Platinum-cobalt alloy catalyst and preparation method thereof

A platinum-cobalt alloy and platinum-carbon catalyst technology, which is applied in the field of materials, can solve the problem of high platinum consumption and achieve the effects of low cost, low energy consumption and good pre-freezing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

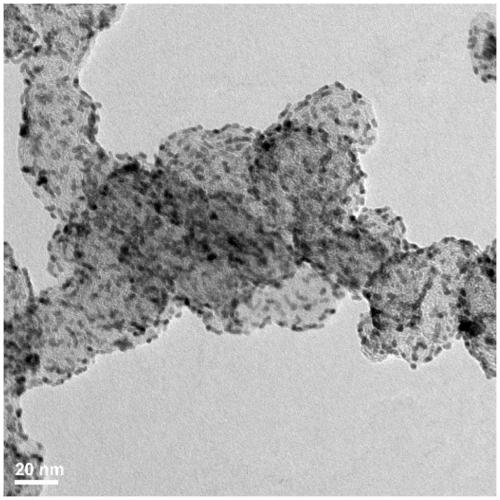

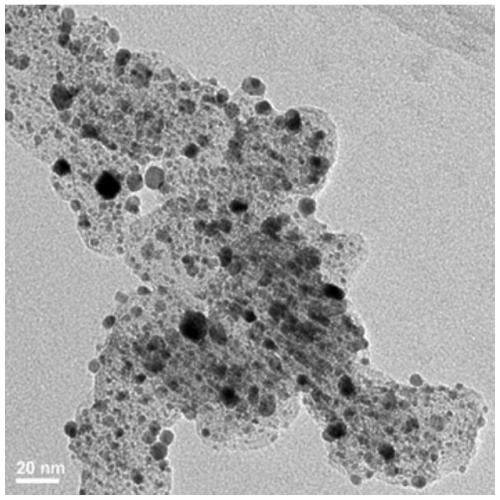

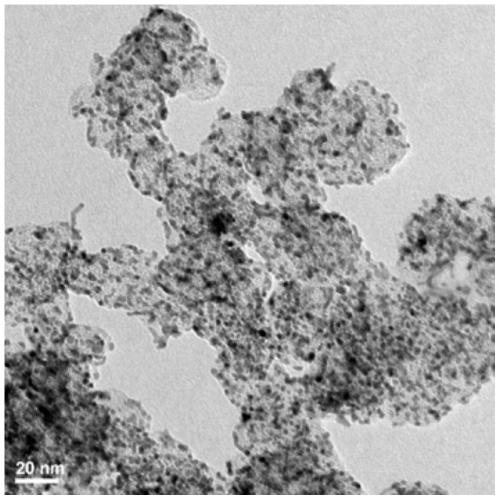

Image

Examples

preparation example Construction

[0035] A preparation method of a platinum-cobalt alloy catalyst, comprising:

[0036] After uniformly mixing the cobalt salt, the platinum-carbon catalyst and the volatile solvent, the temperature is lowered to -70°C to -20°C within 2 hours for pre-freezing, and then vacuum-dried in the range of -50°C to 80°C to obtain the platinum-cobalt precursor;

[0037] The platinum-cobalt precursor is reduced at 200-400° C. under a reducing atmosphere for 1-6 hours at a low temperature, and then heat-treated at a high temperature at 500-900° C. under a reducing atmosphere for 1-3 hours.

[0038] In the examples of the present application, the cobalt salt, platinum carbon catalyst and volatile solvent were evenly mixed, pre-frozen, and then vacuum freeze-dried to remove the solvent, so that the cobalt salt was placed on the surface of the platinum carbon catalyst in situ to avoid Migration and agglomeration of cobalt salts, platinum-cobalt precursors are reduced at a low temperature of 20...

Embodiment 1

[0077] This embodiment provides a platinum-cobalt alloy catalyst, which is mainly prepared through the following steps:

[0078] 1) Disperse 1g of carbon carrier in 200mL of ethylene glycol, add 2.63g of chloroplatinic acid, ultrasonically disperse for 120min, and obtain the first suspension after mechanical rotation and stirring.

[0079] 2) The first suspension was mechanically stirred at room temperature, and the pH value was adjusted to 11 with sodium hydroxide to obtain the second suspension.

[0080] 3) The second suspension was irradiated with 2000w microwave for 500s, washed with deionized water, and vacuum-dried at 80°C to obtain a Pt / C catalyst.

[0081] 4) Dissolve 0.305g of cobalt chloride in ethanol, and ball-mill the Pt / C catalyst prepared in step 3) at 250r / min for 150min, then pre-freeze at -70°C for 2h, and use 5°C / h under the condition of absolute vacuum 30Pa The heating rate is to raise the temperature of the partition plate of the freeze dryer from -50°C t...

Embodiment 2

[0085] This embodiment provides a platinum-cobalt alloy catalyst, which is mainly prepared through the following steps:

[0086] 1) Disperse 1g of carbon carrier in 100mL of ethylene glycol, add 6.14g of chloroplatinic acid, ultrasonically disperse for 240min, and obtain the first suspension after mechanical rotation and stirring;

[0087] 2) The first suspension was mechanically stirred at room temperature, and the pH value was adjusted to 14 with sodium hydroxide to obtain a second suspension.

[0088] 3) The second suspension was irradiated with a microwave at 500w for 900s, washed with deionized water, and vacuum-dried at 80° C. to obtain a Pt / C catalyst.

[0089] 4) Dissolve 1.059g of cobalt acetate in ethanol, and ball mill with the Pt / C catalyst prepared in step 3) at a speed of 750r / min for 30min, then pre-freeze at -40°C for 2h, and then freeze it at 5°C / h heating rate to raise the temperature of the freeze dryer partition from -40°C to -5°C, and keep it at -5°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com