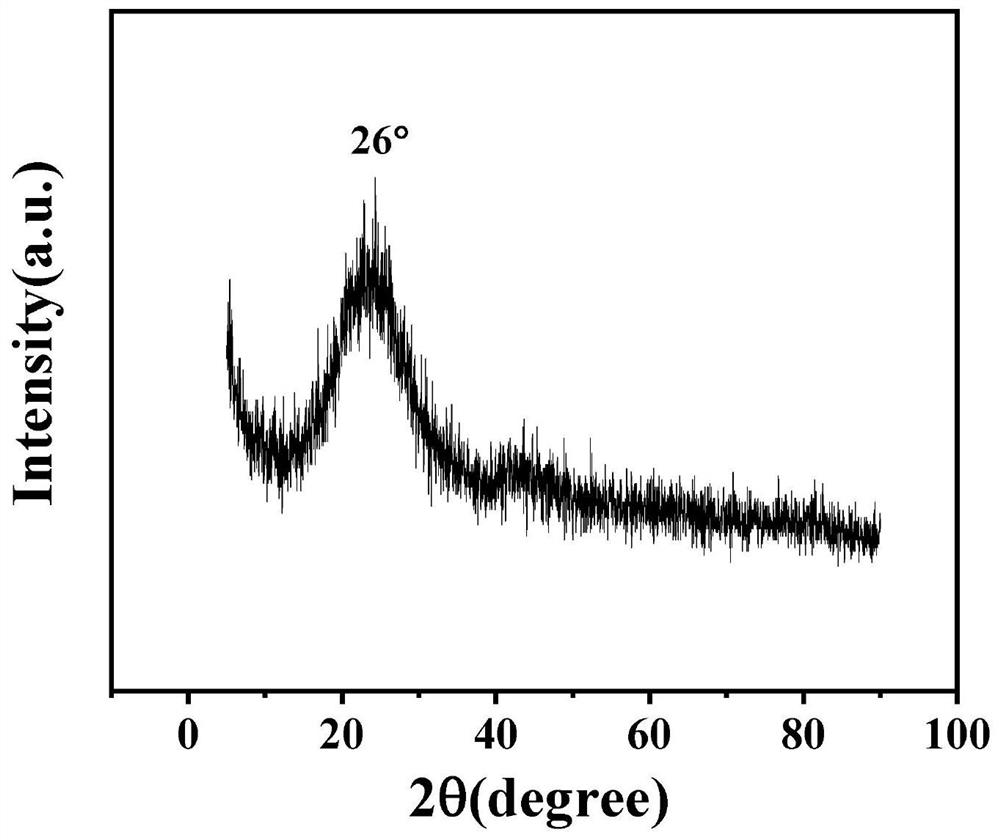

Silicon-doped iron-nitrogen/carbon composite catalyst as well as preparation method and application thereof

ActiveCN111864219ALow priceChemically stableMaterial nanotechnologyCell electrodesCarbon compositesPtru catalyst

The invention discloses a silicon-doped iron-nitrogen / carbon composite catalyst as well as a preparation method and application thereof. Mesoporous silicon dioxide spheres are adopted as a template, different types of iron precursors and pyrrole are adopted as raw materials, gas-phase polymerization is performed in pyrrole steam to obtain a Fe / mSiO2@PPY composite material, and then high-temperature roasting hydrofluoric acid treatment is performed to obtain Si-doped iron nitrogen / carbon (Si-FeNx / C). According to the invention, Si-doped iron nitrogen / carbon is used as a cathode material of thefuel cell, and the oxygen reduction catalyst with excellent performance is constructed. The Si-doped iron-nitrogen / carbon catalyst prepared by the method has catalytic activity superior to that of commercial Pt / C under an alkaline condition and has the advantages of high stability and tolerance to methanol.

Owner:SHANGHAI UNIV

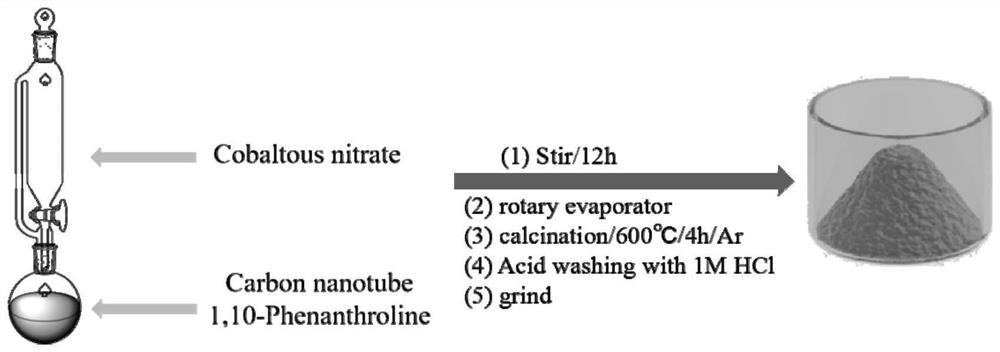

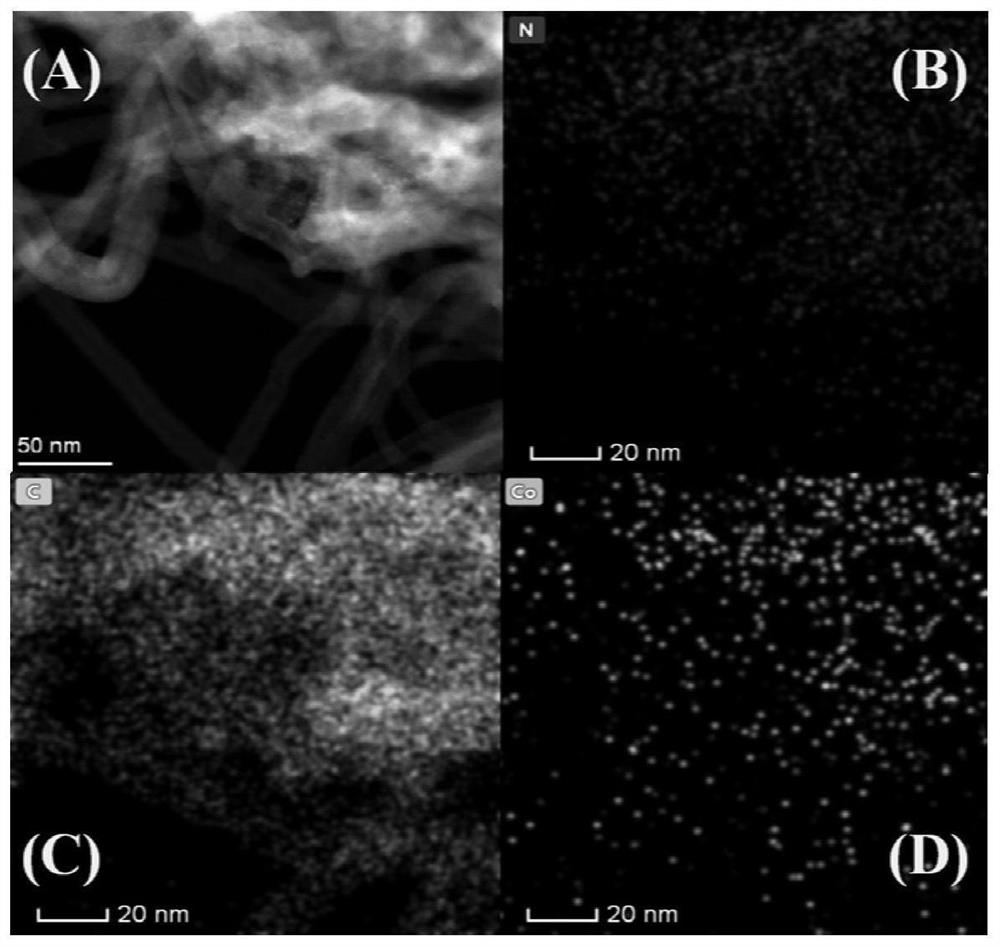

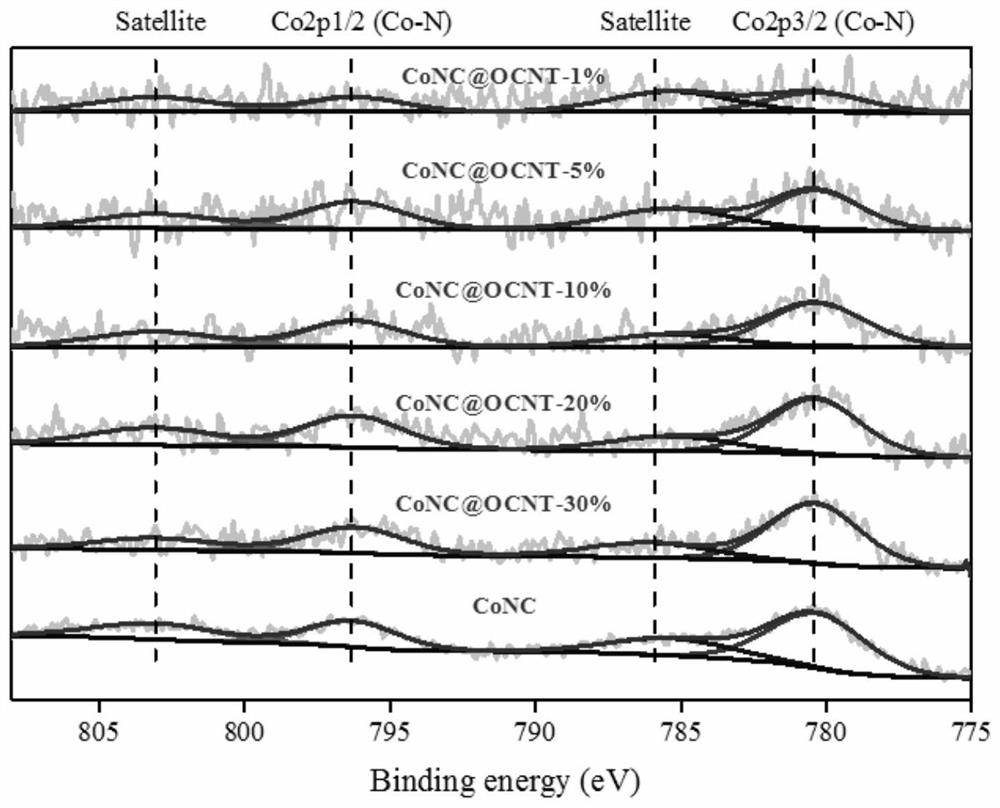

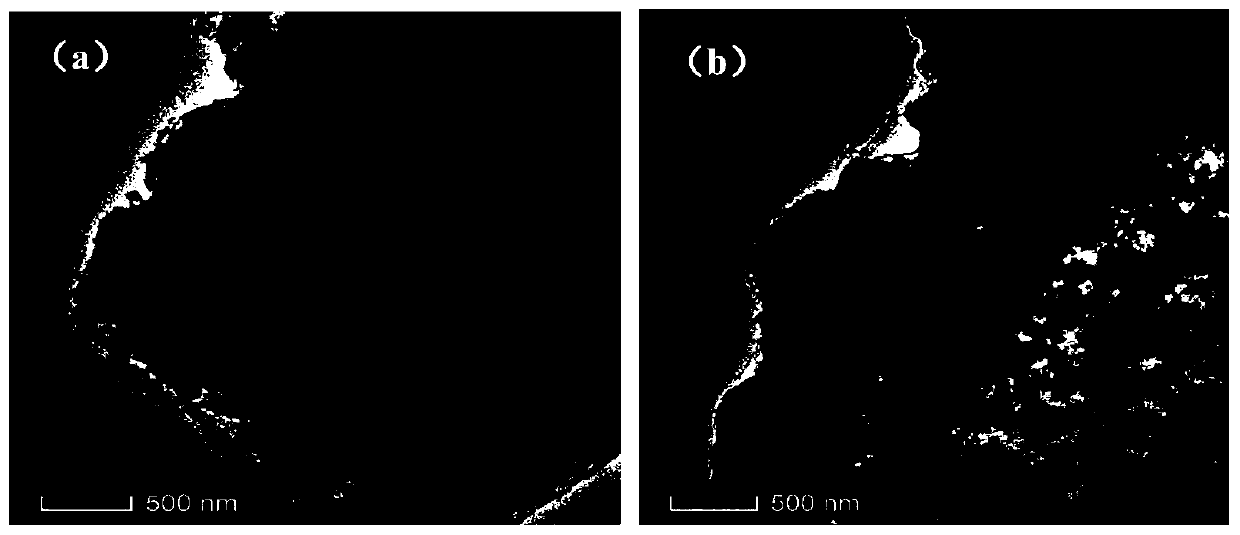

Nano carbon-loaded cobalt-nitrogen-carbon catalytic material as well as preparation method and application thereof

ActiveCN111672529AStable structureKeep activeCatalystsHydrocarbon preparation catalystsPtru catalystPhenanthroline

The invention discloses a nano carbon-loaded cobalt-nitrogen-carbon catalytic material as well as a preparation method and application thereof, and belongs to the technical field of propane dehydrogenation reaction catalysts. The compounding of nano carbon and cobalt-nitrogen-carbon is completed by the processes of complexing a cobalt salt precursor and a phenanthroline ligand, in-situ dipping thecobalt salt precursor and the phenanthroline ligand on the nano carbon surface, calcining, and pickling. The composite material can solve the problems of low catalytic performance of nano carbon andlow utilization efficiency and poor stability of an active cobalt-nitrogen-carbon component. The catalytic material is used as a catalyst for propane dehydrogenation reaction, propane is catalyzed tobe directly dehydrogenated to generate propylene under the conditions of no water, no oxygen and normal pressure, and the use temperature of the catalyst is 400-600 DEG C. The catalyst is stable in performance, and is high in catalytic activity and high in propylene selectivity in direct dehydrogenation reaction, carbon deposition is not prone to happening in the reaction process, the preparationmethod is simple and convenient, and raw materials are easy to obtain.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

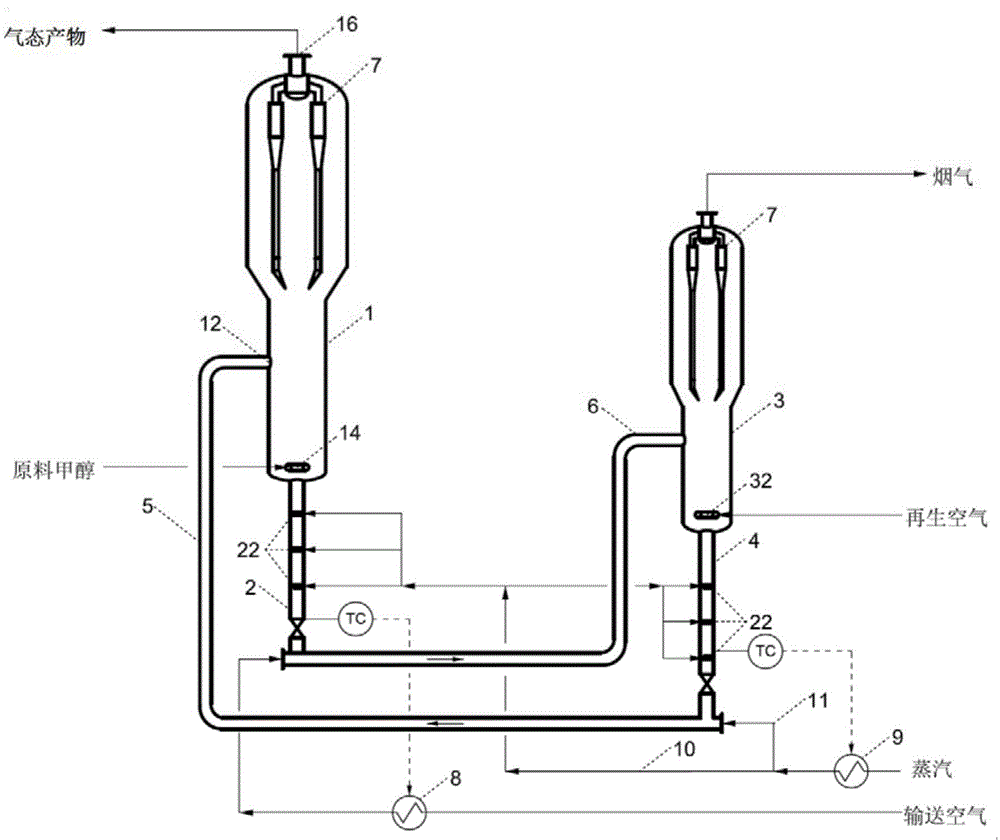

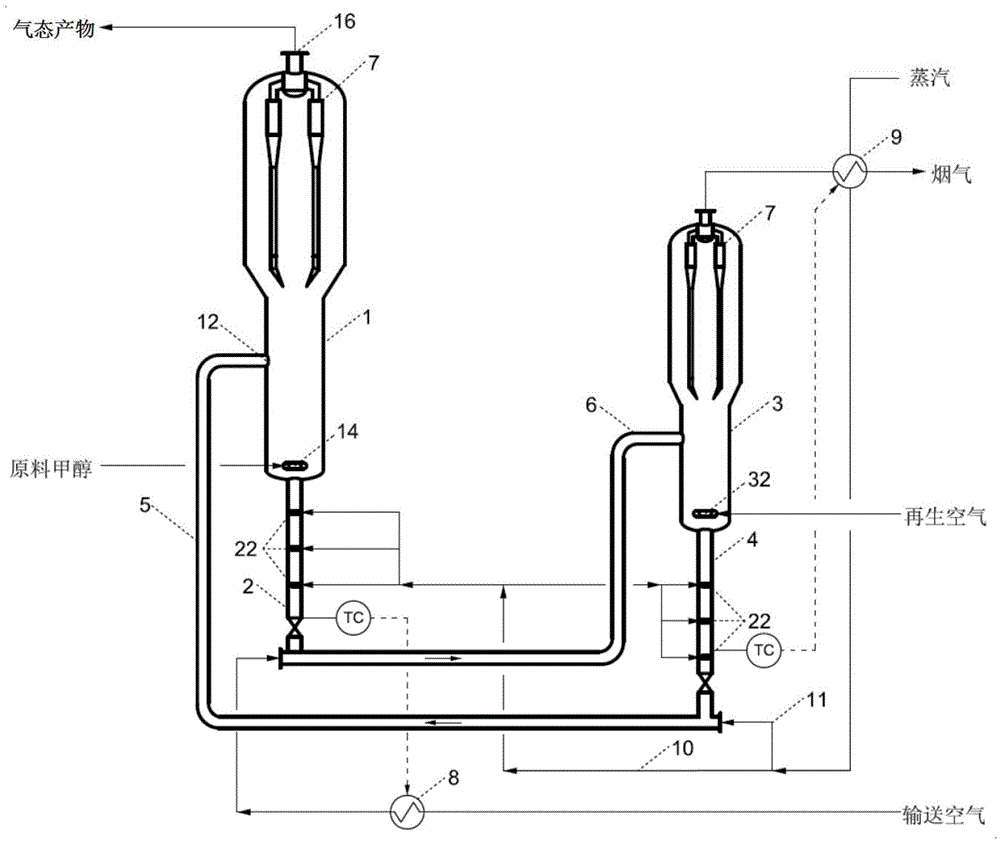

Method for carrying out gas-solid fluidized bed reaction

ActiveCN105771818AReduce wearHydrocarbon from oxygen organic compoundsChemical recyclingGas solidFlue gas

The invention relates to a method for carrying out a gas-solid circulation fluidized bed reaction. The method comprises the following steps: (1) in a fluidized bed reactor, an exothermic reaction is carried out under a condition that a gaseous raw material contacts a solid catalyst, such that a mixed product comprising a gaseous product and the solid catalyst is produced; (2) gas-solid separation is carried out in the upper part of the reactor; a part of the catalyst with charcoal deposit is delivered to a catalyst regenerator; (3) in the catalyst regenerator, the catalyst with charcoal deposit contacts regeneration air, such that a charcoal burning reaction is carried out; catalyst activity is recovered, and flue gas is generated; (4) the regenerated catalyst is delivered to the fluidized bed reactor through a regenerated catalyst delivery pipe; (5) the absolute value of the difference between the temperature of steam used for delivery and stripping and the temperature of the solid catalyst in a regenerated catalyst stripping section is 0-100 DEG C; and the absolute value of the difference between the temperature of delivery air used for delivering and the temperature of the solid catalyst in a spent catalyst stripping section is 0-100 DEG C. With the method, catalyst powdering damage caused by thermal expansion and contraction is effectively reduced.

Owner:SHANGHAI BI KE CLEAN ENERGY TECH +1

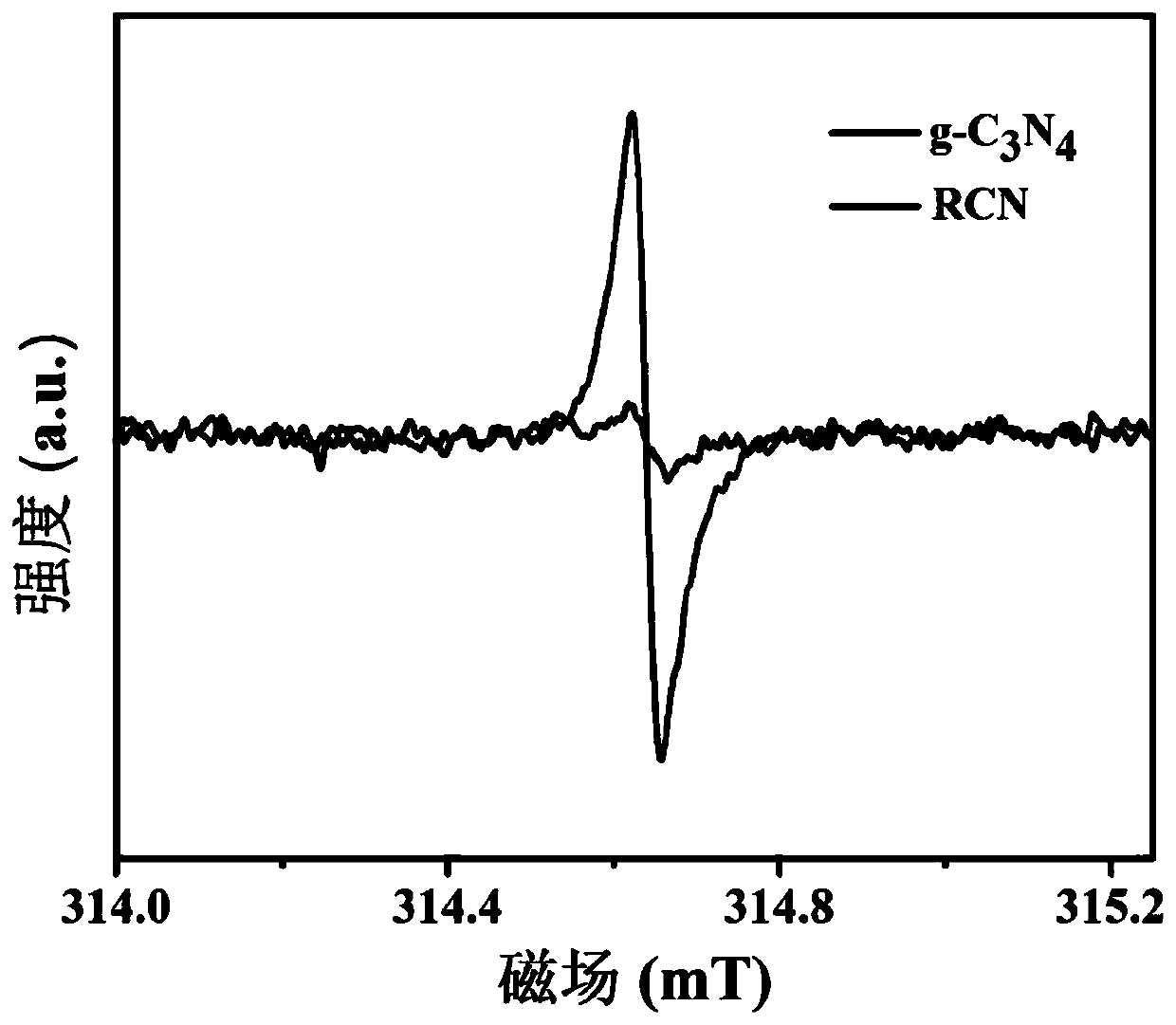

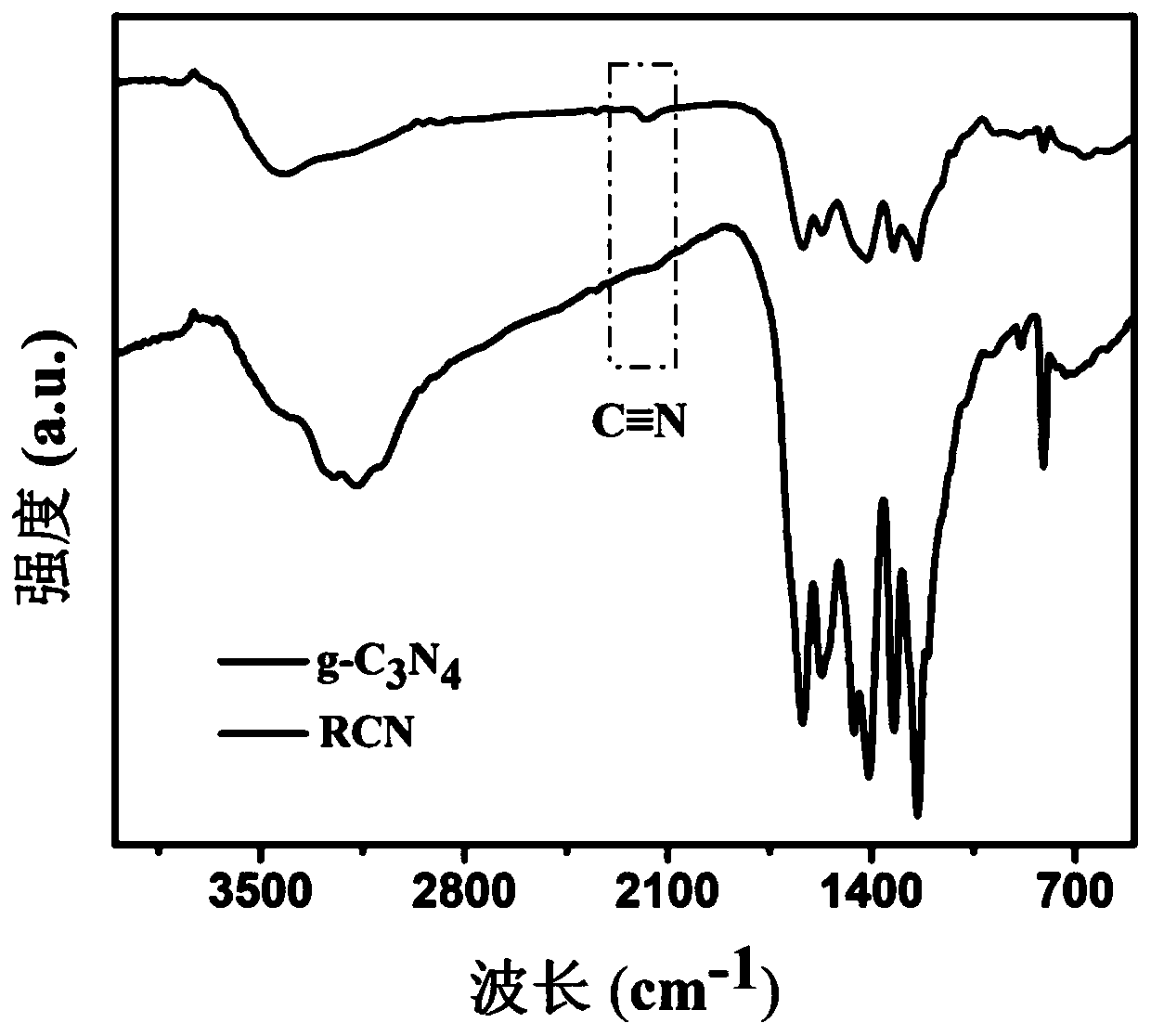

Reducing carbon nitride photocatalyst, preparation method and application thereof

ActiveCN110961129APromote absorptionReduced bandgap widthWater/sewage treatment by irradiationWater treatment compoundsPtru catalystPhysical chemistry

Belonging to the technical field of photocatalysis, the invention discloses a reducing carbon nitride photocatalyst, a preparation method and application thereof. The photocatalyst is prepared by thesteps of: heating melamine to 520-550DEG C, performing roasting, and conducting grinding to obtain g-C3N4 powder; mixing NaBH4 with g-C3N4 powder, and then performing heating to 570-600DEG C in a protective atmosphere; and performing cooling, then cleaning the product with deionized water and ethanol, and conducting drying. The reducing carbon nitride catalyst does not contain metal, and has the advantages of environmental protection, stability, low cost and the like. According to the invention, reducing carbon nitride is applied to photocatalytic degradation of diclofenac sodium for the firsttime, also shows excellent photocatalytic performance, and has good stability.

Owner:GUANGDONG UNIV OF TECH

Method for efficiently and synergistically treating chemical industry high-concentration organic wastewater and sludge

InactiveCN111003863AImprove adsorption capacityImprove catalytic oxidation performanceSludge treatmentSpecific water treatment objectivesChemical industryPtru catalyst

The invention discloses a method for efficiently and synergistically treating chemical industry high-concentration organic wastewater and sludge. The method comprises the following steps: (1) uniformly mixing high-concentration organic wastewater and industrial sludge, and supplementing a surfactant, an initiator and a metal salt; (2) carrying out microwave hydrothermal treatment on the mixed solution under the conditions that the temperature is 130-250 DEG C and the pressure is 2-10MPa, so that the carbon source in the high-concentration organic wastewater and the metal elements in the sludgeare subjected to an in-situ reaction to generate a composite hydrothermal carbon catalyst; (3) introducing an oxidizing agent, and carrying out catalytic wet oxidation on the mixed solution under a microwave condition; and (4) carrying out solid-liquid separation on the reaction solution obtained in the step (3), carrying out drying treatment on the solid phase so as to be used as a catalyst forrepeated utilizing, and carrying out secondary treatment on the liquid phase as required so as to be reused or carrying out biochemical treatment. According to the invention, the efficient and synergetic treatment and resource utilization of high-concentration organic wastewater and sludge can be realized.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com