Nano carbon-loaded cobalt-nitrogen-carbon catalytic material as well as preparation method and application thereof

A cobalt-nitrogen-carbon catalytic material and technology for catalytic materials, which are used in catalyst activation/preparation, carbon compound catalysts, chemical instruments and methods, etc., can solve the problems of low activity of nano-carbon catalysts, environmental pollution by toxic catalysts, and poor long-term stability. Achieve good thermal stability and anti-carbon deposition, good structural stability and chemical activity, and specific surface area to resist carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

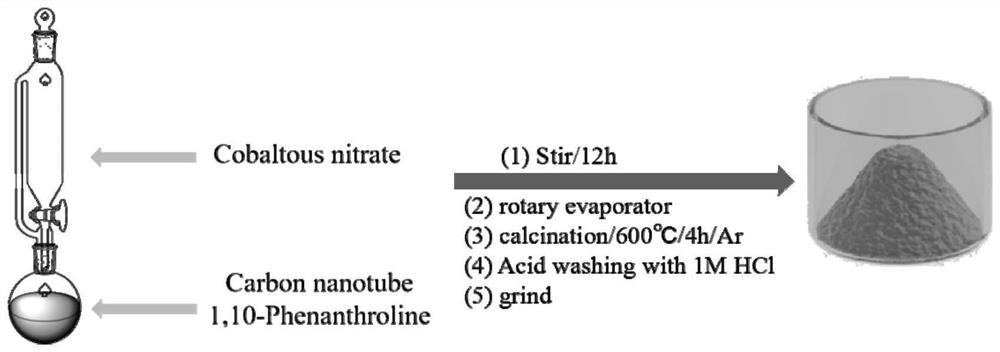

[0053] Weigh 1g of oxidized carbon nanotube powder into a 200ml round bottom flask, add 100ml of absolute ethanol as a solvent, and place it in a 100W ultrasonic oscillator for 30 minutes to disperse the oxidized carbon nanotubes evenly. After dissolving 135 mg of phenanthroline in 40 ml of absolute ethanol, it was added to the carbon dioxide nanotube dispersion and stirred at room temperature for 30 min. Then the cobalt nitrate of 100mg is dissolved in the dehydrated alcohol of 60ml, and it is added in the constant pressure funnel of 60ml and is installed on the round bottom flask, open the funnel switch and make the cobalt salt solution drop by drop in the mixed dispersion liquid, Continue stirring at room temperature for 12 hours after the cobalt salt solution is completely dripped. After the stirring time expired, the solvent was distilled off under reduced pressure using a rotary evaporator at 40° C. to obtain a solid powder. Afterwards, put the obtained solid powder int...

Embodiment 2

[0060] Take by weighing 250mg the nano-carbon supported cobalt-nitrogen-carbon powder catalyst synthesized in Example 1 and pack it into a Φ10 fixed-bed quartz tube, with 15ml min -1 A mixed feed gas with a volume percentage of 2% propane and helium in equilibrium was introduced at a flow rate, and reacted at 550° C. for 8 hours. After the reaction, the gas was continuously detected by gas chromatography. The conversion of propane was 14%, the selectivity of propylene was 96%, and the total selectivity of other C1 and C2 was 4%.

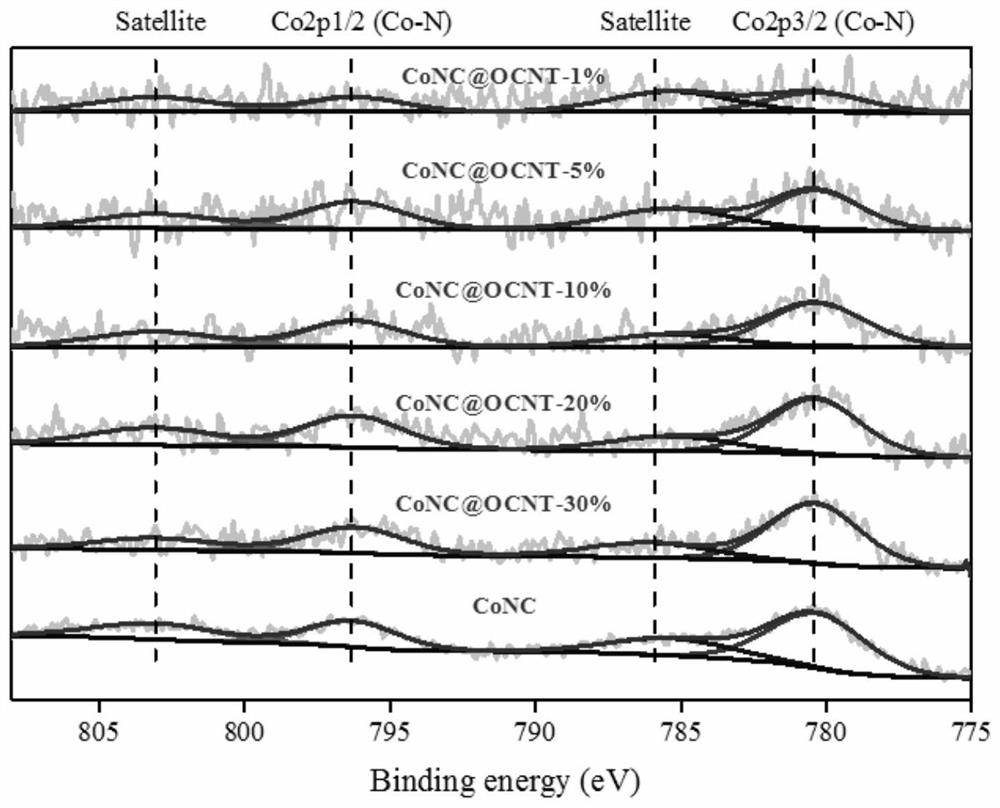

[0061] Figure 6 It is a comparison chart of the activity of oxidized carbon nanotubes loaded with different contents of cobalt, nitrogen and carbon catalysts and reference materials in the propane dehydrogenation reaction. From the data in the figure, it can be seen that the catalytic activity of nano-carbon-supported cobalt-nitrogen-carbon catalytic materials comes from the cobalt-nitrogen-carbon layer, and the catalytic performance of the composi...

Embodiment 3

[0063] Take by weighing 200mg the nanometer carbon supported cobalt nitrogen carbon powder catalyst synthesized in embodiment 1 and pack in Φ10 fixed-bed quartz tube, with 15ml min -1 The mixed raw material gas of propane and helium with a flow rate of 2% by volume was introduced, and reacted at 570° C. for 20 hours. After the reaction, the gas was continuously detected by gas chromatography. The conversion of propane was 20%, the selectivity to styrene was 95%, and the total selectivity of other C1 and C2 was 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com