Oxidation and reduction double-effect micro electrolysis combined reactor and application thereof

A reactor and micro-electrolysis technology, applied in chemical instruments and methods, sterilization/microdynamic water/sewage treatment, water/sewage treatment, etc. The effect of reducing the footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

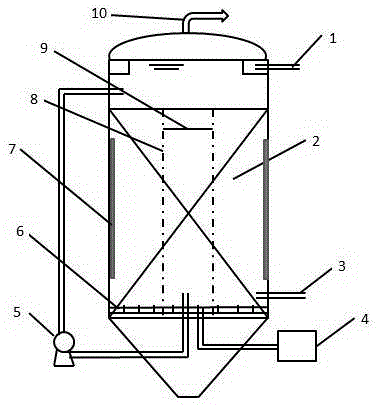

[0033] Such as figure 1 An oxidation and reduction double-effect micro-electrolysis composite reactor shown includes a cylinder body and a special iron-carbon catalytic packing, the center of the cylinder body is provided with a channel baffle 8, and the channel baffle 8 is a sieve-holed Cylindrical baffle, the special iron-carbon catalytic filler is filled in the packing area 2 formed between the channel baffle 8 and the cylinder; the channel baffle 8 is provided with a circulation pipeline inside, and the circulation pipeline passes through the pump 5 It is connected with the upper end of the cylinder; the bottom of the packing area 2 is provided with a microporous aeration plate 6, and the microporous aeration plate 6 is connected with the aeration generator 4; the bottom of the cylinder is provided with a water inlet 3, and the top A water outlet 1 is provided; the height of the water inlet 3 is higher than the bottom of the filling area 2, and the height of the water out...

Embodiment 2

[0035] According to the equipment described in Example 1, wherein the special iron-carbon catalytic filler is an iron-carbon filler loaded with lanthanum chloride, the electroplating industry wastewater is taken, wherein the heavy metals exceeding the standard include Cd and Ni elements, the pH of the solution is adjusted to about 4, and the wastewater is passed into In the new composite reactor of oxidation and reduction double-effect micro-electrolysis, after 1 hour of stirring by water conservancy, samples were taken for determination. The heavy metals were determined by ICP-MS, and the data determination results are shown in Table 1.

[0036] Table 1 data measurement results

[0037] sample 111Cd (ug / L) 59Ni (mg / L) Initial concentration of wastewater 161.55 1668 Pretreatment reactor effluent 20.20 37

[0038] From the data in Table 1, it can be seen that compared with the initial concentration of heavy metals in wastewater, the cadmium (Cd)...

Embodiment 3

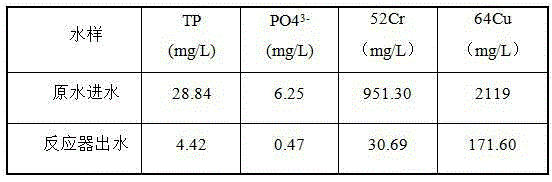

[0040]According to the equipment described in Example 1, wherein the special iron-carbon catalytic filler is an iron-carbon filler loaded with cerium chloride, the electroplating industry wastewater is taken, wherein its total phosphorus content and heavy metal elements exceed the standard, the pH of the wastewater itself is about 2, and the wastewater Directly pass into the oxidation and reduction double-effect micro-electrolysis new composite reactor, hydraulically stir for 1 hour to remove heavy metal elements, then ozone aerate and stir for 1 hour to remove total phosphorus, and then take samples for measurement. Heavy metals were determined by ICP-MS, and organics were determined by indophenol blue colorimetry. The data measurement results are shown in Table 2.

[0041] Table 2 data measurement results

[0042]

[0043] As can be seen from the data in Table 2, the reactor in the present invention can have a good removal rate to total phosphorus and heavy metal element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com