Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

162results about How to "Process energy saving" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

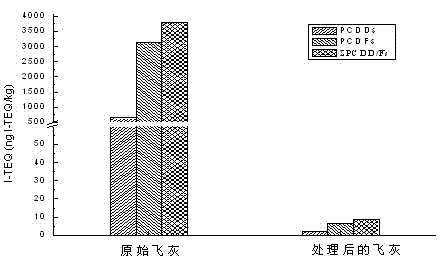

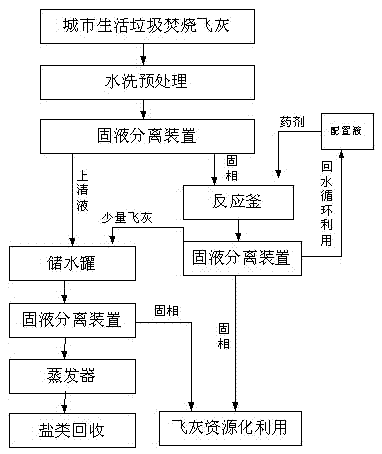

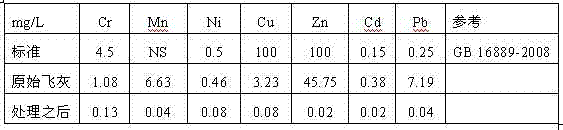

Harmless treatment method for urban garbage incineration fly ash

The invention discloses a harmless treatment method for urban garbage incineration fly ash. Due to the adoption of a treatment system and a method disclosed by the invention, heavy metals in incineration fly ash can be effectively stabilized and dioxin can be degraded; the leaching toxicity of heavy metals is fully accordant with the national standard; the toxicity of dioxin is removed by 99.9 percent; and meanwhile, the chloride ions in fly ash can be effectively removed, salt substances are recovered, and zero discharge of waste liquids is ensured. A process and the method have the remarkable characteristics of energy saving, environmental friendliness, remarkable economic benefit and remarkable social benefit; and meanwhile, the treated fly ash has novel physicochemical properties, canbe applied to the industries of environmental protection, construction and the like, and has application and popularization values.

Owner:ZHEJIANG UNIV

Aluminum alloy chromate-free passivation treatment method and aluminum alloy chromate-free passivation treatment fluid thereof

ActiveCN106086846AImprove corrosion resistanceImprove hydrophobicityMetallic material coating processesEnvironmental resistanceProtection layer

The invention relates to the technical field of metal surface anti-corrosion treatment, and provides an aluminum alloy chromate-free passivation treatment method and aluminum alloy chromate-free passivation treatment fluid thereof. The treatment fluid is composed of 0.5 to 10.0 g / L of titaniferous compounds, 0.1 to 8.0 g / L of zirconium salt, 0.1 to 10 g / L of fluoride, 0.5 to 20 g / L of oxidizing agents and 0.2 to 15 g / L of complexing agents, wherein the pH ranges from 3.6 to 4.5. Aluminum alloy is treated for 1 to 5 minutes at the room temperature in the chromate-free passivation treatment fluid, and then is subjected to chromate-free passive membrane sealing treatment for 60 seconds to 120 seconds at the room temperature in sealing treatment fluid composed of 1% to 15% of organosilane, 2% to 40% of water-soluble fluorocarbon emulsion and 65% to 97% of deionized water, so that a compound chromate-free passive membrane is formed on the surface of the aluminum alloy, and after the compound chromate-free passive membrane is dried, the compound chromate-free passive membrane with high corrosion resistance is obtained on the surface of the aluminum alloy and can be directly used as the terminal protection layer of the aluminum alloy; and the chromate-free passivation treatment fluid does not contain heavy metal ions such as chromium ions, and is non-toxic, harmless to human bodies or the environment, clean and friendly to the environment.

Owner:CRRC QINGDAO SIFANG CO LTD

Normal-pressure low-temperature plasma preprocessing technique of textile for digital inking printing

InactiveCN101100808AImprove clarityImprove color vibrancyUltrasonic/sonic fibre treatmentDyeing processEngineeringPre treatment

The invention relates to fabric plasma surface modification processing technology used in dye ink digital inking printing. The fabric is processed inking printing by dye ink in the digital inking printing machine after processing by impulse normal pressure air low temperature plasma, then baking to form the finished product. Compared with the traditional preprocessing technology, the invention has the advantages of fast, convenient, saving water and energy, low cost, no social effects of pollution, suiting for industrialization continuous production etc.

Owner:JIANGNAN UNIV

Open type method for producing fermentated lacitc acid and feedstuff using kitchen residue

InactiveCN1843152AIncrease productionLow crude protein contentFood processingSolid waste disposalLactic acid bacteriumOrganic acid

The invention relates to a method for preparing lactic acid and feed stuff with kitchen refuse in open type. The invention saves steps in current close-type process of strict sterilization and zymogeneous bacteria inoculation, nutrient addition and improves the lactic acid yield and protein content in prepared feed stuff. The lactic acid preparation comprises following steps: (1) drying and disintegrating kitchen refuse; (2) adding water; (3) adding cellulase and amylase; (4) open fermenting; (5) solid-liquid separating; (6) purifying and getting the lactic acid in fermentation liquor. The feed stuff preparation comprises following steps: (1) drying and disintegrating kitchen refuse; (2) adding water; (3) adding cellulase and amylase; (4) open fermenting; (5) solid-liquid separating; (6) sterilizing and drying the leavings, getting the feed stuff. The lactic acid content percent in organic acid is 94-98%, and its yield amounts to 64-75 g / l. The coarse protein content percent in feed stuff is 25-35% of the total feed stuff.

Owner:HARBIN INST OF TECH

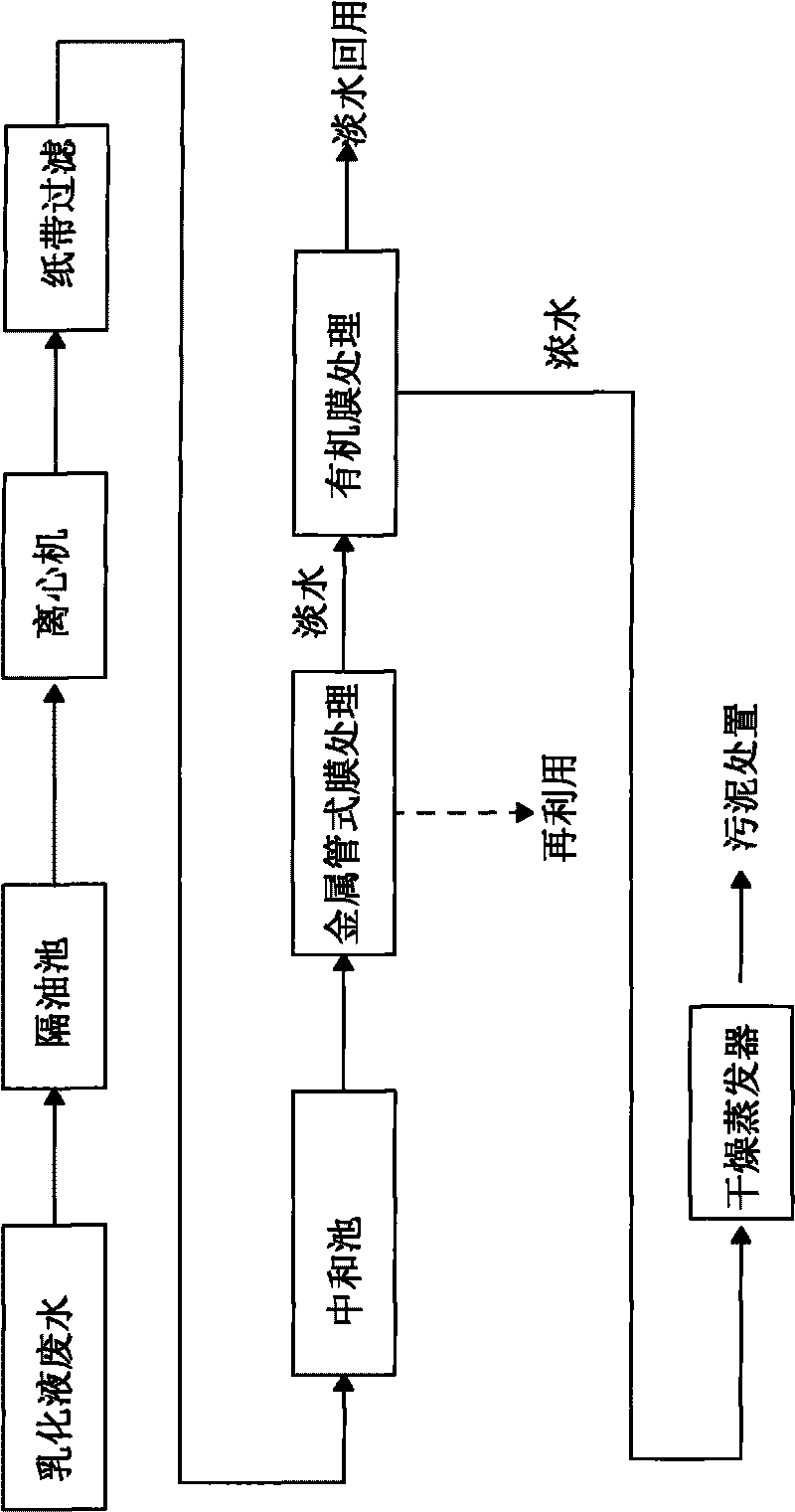

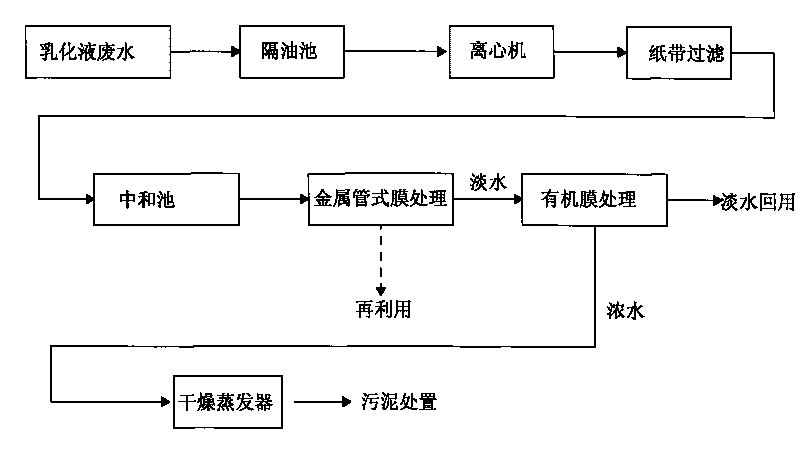

Emulsifying liquid wastewater membrane treatment process

InactiveCN101708912AEfficient treatment processEasy to operateWater/sewage treatment by centrifugal separationFatty/oily/floating substances removal devicesUltrafiltrationChemistry

The invention discloses an emulsifying liquid wastewater membrane treatment process. The process comprises the steps of pretreatment, metal tube type membrane ultrafiltration and organic membrane pretreatment. The process has the advantages that the problem that the current emulsifying liquid wastewater treatment has high cost, complex operation, low treatment efficiency and poor comprehensive recycling effect can be effectively solved so that the oil content of the treated emulsifying liquid wastewater is 10mg / l or less, the suspended substance (SS) content is 30mg / l or less and the chemical oxygen demand (CODcr) is 100mg / l or less, the problem that the emulsifying liquid wastewater is treated and discharged according to the related standard or is reused is fully solved; and the comprehensive utilization of the emulsifying oil is realized, the treatment process is efficiency and energy-saving, is easy to operate and use, the environmental pollution is reduced, the cost is low, and the process has great economic and social benefits.

Owner:苏州凯新分离科技有限公司

Preparation method of lithium-rich anode material

ActiveCN103094550AImprove electrochemical performanceWell mixedCell electrodesSecondary cellsSlurryCobalt

The invention discloses a preparation method of a lithium-rich anode material having a chemical formula of xLi2O.yMOb (wherein M is at least one of Mn, Ni, Co and Al, x / y is greater than 0.51 and lower than 0.95, and b is not lower than 1 and not greater than 2). The method comprises the following steps: 1, weighing raw materials comprising a lithium sauce and at least one of a manganese source, a cobalt source, a nickel source and an aluminum source according to the molar ratio in xLi2O.yMOb; 2, adding a liquid into the raw materials, and grinding to form a slurry, wherein the median particle size D50 of particles of the slurry is less than 0.05mum; 3, drying the slurry in a spray manner; and 4, roasting the material obtained after drying. The method has the advantages of simple process and easy industrialized production; the primary particles of the obtained powder are small, and the secondary particles are spherical in shape; and the lithium-rich anode material prepared through adopting the method has a large discharge specific capacity, and the specific energy of the lithium ion battery prepared through using the lithium-rich anode material is high.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

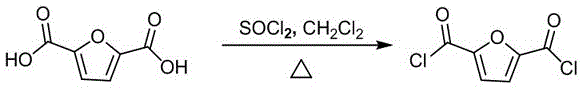

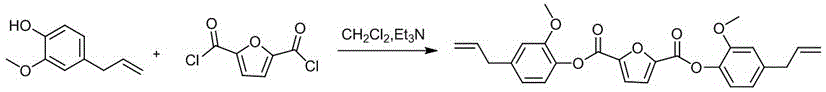

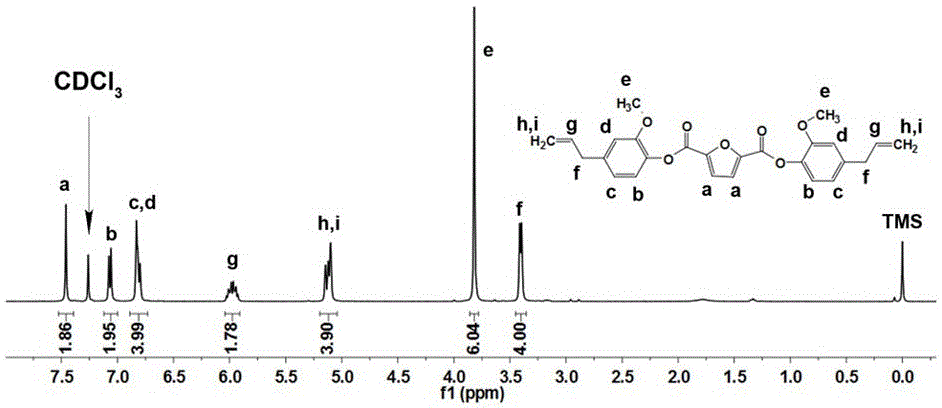

Modified bismaleimide resin and preparation method thereof

ActiveCN106700073AIncrease crosslink densityImprove thermal performanceOrganic chemistryFuranEugenol

The invention discloses a modified bismaleimide resin and a preparation method thereof. The method comprises the following steps: acidating biomass-based 2, 5-furandicarboxylic acid and thionyl chloride under the condition of using N,N-dimethyl formamide as the catalyst to obtain 2,5-furandicarbonyl dichloride, respectively dissolving the 2,5-furandicarbonyl dichloride and biomass-based eugenol in dichloromethane, and carrying out an esterification reaction under the condition of tertiary amine to obtain bis(4-allyl-2-methoxyphenyl)furan-2,5-dicarboxylic ester based on total biomass, and using the bis(4-allyl-2-methoxyphenyl)furan-2,5-dicarboxylic ester to prepare the modified bismaleimide resin. The modified bismaleimide resin prepared by the invention has excellent thermal performance and rigidity; and the preparation method adopts the biomass-based 2,5-furandicarboxylic acid and the biomass-based eugenol, the raw materials are green, environment-friendly and renewable, and the production process is simple, and the resin has a wide application prospect in the fields of aerospace, electronic information, electrical insulation and the like.

Owner:SUZHOU UNIV

Method for treating high-concentration acidic wastewater containing phosphorus and fluorine

InactiveCN102070267AReduce fluorine contentReduce phosphorus contentWater contaminantsMultistage water/sewage treatmentAluminium saltsChemistry

The invention discloses a method for treating acidic wastewater containing phosphorus and fluorine, which comprises the following steps: (1) firstly, adding calcium hydroxide into the acidic wastewater containing phosphorus and fluorine, and controlling the pH value of the system at 12-14 to obtain a precipitate-containing reaction system which is marked as a reaction system 1; (2) removing the precipitate in the reaction system 1, adding sulfuric acid into the residual liquid to regulate the pH value to 9-11, and then, adding aluminum sulfate to regulate the pH value to 6-7, thereby obtaining a precipitate-containing reaction system 2; and (3) settling down the precipitate in the reaction system 2, and removing the precipitate to obtain the treated wastewater. In the wastewater treated by the method disclosed by the invention, the content of fluorine is lower than 10 mg / L, the content of phosphorus is lower than 0.5 mg / L, and the pH value is 6-7, thus the treated wastewater achieves the Discharge Standard of Water Pollutants for Phosphate Fertilizer Industry (GB 15580-95). In the whole technological process, water overflows under the action of the gravity without an external energy supply, thereby saving the energy.

Owner:湖北大峪口化工有限责任公司

Domestic antistatic warp-knitted short floss sofa fabric

InactiveCN104088079AImprove antistatic performanceEnvironmentally friendly processingFibre typesWarp knittingEngineeringFilament yarn

The invention provides a domestic antistatic warp-knitted short floss sofa fabric. A preparation process of the domestic antistatic warp-knitted short floss sofa fabric comprises the following steps: firstly, weaving a piece of blank cloth, namely, weaving the blank cloth of a three-comb full-cross texture structure from long polyester yarns which are 5.6-12.4tex / 24-36F and used as surface yarns and another long polyester yarns which are 5.6-12.4tex / 24-36F and used as middle yarns and bottom yarns, wherein a front-comb full-cross floss stitch is formed into a bottom stitch, a middle-comb full-cross floss stitch is formed into a plain stitch, and the rear-comb full-cross stitch weaves for 3-11 needles to form a warp stitch; secondly, performing pretreatment, preforming, fluffing, refixing, ironing, dyeing, scotching, antistatic finish and ironing-cutting on the blank cloth to obtain the domestic antistatic warp-knitted short floss sofa fabric. The domestic antistatic warp-knitted short floss sofa fabric is relatively good in antistatic property.

Owner:ZHEJIANG LAIMEI TEXTILE & PRINTING & DYEING SCI TECH

Method for producing semi-tempered glass

ActiveCN102531365AProcess stabilityProcess energy savingGlass tempering apparatusToughened glassDouble stage

The invention relates to a method for producing semi-tempered glass. A double-stage cooling method is adopted in a cooling process of the method for producing the semi-tempered glass, namely secondary cooling is added on the basis of reservation of conventional primary cooling, so that the influence of abrupt change of wind pressure on the flatness of the glass is reduced in the cooling process, the semi-tempered glass with better flatness is obtained, and the effects of saving the cooling time, reducing the total energy-saving quantity of the semi-tempered glass to 10 percent of the prior art and promoting the flatness of the semi-tempered glass from 3 / 1,000 to 1 / 1,000 can be achieved.

Owner:LUOYANG NORTHGLASS TECH +2

Method for preparing reclaimed rubber by continuous low-temperature high shear

The invention relates to a method for preparing reclaimed rubber by continuous low-temperature high shear and belongs to the field of waste rubber recycling. The preparation method includes that by means of two or more serially connected screw extruders, preprocessed waste rubber powders are subjected to continuous low-temperature high shear actions of a plurality of the screw extruders to crush a three-dimensional cross-linked network of the waste rubber so as to obtain the reclaimed rubber. According to the method for preparing the reclaimed rubber by continuous low-temperature high shear, used devices are the two or more serially connected screw extruders, the technological process is simple, desulfuration temperatures are low, and the method has the advantages of being energy-saving, environment-friendly, continuous and high in stability of product qualities.

Owner:NANJING L J R RUBBE & PLASTIC CO LTD

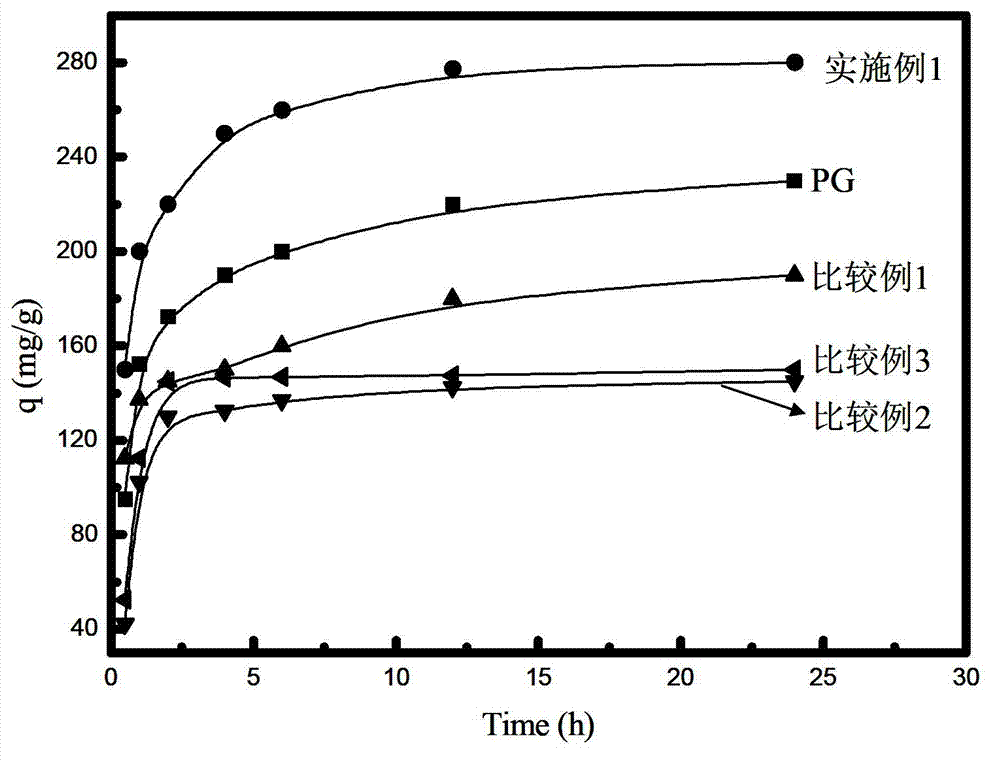

Method for improving adsorption property of attapulgite by using hydrothermal process

InactiveCN103191696AEasy to operateProcess energy savingOther chemical processesWater contaminantsReaction temperatureNuclear chemistry

The invention discloses a method for improving the adsorption property of an attapulgite by using a hydrothermal process. The attapulgite is treated by using the hydrothermal process, and treatment parameters such as reaction temperature, reaction time and raw material concentration are optimized, so that the adsorption property of the attapulgite can be remarkably improved. Compared with a natural attapulgite, the attapulgite subjected to hydrothermal treatment has the advantages that the specific surface area of the attapulgite is remarkably increased, and the equilibrium adsorption capacity of the attapulgite to methylene blue in water is remarkably increased. The equilibrium adsorption capacity of the raw ore of the attapulgite to the methylene blue is 220mg / g, the adsorption capacity of the attapulgite which is subjected to hydrothermal treatment at the temperature of 110 DEG C for 12h to the methylene blue is highest, and the equilibrium adsorption capacity is up to 277.5mg / g which is increased by 26% as comparison with that of the raw ore.

Owner:HEFEI UNIV OF TECH

Method for producing polyaluminum chloride without heating

The invention discloses a method for producing polyaluminum chloride without heating. The method comprises the following concrete steps: (1) sequentially adding a waste aluminum chloride liquor generated in a Friedel-Craft reaction, an aluminiferous hydrochloric acid, an industrial hydrochloric acid and water into a heat insulating reaction kettle to prepare a mixed acid in which the percentage of Al2O3 is 1% to 4% and the percentage of HCl is 12% to 18%; (2) adding aluminum oxidized sludge into the mixed acid, stirring for 60-90 minutes until the aluminum oxidized sludge is completely dissolved, heating to the reaction temperature of 60 DEG C to 80 DEG C, controlling the percentage of the HCl in a semi-finished product to be 0.5% to 3.5% and the percentage of the Al2O3 in the semi-finished product to be not less than 5.0%; (3) adding calcium aluminate powder into a semi-finished product liquid, regulating the percentage of the Al2O3 in the reaction liquid to be 11% to 12% and the basicity of the reaction liquid to be 60% to 90%, maintaining the temperature required by the reaction by utilizing the heat generated in the reaction, timing when the temperature rises to 90 DEG C, reaction under preserved temperature for 60-90 minutes and performing a filter pressing treatment to obtain a finished polyaluminium chloride product. By adopting the method to prepare the polyaluminium chloride, the production process is simple, no steam does need to be heated, the emission of acid mist and waste slag is reduced, the production cost is lowered and the recycle of waste resources is realized; therefore, the method is an economical and practical production method which saves energy and reduces emissions.

Owner:CHANGZHOU WUJIN YOUBANG WATER PURIFICATION MATERIALS

Processing method of complex raffinate

InactiveCN104261607AReduce processing costsReduce pollutionMultistage water/sewage treatmentWater/sewage treatment by heatingReverse osmosisCobalt

The invention discloses a processing method of complex raffinate. The processing method comprises the following steps of carrying out three-stage freezing crystallization on complex raffinate generated after P204 or P507 extraction in nickel-cobalt metallurgy and carrying out centrifugal separation to obtain purified sodium sulfate decahydrate crystals and a frozen-crystallized solution; adjusting the pH value of the frozen-crystallized solution and feeding the frozen-crystallized solution to a deaminizing device for deaminizing so as to recover ammonia water and valuable metals; concentrating the deaminized solution by virtue of DTRO (Disk Tubular Reverse Osmosis), carrying out hot melting on sodium sulfate decahydrate crystals, feeding into a MVR (Mechanical Vapor Recompression) evaporator for crystallizing, filtering, feeding to a fluidized bed and drying to obtain high-purity anhydrous sodium sulphate. Due to adoption of the process, zero emission and recycling of raffinate wastewater are achieved and the valuable metals are recovered, the high-purity anhydrous sodium sulphate product is prepared so that the processing method has the advantages of low energy consumption, resource conservation and the like.

Owner:ZHEJIANG HUAYOU COBALT

Heterogeneous and synchronous ultramicro original liquid extraction method and apparatus thereof

InactiveCN105169726ATo achieve the effect of separation and extractionLow boiling pointEvaporationActive componentConvection

The invention relates to the technical field of plant extraction, and especially relates to a heterogeneous and synchronous ultramicro original liquid extraction method and an apparatus thereof. The heterogeneous and synchronous ultramicro original liquid extraction method comprises the following steps: heating a plant full of water to 180-230DEG C, and cooling the upper portion of the plant to maintain the temperature in a range of 15-25DEG C and make the upper portion and a lower portion form convection current in order to form vacuum negative-pressure environment; cooling the plant to 75-95DEG C, and maintaining for 10-30h; and collecting the condensate liquid in the cooled position of the upper portion in order to obtain an extract liquid. The invention also provides the apparatus for enforcing the method. The apparatus comprises a raw material bin, an extraction bin, a heating device and a cooling device. A pyrolysis mode is adopted to rapidly puff cells in a raw material in order to make effective active components become micro-molecules easy to extract; the vacuum and negative-pressure low temperature extraction effectively protects nutrients in the raw materials; and fracture of molecular energy bonds supplements energy in the extraction process, so compared with traditional methods, the method disclosed in the invention has the advantages of environmental protection and energy saving.

Owner:陈峰

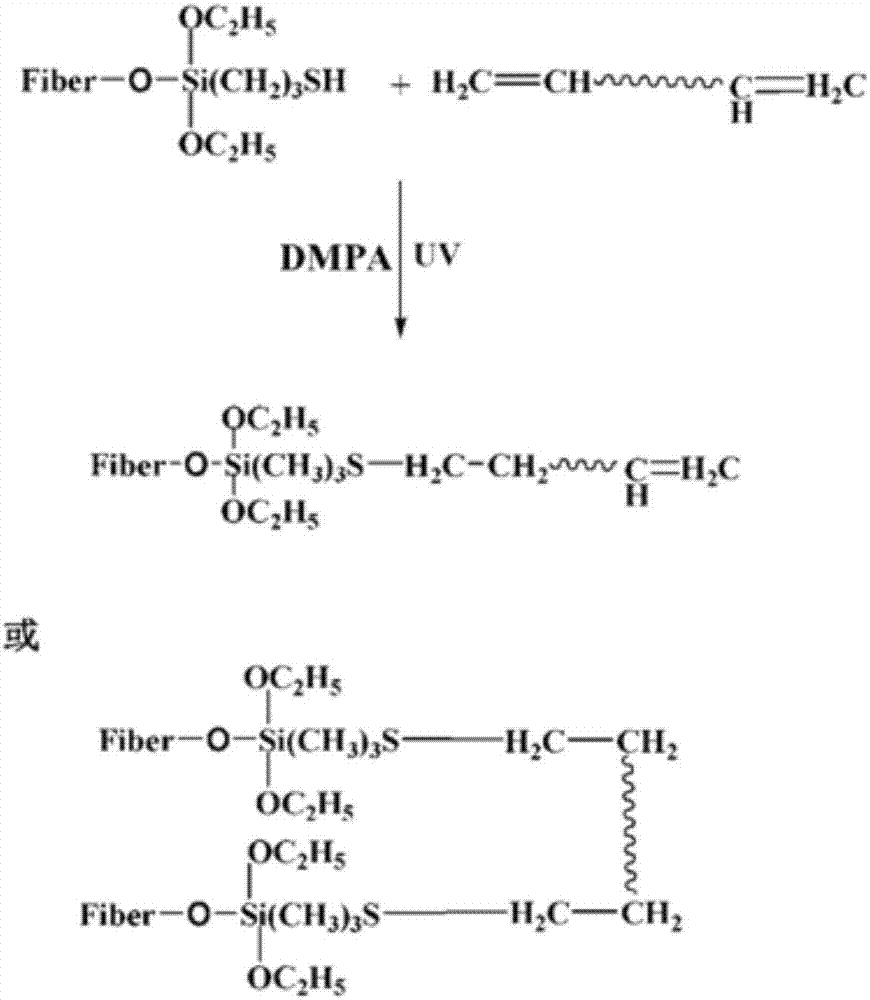

Click chemistry-based cotton fabric durable anti-crease finishing method

InactiveCN107299529AHarm reductionProcess energy saving and environmental protectionVegetal fibresTriethoxysilaneSilanes

The invention relates to a click chemistry-based cotton fabric durable anti-crease finishing method. The click chemistry-based cotton fabric durable anti-crease finishing method comprises the following steps: putting coarsened cotton fabric into a 3-thiopropyl triethoxy silane solution and performing sulfydryl modification to obtain sulfydryl modified cotton fabric; ultrasonically mixing photocurable waterborne polyurethane acrylate, sulfydryl silane and a photoinitiator to obtain finishing liquid; dipping the sulfydryl modified cotton fabric into the finishing liquid and performing ultraviolet curing to obtain the durable anti-crease cotton fabric. The method provided by the invention is simple in operation, high in efficiency, energy-saving and environmentally friendly; after finishing is conducted, the anti-crease effect is remarkable, the durability is high, and the influence on the whiteness of the fabric is little. After the cotton fabric is finished by the anti-crease process, the wearability can be improved, the application field can be enlarged, and the requirements of people on flat appearance and wear comfortability of clothes can be met.

Owner:DONGHUA UNIV

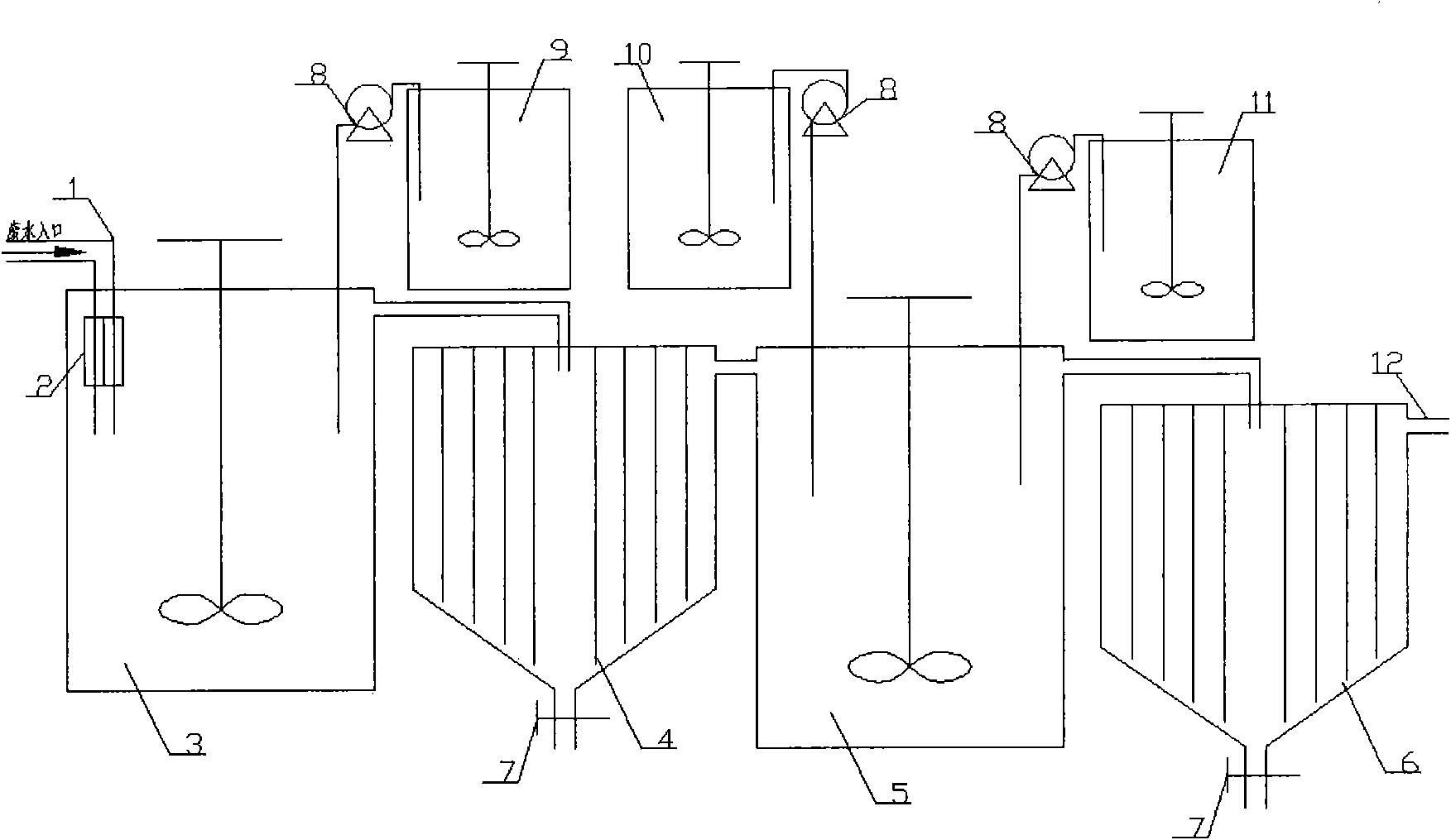

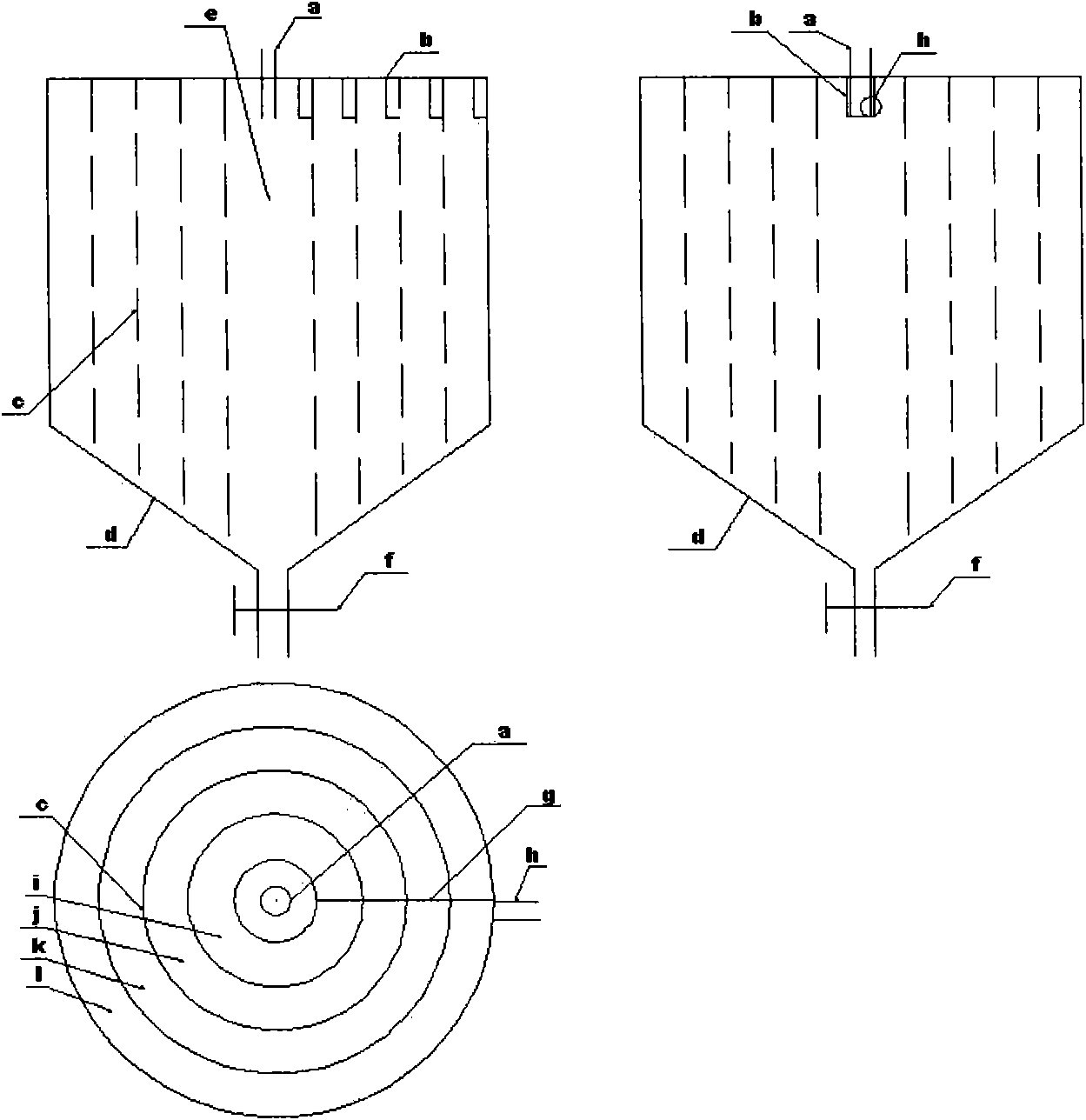

Method for producing hydrogen and/or methane through fermentation of fiber wastes and device thereof

InactiveCN101760481ASolve pollutionWidely used valueBioreactor/fermenter combinationsBio-organic fraction processingFiberLiquid storage tank

The invention provides a method for producing hydrogen and / or methane through fermentation of fiber wastes and a device thereof. The method comprises the following steps: smashing a straw into a certain grain diameter, placing into a hydrogen production reactor, adding a given amount of water and nutrient solution and then mixing with thermophile bacteria seed liquid together for fermentation to prepare the hydrogen; pumping hydrogen fermentation liquid into a liquid storage tank, continuously pumping into the hydrogen production reactor for fermentation to prepare the methane after pH is adjusted. Because of adopting fiber wastes, raw materials used by the invention have rich resource and low cost, effectively solve the resource problem of biological hydrogen production and overcome the problem that the fiber raw materials of the traditional straw are hard to effectively produce the hydrogen when being not subjected to pretreatment; and the semi-continuous hydrogen production is achieved through the fiber waste dynamic immobilization technology. The invention is easier to popularize and apply by adopting a coupled continuous methane production system and has the advantages of simple and highly-efficient method, energy conservation, low cost and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

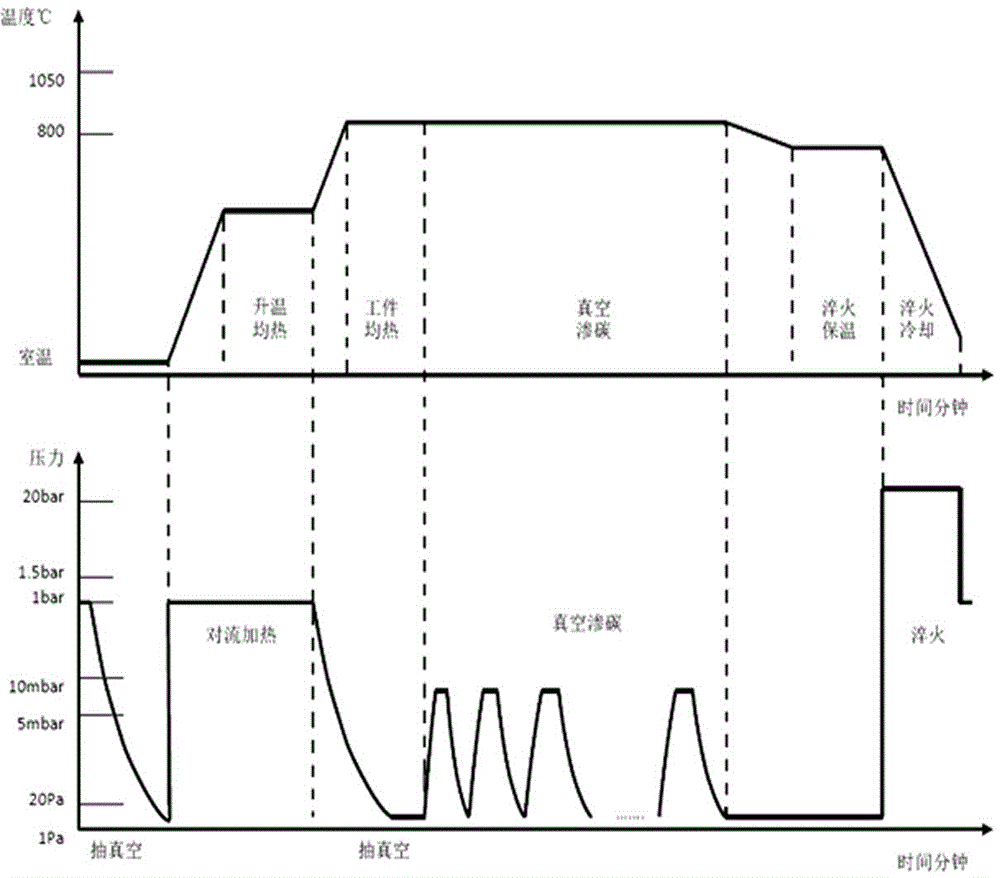

Low-pressure vacuum carburizing process

InactiveCN106756752AEffective control of surface carbon contentEffective control depthSolid state diffusion coatingMetallurgyPulse period

The invention discloses a low-pressure vacuum carburizing process. The low-pressure vacuum carburizing process comprises a temperature rising stage, a carburizing stage, a diffusing stage and a precooling stage. The temperature rising stage comprises the steps that a workpiece is vacuumized, and the vacuum degree is controlled within 1 Pa-20 Pa; and after vacuumizing is completed, heating is started, and the carburizing temperature ranges from 800 DEG C to 1050 DEG C. The carburizing stage comprises the steps that after the temperature of the workpiece reaches the set temperature of the process, acetylene gas is introduced into a furnace to maintain the carburizing gas partial pressure, which is named as a carburizing gas inflation pulse stage; after the carburizing gas inflation pulse stage is kept for a set time, vacuumizing is started, a certain time is kept under vacuum, which is named as a vacuumizing diffusion stage, and the carburizing gas inflation pulse stage and the vacuumizing diffusion stage are combined to serve as a carburizing pulse period; the whole carburizing stage is composed of a plurality of carburizing pulse periods; and when the carburized layer depth reaches the carburized layer depth set by the process, the carburizing pulse is stopped. The low-pressure vacuum carburizing process can effectively control the surface carbon content and the carburized layer depth of the workpiece, and the optimal carburizing effect of the workpiece is achieved.

Owner:上海先越冶金技术股份有限公司

Heat-insulation flame-retardant asphalt shingle and preparation method thereof

ActiveCN104358362ALow production temperatureProcess energy savingRoof covering using tiles/slatesLaminationPolyolefinButadiene-styrene rubber

The invention relates to a heat-insulation flame-retardant asphalt shingle and a preparation method thereof. The asphalt shingle comprises a glass fiber body, a modified asphalt coating, a facing material layer and an isolation material layer; the modified asphalt coating adopts the following raw material formula in percentage by weight: 30 percent to 50 percent of 10# petroleum asphalt, 5 percent to 10 percent of 90# road asphalt, 1 percent to 3 percent of a polyolefin processing modifier, 15 percent to 25 percent of magnesium hydroxide, 6 percent to 12 percent of rubber powder and the balance of filling; the facing material layer adopts the following raw material formula in percentage by weight: 30 percent to 40 percent of hollow ceramic microbeads, 2 percent to 5 percent of powder butadiene styrene rubber and the balance of color sand. The asphalt shingle disclosed by the invention has excellent fireproof, flame-retardant, heat insulation and heat preservation effects, aging resistance and low flexibility, has both decoration performance and attraction performance and is low in cost.

Owner:中建材苏州防水研究院有限公司

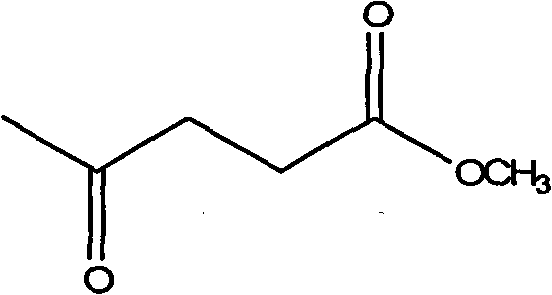

Method for preparing methyl ester levulinate by alcoholysis of hexamylose in near-critical methanol

InactiveCN101709033AFew reaction stepsSimple processOrganic compound preparationCarboxylic acid esters preparationSolventBoiling point

The invention discloses a method for preparing methyl ester levulinate by the alcoholysis of hexamylose in near-critical methanol. The method comprises the following steps of: (1) adding methanol, hexamylose and an acid catalyst into a high-pressure reaction kettle, replacing air in the kettle by using nitrogen gas after sealing, and stirring, wherein the mass concentration of the hexamylose is 10-120g / L, and the molarity of the acid catalyst is 0.01-0.20mol / L; (2) heating to the temperature of 150-200 DEG C and carrying out alcoholysis for 0.5-11h; (3) after finishing the alcoholysis, cooling to room temperature, opening an exhaust valve and collecting dimethyl ether; and (4) regulating the pH value of alcoholysis liquid to a neutral state, distilling off a product with low boiling point and a solvent by normal-pressure distillation and then decompressing and distilling to obtain the methyl ester levulinate. The invention reduces the purification of levulinate in the traditional process, prepares the methyl ester levulinate directly by a one-step method and has the advantages of simple process, high product yield, low cost, little three wastes and the like.

Owner:ZHEJIANG UNIV

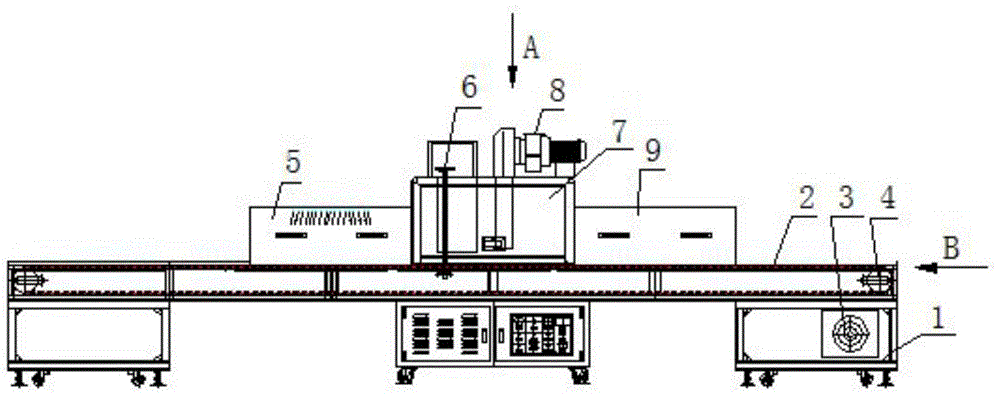

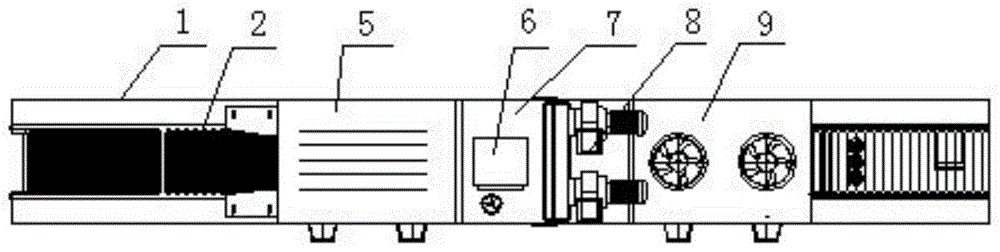

High-purity copper powder production process utilizing waste copper enameled wires

The invention discloses a high-purity copper powder production process utilizing waste copper enameled wires. The process includes S1, sorting, namely sorting capillary copper enameled wires with the diameters ranging from 0.04mm to 0.1mm, cleaning and drying the waste copper enameled wires sequentially; S2, conveying the sorted capillary copper enameled wires into a melting furnace and heating for pyrolysis in the sealed and oxygen-free environment, and cooling in a forced manner; S3, crushing and winnowing the furnace material formed by cooling after melting furnace heating pyrolysis, crushing the furnace material in a rough manner, and removing the active carbon ash produced by pyrolysis; S4, performing ball milling or turbine self-cooling crushing and screening operation on rough-crushed furnace material sequentially to obtain high-purity copper powder. The process is capable of producing high-level copper powder through short procedures and low cost.

Owner:铜陵市卓翔铜材科技有限公司

Livestock waste nutrient recovery and water quality standard-reaching technical method

InactiveCN108640453AUnderstand the purposeLearn about featuresExcrement fertilisersWaste water treatment from animal husbandryChemical reactionSlag

The invention discloses a livestock waste nutrient recovery and water quality standard-reaching technical method. According to the invention, primary solid-liquid separation is carried out on livestock waste, the separated solid manure slag is taken as an organic fertilizer raw material nutrient for outward transport for sale for benefit-increasing cycle utilization or returning utilization, scientific circulation uses combination of farming and animal husbandry, urine through emission reduction, solid-liquid separating and interception, sewage and domestic water flow into an equalizing tank,a solid-liquid separating biological slag removal apparatus, a black film methane tank, a combination reaction environmental-protection pool, a MBR membrane pool, and a ball algae treatment pool in order for multilevel processing, during a whole process, solid-liquid-gas omnibearing processing utilization is carried out on waste, the method is characterized in that biogas is used for generating orproduction and living, the processed water is subjected to nutrient recovery and returning utilization, the filtered manure slag stockyard is subjected to organic fertilizer recovery or returning utilization, and the energy cycle utilization is realized. The processed reclaimed water through a chemical reaction can reach standard time-limited zero pollution discharge, and the environmental protection performance is good.

Owner:HUIZHOU BAIOUJIA TECH

Low-temperature plasma treating process for pigment ink digital injection stamping fabric

InactiveCN101113567AClear patternBright colorUltrasonic/sonic fibre treatmentDyeing processTextile printerWater saving

The invention relates to a plasma body treatment technology of a textile used for colorant ink digital ink jet printing under low temperature, pertaining to fabric printing technical field. The invention is characterized in that the textile is put into a reaction chamber of a processor to be treated by low temperature plasma: the procedure is that: the non-collective air is flowed in, pressure adjusted, then discharged; the colorant ink is jetted and printed to textile treated by low-temperature plasma through a jet-printing machine, thus, the finished products are acquired after the textile being baked. The invention uses non-polymerized gas and low temperature plasma to modify the surface of the textile to improve moisture absorption and hydrophilicity of the modified textile, thus avoiding the problem of bleeding and too light color caused by fabric jet printing directly. The technology is characterized by rapidness, simplicity, water saving, energy conversation, harmlessness and environmental protective, etc.

Owner:JIANGNAN UNIV

Light curing forming process for resin lens

InactiveCN105690783AHigh technology automationExcellent performanceOptical articlesSolid-stateUV curing

The invention provides a light curing forming process for a resin lens. The light curing forming process comprises the following steps of raw material blending, raw material pouring, ultraviolet light curing, mold making and postcuring; specifically, blended monomer raw materials are put into a special curing machine after raw material pouring, a to-be-cured mold are sequentially subjected to an IR preheating stage, a UV curing stage, a cooling stage and then discharging; after the mold receives light energy at the UV curing stage, monomers are polymerized into a solid state from the liquid state in the mold; and a preliminarily formed product obtained through mold making is fed into a postcuring furnace, and a finally formed product is obtained after curing. Light-heat combination curing is adopted for the light curing forming process for the resin lens, a forming cycle only needs several minutes, and the light curing forming process is a first creation in China and in the world. The light curing forming process for the resin lens is different from the current resin lens heat curing forming process of which a forming cycle needs twenty hours. The light curing forming process for the resin lens is capable of saving energy, protecting the environment, efficient, high in technological automation, simple and easy to learn. The finished product is more excellent in performance through detection.

Owner:蔡征宇 +3

Process for treating top gas of reduction shaft furnace

ActiveCN101603109ALess investmentEliminate the pressurization stepShaft furnaceGas emission reductionShaft furnaceMaterials science

The invention belongs to the metallurgical chemical technology, and relates to a process for treating top gas of a reduction shaft furnace. The treatment process is characterized in that after the top gas exhausted from the reduction shaft furnace is subjected to dust removal and cooling treatment, the top gas enters a carbon removal system to remove CO2 in the gas; and one part of the carbon removal gas after carbon removal and compression is directly mixed with the high-temperature gas exhausted from a smelting gas-making furnace to enter the reduction shaft furnace, and the other part of the carbon removal gas is heated and then enters the reduction shaft furnace. The process for treating the top gas of the reduction shaft furnace has the advantages of reasonable flow, optimized energy conservation and discharge reduction and technical domestication, and can be used for an iron-making process of an SDRF furnace.

Owner:CISDI ENG CO LTD

Ceramic surfacing-welding electrode for restoring ceramic composite steel pipe and surfacing-welding method

InactiveCN101704171AGood chemical stabilityHigh hardnessArc welding apparatusWelding/cutting media/materialsCeramic compositeRound bar

The invention relates to a ceramic surfacing-welding electrode for restoring a ceramic composite steel pipe and a surfacing-welding method. The surfacing-welding method comprises the following processes: preparing an aluminium thermal soldering flux, adding alumina of different proportions in the aluminium thermal soldering flux and uniformly mixing the mixture respectively so as to prepare the aluminium thermal soldering flux containing the alumina of different proportions, and mixing a water-soluble organosol and the aluminium thermal soldering flux containing the alumina of different proportions; subsequently adopting a hydraulic machine and an upper semi-round die as well as a lower semi-round die to press and prepare a prefabricated blank semi-finished product of the round bar-shaped ceramic electrode; subsequently, arranging the prefabricated blank semi-finished product of the round bar-shaped ceramic electrode in a drying furnace which is vacuum or protected by argon, heating the drying furnace to the temperature of 350 plus or minus 100 DEG C, drying the drying furnace so as to remove the gas for 4 plus or minus 1 hours; burning the gas; burying the semi-finished product in the sand after burning; waiting for natural cooling and obtaining the round bar-shaped ceramic electrode; adopting an argon arc welder to carry out surfacing-welding operation layer by layer at a damaged position of the ceramic composite steel pipe by adopting the ceramic electrode according to the proportion of the alumina from high to low; and completing the restoration after surfacing-welding and grinding. The ceramic composite steel pipe restored by the method has good high temperature resistance.

Owner:江阴东大新材料研究院

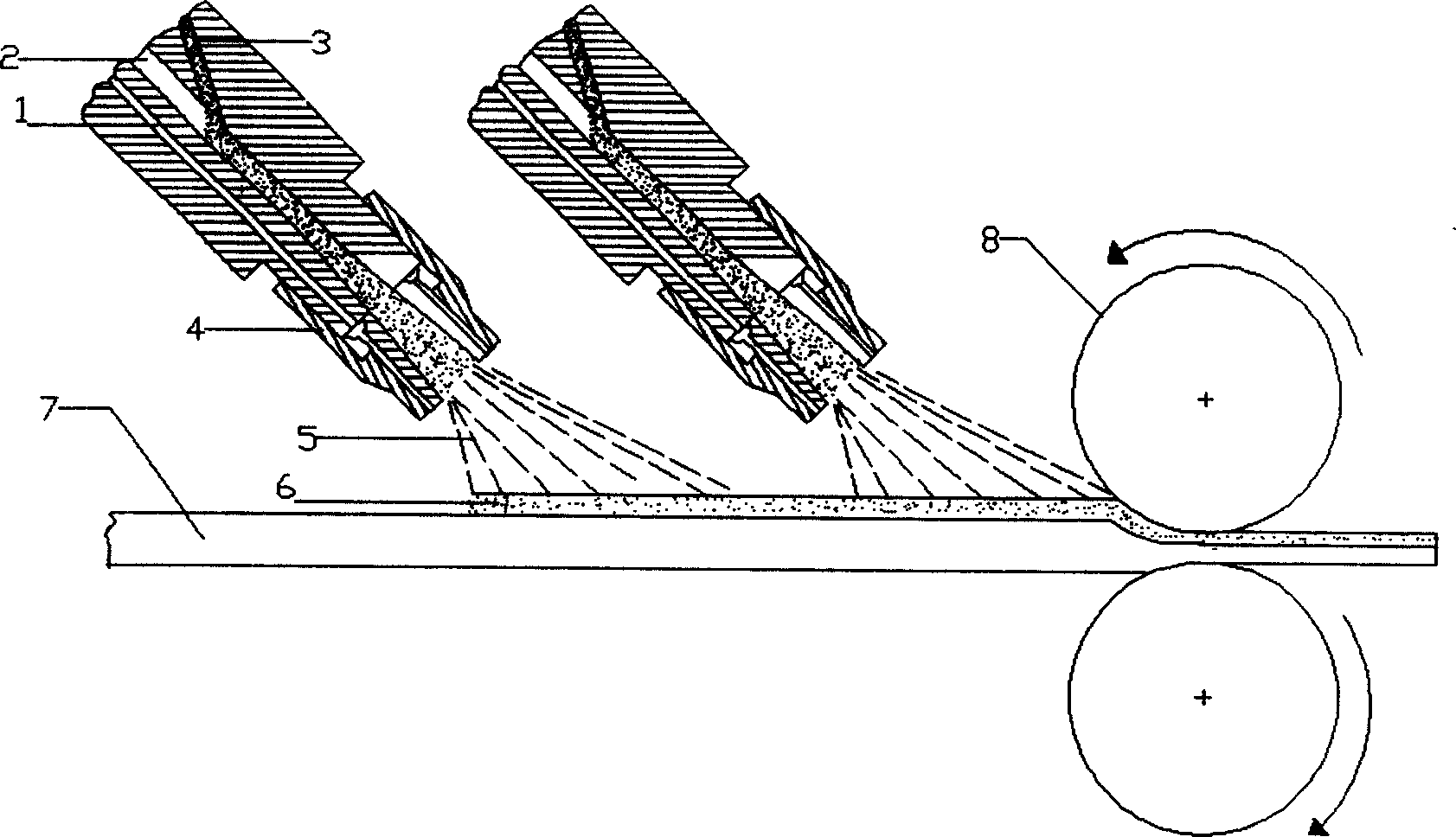

Method for preparing metal ceramic gradient coated steel plate by self-stretching continuous mill

InactiveCN1743089AFully meltedLight in massMolten spray coatingMetal rolling arrangementsProduction lineSelf-propagating high-temperature synthesis

On the hot-rolling production line, before the steel sheet to be hot-rolled is fed into hot-rolling rolls a self-spreading metal-ceramic gradient coating layer can be hot-sprayed on the surface of said steel sheet to be hot-rolled, after the hot-spraying process is completed, said steel sheet can be promptly hot-rolled, so that on the surface of steel sheet a Ti-C-Ni gradiet coating layer with excellent comprehensive performance can be formed. Said invention also provides the concrete steps of said hot-spraying process and the composition of said coating layer.

Owner:JIANGSU FASTEN TECH DEV CENT

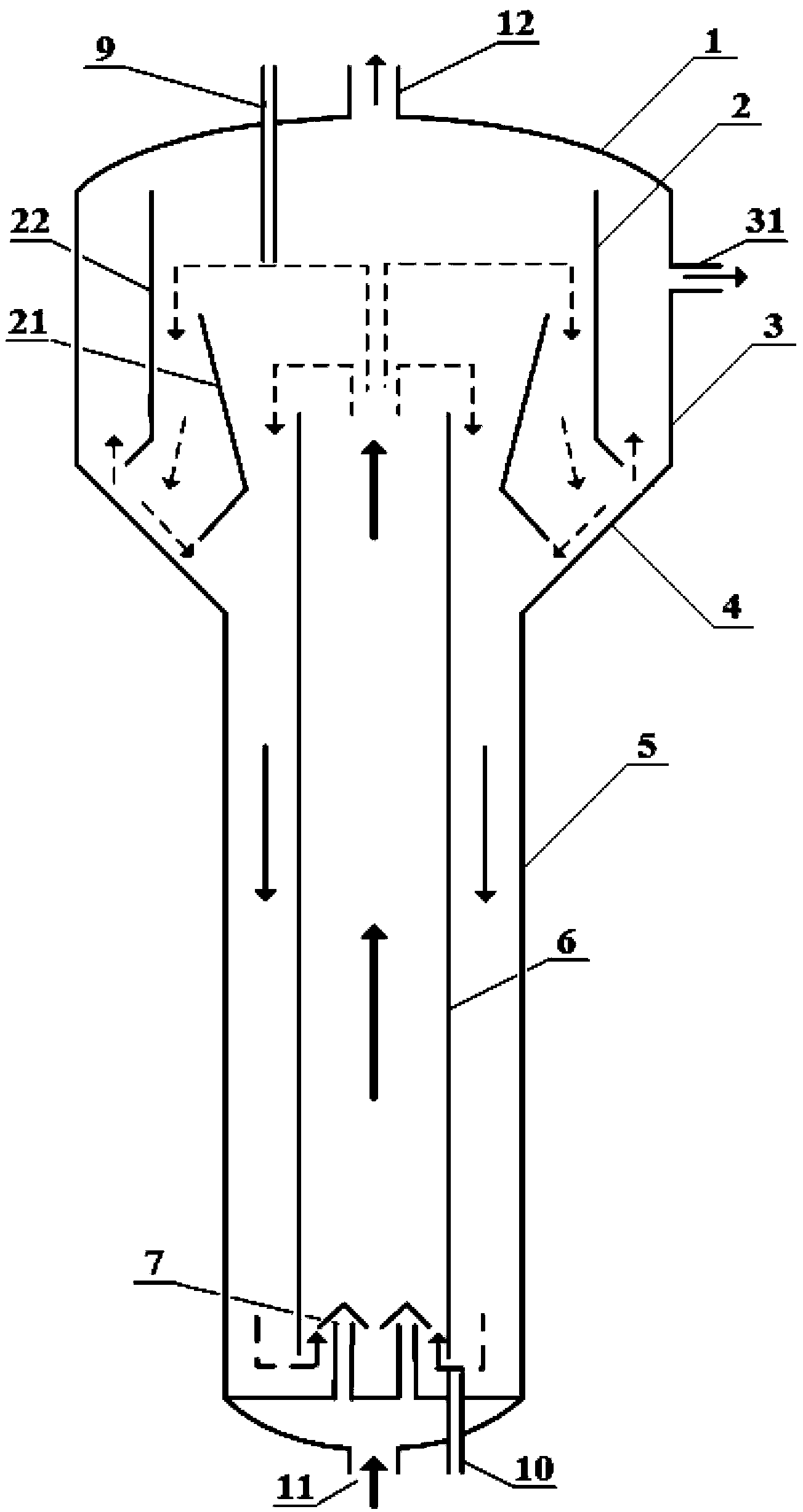

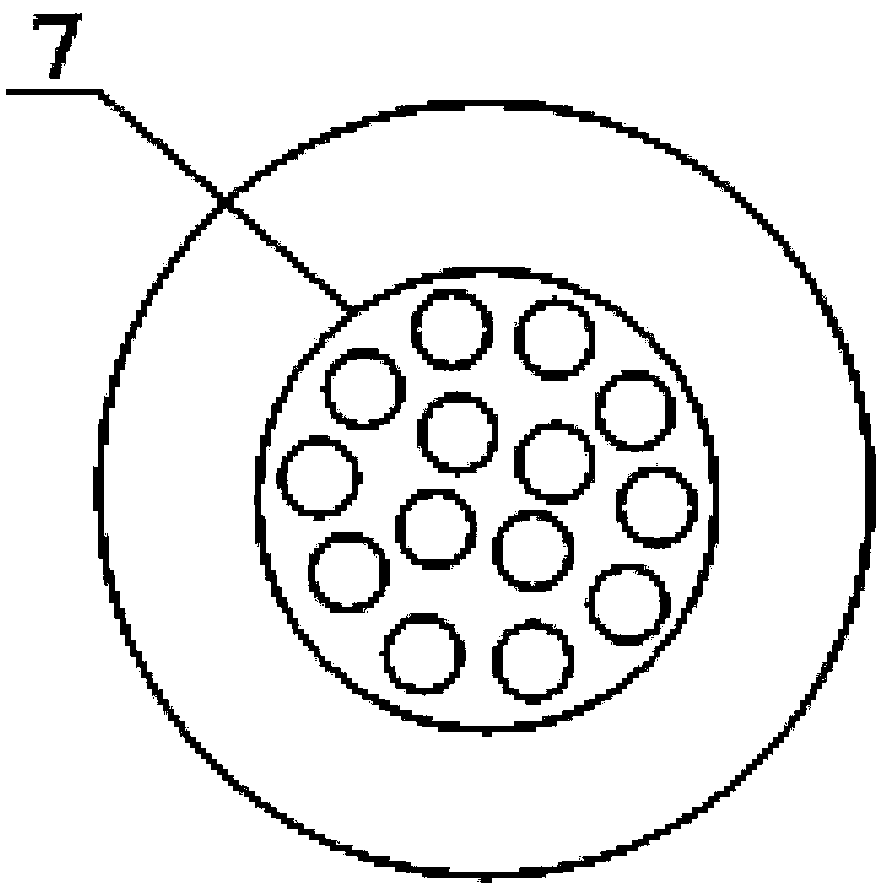

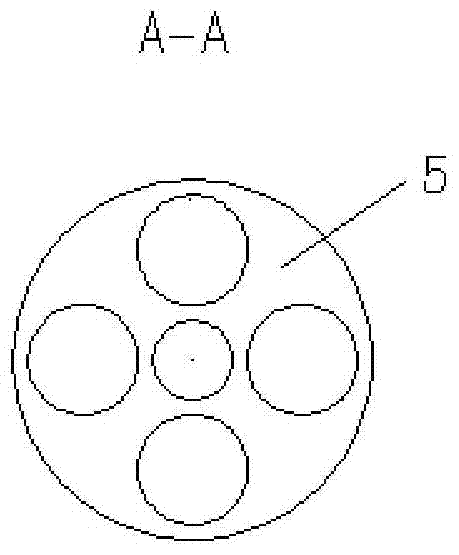

Fluidized bed reactor

ActiveCN103769010AProcess energy savingEasy to operateChemical/physical processesHydrogenFluidized bed

The present invention relates to a fluidized bed reactor, which comprises a housing and a three-phase separation part, wherein the housing sequentially comprises an enlargement section, a transition section and a straight tube section from top to bottom, the three-phase separation part is arranged inside the enlargement section and the transition section, and the side wall of the enlargement section is provided with a liquid discharge port. The fluidized bed reactor further comprises an inner pipe and a gas-liquid distributer, wherein the inner pipe is arranged inside the housing and extends from the lower portion of the straight tube section to the lower portion of the enlargement section, the lower end opening of the inner pipe is communicated with the straight tube section, the upper end opening of the inner pipe is communicated with the enlargement section, the three-phase separation part is distributed around the upper portion of the inner pipe, and the gas-liquid distributer is arranged in the straight tube section and is positioned on the bottom of the inner pipe. According to the fluidized bed reactor, material circulation can be driven completely through the kinetic energy of the material on the inlet and the density difference of the materials in different areas in the reactor, such that the whole process has the characteristic of energy saving; and the reactor utilization efficiency is high, such that the generation of the thermal cracking reaction in the absence of the hydrogen can be substantially reduced during the heavy oil hydrocracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

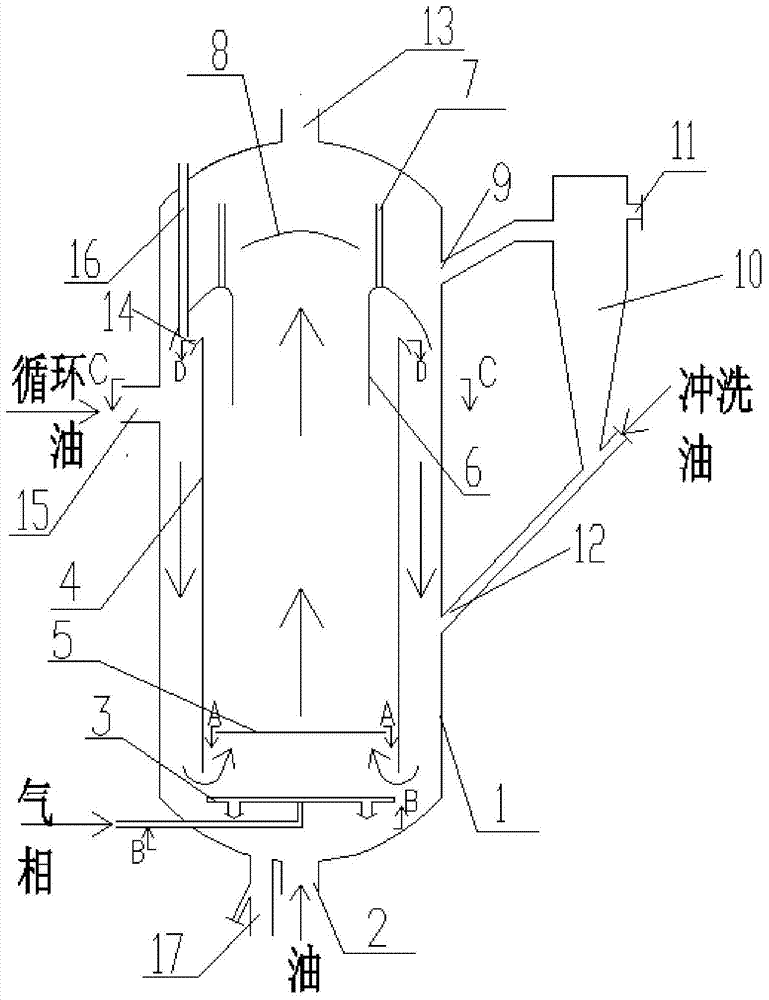

A kind of internal circulation ebullating bed reactor

ActiveCN105363392BUniform temperatureImprove heat transfer performanceChemical/physical processesFluidized bedReaction zone

The invention discloses an inner circulation fluidized bed reactor. The reactor includes a shell, and the shell includes a three-phase separation section and a reaction section from top to bottom; it also includes a three-phase separation component arranged in the three-phase separation section; a flow guide is set in the reaction section Cylinder; a gas uniform distribution device is arranged under the opening of the lower end of the flow guiding cylinder, at least one material distributor is arranged in the inside of the guiding cylinder and above the gas uniform distribution device, and on the outer wall of the upper opening of the guiding cylinder A number of baffles are set; a baffle plate arranged above the guide structure is also included; and a number of gas separation pipes connected with the guide structure are also included. The above-mentioned reactor produces directional circulation in the reactor, which saves energy in the process; fresh material and circulating oil are fed in different areas, which strengthens the circulation flow mode; strengthens oil-gas mixing and gas-liquid distribution, and gas disturbance can effectively avoid the dead zone at the bottom of the reactor. Generated, and can act as a buffer to reduce the impact on the distribution plate.

Owner:HUADIAN HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com