Method for producing porous nano silica and active carbon by utilizing rice hull ash

A technology of nano-silica and rice husk ash, which is applied in the field of comprehensive utilization of biological waste resources, can solve problems such as low quality, decreased yield, serious problems, etc., and achieve the effects of increased reaction area, increased reaction speed, and good extinction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

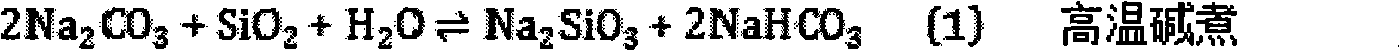

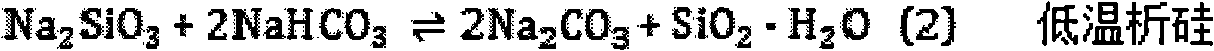

Method used

Image

Examples

Embodiment 1

[0031] (1) Take 10Kg rice husk ash, wash the rice husk ash with water twice according to the volume ratio of rice husk ash and water 1:1.5, remove the incompletely burned rice husk in the upper layer and the silt deposited at the bottom, 110°C Dried to a water content lower than 1%, crushed, and passed through a 100-mesh sieve to remove large particles;

[0032] (2) Soak in a sulfuric acid solution with a pH value of 3 at 60°C for 4 hours, the volume ratio of the sulfuric acid solution to rice husk ash is 1:1.5, stir continuously during the soaking process, filter directly after soaking, and separate the filter residue and acid solution ;Acid recycling;

[0033] (3) Add the filter residue obtained in step (2) into the potassium carbonate solution with a mass concentration of 15%, the volume ratio of the filter residue to the potassium carbonate solution is 1: 1.2, stir and react at 98°C for 3 hours, and filter under the temperature of the system ;

[0034] (4) Place the filt...

Embodiment 2

[0047] (1) Get 10Kg of rice husk ash, wash the rice husk ash 3 times according to the ratio of rice husk ash and water volume ratio of 1:2, remove the incompletely burned rice husk on the upper layer and the silt deposited on the bottom, 110 ℃ Dried under high temperature until the water content is lower than 1%, crushed, and passed through a 60-mesh sieve to remove large particles;

[0048] (2) Soak with a hydrochloric acid solution with a pH value of 4 at 40°C for 2 hours. The volume ratio of the hydrochloric acid solution to rice husk ash is 1:1.2. Stir continuously during the soaking process. After soaking, filter directly to separate the filter residue and acid solution. Acid recycling;

[0049] (3) Add the filter residue obtained in step (2) into the sodium carbonate solution with a mass concentration of 15%, the volume ratio of the filter residue to the sodium carbonate solution is 1: 1.5, stir and react at 95°C for 4 hours, and filter under the temperature of the syste...

Embodiment 3

[0063] (1) get 10Kg power generation rice husk ash, according to the ratio of rice husk ash and water volume ratio of 1: 1.3, the power generation rice husk ash is cleaned 3 times, remove the rice husk that the upper layer burns incompletely and the silt deposited at the bottom, Dried at 80°C until the water content is less than 1%, crushed, and passed through a 40-mesh sieve to remove large particles;

[0064] (2) Soak at 55°C for 3 hours with a nitric acid solution with a pH value of 4. The acid solution: rice husk ash volume ratio is 1: 1.4. Stir continuously during the soaking process. After soaking, directly filter and separate the filter residue and acid solution. Acid recycling;

[0065] (3) adding the filter residue obtained in step (2) into a sodium carbonate solution with a mass concentration of 15%, the volume ratio of the two is 1: 1.3, stirring and reacting at 100° C. for 4 hours, and filtering under the temperature of the system;

[0066] (4) Put the filtrate of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Oil absorption value | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com