Metal-nitrogen-carbon catalyst for carbon dioxide electroreduction and preparation method of metal-nitrogen-carbon catalyst

A technology of carbon dioxide and carbon catalysts, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve high degree of graphitization, good electrical conductivity, and the effect of promoting charge and material transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preparation method of metal-nitrogen-carbon catalyst for carbon dioxide electroreduction of the present invention comprises the following steps:

[0024] Provide carbon-based nanocages;

[0025] providing a transition metal salt solution;

[0026] After dispersing the carbon-based nanocages with a solvent, adding a transition metal salt solution, reacting, and drying to obtain a precursor;

[0027] The precursor is heat-treated at 800-1000° C. under an inert atmosphere, then pickled and dried to obtain a metal-nitrogen-carbon catalyst for carbon dioxide electroreduction.

[0028] The invention provides a three-dimensional hierarchical carbon-based nanocage with a high specific surface area, by preparing a metal ion salt solution; ultrasonically dispersing the carbon-based nano-cage and evaporating the solvent to dryness; complexing the metal loaded on the carbon-based nano-cage The metal-nitrogen-carbon unit site is formed by heat treatment of the precursor in an ...

Embodiment 1

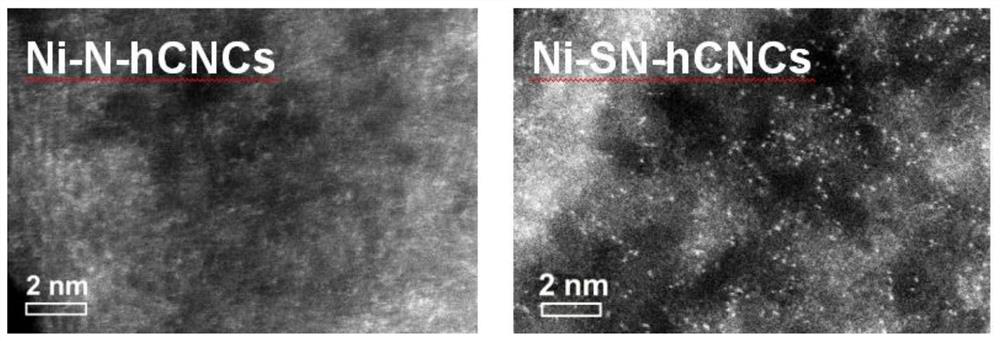

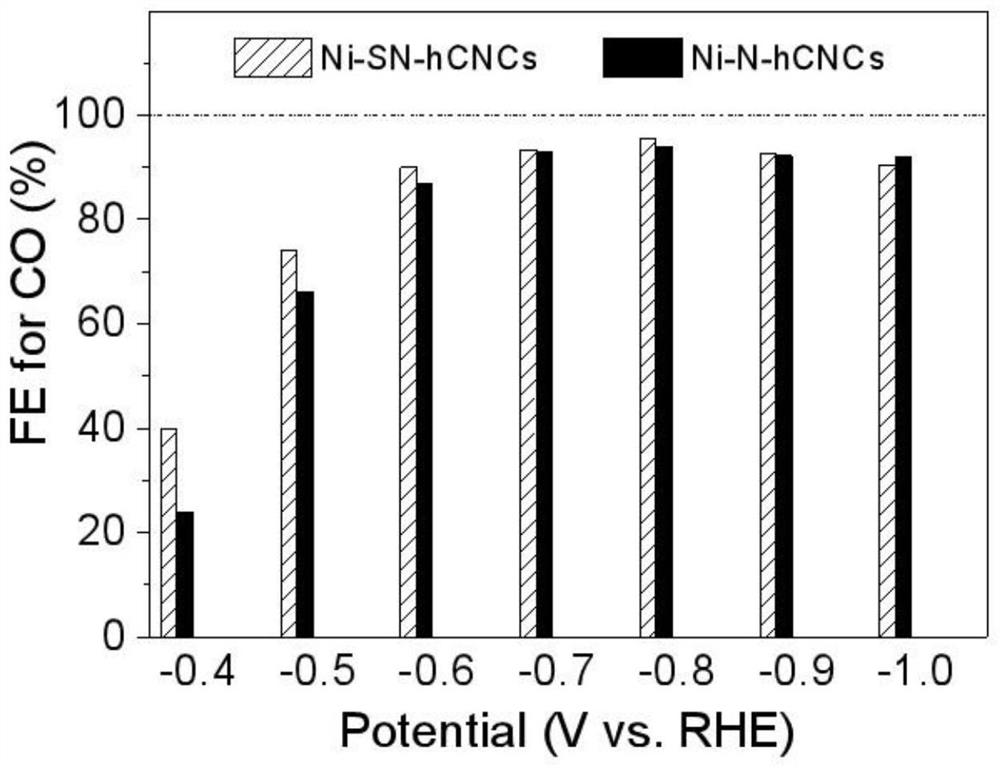

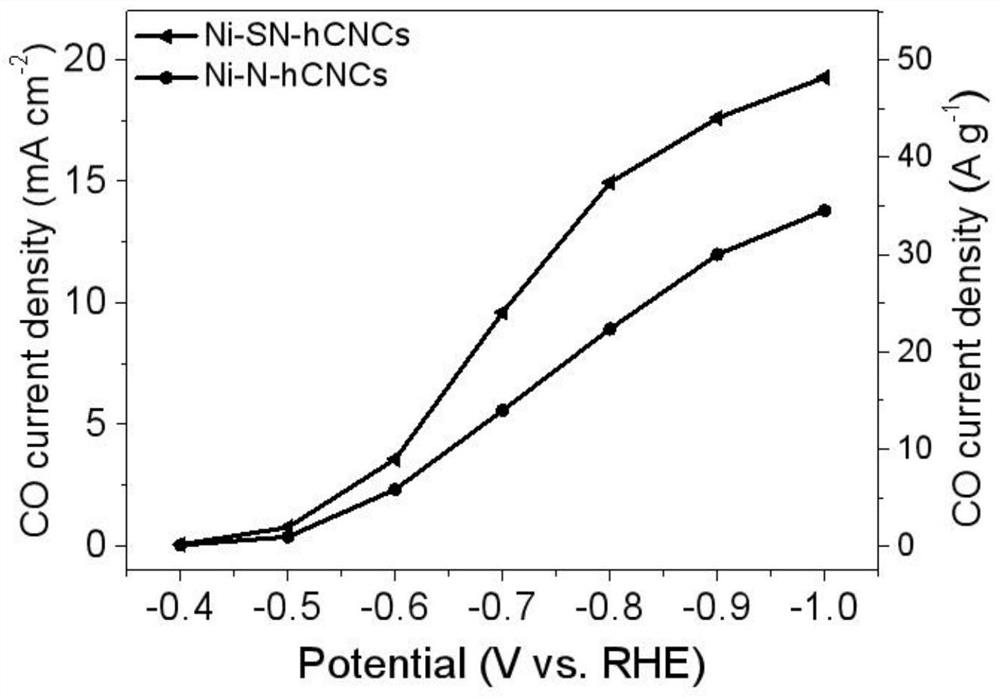

[0030] Ni-N-hCNCs:

[0031] Weigh 64.8 mg of nickel chloride and 180.2 mg of phenanthroline, add 20 mL of ethanol to dissolve, and prepare the precursor solution of phenanthroline and nickel for future use. Weigh 50 mghCNCs, add it to the precursor solution, mix and stir for 30 min at room temperature, and ultrasonicate for 30 min, then stir the mixed solution at 70 ° C to evaporate the solvent; grind it into powder and place it in a tube furnace, and heat it at 200 mL min -1 Under the protection of Ar flow, at 10°C min -1 After the temperature was raised to 900°C, it was fired for 2 hours. After the sample is cooled to room temperature, the sample is taken out to obtain a catalyst containing nickel nanoparticles. The prepared catalyst containing nickel nanoparticles was placed in a flask, and 250mL1molL was added -1 The hydrochloric acid solution was stirred and washed at 80°C for 16h to dissolve the nickel nanoparticles; after filtration, it was dried in a drying oven at ...

Embodiment 2

[0034] Fe-N-hCNCs:

[0035] Weigh 81.1 mg of ferric chloride and 180.2 mg of phenanthroline, add 20 mL of ethanol to dissolve, and prepare the precursor solution of phenanthroline and iron for future use. Weigh 50 mghCNCs, add it to the precursor solution, mix and stir for 30 min at room temperature, and ultrasonicate for 30 min, then stir the mixed solution at 70 ° C to evaporate the solvent; grind it into powder and place it in a tube furnace, and heat it at 200 mL min -1 Under the protection of Ar flow, at 10°C min -1 After the temperature was raised to 900°C, it was fired for 2 hours. After the sample is cooled to room temperature, the sample is taken out to obtain a catalyst containing iron nanoparticles. The prepared iron-containing nanoparticles catalyst was placed in a beaker, and 250mL1molL was added -1The hydrochloric acid solution was stirred and washed at 80°C for 16h to dissolve the iron nanoparticles; after filtration, it was dried in a drying oven at 70°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com