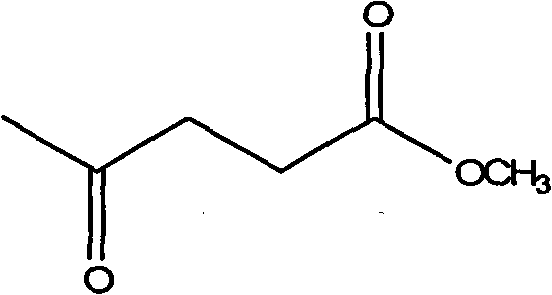

Method for preparing methyl ester levulinate by alcoholysis of hexamylose in near-critical methanol

A technology of methyl levulinate and hexavalent sugar alcohol, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of high operating costs, reduce the reaction temperature, shorten the reaction time, The effect of reducing the reaction steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add methanol 300mL, glucose 3g and sulfuric acid (98%) 0.6g (glucose mass concentration is 10g / L, sulfuric acid molar concentration 0.02mol / L) in 500mL intermittent autoclave, replace the air in the kettle with nitrogen after airtight, start stirring ; heat up to 170°C for alcoholysis for 4 hours; after alcoholysis, cool to room temperature, open the exhaust valve to collect dimethyl ether; add sodium bicarbonate aqueous solution to the alcoholysis solution to adjust the pH value to neutral, and distill under normal pressure to remove the low boiling point The product and solvent were then distilled under reduced pressure to obtain 0.61 g of methyl levulinate, with a molar yield of 28.1% and a purity of 98.1% (GC).

Embodiment 2

[0027] Add methanol 300mL, glucose 6g and sulfuric acid (98%) 0.3g (glucose mass concentration is 20g / L, sulfuric acid molar concentration 0.01mol / L) in 500mL intermittent autoclave, replace the air in the kettle with nitrogen after airtight, start stirring ; heat up to 170°C for alcoholysis for 4 hours; after alcoholysis, cool to room temperature, open the exhaust valve to collect dimethyl ether; add sodium bicarbonate aqueous solution to the alcoholysis solution to adjust the pH value to neutral, and distill under normal pressure to remove the low boiling point The product and solvent were then distilled under reduced pressure to obtain 0.94 g of methyl levulinate, with a molar yield of 21.6% and a purity of 98.5% (GC).

Embodiment 3

[0029] Add methanol 300mL, glucose 6g and sulfuric acid (98%) 1.2g (glucose mass concentration is 20g / L, sulfuric acid molar concentration 0.04mol / L) in 500mL intermittent autoclave, replace the air in the kettle with nitrogen after airtight, start stirring ; heat up to 170°C for alcoholysis for 4 hours; after alcoholysis, cool to room temperature, open the exhaust valve to collect dimethyl ether; add sodium carbonate aqueous solution to the alcoholysis solution to adjust the pH value to neutral, and distill off the low boiling point products under normal pressure and solvent, and then distilled under reduced pressure to obtain 1.77 g of methyl levulinate, with a molar yield of 40.7% and a purity of 97.5% (GC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com