Flexible solvent-free epoxy fireproof paint and preparation method thereof

A fire-resistant coating, solvent-free technology, applied in the direction of fire-resistant coatings, epoxy resin coatings, anti-corrosion coatings, etc., can solve the problems that the internal stress of the paint film cannot be eliminated, the fire-resistant coating is easy to crack, and the fire-proof performance of the fire-resistant coating is reduced, so as to achieve convenience Develop solvent-free coatings, avoid migration and exudation, and avoid the effects of dissolution and exudation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

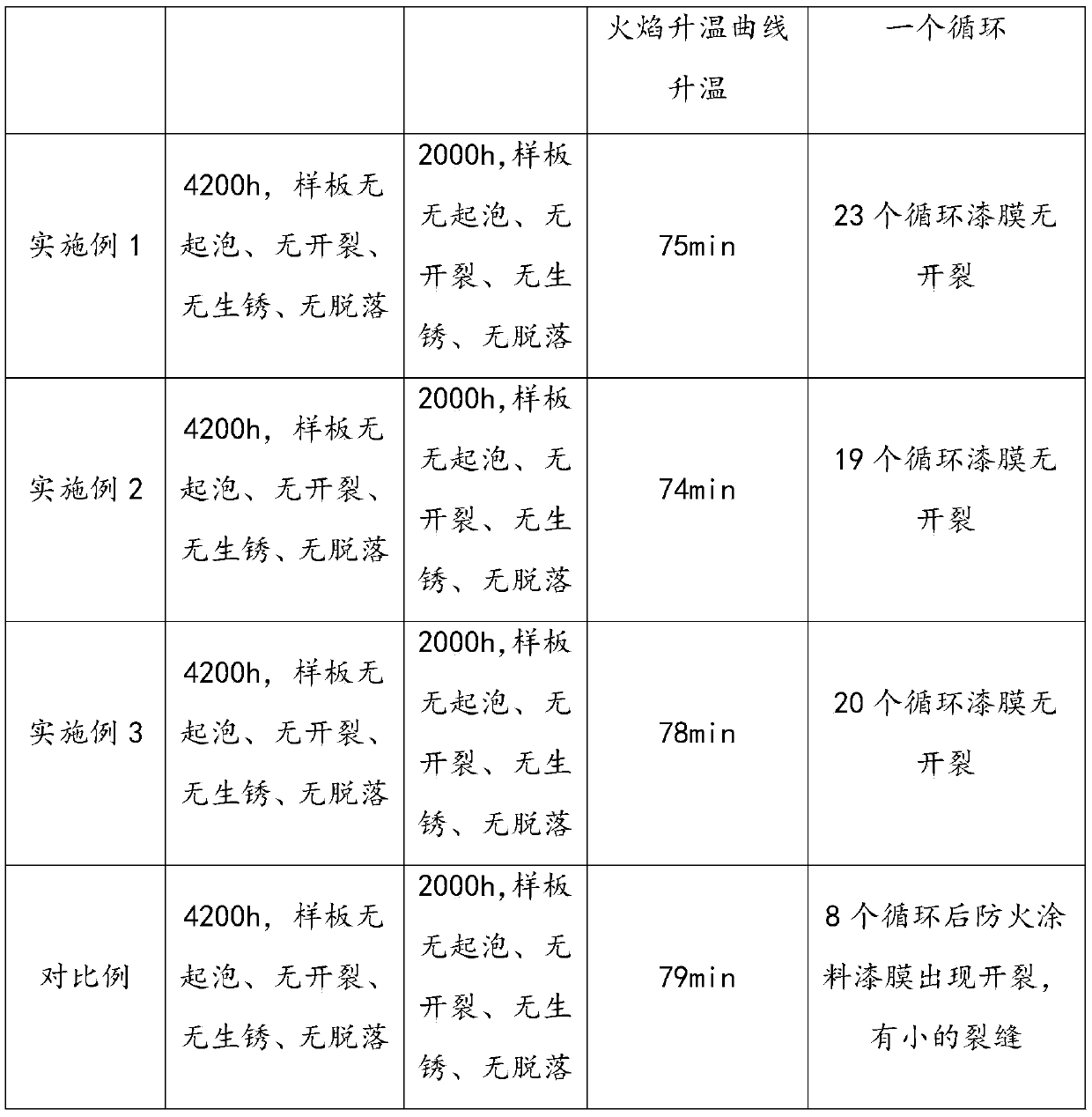

Embodiment 1

[0038] The flexible solvent-free epoxy fireproof coating of the present embodiment comprises A component and B component, and the weight ratio of A component and B component is 3:1, and wherein A component is made up of the component of following parts by weight:

[0039] 20 parts of bisphenol A liquid epoxy resin YD-128, 10 parts of Thioplast EPS 70, 5 parts of flame retardant zinc borate, 25 parts of carbon-forming catalyst ammonium polyphosphate, 10 parts of blowing agent A melamine, pigment A TiO 2 15 parts, refractory filler A expanded perlite 10 parts, glass fiber A 2 parts, thixotropic agent R-972 1.5 parts, defoamer DF 6800 1 part, wetting and dispersing agent BYK-1100.5 parts;

[0040] B component is made up of the component of following parts by weight:

[0041] Curing agent Ancamide 502 50 parts, curing agent accelerator tri-(dimethylaminomethyl) phenol 3.5 parts, blowing agent B melamine 15 parts, refractory filler B wollastonite 14 parts, titanium dioxide 10 parts,...

Embodiment 2

[0055] The flexible solvent-free epoxy fireproof coating of the present embodiment comprises A component and B component, and the weight ratio of A component and B component is 3.5:1, and wherein A component is made up of the component of following parts by weight:

[0056] Bisphenol A type liquid epoxy resin YD-128 23 parts, Thioplast EPS 25 3 parts, Thioplast EPS 704 parts, flame retardant triphenyl phosphate 8 parts, carbon forming catalyst ammonium polyphosphate 20 parts, blowing agent A melamine 13 parts, TiO 2 11 parts, carbon black 0.1 part, expanded perlite 6 parts, light calcium carbonate 6 parts, glass fiber 3 parts, thixotropic agent R-974 1 part, defoamer DF6800 1.2 parts, wetting and dispersing agent BYK-110 0.7 share;

[0057] B component is made up of the component of following parts by weight:

[0058] 55 parts of curing agent Ancamide 502, 3 parts of curing agent accelerator tris-(dimethylaminomethyl)phenol, 12 parts of foaming agent B melamine, 12 parts of...

Embodiment 3

[0072] The flexible solvent-free epoxy fireproof coating of the present embodiment comprises A component and B component, and the weight ratio of A component and B component is 4:1, and wherein A component is made up of the following components by weight:

[0073] Bisphenol A type liquid epoxy resin YD-128 25 parts, Thioplast EPS 25 5 parts, flame retardant boric acid 10 parts, carbon forming catalyst ammonium polyphosphate 15 parts, blowing agent A melamine 15 parts, TiO 2 8 parts, 0.2 parts of carbon black, 15 parts of light calcium carbonate, 4 parts of glass fiber, 0.5 parts of thixotropic agent R-208, 1.4 parts of defoamer DF 6800, 0.9 parts of wetting and dispersing agent BYK-110;

[0074] B component is made up of the component of following parts by weight:

[0075] 59 parts of curing agent Ancamide 502, 2 parts of curing agent accelerator tris-(dimethylaminomethyl)phenol, 10 parts of foaming agent B melamine, 10 parts of refractory filler B wollastonite, 14 parts of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com