Method for improving adsorption property of attapulgite by using hydrothermal process

A technology of attapulgite and adsorption performance, applied in chemical instruments and methods, adsorbed water/sewage treatment, water pollutants, etc., can solve the problems of high energy consumption, high cost, cumbersome modification methods, etc. The effect of improving adsorption performance and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

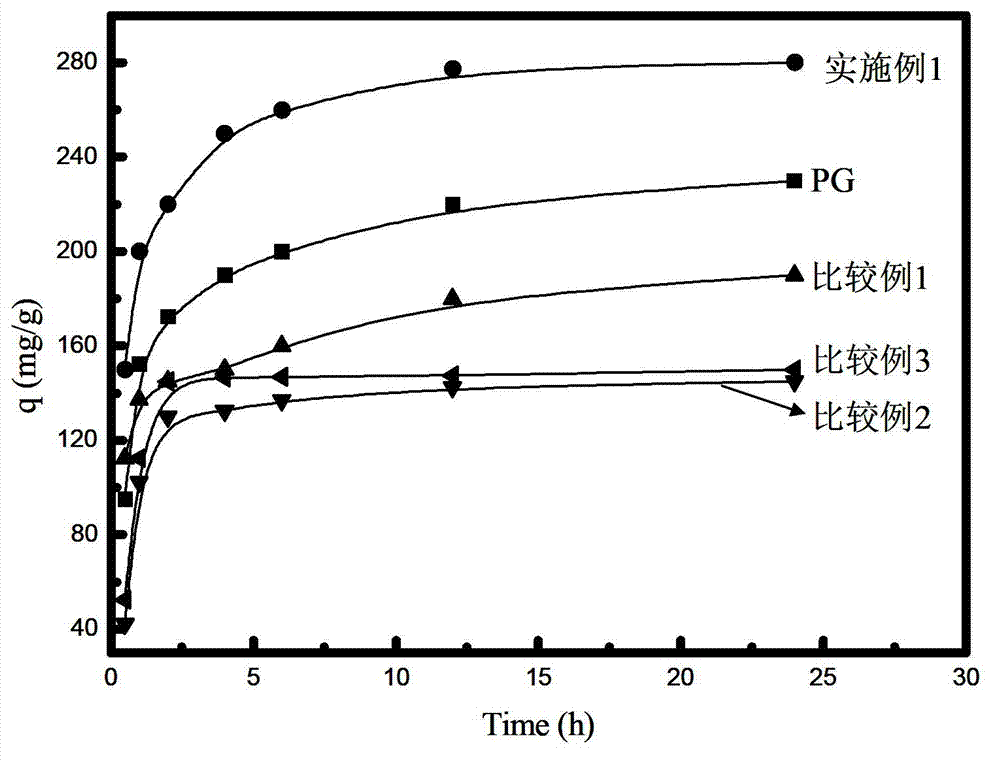

Embodiment 1

[0022] Pulverize the attapulgite clay ore with a content of 95wt% attapulgite and pass it through a 200-mesh sieve to obtain attapulgite powder, take 1 g of attapulgite powder, add 16 mL of distilled water, stir with a magnetic stirrer for 2 hours, and mix the solution uniformly to obtain a mixed solution , the pH value of the mixture was measured at 7;

[0023] The mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, the reaction temperature was 110 °C, and the reaction time was 12 h; after the reaction, it was naturally cooled to room temperature, centrifuged, washed with water, and dried at 60 °C to obtain the modified unevenness. stick rock.

[0024] It can be seen from the infrared spectrum analysis that after hydrothermal treatment, at 1656 cm -1 The intensity of the peaks is weakened. This is because during the hydrothermal reaction, the attapulgite removes water molecules of different forms, thereby weakening the intensity of the peaks (se...

Embodiment 2

[0028] Pulverize the attapulgite clay ore with a content of 95wt% attapulgite and pass through a 200-mesh sieve to obtain attapulgite powder, take 1g of attapulgite powder, add 8mL of distilled water, stir with a magnetic stirrer for 2h, and mix the solution uniformly to obtain a mixed solution , the pH value of the mixture was measured at 7;

[0029] The mixed solution was transferred to a polytetrafluoroethylene hydrothermal kettle, the reaction temperature was 110 °C, and the reaction time was 12 h; after the reaction, it was naturally cooled to room temperature, centrifuged, washed with water, and dried at 60 °C to obtain the modified unevenness. stick rock.

[0030] It can be seen from the BET value analysis that the BET value of the obtained modified attapulgite is 225, which is higher than that of the original attapulgite (see Table 1).

[0031] Take the methylene blue solution with an initial concentration of 500mg / L as the organic pollutant, the solid-liquid ratio of...

Embodiment 3

[0033] Pulverize the attapulgite clay ore with a content of 95wt% attapulgite and pass through a 200-mesh sieve to obtain attapulgite powder, take 1g of attapulgite powder, add 32mL of distilled water, stir with a magnetic stirrer for 2h, and mix the solution uniformly to obtain a mixed solution , the pH value of the mixture was measured at 7;

[0034] The mixed solution was transferred to the polytetrafluoroethylene hydrothermal kettle, the reaction temperature was 110°C, and the reaction time was 12h; after the reaction was finished, it was naturally cooled to room temperature, and after centrifugation and washing with water, drying was performed at 60°C to obtain a modified solution. Sexual attapulgite.

[0035] It can be seen from the BET value analysis that the BET value of the obtained modified attapulgite is 216, which is higher than that of the original attapulgite (see Table 1).

[0036] Take the methylene blue solution with an initial concentration of 500mg / L as the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com