Spherical catalytic microelectrolytic environment-friendly material and preparation method therefor

An environmentally friendly material, micro-electrolysis technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

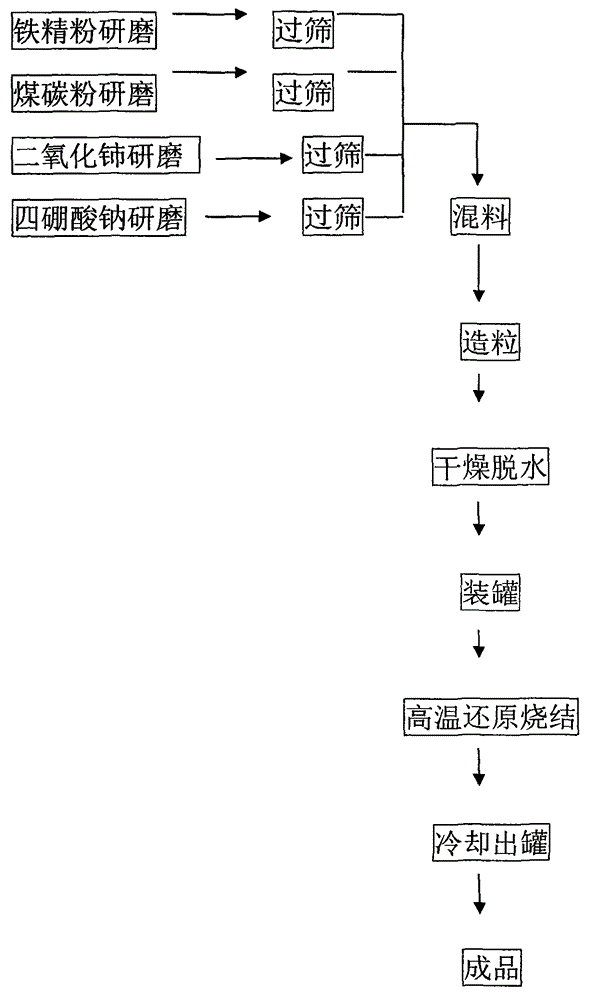

[0024] Embodiment 1 130-147 parts of fine iron powder, 25-29 parts of coal, 1-5 parts of catalyst, 1-3 parts of sintering agent

[0025] Example 1 Grind dry iron concentrate (grade 60), coal (grade 5000 cal or more), specially made cerium dioxide, and sodium tetraborate to 200 mesh respectively, and sieve them for later use; weigh the prepared raw materials by weight Mix 130 parts of fine iron powder, 29 parts of coal, 5 parts of catalyst, and 3 parts of sintering agent; granulate the uniformly mixed fine material into small balls with a diameter of 12 to 16 mm, dry and dehydrate, pack into cans, and heat up in a reducing atmosphere Sinter at 1000-1050 degrees Celsius for 4 hours, then cool out of the tank and serve. The product composition is: zero-valent active iron (78wt.%), carbon (14wt.%), catalyst (5wt.%).

Embodiment 2

[0026] Example 2 Grind dry iron concentrate (grade 60), coal (grade 5000 cal or more), specially made cerium dioxide, and sodium tetraborate to 200 mesh respectively, and sieve them for later use; weigh the prepared raw materials by weight Mix 140 parts of fine iron powder, 27 parts of coal, 3 parts of catalyst, and 2 parts of sintering agent; granulate the uniformly mixed fine material into small balls with a diameter of 12 to 16 mm, dry and dehydrate, pack into cans, and heat up in a reducing atmosphere Sinter at 1000-1050 degrees Celsius for 4 hours, then cool out of the tank and serve. The product composition is: zero-valent active iron (84wt.%), carbon (12wt.%), catalyst (3wt.%).

Embodiment 3

[0027] Example 3 Grind dry iron concentrate (grade 60), coal (grade 5000 cal or more), specially made cerium dioxide, and sodium tetraborate to 200 mesh respectively, and sieve them for later use; weigh the prepared raw materials by weight Mix 147 parts of fine iron powder, 25 parts of coal, 1 part of catalyst, and 1 part of sintering agent; granulate the uniformly mixed fine material into small balls with a diameter of 12 to 16 mm, dry and dehydrate, pack into cans, and heat up in a reducing atmosphere Sinter at 1000-1050 degrees Celsius for 4 hours, then cool out of the tank and serve. The product composition is: zero-valent active iron (88wt.%), carbon (10wt.%), catalyst (1wt.%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com