High catalytic activity graphene-Pd @ Pt core-shell structure nanoflower compound and preparation method thereof

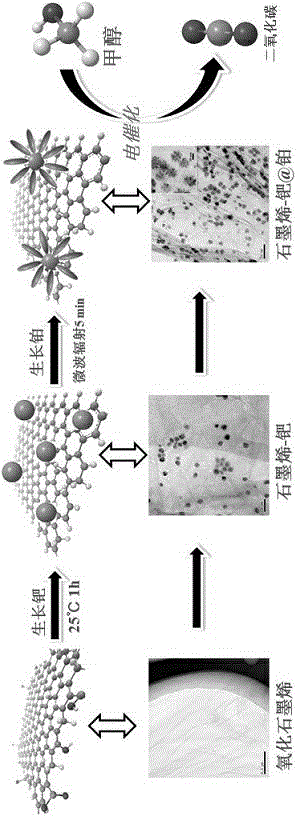

A technology with high catalytic activity and core-shell structure, which is applied in the field of graphene-palladium-platinum core-shell structure nanoflower composites and its preparation, can solve the problems of weak binding force between nanoparticles and graphene, complex process, and reduced graphene Conductivity and other issues, to achieve the effect of improving atom utilization efficiency, simple process, and reducing the use of precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] First, graphene oxide was prepared by the modified Staudenmaier method. The specific operation steps are as follows: Add 72ml of concentrated sulfuric acid with a mass concentration of 95-98% and 36ml of concentrated nitric acid with a mass concentration of 65-68% in a 500ml round bottom flask, stir magnetically for 15 minutes under ice bath conditions at 0°C, and then add 4g of natural Flake graphite, stirred vigorously to prevent agglomeration; after the dispersion is uniform, add 44g of potassium chlorate, and finally remove the ice bath and react for 96 hours; after the reaction is completed, the product is washed, ultrasonically stripped, flocculated with sodium hydroxide and dried at 60°C for 24 hour, grind to obtain graphene oxide solid powder;

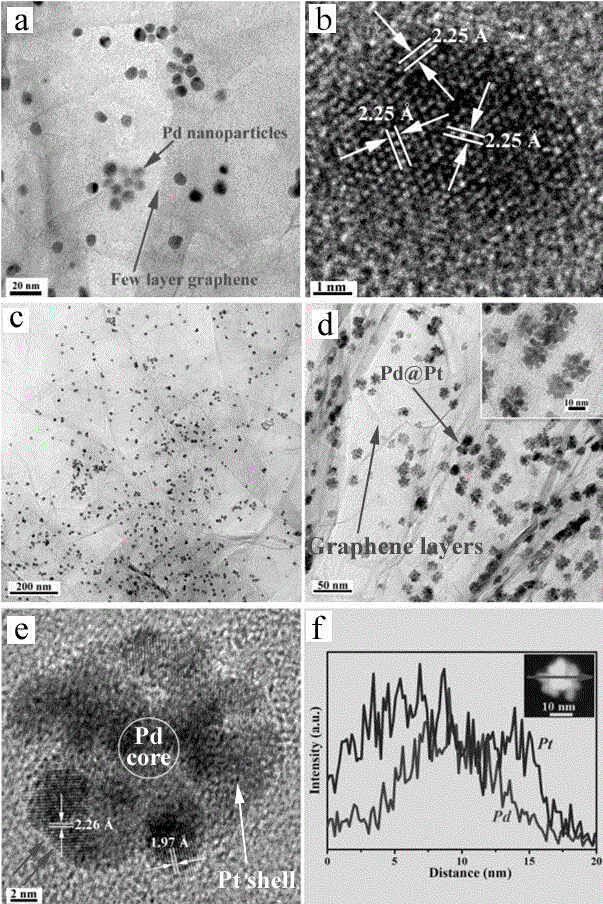

[0027] Then the graphene-palladium composite was prepared, and the specific steps were as follows: 10 mg graphene oxide powder was ultrasonically dispersed in 100 ml deionized water to obtain a monodisperse graphene...

Embodiment 2

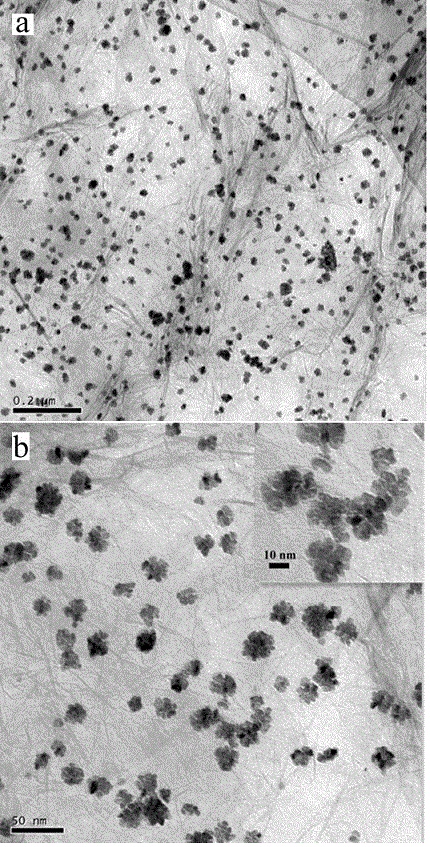

[0032]According to the preparation method of embodiment 1, just the reaction time of the preparation graphene-palladium composite stage is adjusted to 30 min by 60 min, obtain as follows figure 2 The shape shown.

Embodiment 3

[0034] Press the preparation method of embodiment 1, just adjust the reaction time of preparing graphene-palladium composite stage from 60 min to 90 min, obtain the same as figure 2 The results shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com