Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

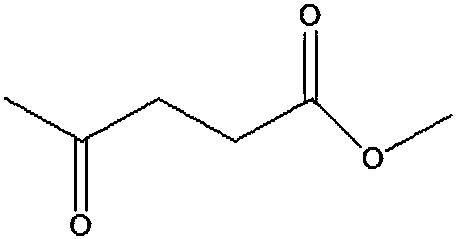

52 results about "Methyl levulinate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-synthetic metal cutting fluid

InactiveCN104830513AImprove cooling effectGood anti-corrosion and anti-rustAdditivesCarboxylic saltEngineering

The invention relates to cutting fluid, in particular to semi-synthetic metal cutting fluid. The semi-synthetic metal cutting fluid is prepared by methyl levulinate, (R)-(+)-2,4-dyhydroxy-N-(3-hydroxypropyl)-3,3-dimethylbutyramide, 2-oxo-1,5-disoidum glutarate dihydrate, 4-piperidone-3-carboxylate hydrochloride and trimethylsilylketene. The semi-synthetic metal cutting fluid has good cooling, anticorrosion, antirust and lubricating performance, service life of a knife can be prolonged effectively, and excellent machining accuracy can be realized; the semi-synthetic metal cutting fluid can play a role in safely and reliably protecting and inhibiting corrosion of nonferrous metal like aluminum and steel and ferrous metal, so that time and cost for subsequent treatment can be omitted; the semi-synthetic metal cutting fluid is suitable for being widely popularized and applied in the field of the cutting fluid.

Owner:烟台顺隆化工科技有限公司

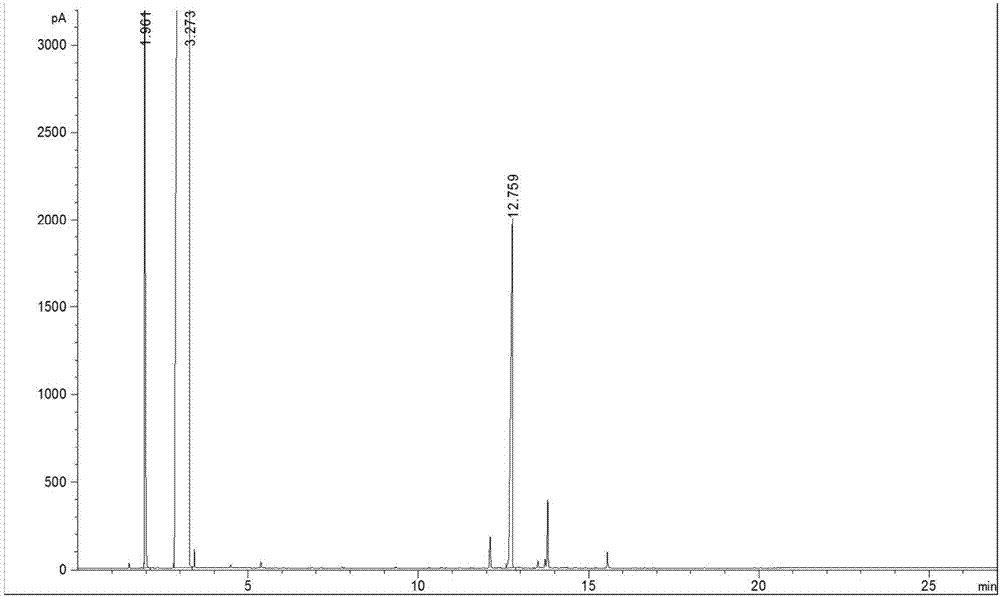

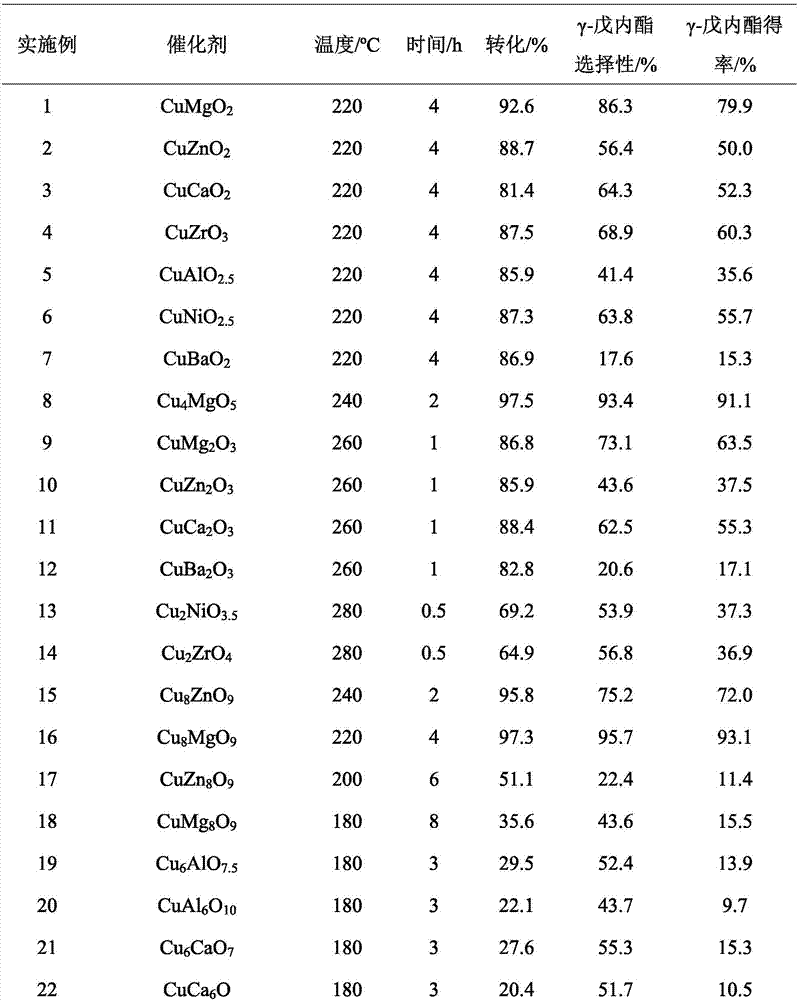

Synthetic method of gamma-valerolactone

ActiveCN107253937AImprove catalytic performanceImprove reusabilityOrganic chemistryAlcoholRoom temperature

The invention discloses a synthetic method of gamma-valerolactone. The synthetic method of gamma-valerolactone comprises the following steps of: (1) fully mixing methyl levulinate with an alcohol to obtain a mixed raw material liquid, wherein the concentration of the methyl levulinate in the mixed raw material liquid is 2-12wt%; and (2) adding a double metal catalyst into the mixed raw material liquid, heating the mixed raw material liquid in a high pressure reaction kettle to 170-290 DEG C to react for 0.5-9h, and cooling the mixture to room temperature to obtain gamma-valerolactone. By applying a copper-based double metal catalyst, the activity of the catalyst is adjusted by doping a second active metal, so that gamma-valerolactone can be prepared by catalytic in-situ hydrogen production by alcohol and selective catalytic hydrogenation of methyl levulinate.

Owner:XIAMEN UNIV

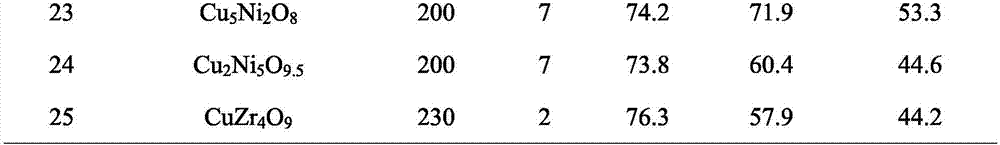

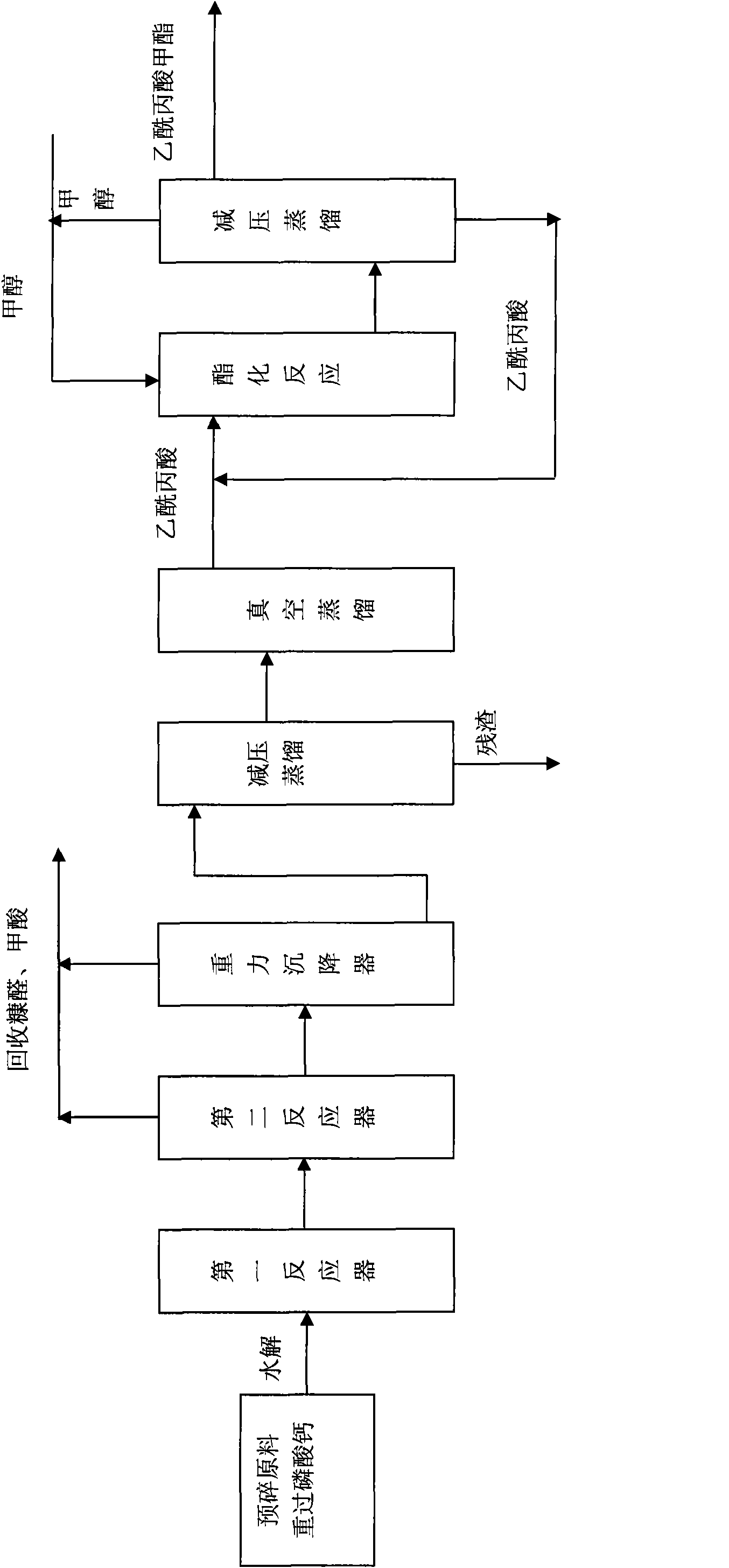

Method for preparing methyl levulinate through clean conversion of biomass sugar and separating methyl levulinate

InactiveCN102399144AReduce generationStable pressureOrganic compound preparationCarboxylic acid esters separation/purificationChemical industryLiquid product

The invention discloses a method for preparing methyl levulinate through the clean conversion of biomass sugar and separating methyl levulinate. The method comprises the following steps: 1, calcinating a solid acid at 300-700DEG C for 1-5h; 2, adding a biomass sugar methanol solution with the mass concentration of 10-200g / L and the solid acid to a high pressure reactor to obtain a mixed solution; 3, heating the mixed solution to 180-220DEG C, and keeping the temperature for 1-5h; 4, cooling to room temperature, and separating a solid catalyst from a liquid product by filtering; 5, carrying out normal pressure distillation on the liquid product to remove low boiling point substances to obtain a residue; and 6, adding a distillation assistant to the residue, and carrying out reduced pressure distillation to obtain methyl levulinate. The method of the invention, which adopts the clean solid super acid to catalyze the conversion of the biomass sugar into methyl levulinate and has the advantages of no corrosion to equipment, easy separation of the catalyst from the product, environment protection and the like, accords with the greening development trend of the current chemical industry.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing methyl levulinate by utilizing plant straws

InactiveCN102060704AHigh purityHigh yieldOrganic compound preparationCarboxylic acid esters preparationAlcoholAcid hydrolysis

The invention discloses a method for preparing methyl levulinate by utilizing plant straws, comprising the steps of: (1) leading the plant straws and triple superphosphate to undergo acid hydrolysis reaction to prepare levulinate; and (2) undergoing esterification reaction on the levulinate and methyl alcohol. For the methyl levulinate prepared with the method, the yield is high, the purity of products is high, the yield of levulinic acid as an intermediate product prepared by reaction of the straws and the triple superphosphate and hydrolysis under the conditions of high temperature and high pressure is high, the triple superphosphate is degraded gradually in reaction to form acidity in medium, H<+> ions are softly released, the polymerization and the coking of reactants are effectively inhabited, the yield of the levulinic acid as an intermediate product is high, the corrosion to the equipment is less, the process is simple and the environmental pollution is less.

Owner:INNER MONGOLIA JINDI BIOMASS

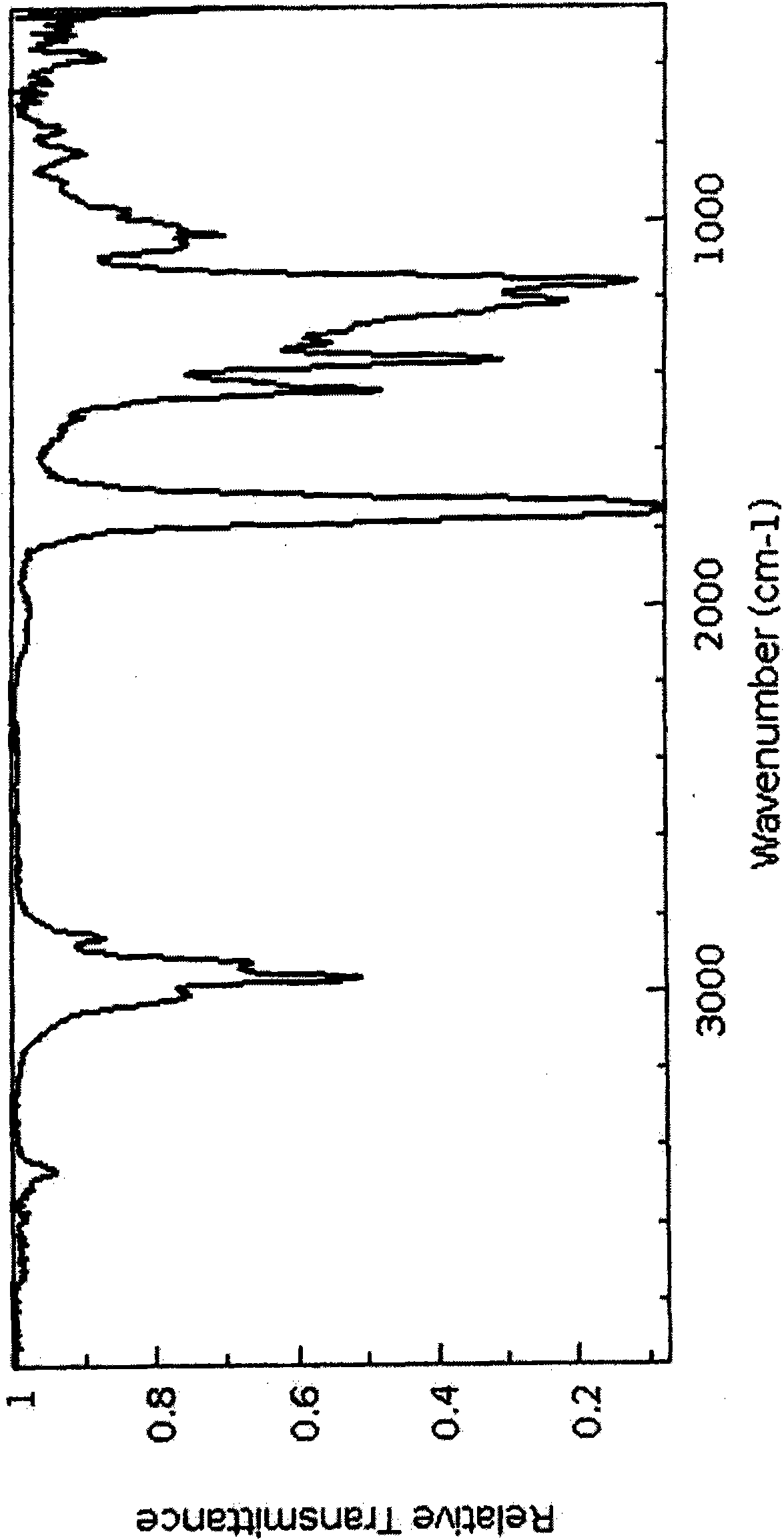

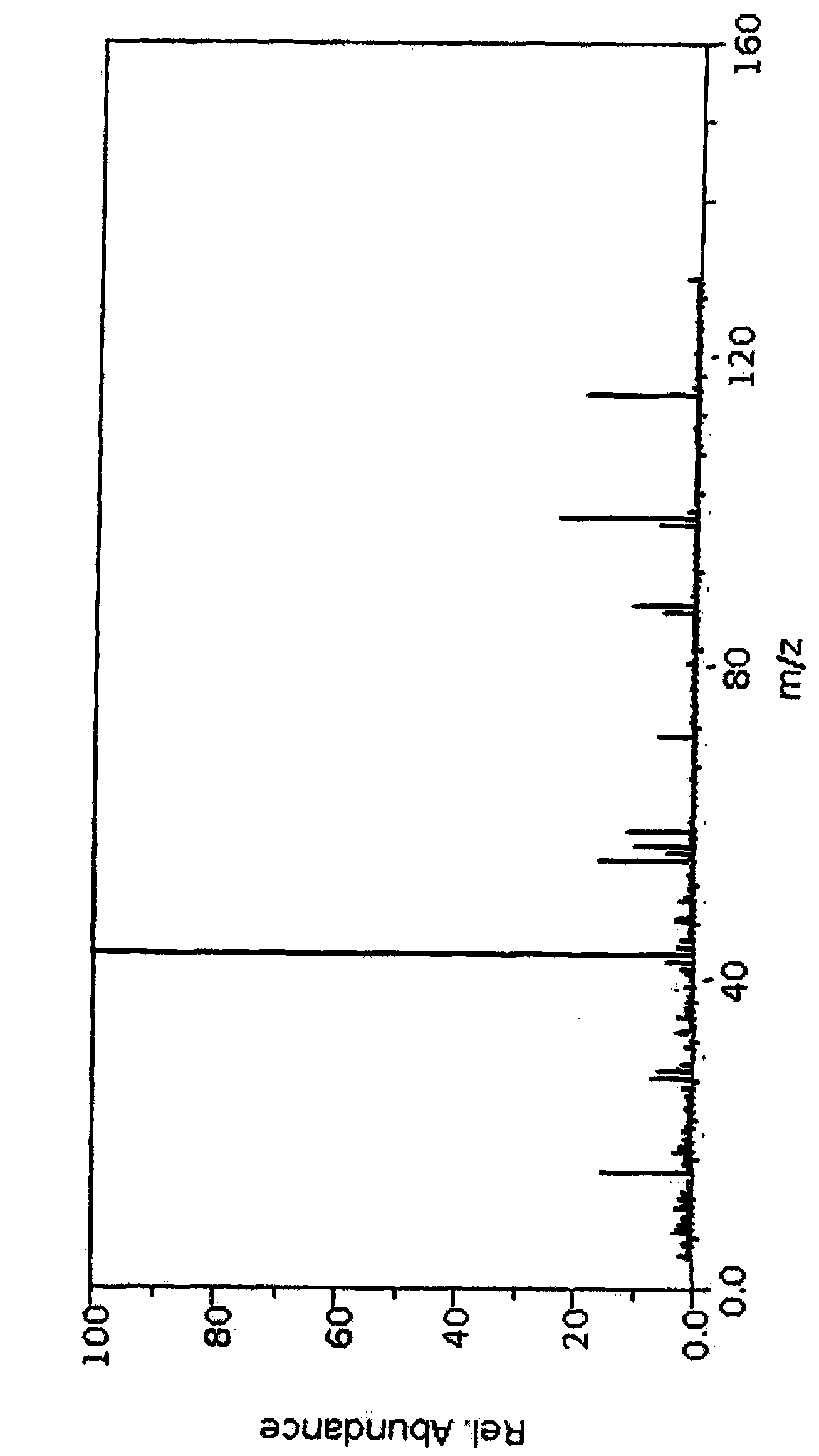

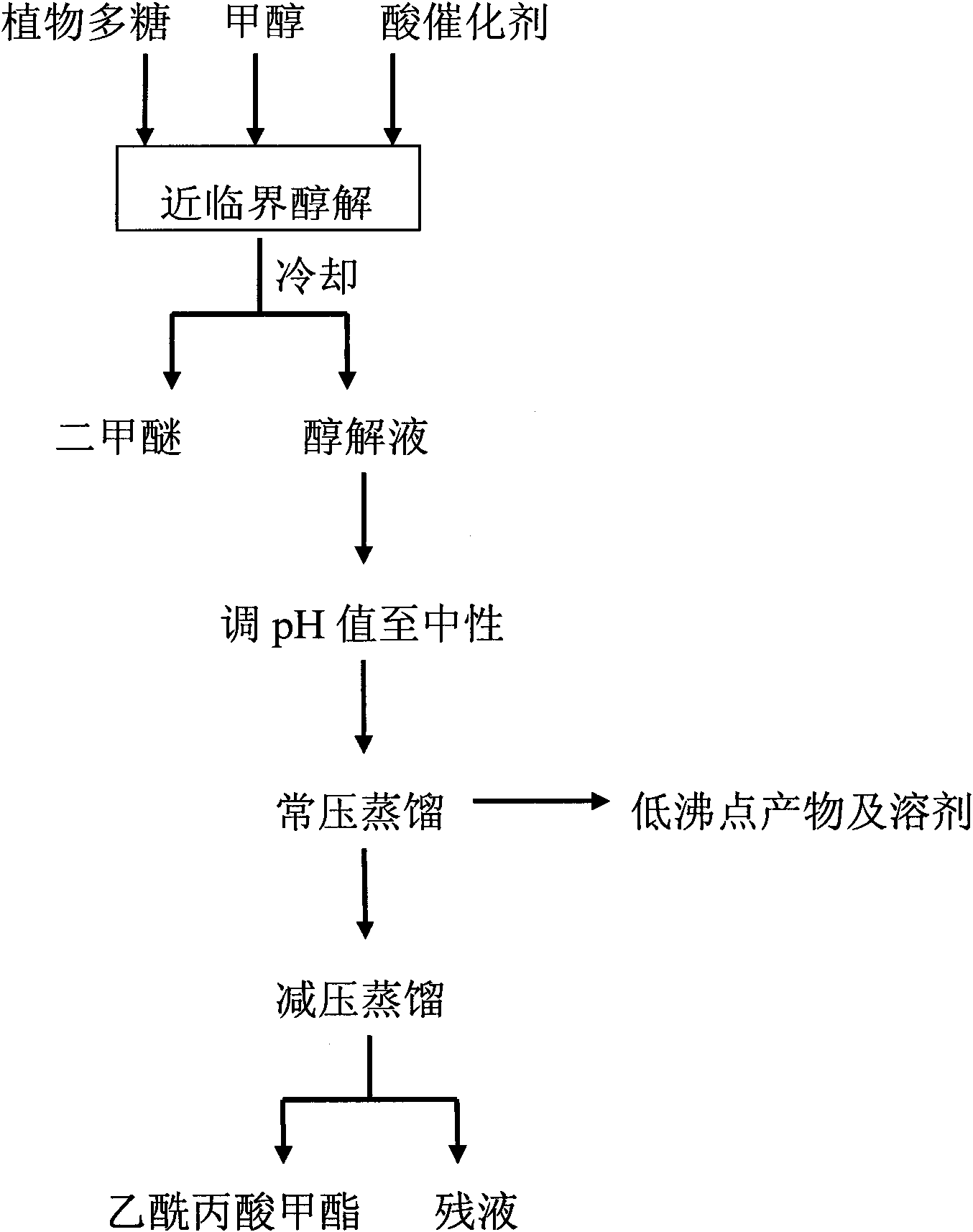

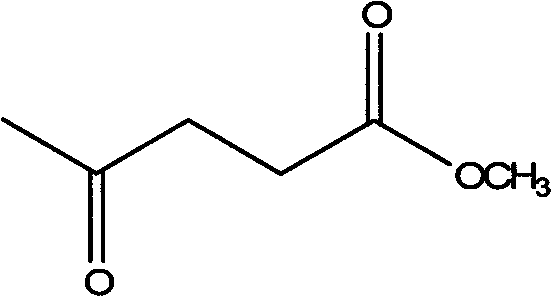

Method for preparing methyl levulinate in near-critical methanol by plant polysaccharide alcoholysis one-pot method

InactiveCN101781210AEasy to makeGreen preparationOrganic compound preparationCarboxylic acid esters preparationExhaust valveSolvent

The invention discloses a method for preparing methyl levulinate in near-critical methanol by a plant polysaccharide alcoholysis on-pot method. The method comprises the following steps: 1) adding methanol, plant polysaccharide and acid catalyst in a high pressure reaction kettle, wherein the mass concentration of the plant polysaccharide is between 10 and 120g / L, and the molar concentration of the acid catalyst is between 0.01 and 0.06 mol / L, replacing air in the kettle by nitrogen after the kettle is closed, and starting stirring; 2) heating the materials to the temperature of between 160 and 200 DEG C for alcoholysis for 1 to 10 hours; 3) cooling the materials to the room temperature after the alcoholysis is completed, and opening an exhaust valve to collect dimethyl ether; and 4) regulating pH value of the alcoholysis solution to be neutral, distilling the solution under the normal pressure to remove low-boiling products and solvent, and distilling the solution under reduced pressure to obtain the methyl levulinate. The method has the advantages of biomass raw materials, abundant resources and simple and green one-pot preparation process, and has important industrial application value.

Owner:ZHEJIANG UNIV

Biodiesel fuel and preparation method thereof

InactiveCN103320178AFully develop the utilizationReduce pollutionOrganic compound preparationCarboxylic acid esters preparationOxidation stabilityEthyl ester

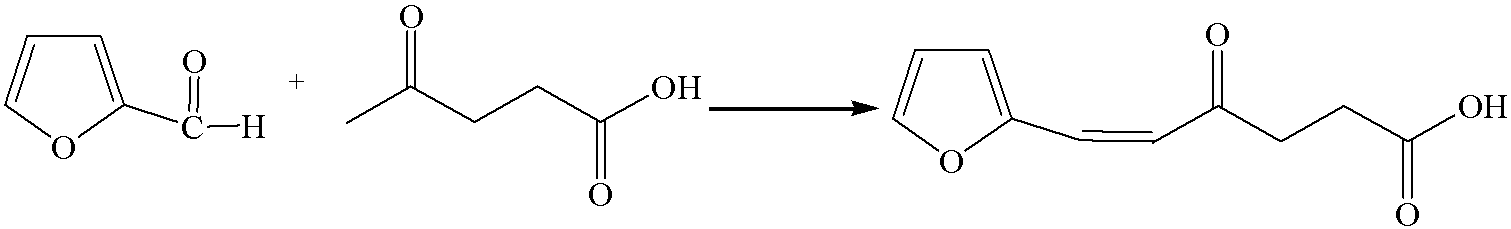

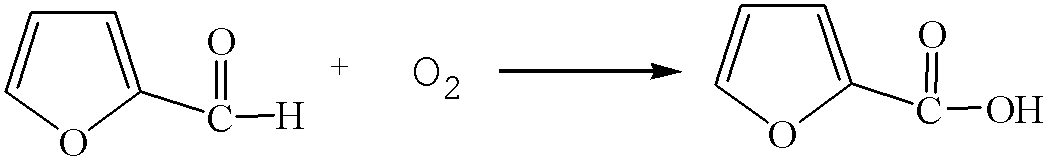

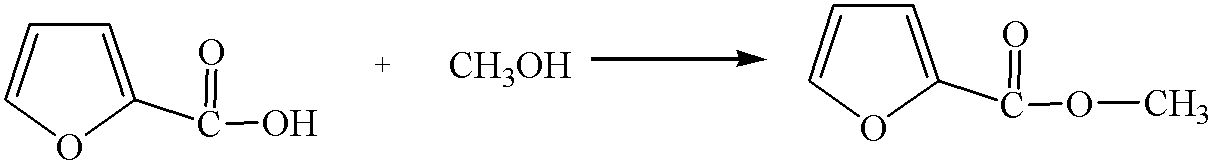

The invention discloses biodiesel fuel and a preparation method thereof. The biodiesel fuel is prepared by using biomass derivative furfural and acetylpropionic acid as raw materials and by the technology of condensation, oxidation, esterification and complex formulation. The biodiesel fuel contains components of 6-furfurylidene levulinate, methyl furoate and methyl levulinate or ethyl levulinate with carbon atom number between 11 and 18. The advantages comprise that: the biodiesel fuel has high cetane number and oxidation stability, and its thermal efficiency is raised 30-40% than that of tradition biodiesel fuel. The biodiesel fuel can 100% directly be used, and can also be mixed with petroleum diesel fuel for using.

Owner:俏东方生物燃料集团有限公司

High-yield levulinic acid ester preparation method under catalysis of solid acid

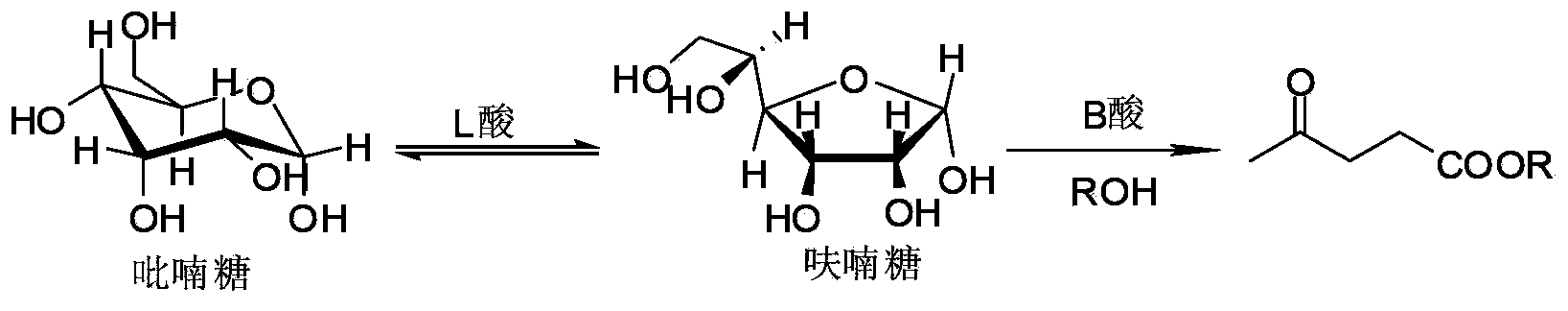

ActiveCN103408422AHigh yieldCatalytic conversionOrganic compound preparationCarboxylic acid esters preparationFood additivePropanoic acid

The invention discloses a high-yield levulinic acid ester preparation method under catalysis of solid acid and belongs to the field of organic synthesize. The method comprises the following steps: uniformly mixing 1 part of sugar, 10-100 parts of alcohol, 0.01-0.2 part of acid B and 0.1-1 part of acid L, and performing reaction under the temperature of 130-190 DEG C for 1-20 h to obtain a levulinic acid methyl ester solution, wherein the acid L is stanniferous molecular sieve, and the acid B is SBA-15-SO3H, Carbon-SO3H or Amberlyst-15. According to the method, the carbohydrate is low in cost and easy to obtain; with the acid B and acid L which can be used repeatedly, the catalysis effect basically remains the same; the levulinic acid ester compound prepared in one step can be widely applied to industries of food additives, essence spices, chemical reaction intermediates, gasoline, diesel-dopes and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

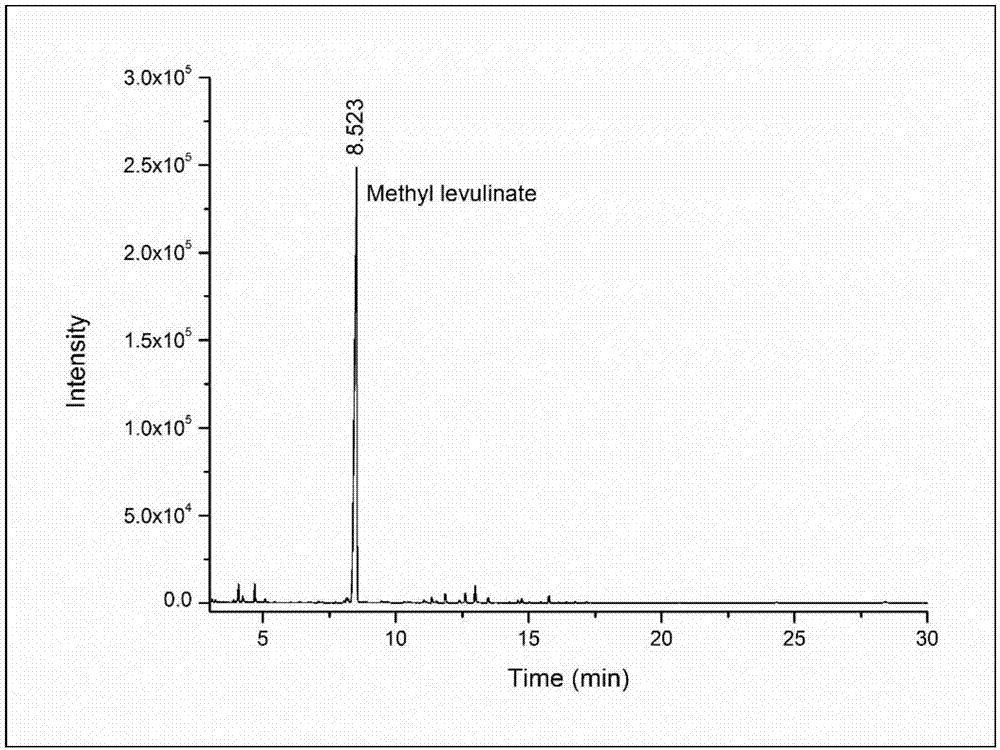

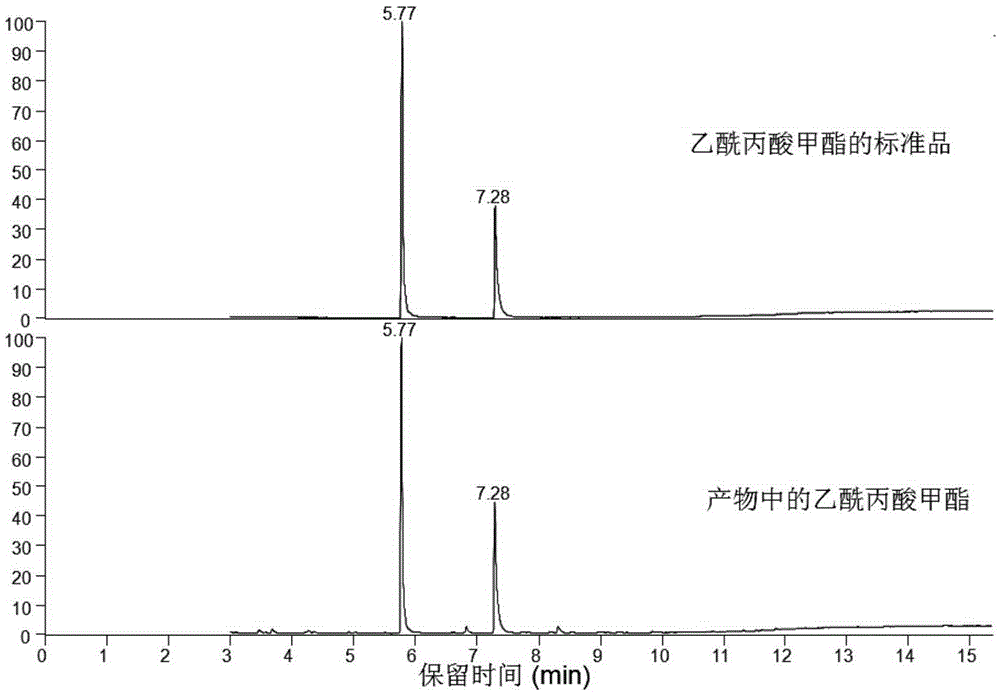

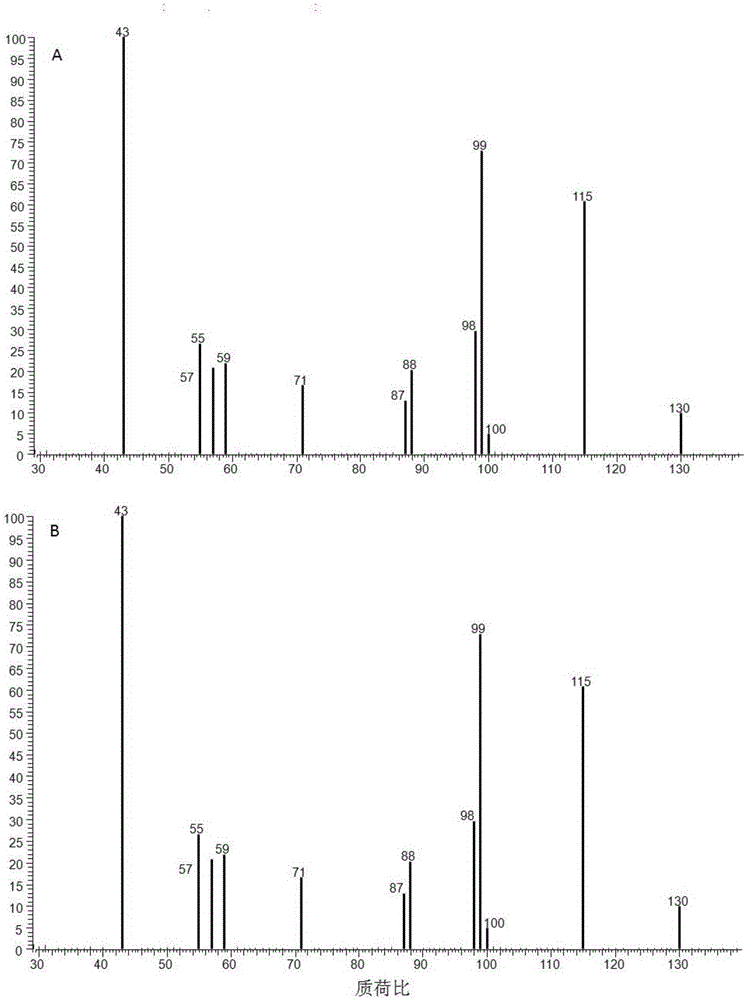

Method for preparing methyl levulinate from biomass saccharide by using acidified montmorillonite as catalyst

InactiveCN104478718AEasy to makeReusablePhysical/chemical process catalystsOrganic compound preparationFood additiveHydrogen

The invention relates to a method for preparing methyl levulinate from biomass saccharide by using acidified montmorillonite as a catalyst, belonging to the technical field of organic synthesis. According to the method, biomass saccharide and methanol used as raw materials react in a reaction kettle at 160-220 DEG C for 2-5 hours by using sulfated montmorillonite or hydrogen-type montmorillonite as a solid acid catalyst to synthesize the methyl levulinate. The sulfated montmorillonite or hydrogen-type montmorillonite is prepared by the following steps: treating montmorillonite with sulfuric acid, filtering, washing with water, and calcining. The invention provides a new solid acid catalyst and new reaction route for converting biomass saccharide into methyl levulinate, and the methyl levulinate can be prepared by using the simple catalyst under mild conditions. The methyl levulinate can be widely used as an important platform compound in the biomass conversion process, and can be used as a food additive, essence, gasoline additive, biofuel or the like.

Owner:JILIN UNIV

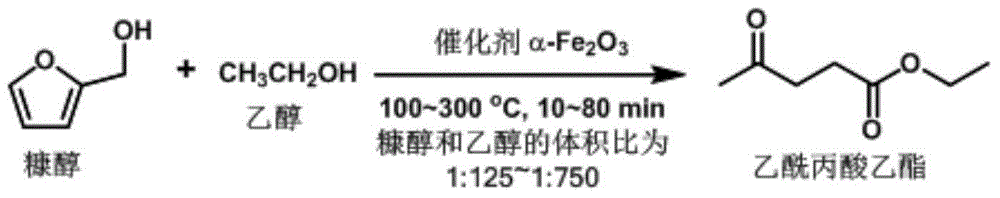

A method of preparing levulinates by utilizing furfuryl alcohol

ActiveCN105646227AAlleviate energy problemsHigh efficiency and low consumption conversionOrganic compound preparationCarboxylic acid esters preparationChemical productsEthyl levulinate

A method of preparing levulinates by utilizing furfuryl alcohol is disclosed. The method adopts the furfuryl alcohol that is a biomass derivative as a raw material, adopts a metal oxide as a catalyst, and includes reacting in a sealed manner in a reactor at 100-300 DEG C for 10-80 min. The highest yields of methyl levulinate, ethyl levulinate or n-butyl levulinate in different solvent systems can be 73%, 83% and 86% respectively. The method can efficiently synthesize the levulinates with high selectivity. The biomass derivative that is rich in reserve in the nature, wide in distribution and reproducible is adopted as the raw material, thus avoiding consumption of a large amount of fossil fuels. The method is free of preparation of complex catalysts and simple in operation, alcohols are adopted as solvents, and reactants are low in environment pollution and high in conversion ratio, thus facilitating industrial production. The levulinates which are products can be widely used as green solvents, perfume, fuel additives, and the like, and can be adopted as intermediates for synthesizing other chemical products with high added value.

Owner:SHANGHAI JIAO TONG UNIV

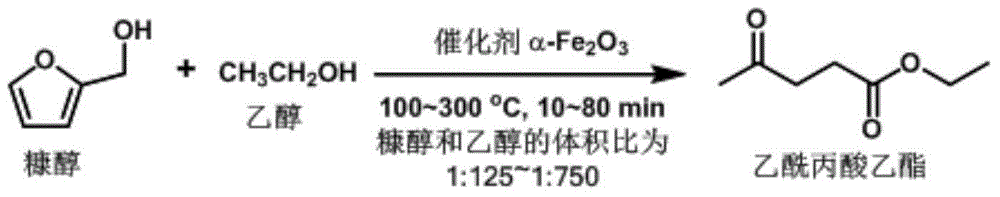

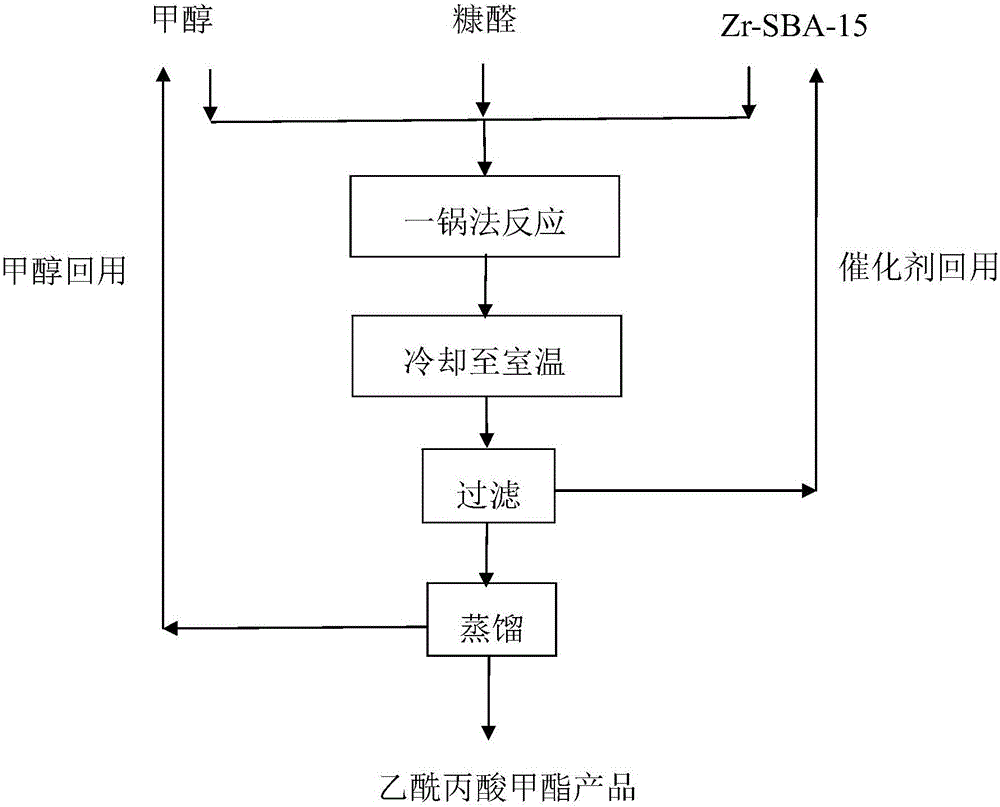

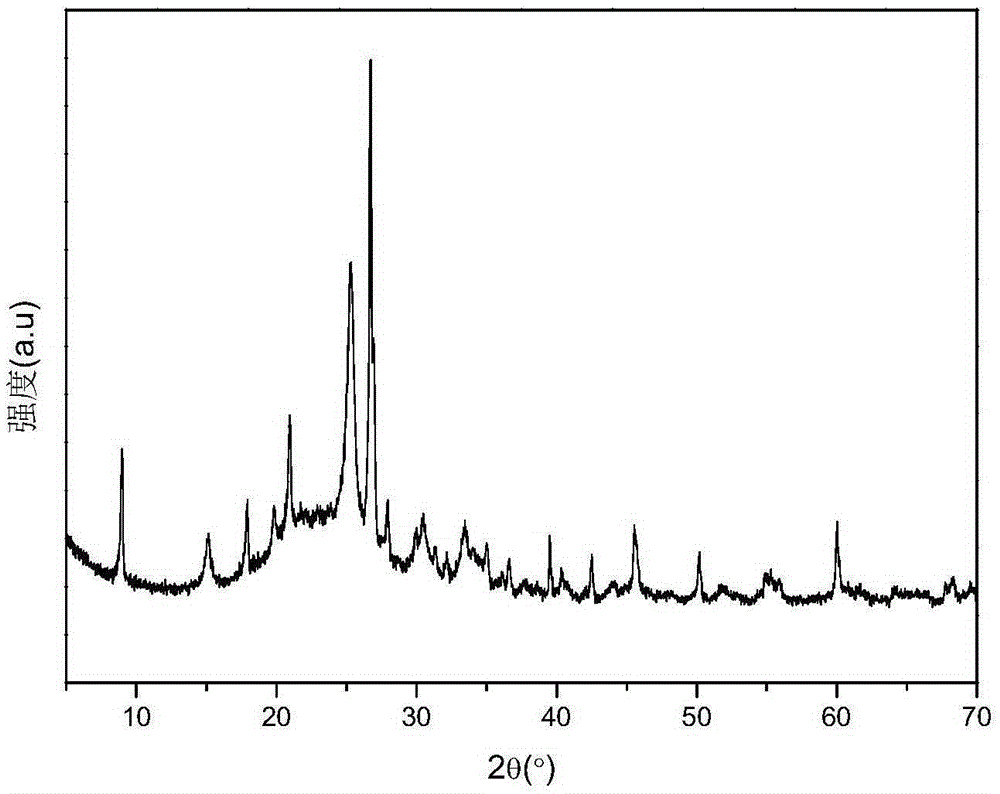

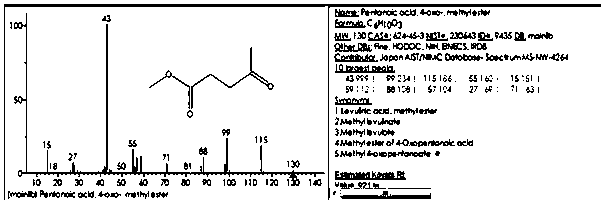

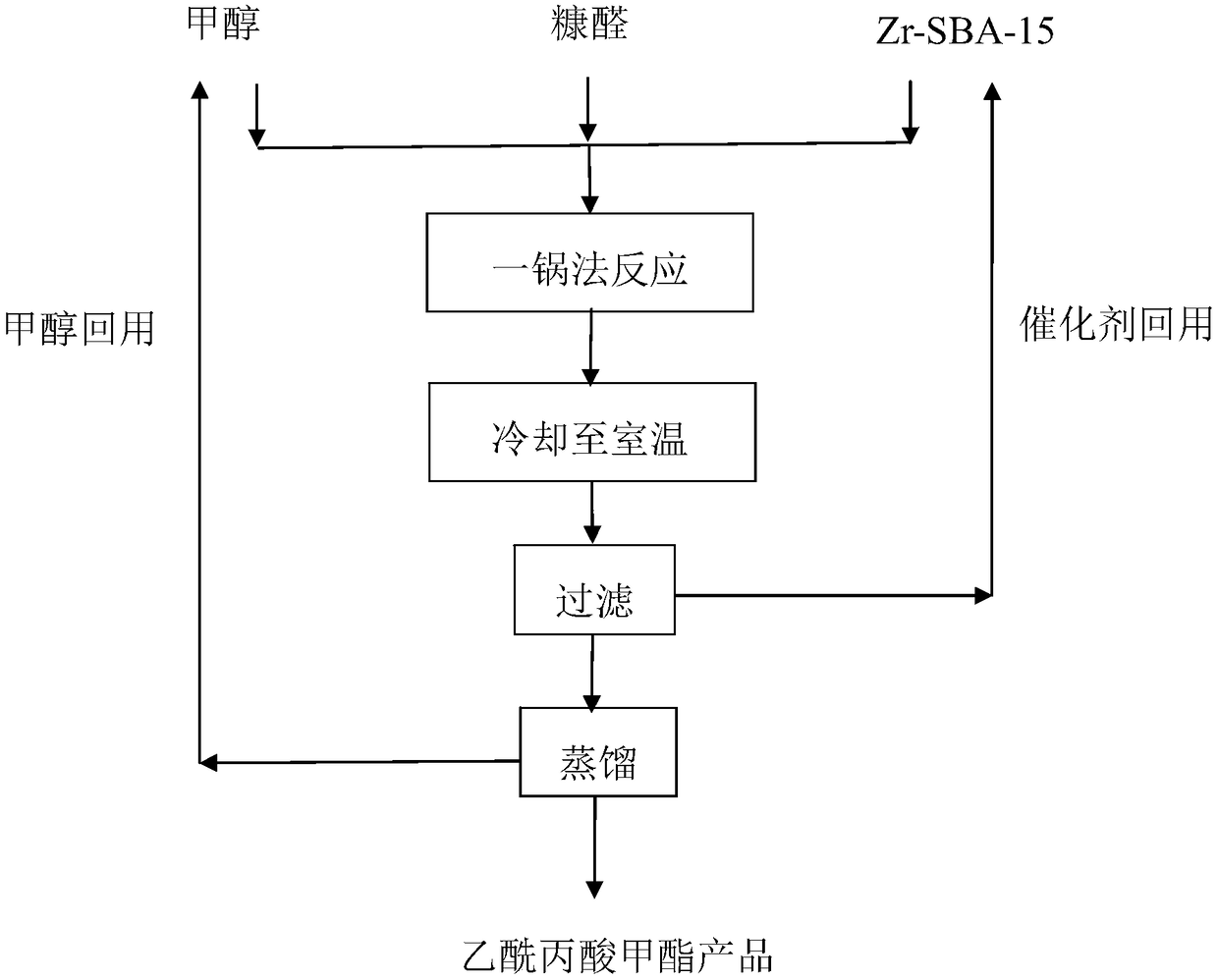

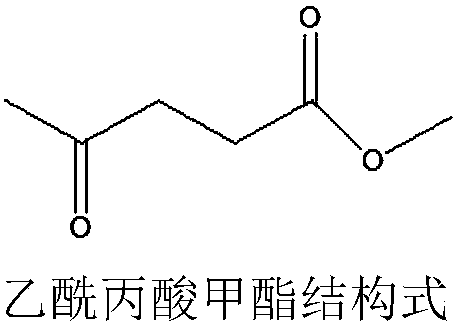

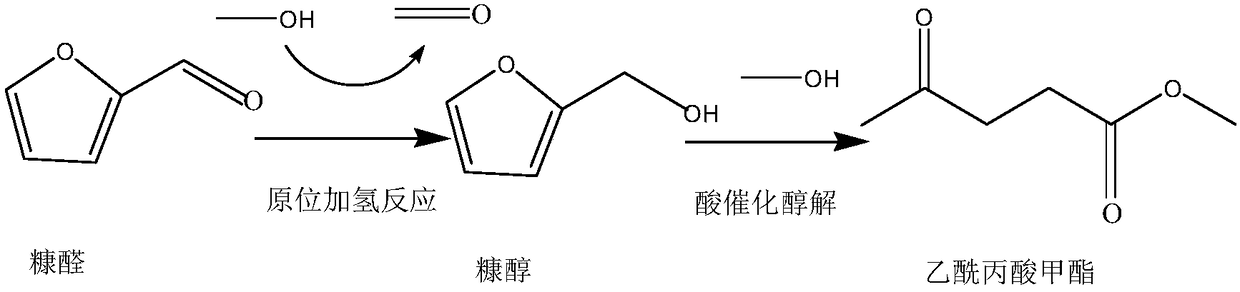

One-pot method for preparing methyl levulinate by catalyzing furfural through Zr-SBA-15 mesoporous molecular sieve in near-critical methanol medium

ActiveCN106187752ASimple processProcess safetyMolecular sieve catalystsOrganic compound preparationMolecular sieveRoom temperature

The invention discloses a one-pot method for preparing methyl levulinate by catalyzing furfural through a Zr-SBA-15 mesoporous molecular sieve in a near-critical methanol medium. The method comprises the following steps: (1) adding furfural and methanol into a high-temperature and high-pressure reaction kettle with a stirring function, and adding the Zr-SBA-15 mesoporous molecular sieve, wherein the Si / Zr molar ratio of the Zr-SBA-15 mesoporous molecular sieve is 5-100; (2) stirring, heating to 200-280 DEG C, and carrying out one-pot method reaction for 1-16 hours; and (3) after the reaction, cooling to the room temperature, filtering, distilling filtrate to obtain a methyl levulinate product, recycling methanol for later use, collecting filter residues, namely the Zr-SBA-15 mesoporous molecular sieve, washing with methanol, and drying and roasting for later use. The one-pot method has the beneficial effects that the process is simple, the process is environmentally friendly, and the cost is low and further has a good industrial production prospect.

Owner:ZHEJIANG UNIV

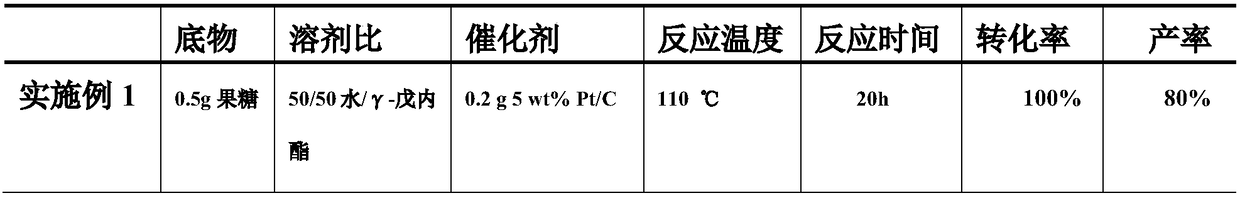

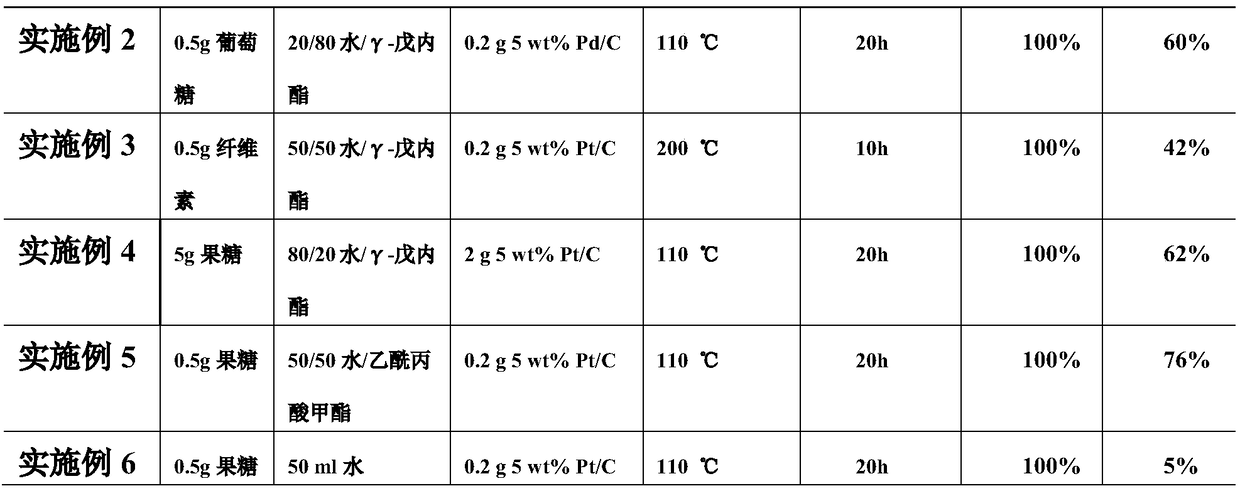

Method for preparing 2,5-furandicarboxylicacid

InactiveCN108503613APromote recrystallizationImprove reaction efficiencyOrganic chemistryCelluloseIsomerization

The invention discloses a method for preparing 2,5-furandicarboxylicacid. The method comprises the steps that a reaction substrate and a catalyst are added in a system, wherein the reaction system iscomposed of water and a biomass-base solvent; in a certain of oxidizing atmosphere, the product 2,5-furandicarboxylicacid is obtained through high-temperature hydrolysis, isomerization, dehydration and oxidization, wherein the biomass-base solvent is one or two or more of gamma-valerolactone, ethyl acetate and methyl levulinate; the reaction substrate is one or two or more of cellulose, cellobiose, glucose and fructose; the catalyst is one or two or more of Ru / C, Pt / C, Pd / C, Rh / C, Cu / C, Ni / C and Co / C; the oxidizing atmosphere is one or two of oxygen and air. In the method, the water and the biomass-base solvent serve as reaction media, the reaction efficiency is high, the water and the biomass-base solvent do not interfere with each other, the product is helped to be obtained through recrystallization, and a good idea and method are provided for preparing common chemicals. The preparation process is environmentally friendly, and the method is environmentally friendly and high in operability.

Owner:昆山普瑞凯纳米技术有限公司

Nicotine-containing pharmaceutical compositions

InactiveCN102933199ANervous disorderPharmaceutical delivery mechanismNicotine replacementsPharmaceutical Substances

A composition intended to be employed for therapeutic purposes incorporates a source of nicotine and at least one levulinate moiety. Representative forms of nicotine include free base (e.g., as a mixture of nicotine and microcrystalline cellulose), a nicotine salt (e.g., as nicotine bitartrate) or nicotine polacrilex. The levulinate moiety can have the form of an acid (e.g., levulinic acid), a levulinate salt (e.g., sodium levulinate), or an ester of levulinic acid (e.g., methyl levulinate or ethyl levulinate). The composition can incorporate nicotine and levulinic acid in a salt form (e.g., nicotine levulinate). The composition can be composed of at least two forms of nicotine, and one of the forms of nicotine is in the form of nicotine levulinate. The composition is useful for treatment of central nervous system conditions, diseases, and disorders, and as a nicotine replacement therapy.

Owner:NICONOVUM USA

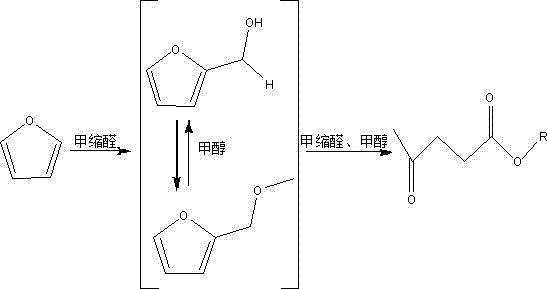

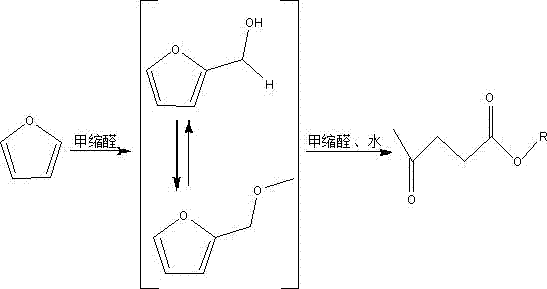

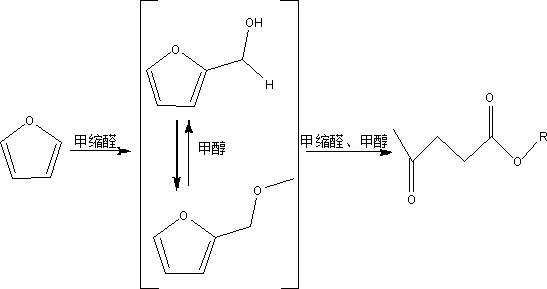

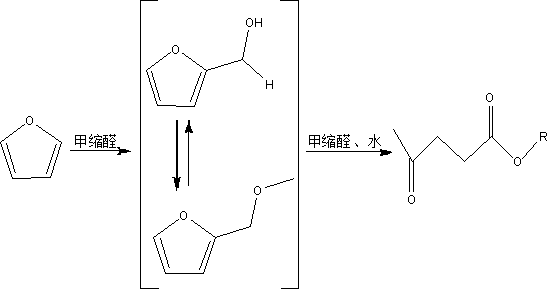

Method using furan to prepare methyl levulinate

InactiveCN107162900AHigh yieldAvoid PolymerizationOrganic compound preparationCarboxylic acid esters preparationFuranPropanoic acid

The invention provides a method using furan to prepare methyl levulinate. The method includes: adding the furan, cation exchange resin 70 and a solvent into a reactor, heating to 140-180 DEG C within 10 minutes, and stirring for 1.8-2.2 hours at the stirring speed of 450-550rpm to obtain the methyl levulinate and levulinic acid, wherein the solvent is methylal or the mixed liquid of methylal and a cosolvent, and the cosolvent is methanol or water. The method has the advantages that the method uses the furan to prepare the methyl levulinate in one step, the methylal is the electrophilic reagent of electrophilic substitution reaction for converting intermediate product sugar alcohol, and the methanol serving as the cosolvent and the reactant plays an important role; the reaction process does not need hydrogenation, and the method is simple in reaction condition and capable of saving cost.

Owner:UNIV OF JINAN

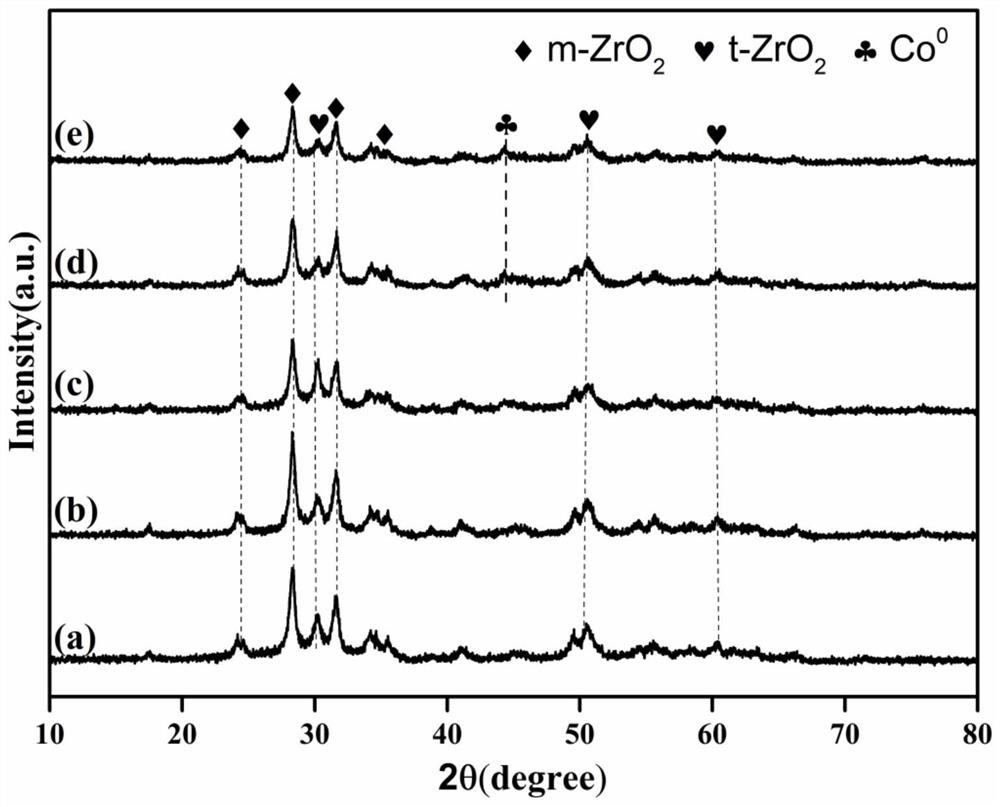

Method for catalytically synthesizing gamma-valerolactone by using cobalt-based hydrogenation catalyst

PendingCN111848553AHigh catalytic activityShort reaction timeOrganic chemistryChemical industryPtru catalystPropanoic acid

The invention discloses a method for synthesizing gamma-valerolactone through hydrogenation of methyl levulinate under the catalysis of a cobalt-based hydrogenation catalyst Co / ZrO2-Nb2O5. The catalyst has the advantages of high catalytic activity, good reusability, difficulty in loss of active components, easiness in separation from a liquid product and the like; when a mass ratio of the catalystto the reaction raw material methyl levulinate to the reaction solvent isopropanol is 0.2: 1: 20, a reaction temperature is 200 DEG C, and reaction time is 2 hours, the molar yield of the obtained hydrogenation product gamma-valerolactone is 98.32%, and the mass percent of the purity of the product is 99.01%.

Owner:XIANGTAN UNIV

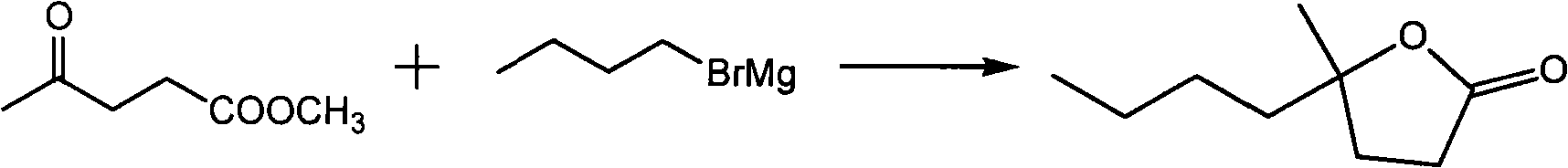

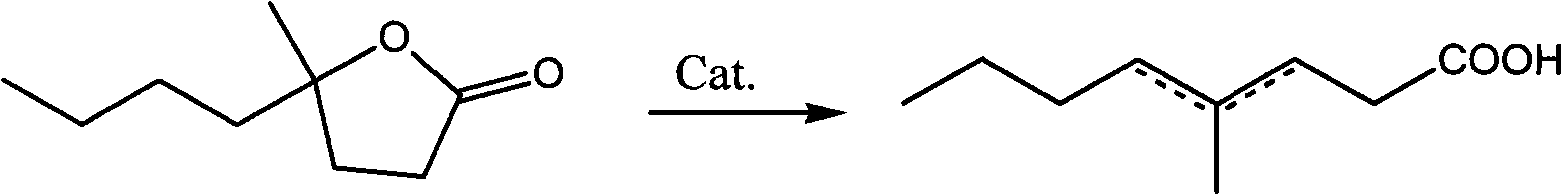

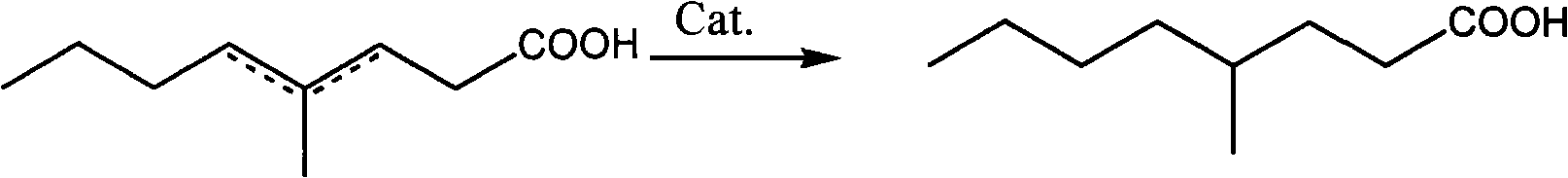

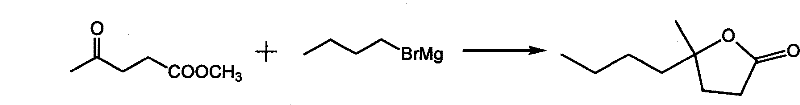

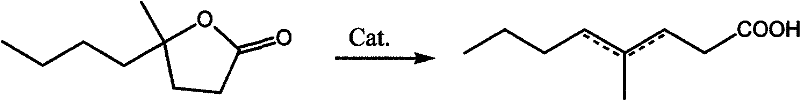

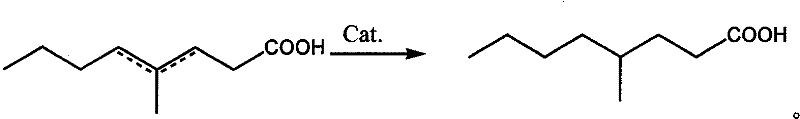

4-Method for synthesizing 4-Methyloctanoic Acid

ActiveCN101684070ARaw materials are easy to getHigh yieldPreparation from carboxylic acid esters/lactonesSulfateGrignard reaction

The invention relates to a method for synthesizing 4-Methyloctanoic Acid. Firstly, an intermediate of 4-methyl-5-octanolide is obtained by grignard reaction of 4-Oxovaleric acid methyl ester with 1-bromobutyl-magnesium halide, the intermediate of 4-methyl-5-octanolide and calcium sulfate for dehydroxylation to generate 4-Methyl-Octenoic acid, and the 4-Methyl-Octenoic acid is catalytically hydrogenated to obtain the target product. Compared with prior art, the raw material of the method is easy to get, the method need not high-temperature and high pressure environment, the reaction condition is moderate, and the method reduces production cost and difficulty, simultaneously obtains high yield, and is suitable for industrial production.

Owner:黄山科宏生物香料股份有限公司

Thickened grease composition

InactiveUS20140303052A1Drop separationDrop stabilityThickenersAdditivesGlutaric acidLithium hydroxide

A thickened grease composition is provided by process of heating a mineral oil and 12-hydroxystearic acid with lithium hydroxide and forming a simple lithium grease to which at least one component selected from the group comprising succinic acid, glutaric acid, adipic acid, 6-hydroxycaproic acid, dimethyl succinate, dimethyl glutarate, dimethyl adipate, methyl hydroxycaproate, cyclohexanediols, methyl 5-hydroxyvalerate, methyl valerate, gamma butyrolactone, and methyl levulinate or mixtures thereof.

Owner:INVISTA NORTH AMERICA R L

Solid acid catalyst and application thereof in catalytically converting glucose to prepare methyl levulinate

InactiveCN104549200AEasy to prepareImprove stabilityOrganic compound preparationCarboxylic acid esters preparationPropanoic acidSolid acid

The invention discloses a solid acid catalyst and an application thereof in catalytically converting glucose to prepare methyl levulinate. The carrier of the catalyst is sodium-based montmorillonite, the active ingredient of which is any one of In<3+>, Cr<3+>, Cu<2+>, Sn<4+> and Al<3+>. The loading capacity of the active ingredient is 5-40wt.%. The catalyst is prepared by using an ion exchange method, the preparation method is simple, and the solid acid catalyst is good in stability, environment-friendly, free of pollution and less in corrosion on equipment, and the catalyst for catalytically converting glucose to prepare methyl levulinate is good in catalytic activity, high in selectivity, easy to be separated and recovered from reactants, recyclable and good in cycling stability, and can be used for fully catalytically converting glucose. The highest yield of methyl levulinate can reach over 60%.

Owner:SHAANXI NORMAL UNIV

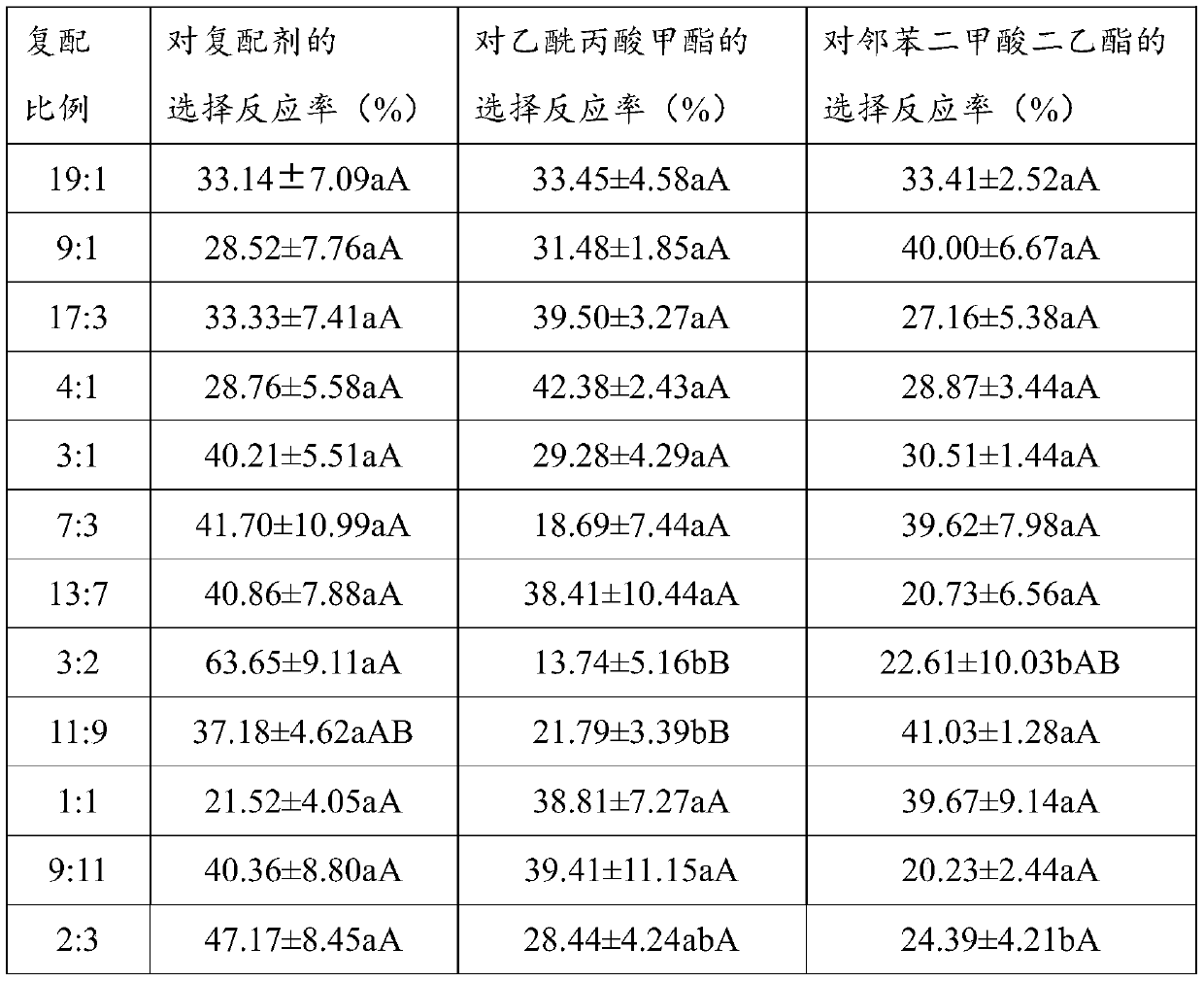

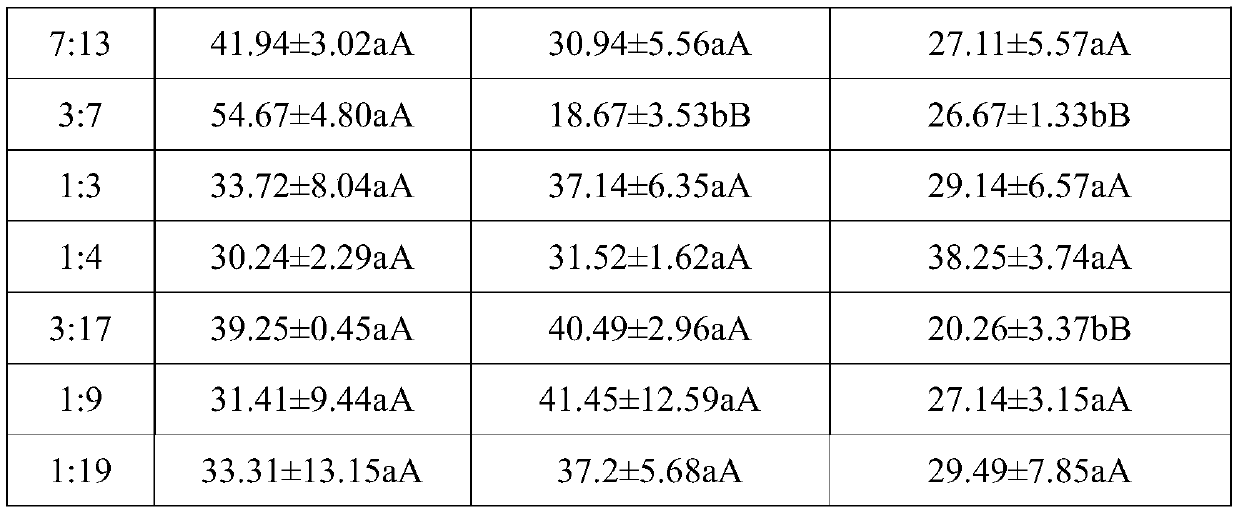

Miridae attractant and using method thereof

The invention discloses a miridae attractant and a using method thereof. The miridae attractant comprises methyl levulinate and / or diethyl phthalate; according to the miridae attractant, methyl levulinate and / or diethyl phthalate are / is used as functional components; pest control is carried out by utilizing the luring effect of methyl levulinate and diethyl phthalate on miridae pests, the pertinence is excellent, the control effect is good, the environmental pollution is small, the toxicity of methyl levulinate and diethyl phthalate is extremely low, the toxicity to human beings and animals issmall, and the miridae attractant is safe and reliable to use.

Owner:INST OF PLANT PROTECTION & SOIL FERTILIZER HUBEI ACAD OF AGRI SCI

Synthesis method of (R)-5-methylpyrrolidone-2-one

ActiveCN110845385ALow priceAtom utilization is highOrganic chemistry methodsChemical synthesisMethyl aminolaevulinate

The invention discloses a synthesis method of (R)-5-methylpyrrolidone-2-one. The synthesis method comprises following steps: step one, adding methyl levulinate, borane dimethyl sulfide, and a catalystinto a solvent, and carrying out reactions for 1 to 5 hours to obtain (R)-4-hydroxylmethyl pentanoate; step two, adding (R)-4-hydroxylmethyl pentanoate obtained in the step (1) into a reactor, introducing a nitrogen source and Raney nickel into the reactor, and carrying out catalytic reactions under a pressurized condition to obtain (R)-4-aminomethyl pentanoate; step three, adding (R)-4-aminomethyl pentanoate into a solvent, adding an alkaline catalyst, raising the temperature to 30-80 DEG C, and carrying out reactions for 0.5 to 5 hours to obtain the target product (R)-5-methylpyrrolidone-2-one; wherein the solvent in the step (1) is one or more of dichloromethane, toluene, dimethyl formamide, dimethyl sulfoxide, dichloromethane, and tetrahydrofuran. The synthesis method has the advantages of easily available and cheap raw materials, high atom utilization rate, high purity, easy purification, and high yield, and the chiral center does not need to be splitted.

Owner:SUZHOU UUGENE BIOPHARMA

Method for preparing methyl levulinate from cellulose under mild conditions of mechanical force chemocatalysis

InactiveCN106928066ALow temperature resistanceLow corrosion resistance requirementsOrganic compound preparationCarboxylic acid esters preparationCelluloseEcological environment

The invention discloses a method for preparing methyl levulinate from cellulose under mild conditions of mechanical force chemocatalysis. The method comprises the steps of carrying out ball milling on sulfuric acid dipped cellulose, and enabling the cellulose to react with methanol, so as to obtain methyl levulinate. By utilizing a technique of combining the sulfuric acid dipped cellulose with ball milling, the depolymerization degree of the cellulose is increased, and the crystallinity degree of the cellulose is greatly decreased. Compared with cellulose which is not processed by the technique, the method has the advantage that the molar yield of methyl levulinate is greatly increased. The method has the advantages that a production process is simple, process conditions are easily controlled, the reaction temperature is low, the use amount of a catalyst is low, the requirements on high temperature resistance, high pressure resistance and corrosion resistance of reaction equipment are relatively low, and the synthetic yield is high. The technique has positive significances to the guidance of the development and utilization of biomass resources in China and the protection of ecological environments.

Owner:CHINA AGRI UNIV

Preparation method of cyclopropyl methyl ketone

PendingCN113816841ARaw materials are easy to getLow costOrganic compound preparationPreparation from heterocyclic compoundsPropanoic acidGlycol synthesis

The invention discloses a preparation method of cyclopropyl methyl ketone. The method comprises the following steps: carrying out reflux reaction on methyl levulinate and ethylene glycol to obtain 3-(2-methyl-1, 3-dioxolane-2-yl) methyl propionate; dissolving 3-(2-methyl-1, 3-dioxolane-2-yl) methyl propionate in tetrahydrofuran, adding zinc chloride, adding sodium borohydride, and after addition, carrying out reflux reaction to obtain 3-(2-methyl-1, 3-dioxolane-2-yl) propyl-1-ol; adding a mixed aqueous solution of anhydrous zinc chloride and hydrochloric acid, and carrying out reflux reaction to obtain 5-chloro-2-pentanone; and carrying out a reaction on 5-chloro-2-pentanone and a sodium hydroxide aqueous solution at 90-95 DEG C for 0.5 h to obtain the target product cyclopropyl methyl ketone. According to the process, methyl levulinate is preferably selected as a starting raw material to prepare cyclopropyl methyl ketone, so that the raw materials are easy to obtain, the cost is low, large-scale industrial production is facilitated, in the preparation process, all steps and reaction conditions are mild and easy to control, post-treatment is simple, part of intermediates do not need to be refined and can be directly used as raw materials for next-step preparation, and the preparation process is greatly simplified.

Owner:JIANGSU YUXIANG CHEM

Method for preparing methyl levulinate from acidified montmorillonite catalyzed biomass sugar

InactiveCN104478718BEasy to makeReusablePhysical/chemical process catalystsOrganic compound preparationFood additiveOrganic synthesis

The invention relates to a method for preparing methyl levulinate from biomass saccharide by using acidified montmorillonite as a catalyst, belonging to the technical field of organic synthesis. According to the method, biomass saccharide and methanol used as raw materials react in a reaction kettle at 160-220 DEG C for 2-5 hours by using sulfated montmorillonite or hydrogen-type montmorillonite as a solid acid catalyst to synthesize the methyl levulinate. The sulfated montmorillonite or hydrogen-type montmorillonite is prepared by the following steps: treating montmorillonite with sulfuric acid, filtering, washing with water, and calcining. The invention provides a new solid acid catalyst and new reaction route for converting biomass saccharide into methyl levulinate, and the methyl levulinate can be prepared by using the simple catalyst under mild conditions. The methyl levulinate can be widely used as an important platform compound in the biomass conversion process, and can be used as a food additive, essence, gasoline additive, biofuel or the like.

Owner:JILIN UNIV

Synthesis method for 5-bromo-ethyl levulinate

InactiveCN103030561AThe synthesis method is simpleImprove conversion rateOrganic compound preparationCarboxylic acid esters preparationSynthesis methodsDiethyl ether

A synthesis method for 5-bromo-ethyl levulinate relates to a 5-aminolevulinic acid. Ethyl levulinate and liquid bromine are used as raw materials. The provided synthesis method for the 5-bromo-ethyl levulinate has the advantages of simplicity, wide raw material source, cheap raw materials, high yield and easiness in industrial production. The synthesis method comprises the following steps of: adding the ethyl levulinate raw material and a solvent into a reactor and reacting, and in the reaction process, adding the liquid bromine into the reactor to carry out bromination reaction; after the reaction is over, recycling the solvent in reaction liquid by a reduced pressure distillation method; dissolving distillation residues by water, adding diethyl ether for extraction, and obtaining a diethyl ether layer; washing the diethyl ether layer by a saturated sodium carbonate solution until the pH (Potential of Hydrogen) of the diethyl ether layer is neutral; drying and filtering by anhydrous magnesium sulfate, and recycling the diethyl ether through distillation so as to obtain a 5-bromo-ethyl levulinate crude product; and dissolving the 5-bromo-ethyl levulinate crude product in a mixed solvent of the diethyl ether and cyclohexane, and carrying out cooling crystallization in a cold trap to obtain the 5-bromo-ethyl levulinate.

Owner:XIAMEN UNIV

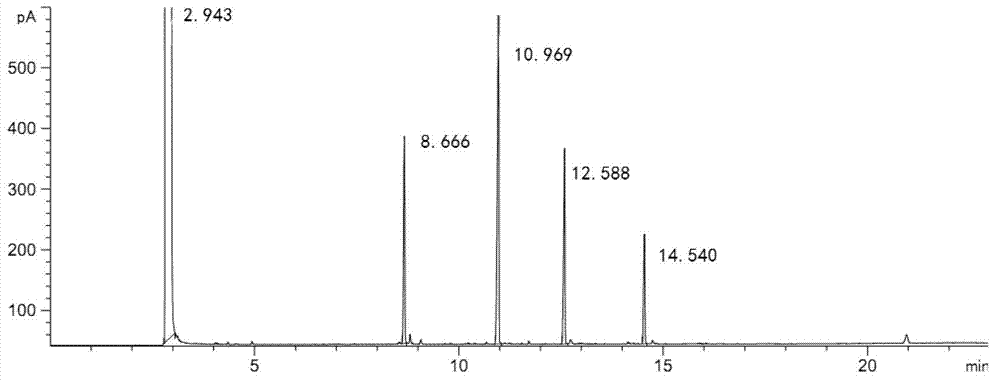

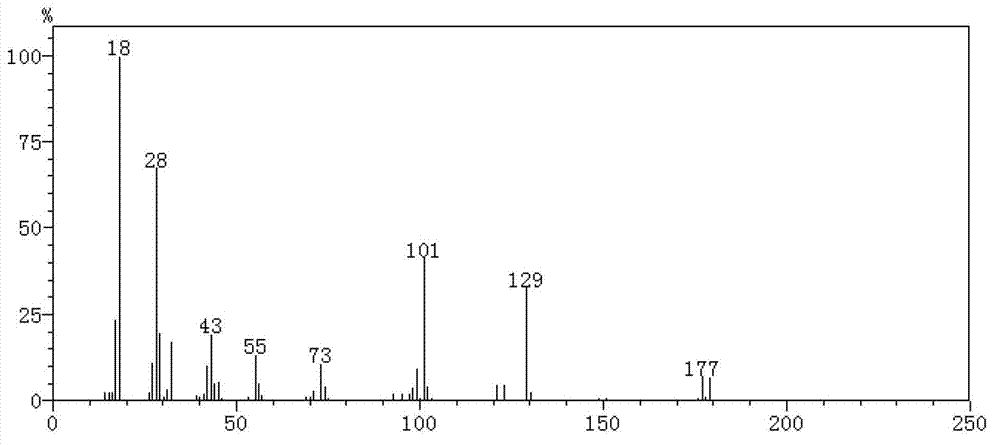

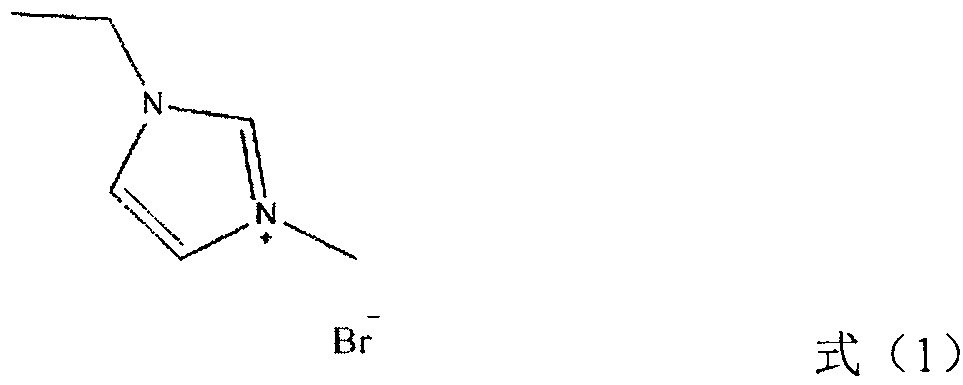

Preparation method of methyl levulinate catalyzed by ionic liquid

ActiveCN107935844BWide variety of sourcesEasy to manufactureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSucrosePtru catalyst

The invention discloses a preparation method of methyl levulinate by ion liquid catalysis. The method is characterized in that furfuryl alcohol, glucose, sucrose and the like are used as raw materials; imidazole ion liquid and SnCl4.5H2O are used as catalysts; methanol is used as a raw material and a reaction medium; under the heating condition, a target compound is prepared. The method has the advantages that (1) the used raw materials are renewable resources and conform to the circulation economy development trends; (2) the sources of all raw and auxiliary materials are wide; the preparationis convenient; the cooperated effects of the catalyst are good; the raw material conversion rate is high; the product selectivity is high; (3) the preparation process has low requirements on equipment; the reaction is performed at the normal pressure; the post treatment is convenient; the method is a clean preparation method of the methyl levulinate, and is favorable for scaled industrial development.

Owner:YANCHENG TEACHERS UNIV

A kind of solid acid catalyst and its application in catalytic conversion of glucose to prepare methyl levulinate

InactiveCN104549200BEasy to prepareImprove stabilityOrganic compound preparationCarboxylic acid esters preparationCatalytic transformationPtru catalyst

The invention discloses a solid acid catalyst and an application thereof in catalytically converting glucose to prepare methyl levulinate. The carrier of the catalyst is sodium-based montmorillonite, the active ingredient of which is any one of In<3+>, Cr<3+>, Cu<2+>, Sn<4+> and Al<3+>. The loading capacity of the active ingredient is 5-40wt.%. The catalyst is prepared by using an ion exchange method, the preparation method is simple, and the solid acid catalyst is good in stability, environment-friendly, free of pollution and less in corrosion on equipment, and the catalyst for catalytically converting glucose to prepare methyl levulinate is good in catalytic activity, high in selectivity, easy to be separated and recovered from reactants, recyclable and good in cycling stability, and can be used for fully catalytically converting glucose. The highest yield of methyl levulinate can reach over 60%.

Owner:SHAANXI NORMAL UNIV

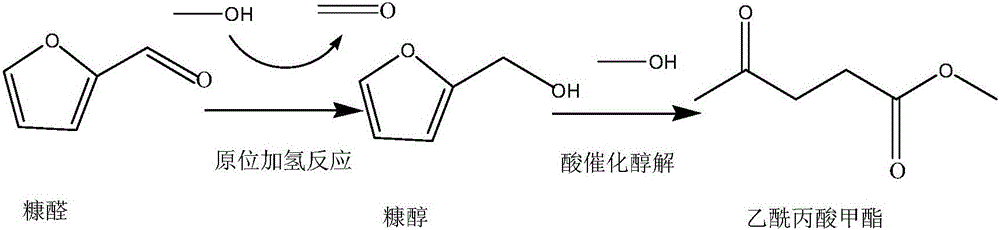

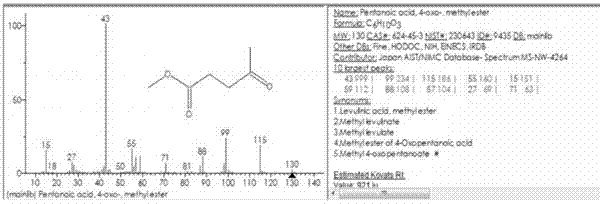

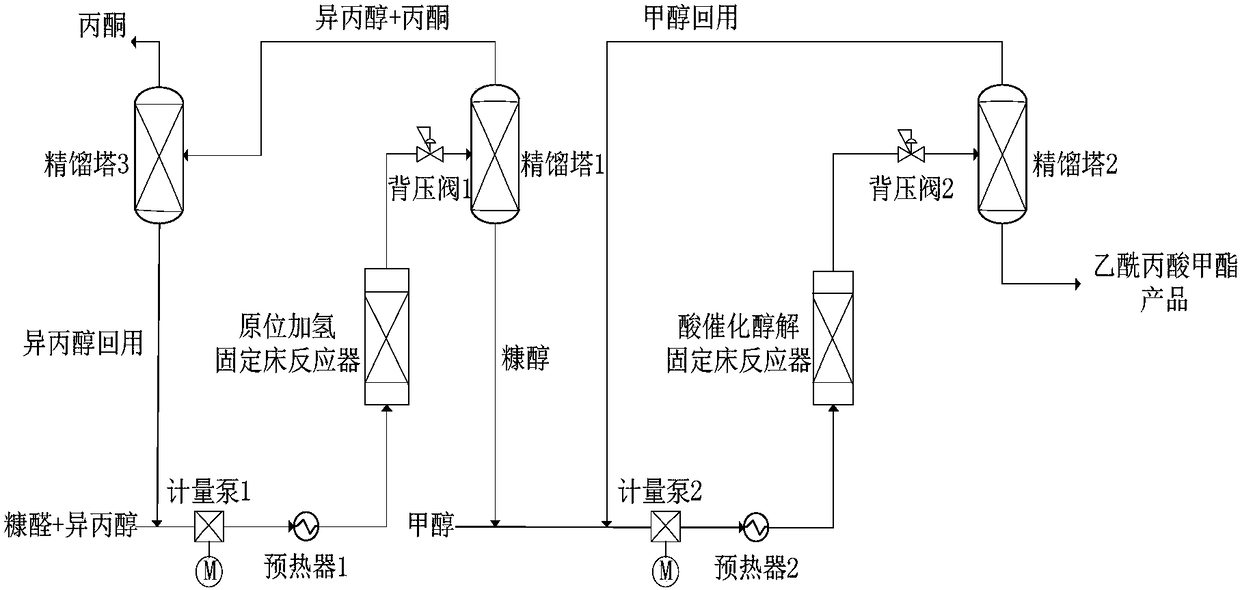

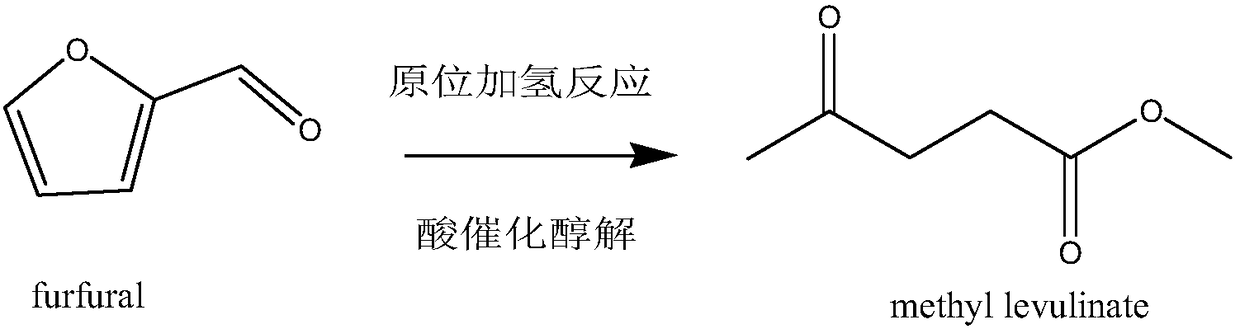

A kind of technique for the continuous preparation of methyl levulinate by furfural two-step method

ActiveCN105884616BProcess safetyEasy to separate and recycleOrganic compound preparationCarboxylic acid esters preparationAcid catalyzedFixed bed

The invention discloses a technique for continuously preparing methyl levulinate by a furfural two-step process. The technique comprises the following steps: 1) filling an in-situ hydrogenation fixed-bed reactor with a supported non-noble metal catalyst, and filling an acid-catalyzed alcoholysis fixed-bed reactor with a solid acid catalyst; 2) dissolving furfural in isopropanol to form a homogeneous solution, pressurizing the solution through a measuring pump 1, preheating the solution through a preheater 1, continuously adding the solution into the in-situ hydrogenation fixed-bed reactor, and reacting; 3) separating the reaction solution by a rectification tower 1, mixing the furfuryl alcohol obtained on the tower bottom with methanol to form a homogeneous solution, pressurizing the solution through a measuring pump 2, preheating the solution through a preheater 2, continuously adding the solution into the acid-catalyzed alcoholysis fixed-bed reactor, and reacting; and 4) separating the reaction solution by a rectification tower 2, and obtaining the methyl levulinate product from the tower bottom. The technique implements continuous production on the methyl levulinate, has the advantages of high treatment capacity, stable long-time operation catalytic activity and high product yield, is suitable for large-scale industrial application, and has favorable industrialization application prospects.

Owner:ZHEJIANG UNIV

Furan prepares the method for methyl levulinate

InactiveCN107162900BHigh yieldAvoid PolymerizationOrganic compound preparationCarboxylic acid esters preparationFuranPropanoic acid

The invention provides a method using furan to prepare methyl levulinate. The method includes: adding the furan, cation exchange resin 70 and a solvent into a reactor, heating to 140-180 DEG C within 10 minutes, and stirring for 1.8-2.2 hours at the stirring speed of 450-550rpm to obtain the methyl levulinate and levulinic acid, wherein the solvent is methylal or the mixed liquid of methylal and a cosolvent, and the cosolvent is methanol or water. The method has the advantages that the method uses the furan to prepare the methyl levulinate in one step, the methylal is the electrophilic reagent of electrophilic substitution reaction for converting intermediate product sugar alcohol, and the methanol serving as the cosolvent and the reactant plays an important role; the reaction process does not need hydrogenation, and the method is simple in reaction condition and capable of saving cost.

Owner:UNIV OF JINAN

A kind of preparation method of high-efficiency composite alcohol-based fuel

ActiveCN108949252BOptimize the impurity removal processDecreased fuel evaporation rateLiquid carbonaceous fuelsPropanoic acidAlcohol

The invention relates to a method for preparing a high-efficiency composite alcohol-based fuel. Methanol, concentrated sulfuric acid and levulinic acid are sequentially poured into a reactor with a condensation recovery device, and the materials inside the reactor are heated to 65-70°C for 6-8 hours; The product inside the reaction kettle is subjected to an impurity removal process to obtain a premix containing methyl levulinate and methanol; the premix and veratrole are mixed and stirred evenly to obtain a finished product. The present invention utilizes levulinic acid and methanol to synthesize and convert into methyl levulinate, and then optimizes the impurity removal process of methyl levulinate, so that the impurity removal of methyl levulinate can be achieved without rectification means; compared to direct For burning methanol, the fuel evaporation rate of the complex alcohol-based fuel of the present invention is reduced by 67%. High fuel utilization rate and good combustion effect.

Owner:ANHUI SHENGBAO NEW ENERGY TECH CO LTD

One-pot method for preparing methyl levulinate by mesoporous molecular sieve catalyzed furfural in a near-critical methanol medium

ActiveCN106187752BSimple processProcess safetyMolecular sieve catalystsOrganic compound preparationMolecular sieveRoom temperature

The invention discloses a one-pot method for preparing methyl levulinate by catalyzing furfural through a Zr-SBA-15 mesoporous molecular sieve in a near-critical methanol medium. The method comprises the following steps: (1) adding furfural and methanol into a high-temperature and high-pressure reaction kettle with a stirring function, and adding the Zr-SBA-15 mesoporous molecular sieve, wherein the Si / Zr molar ratio of the Zr-SBA-15 mesoporous molecular sieve is 5-100; (2) stirring, heating to 200-280 DEG C, and carrying out one-pot method reaction for 1-16 hours; and (3) after the reaction, cooling to the room temperature, filtering, distilling filtrate to obtain a methyl levulinate product, recycling methanol for later use, collecting filter residues, namely the Zr-SBA-15 mesoporous molecular sieve, washing with methanol, and drying and roasting for later use. The one-pot method has the beneficial effects that the process is simple, the process is environmentally friendly, and the cost is low and further has a good industrial production prospect.

Owner:ZHEJIANG UNIV

4-Method for synthesizing 4-Methyloctanoic Acid

ActiveCN101684070BRaw materials are easy to getHigh yieldPreparation from carboxylic acid esters/lactonesGrignard reactionHigh pressure

The invention relates to a method for synthesizing 4-Methyloctanoic Acid. Firstly, an intermediate of 4-methyl-5-octanolide is obtained by grignard reaction of 4-Oxovaleric acid methyl ester with 1-bromobutyl-magnesium halide, the intermediate of 4-methyl-5-octanolide and calcium sulfate for dehydroxylation to generate 4-Methyl-Octenoic acid, and the 4-Methyl-Octenoic acid is catalytically hydrogenated to obtain the target product. Compared with prior art, the raw material of the method is easy to get, the method need not high-temperature and high pressure environment, the reaction condition is moderate, and the method reduces production cost and difficulty, simultaneously obtains high yield, and is suitable for industrial production.

Owner:黄山科宏生物香料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com