Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93 results about "Dimethyl glutarate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst and method for preparing 1,5 pentanediol by hydrogenation of 1,5 dimethyl glutarate

InactiveCN1565728AOrganic compound preparationHydroxy compound preparationActive componentCopper oxide

The invention relates to a catalyst for hydrogenation preparation of 1,5-pentanediol by 1,5-dimethyl glutarate and its preparation method. The catalyst consists of active component copper oxide, aid zinc oxide and alumina, in which, copper oxide is 40 to 60% by weight, zinc oxide is 20 to 50% by weight and alumina is 10 to 20% by weight. The preparation process comprises the following steps: soluble salts of copper, zinc and aluminum are mixed by weight and dissolved by water, and pH value is adjusted to 7 by aqueous alkali in the process of heating and stirring, precipitate is filtered, washed, dried and baked, and then the catalyst is obtained.

Owner:PETROCHINA CO LTD +1

Single-component silver filled conductive glue capable of being stored and transported at normal temperature

InactiveCN1931946APlay its due roleAdhesive response is fastAldehyde/ketone condensation polymer adhesivesEpoxy resin adhesivesEpoxyPrinted circuit board

The single-component silver filled conductive glue capable of being stored and transported at normal temperature consists of flaky silver powder as the main component in 70-75 wt%, and supplementary material including organic carrier comprising epoxy resin and phenolic resin 10-15 wt%, curing agent dicyan diamine 0.5-1 wt%, curing promoter carbamide 0.1-0.3 wt%, and diluent mixture of dimethyl adipate, dimethyl glutarate and dimethyl succinate 9-15 wt%. The conductive glue of the present invention is used as the connecting material to replace solder for adhering printed circuit board as well as SMT, quartz resonator, chip, etc. It has excellent conducting performance, high adhesion, easy transportation and storing, and capacity of forming bright and fine cured spot.

Owner:贵州振华亚太高新电子材料有限公司

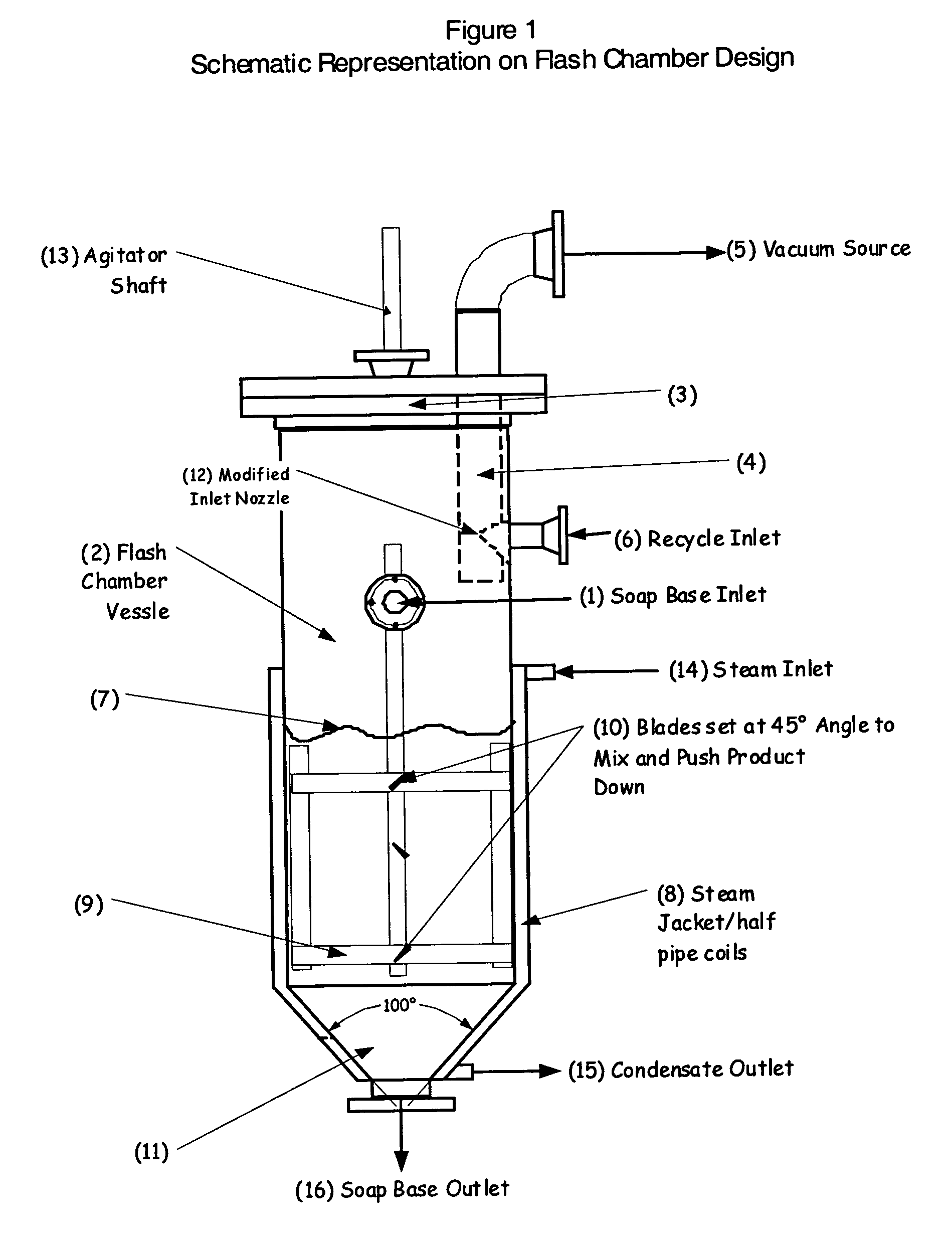

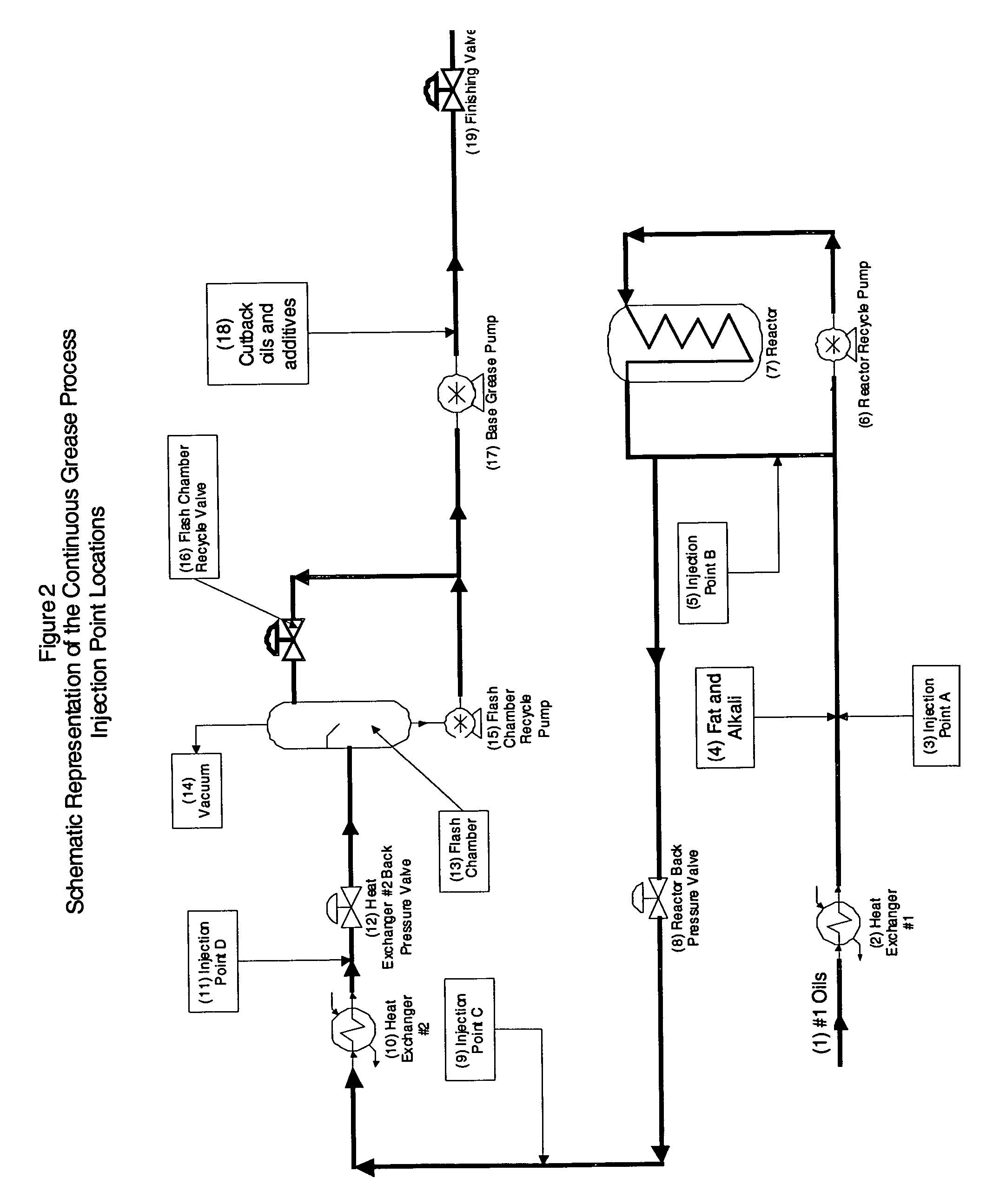

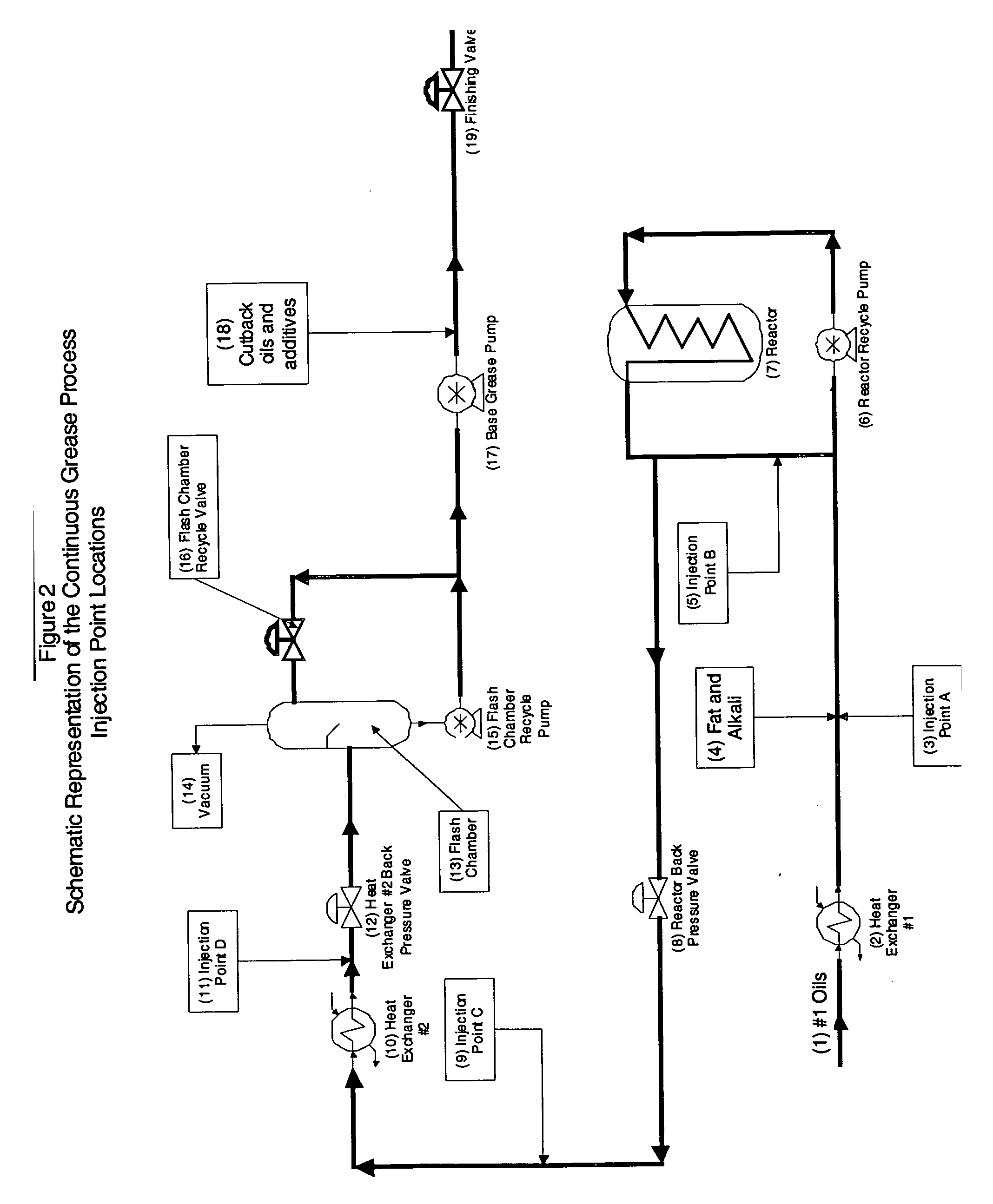

Method and equipment for making a complex lithium grease

A continuous process for preparing lithium complex greases improved by using a complexing agent of dimethyl glutarate, dimethyl adipate, glutaric acid, adipic acid, or mixtures thereof, and preferably also a specialized flash chamber to achieve a penetration split (60X-UW) of within −20 mm / 10 to 10 mm / 10, a roll stability (D1831) of <30 mm / 10, and a dropping point (D2265) of >240° C.

Owner:EXXON RES & ENG CO

Graffiti cleaning solution including a non-aqueous concentrate and diluted aqueous solution

ActiveUS7468345B2Extended shelf lifeConserve costSoap detergents with organic compounding agentsSurface-active detergent compositionsAlcoholEthyl ester

Owner:ECOHLDG

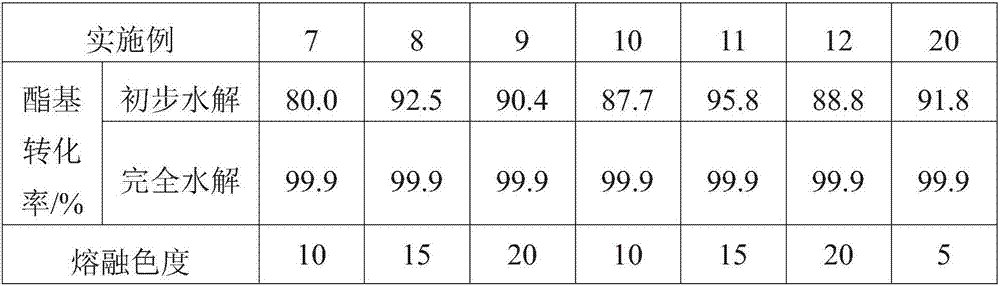

Method for purifying C4 to C6 dibasic acid monomers from adipic acid byproduct mixed dibasic acid

ActiveCN106957223AEasy to separateBreak the reaction balanceOrganic compound preparationCarboxylic acid esters preparationAdipic acidHydrolytic Process

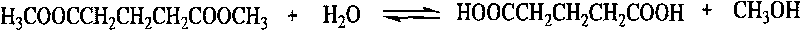

The invention discloses a method for purifying C4 to C6 dibasic acid monomers from an adipic acid byproduct mixed dibasic acid. The method disclosed by the invention comprises the following steps: firstly, carrying out esterification reaction on the adipic acid byproduct mixed dibasic acid and methanol at pre-set temperature in the presence of a catalyst; distilling and separating out mixed dibasic acid dimethyl ester; rectifying to obtain dimethyl succinate, dimethyl glutarate and dimethyl adipate; carrying out hydrolysis reaction on the dimethyl monomers in a rectifying reactor in the presence of a hydrolysis catalyst by two sections; at the first section of the reaction, controlling the conversion ratio of a hydrolysis ester group to be 80 percent to 95 percent and directly utilizing tower top methanol to esterify; at the second section of the reaction, controlling the conversion ratio of the hydrolysis ester group to 99.9 percent or more and directly utilizing a mixture of the tower top methanol and water to hydrolyze raw materials. According to the method disclosed by the invention, the conversion ratio of the ester group and the reaction efficiency are improved; no waste liquid is generated in a hydrolysis process so that the method is a green and environment-friendly production process.

Owner:SHANGHAI HUAFON NEW MATERIAL R&D TECH CO LTD +1

Method and equipment for making a complex lithium grease

A continuous process for preparing lithium complex greases improved by using a complexing agent of dimethyl glutarate, dimethyl adipate, glutaric acid, adipic acid, or mixtures thereof, and preferably also a specialized flash chamber to achieve a penetration split (60X-UW) of within −20 mm / 10 to 10 mm / 10, a roll stability (D1831) of <30 mm / 10, and a dropping point (D2265) of >240° C.

Owner:EXXON RES & ENG CO

Method for synthesizing caulerpin

InactiveCN104016989ARaw materials are cheap and easy to getMild reaction conditionsOrganic chemistryPtru catalystBiochemical engineering

The invention discloses a method for synthesizing caulerpin. In the method, the caulerpin is prepared from phenylhydrazine and 3-oxo-1,5-dimethyl glutarate by the following synthesis route. The method comprises the following steps: 1. carrying out Fischer indole reaction on phenylhydrazine 2 and 3-oxo-1,5-dimethyl glutarate 3 by using an acid catalyst to obtain methyl 2-(3'-methoxycarbonyl)indolyl-acetate 4; 2. carrying out Claisen ester condensation on the methyl 2-(3'-methoxycarbonyl)indolyl-acetate 4 by using an alkali catalyst to prepare an intermediate 5; and 3. carrying out catalytic hydrogenation or NaBH4 reduction on the intermediate 5, and dehydrating to obtain the caulerpin 1.Compared with the existing caulerpin synthesis route, the synthesis method disclosed by the invention has the advantage of cheap and accessible raw materials; the reaction conditions are mild, and every step can be performed at normal temperature; and the method is simple and convenient to operate, is easy for mass synthesis, and is applicable to industrial production.

Owner:SHANGHAI MARITIME UNIVERSITY

Method for preparing glutaric acid from dimethyl glutarate

InactiveCN101696162AHigh activityIncrease reaction rateOrganic-compounds/hydrides/coordination-complexes catalystsPreparation from carboxylic acid esters/lactonesOrganic solventGlutaric acid

The invention discloses a method for preparing glutaric acid from dimethyl glutarate. The glutaric acid is prepared by taking a strongly acidic styrene type cation exchange resin as a catalyst and taking dimethyl glutarate and water as raw materials through a hydrolytic-catalytic reaction. Each liter of reaction solution contains 100 to 330g of resin, the volume ratio of the water to the dimethylglutarate is 6:1-20:1, the heating temperature of a reaction system is between 90 and 140 DEG C, and the reaction time is between 1 and 8h. The hydrolytic-catalytic reaction system is also provided with a fractionating device used for fractionating methanol generated by the reaction. The method has the advantages that: other organic solvents are unnecessarily added, the preparation system is circular and closed, and a preparation process is environment-friendly; the catalyst is high in activity, low in consumption and high in catalytic efficiency, and the conversion ratio of the dimethyl glutarate is can reach over 85 percent; the catalyst can recycled by a simple filtering step, and keeps the stable catalytic performance; and the raw materials and the catalyst are all sold on the market,so that the method has low cost and broad application prospect.

Owner:SOUTH CHINA UNIV OF TECH +1

Emulsus anti-rust oil

InactiveCN104479824AImprove thermal stabilityGuaranteed stabilityLubricant compositionPolyvinyl alcoholRare earth

The invention discloses emulsus anti-rust oil. The emulsus anti-rust oil is prepared from the following raw materials in parts by weight: 0.6-1 part of alpha-bromocinnamaldehyde, 0.1-0.2 part of stannous octoate, 0.6-1 part of ricinoleic acid, 1-2 parts of sodium potassium silicate, 1-2 parts of triglycidyl Isocyanurate, 1-2 parts of sea buckthron oil, 1-2 parts of propenol, 2-3 parts of dimethyl glutarate, 1-2 parts of 8-hydroxyquinoline, 0.4-1 part of Span-80, 5-7 parts of an antirust agent, 70-80 parts of No.30 mechanical oil, 1-2 parts of polyvinyl alcohol, 1-2 parts of triethanolamine oleate, 0.8-1 part of emulsifier OP-10 and 5-6 parts of anti-stripping mechanical oil. According to the emulsus anti-rust oil, film forming mechanical oil namely pentaerythritol oleate which has excellent lubricating performance and excellent surface film forming performance, is added and modified with 2,2,4-trimethyl-1,3-pentanediolmono(2-methylpropanoate) through blending, so that the film forming effect of a finished product can be remarkably improved, and the film forming temperature can be reduced; and the added rare-earth lanthanum ions can generate an insoluble complex with OH<-> which is generated on the surface of a metal substrate in an oxygen absorption corrosion process, so that the electrode reaction of corrosion can be retarded, and a good sustained release effect can be achieved.

Owner:WUHU HONGKUN AUTO PARTS

Diluent for washing photo-sensitive resin

InactiveCN1423171ASemiconductor/solid-state device manufacturingPhotosensitive material processingSolubilityDiluent

The present invention provides an excellent soluble, low poisonove, volatile thinner composition for rinsing photoresist, which is a thinner composition for removing photoresist resin before exposing the pattern of photoresist resin layer, it is selectively chosen from dimethyl glutarate, dimethyl succinate, dimethyl adipate or the dibasic ester (DBE) by the group of these compounds.

Owner:DUKSUNG

Acrylic resin polyurethane powder coating for ceramics

The invention discloses an acrylic resin polyurethane powder coating for ceramics. The acrylic resin polyurethane powder coating comprises the following raw materials: dimethyl glutarate, methacrylic acid, diethanol amine, lead naphthenate, carbon black, polysiloxane, ultraviolet ray absorber, polycarbodiimide, calcium stearate, azelaic acid, flatting agents, sorbitol anhydride monolaurate, butyl maleic acid, dimethyl dodecyl amine and methyl methacrylate; a melting point of the product is 180-200 DEG C and the density is130-150 g / cm<3>, and the phenomena of bubbling and dropping are avoided after the product is soaked for 40-50 days in water; the tensile strength is 20-40 MPa, the elongation rate is 300-400 percent, and the product is soaked for 25-35 days in a 5% hydrochloric acid solution and the abnormal phenomenon is avoided; the lustrousness is 115-135 percent, and the product is soaked for 20-30 days in saturated calcium hydroxide, and the phenomena of bubbling and wrinkling are avoided; the drying time is 20-30 minutes, and the time of the washing fastness is 1,600-2,000 times.

Owner:苏州非特兄弟新材料科技有限公司

Self-cleaning waterproof coating

ActiveCN104119716AImprove thermal insulation performanceGood wipe resistanceCoatingsPhosphatePolypropylene

The invention discloses a self-cleaning waterproof coating which comprises the following raw materials in parts by weight: 62-70 parts of silicone acrylic emulsion, 1-2 parts of linseed oil, 1-2 parts of zinc dihydrogen phosphate, 1-2 parts of sodium lauroyl sarcosine, 2-3 parts of dimethyl glutarate, 2-3 parts of maleic anhydride grafted polypropylene, 1-2 parts of dimethyl diallyl ammonium chloride, 1-2 parts of tetrabutylammonium bromide, 1.2-2 parts of laurate dihydroxyethylamide, 1-2 parts of isopropanol, 3-5 parts of nano bauxite, 6-8.5 parts of vermiculite powder, 0.5-1 part of ascorbic acid, 6-8 parts of film-forming assistant and 10-17 parts of de-ionized water. The waterproof coating has a very good heat insulation effect, and has good wiping resistance, waterproofness, self-cleaning effect, adhesiveness, acid-base resistance, corrosion resistance and storage stability and long shelf life; the formed coating is stable.

Owner:ANHUI KUAILAI WATERPROOFING & ANTI CORROSION

Environment-friendly wave-absorbing coating and preparation method thereof

ActiveCN109627832AEasy to useExtended service lifePolyurea/polyurethane coatingsRadiation-absorbing paintsBenzeneMethyl carbonate

The invention discloses an environment-friendly wave-absorbing coating and a preparation method thereof, and belongs to the field of wave-absorbing materials. The environment-friendly wave-absorbing coating comprises 7-73% of matrix resin, 9-63% of a wave-absorbing agent, 4-26% of a solvent, 0.5-2% of a dispersing agent, 0.4-1% of an anti-settling agent and 1-12% of a curing agent; wherein the solvent is selected from at least one of dimethyl carbonate, tert-butyl acetate, dimethyl adipate, dimethyl glutarate, dimethyl succinate, propylene glycol diacetate and propylene glycol methyl ether acetate. The environment-friendly wave-absorbing coating does not contain benzene, ketone and other solvents with high toxicity, high harm and carcinogenic risk, and has the advantages of environmental friendliness, low toxicity, low harm and no pollution; and a cured coating has good mechanical property and wave-absorbing property. The invention also provides a preparation method of the environment-friendly wave-absorbing coating.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

Lactofen and dicamba diglycol amine liquid formulations

The present invention relates to liquid agricultural formulations comprising from about 15 to about 40% w / w dicamba diglycol amine, from about 1 to about 15% w / w lactofen, from about 5 to about 40% w / w of a solvent selected from the group consisting of: (1) a solvent comprising dimethyl glutarate, dimethyl succinate, and dimethyl adipate; and (2) a solvent comprising a mixture of aromatic hydrocarbons obtained from distillation of aromatic streams derived from crude oil, from about 0.5 to about 5% w / w of a thickener with the chemical formula (Mg,Al)5Si8O20×4H2O, and from about 2 to about 15% w / w of a polyarylphenyl ether sulphate, ammonium salt surfactant, and methods of use thereof.

Owner:VALENT USA CORP

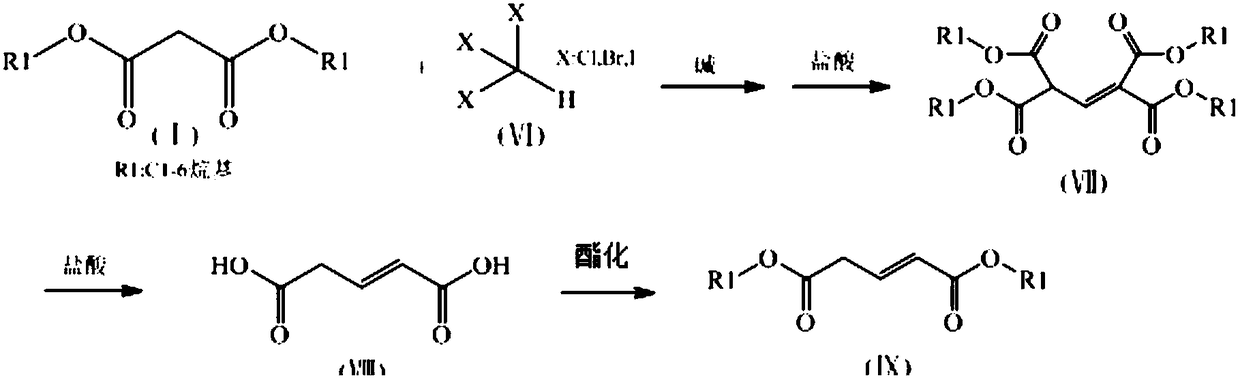

Preparation method of 3-substituted dimethyl glutarate and dimethyl glutaconate

ActiveCN108358783ALow priceWide range of market sourcesOrganic compound preparationCarboxylic acid esters preparationHalomethaneEsterification reaction

The invention relates to the field of fine chemical engineering, and particularly relates to a preparation method of 3-substituted dimethyl pentodiate and pentene diester. According to the preparationmethod of 3-substituted dimethyl pentodiate and pentene diester, malonic ester and halomethane are used as raw materials, substitution reaction is performed under an alkaline action, then decarboxylation and esterification reaction are performed so as to prepare 3-substituted dimethyl pentodiate or pentene diester, a structural formula of 3-substituted dimethyl pentodiate is as shown in a compound (V), and a structural formula of pentene diester is as shown in a compound (IX). The preparation method of 3-substituted dimethyl pentodiate and pentene diester is mild in reaction conditions, is easy to operate and is safe. The formula is shown in the description.

Owner:HAISO TECH

Solvent material formula for polytetrafluoroethylene high-frequency microwave copper-clad plate (CCL)

InactiveCN106634670ACuring time is easy to graspImprove adhesionFilm/foil adhesivesDielectricAdhesive

The invention discloses a solvent material formula for a polytetrafluoroethylene high-frequency microwave CCL, a solvent in an adhesive layer is mixed with dimethyl glutarate, fatty alcohol-polyoxyethylene ether, alkanolamide, polyvinylpyrrolidone, rosin resin, methyl-tri-butanone-oxime silane, triethylene tetramine, dimethyl adipate, dimethyl formamide and polyacrylamide at normal temperature and pressure by stirring, the obtained solvent is applied to the production technology of the CCL, the dielectric property and the mechanical property of the CCL can be improved, at the same time, the service life of the adhesive layer is prolonged and the use performance of the adhesive layer is improved, the curing time of the adhesive is easy to master, and the adhesive force of the adhesive is improved simultaneously.

Owner:金宝电子(铜陵)有限公司

Liquid-phase hydrofining method of 1, 5-pentanediol

PendingCN111099965AReduce the difficulty of operationLess investmentOrganic compound preparationCarboxylic acid esters preparationPtru catalystGlutaric acid

The invention provides a liquid phase hydrofining method of 1, 5-pentanediol. According to the method, a two-step process is adopted, firstly, dimethyl glutarate is generated through an esterificationreaction, and secondly, 1, 5-pentanediol is generated through a dimethyl glutarate liquid-phase hydrogenation process by adopting a modified nickel-based supported catalyst. According to the liquid phase hydrofining method, reaction is carried out on a fixed bed hydrogenation device, the adopted catalyst is a modified nickel supported catalyst, hydrogen required by reaction is providedby a liquidcirculating material, no expensive hydrogen circulating compressor is needed to be arranged in the device, a material passing through a reactor is a single liquid phase material, the production costis reduced, and the product quality is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Graphene-polymer fiber containing vegetable lubricant

The invention discloses a preparation method of a graphene-polymer fiber containing vegetable lubricant. The preparation method comprises adding a graphene-polymer fiber, liquid graphene, and 1-hexyl-3-decyl-3-methylimidazolium tetrafluoroborate into castor oil, stirring, adding isooctyl-3-(3,5-di-tert-butyl-hydroxyphenyl) propionate, polyisobutene disuccinimidyl, polyurethane, a demulsifying agent, an antifreezing agent, a corrosion resistant anti-rust agent, sasol wax, alkyl molybdenum salicylate, dimethyl glutarate, alkylated diphenylamines and a butyl acrylate resin, and stirring, so as toobtain the graphene-polymer fiber containing vegetable lubricant. The graphene-polymer fiber containing vegetable lubricant has characteristics of excellent lubricating property, viscosity-temperature property, low temperature fluidity, corrosion resistance and the like, and the comprehensive performance is excellent.

Owner:颜凤生

Degreasing agent for glass light guide plates

InactiveCN108410586AMiscibleMiscible fastOrganic detergent compounding agentsPolymeric surface-active compoundsDefoaming AgentsPhotochemistry

The invention provides a degreasing agent for glass light guide plates. The degreasing agent comprises, by weight, 35-50% of glycol ether solvent, 30-50% of acid ester solvent, 5-20% of detergents, 0.1-3% of demulsifiers, 0.1-3% of defoaming agents and 0.005-0.01% of chelating agents. The glycol ether solvent is one of propylene glycol monomethyl ether, dipropylene glycol methyl ether and dipropylene glycol mono butyl ether; the acid ester solvent is one of dimethyl succinate, butyl acetate and dimethyl glutarate. The degreasing agent for the glass light guide plates has the advantages that the degreasing agent is efficient in grease removal capacity, only 3% of degreasing agent needs to be added into each glass light guide plate, and accordingly 95% of grease attached to the surfaces of the glass light guide plates can be removed.

Owner:DONGGUAN YINTAIFENG OPTICAL TECH CO LTD

Rotproof and rustproof metal oil

The invention discloses rotproof and rustproof metal oil. The rotproof and rustproof metal oil is composed of the following raw materials in parts by weight: 1-2 parts of nitrilotriacetic acid, 50-60 parts of 500 sn base oil, 10-15 parts of kerosene, 2-3 parts of ethylenediamine tetraacetic acid copper disodium salt, 1-2 parts of fatty alcohol polyoxyethylene ether ammonium sulfate, 2-3 parts of dimethyl glutarate, 1-3 parts of tebelon, 2-4 parts of lanum, 0.8-2 parts of potassium citrate, 0.1-2 parts of isotridecyl alcohol ethoxylate, 0.4-1 part of dialkyl diphenol, 1-2 parts of diammonium hydrogen phosphate and 12-20 parts of rear earth corrosion inhibition hydraulic oil. The rear earth corrosion inhibition hydraulic oil is added in the rustproof oil disclosed by the invention; cis-epoxysuccinic acid is mixed with phosphate to play a good synergistic effect and ensure a stable corrosion inhibition function; the silicon aluminum sol can promote the compatibility of the materials and perfect the film forming effect of the finished product; the added rear earth ions can generate an insoluble complex with OH<-> generated in an oxygen uptake corrosion process with the surface of a metal base material, in order to alleviate the corrosion electrode reaction to play a good slow release effect.

Owner:HEFEI ZHENGTUO DECORATION MATERIALS CO LTD

Preparation method of lenalidomide

ActiveCN105440014ANovel process routeReasonable process conditionsOrganic chemistryGlutaric acidL glutamate

A preparation method of lenalidomide comprises the following steps: 1, reacting a raw material methyl 2-methyl-3-nitro-benzoate with a halogenating reagent to obtain methyl 2-halomethyl-3-nitro-benzoate represented by formula (I); 2, reacting the methyl 2-halomethyl-3-nitro-benzoate with dimethyl D,L-glutamate hydrochloride in the presence of an alkaline compound to obtain dimethyl 3-(7-nitro-1-oxo-1,3-dihydroisoindole-2-yl)glutarate represented by formula (II); 3, hydrolyzing the above compound of formula (II) to obtain 3-(7-nitro-1-oxo-1,3-dihydroisoindole-2-yl)glutaric acid represented by formula (III); 4, reducing the above compound of formula (III) to obtain 3-(7-amino-1-oxo-1,3-dihydroisoindole-2-yl)glutaric acid represented by formula (IV); and 5, carrying out ring closure on the above compound of formula (IV) to obtain lenalidomide represented by formula (V). The method has the advantages of simple process, high safety, cheap and easily available raw materials, good quality of the above product, and suitableness for industrial production.

Owner:HANGZHOU HEZE PHARMA TECH

Ultra-low ESR low-temperature curing silver paste and preparation method thereof

The invention discloses ultra-low ESR low-temperature curing silver paste and a preparation method thereof. The ultra-low ESR low-temperature curing silver paste comprises silver powder, an organic carrier and an additive, wherein the silver powder is mixed flake silver powder of flake silver powder with different particle sizes, the organic carrier comprises a resin, an organic solvent, a curing agent and an accelerant, the resin is ethyl cellulose resin or one or more of epoxy resin and phenolic resin, the organic solvent is composed of one or more of DBE, diethylene glycol butyl ether acetate, dimethyl glutarate and butyl carbitol, the curing agent is blocked isocyanate or dicyandiamide or imidazole, and the additive is one or a mixture of more of triglycerol acetate and fumed silica. According to the invention, the problem that existing organic tantalum capacitor leading-out end silver paste is large in ESR and unstable is solved, and the ultra-low ESR low-temperature curing silver paste is widely applied to the electrode material of the organic tantalum capacitor leading-out end.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

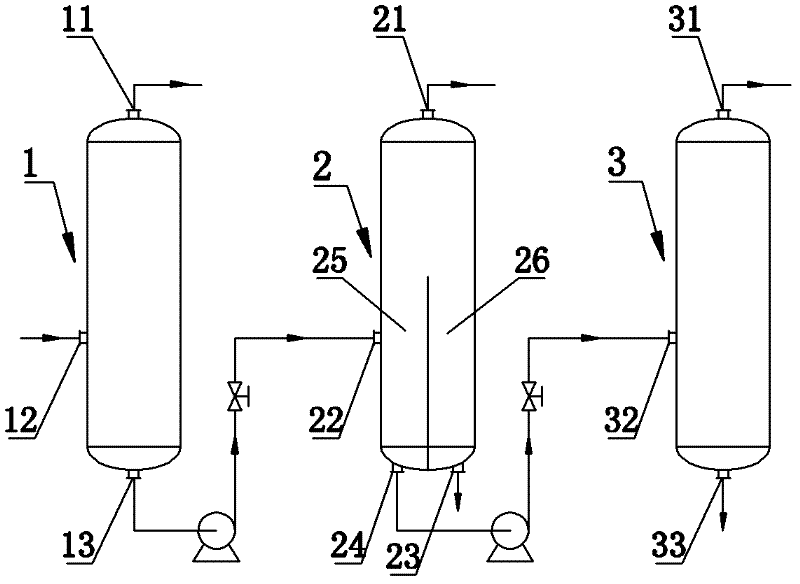

Method for purifying diacid dimethyl esters by plate distillation separation

ActiveCN102432460AReduce consumptionSimple processOrganic compound preparationCarboxylic acid esters preparationGlutaric acidButanedioic acid

The invention discloses a method for purifying diacid dimethyl esters by plate distillation separation. The distillation separation is successively finished in three series-wound distillation towers. The bottom of a second distillation tower is vertically provided with a separator plate, which divides the bottom cavity into a first tower chamber and a second tower chamber. A material inlet of the second distillation tower is positioned below the top of the separator plate. The method provided by the invention comprises the following steps of: mixing a raw material with diacid dimethyl esters, allowing the mixture to enter into the first distillation tower, separating a light component out from the top of first distillation tower, allowing the material at the tower bottom to enter into the second distillation tower, separating 1,4-succinic acid dimethyl ester out from the top of the distillation tower, separating 1,5-dimethyl glutarate out from the bottom of the second tower chamber of the second distillation tower, allowing the material at the tower bottom of the first tower chamber of the second distillation tower to enter into the third distillation tower, separating 1,6-adipic acid dimethyl ester out from the top of the third distillation tower, and discharging a heavier component in the raw material from the tower bottom. Starting with the first distillation tower, the temperature of the distillation towers successively rises and the pressure successively reduces.

Owner:WEIFANG YUANLI CHEM

Method for preparing static-suppressor functional slurry cured at low temperature

InactiveCN104464993AHigh mechanical strengthImprove electrical performanceResistor manufactureOvervoltage protection resistorsSolid componentEpoxy

The invention discloses a method for preparing static-suppressor functional slurry cured at low temperature. The slurry is composed by adding solid constituents using low-temperature-cured organic matter as a carrier. The carrier consists of a resin, a diluent, a curing agent and a curing accelerator at a certain mass ratio, wherein the resin includes epoxy resin and phenolic resin; the diluent is a mixture of dimethyl glutarate, dimethyl adipate and dimethyl succinate; the curing agent is dicyandiamide; and the curing accelerator is organic carbamide. The solid constituents are composed of talcum powder, silica and aluminium powder at a certain mass ratio. According to the invention, the static-suppressor slurry is suitable for a thick-film technology platform and is used to prepare a chip-type static suppressor. Stronger adhesive force is realized between the cured slurry and an alumina ceramic substrate. The slurry has characteristics of great mechanical strength itself, damp and heat resistance, low trigger voltage, and good consistency.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

Method for separating mixed diacid dimethyl ester

InactiveCN103965043AIncrease profitImprove separation efficiencyOrganic compound preparationCarboxylic acid esters preparationRefluxAdipic acid dimethyl ester

The invention discloses a method for separating mixed diacid dimethyl ester. Mixed diacid dimethyl ester successively passes through a rectification tower 1, a rectification tower 2 and a rectification tower 3; dimethyl succinate is separated from the top of the rectification tower 1, dimethyl glutarate is separated from the top of the rectification tower 2, and dimethyl adipate is separated from the top of the rectification tower 3; the reflux ratio of the rectification tower 1, the rectification tower 2 or the rectification tower 3 is 0.5 to 3.0; the mixed diacid dimethyl ester is a product of esterification of methanol and mixed diacid by-produced in production of adipic acid, and comprises 10 to 30 wt% of dimethyl succinate, 40 to 60 wt% of dimethyl glutarate and 20 to 40 wt% of dimethyl adipate. With the method, the recovery rate and purity of dimethyl succinate, dimethyl glutarate and dimethyl adipate are more than 95 wt% and no less than 98%, respectively. According to the invention, a rectification apparatus is divided into the three rectification towers, each rectification tower is provided with 5 to 30 tower plates, the reflux ratio is controlled to be 0.5 to 3, energy consumption is low, the utilization rate of resources is high, and the advantages of easy realization of industrialization and low energy consumption are obtained.

Owner:CHINA PETROLEUM & CHEM CORP

Carbon steel material anti-rust oil

InactiveCN104531315AImprove the lubrication effectGood surface film formationLubricant compositionCoconut diethanolamideManganese

The present invention discloses a carbon steel material anti-rust oil, which comprises the following raw materials, by weight, 1-2 parts of alkenyl succinic anhydride, 90-100 parts of heat conduction oil, 3-5 parts of cypress oil, 4-7 parts of sodium myrastate, 1-2 parts of sodium benzoate, 1-2 parts of dimethyl glutarate, 0.4-1 part of coconut diethanolamide, 1-2 parts of dibutyl maleate, 0.1-0.3 part of manganese isooctanoate, 1-2 parts of sp-80, 2-4 parts of tris(nonylphenyl) phosphite, 0.6-1 part of diammonium phosphate, and 4-6 parts of film forming machine oil. According to the present invention, the added film forming machine oil pentaerythrite oleate with characteristics of excellent lubricity and good surface film forming property and the dodecyl alcohol ester are subjected to co-mixing modification so as to significantly improve the film forming effect of the finished product and reduce the film forming temperature, and the added rare earth lanthanum ions and the OH<-1> produced during the oxygen uptake etching process occurring on the metal substrate surface can produce the insoluble complex so as to slow down the etching electrode reaction and provide the good slow-release effect.

Owner:ANHUI RONGDA VALVE

Nail polish and preparation method thereof

InactiveCN109833231ALess irritatingAvoid harmCosmetic preparationsToilet preparationsWater basedNitrocellulose

The invention belongs to the technical field of cosmetics, and particularly relates to nail polish and a preparation method thereof. The nail polish is prepared from the following raw materials in parts by weight: 30-40 parts of an acrylic acid emulsion, 40-65 parts of water-based acrylic resin, 20-25 parts of glycerol, 10-15 parts of urea, 4-8 parts of dimethyl glutarate, 10-25 parts of nitrocellulose, 3-10 parts of coconut essential oil, 1-10 parts of silica, 2-5 parts of sucrose benzoate, 2-6 parts of titanium dioxide, 2-8 parts of a vegetable pigment, 3-6 parts of an antimicrobial agent, 1-3 parts of linoleic acid oil and 60-80 parts of water. The nail polish disclosed by the invention has the advantages of bright luster, no irritation, water-based film forming agent and the like.

Owner:沈阳邦正科技有限公司

Thickened grease composition

InactiveUS20140303052A1Drop separationDrop stabilityThickenersAdditivesGlutaric acidLithium hydroxide

A thickened grease composition is provided by process of heating a mineral oil and 12-hydroxystearic acid with lithium hydroxide and forming a simple lithium grease to which at least one component selected from the group comprising succinic acid, glutaric acid, adipic acid, 6-hydroxycaproic acid, dimethyl succinate, dimethyl glutarate, dimethyl adipate, methyl hydroxycaproate, cyclohexanediols, methyl 5-hydroxyvalerate, methyl valerate, gamma butyrolactone, and methyl levulinate or mixtures thereof.

Owner:INVISTA NORTH AMERICA R L

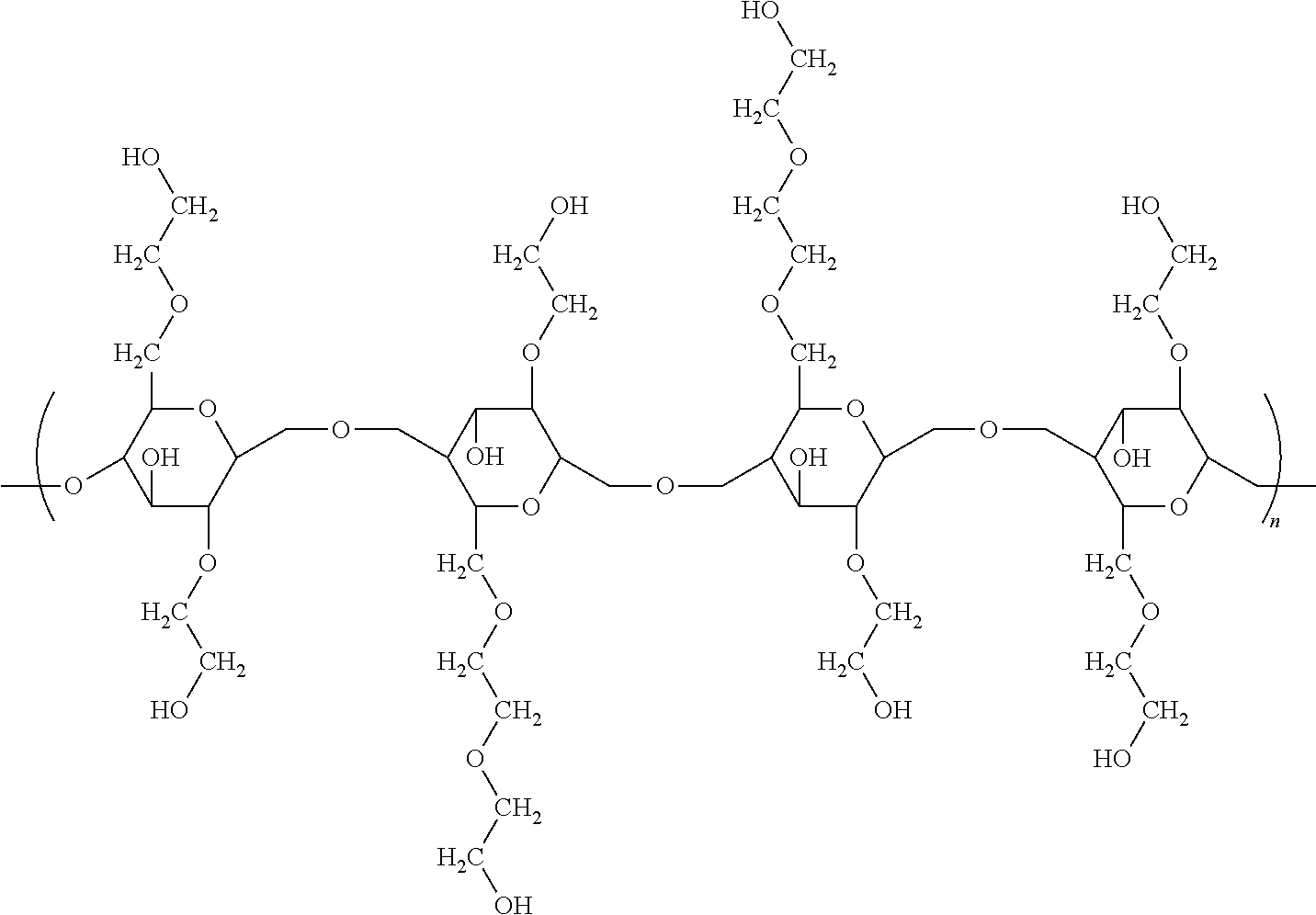

PBAT resin composition and preparation method thereof

The invention relates to a PBAT resin composition and a preparation method thereof, which mainly solve the problems of poor hue and poor melt flowability of PBAT resin in the prior art. The PBAT resin composition comprises poly(butylene adipate terephthalate) and dimethyl glutarate. Based on the total weight of the PBAT resin composition, the weight content of the dimethyl glutarate is 0.05 ppm to 1000 ppm. The PBAT resin composition has excellent glossiness and yellowing resistance, and can improve the flowability of PBAT melt and improve the processability.

Owner:WANHUA CHEM GRP CO LTD

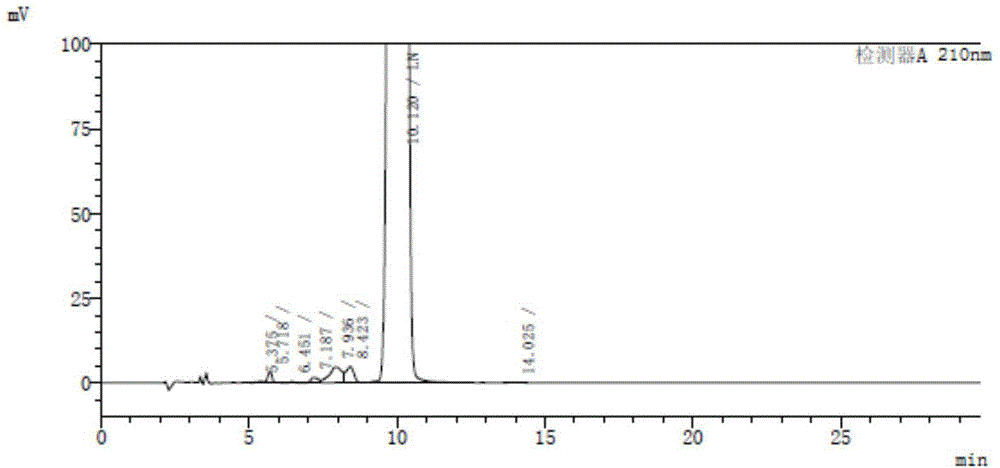

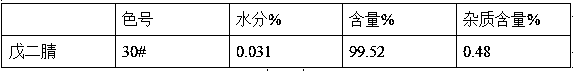

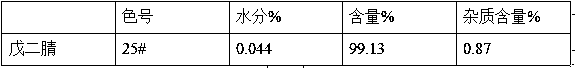

Production method for preparing glutaronitrile by aminolysis of ester substances

ActiveCN111454172AShort reaction timeImprove conversion efficiencyOrganic compound preparationCarboxylic acid amides preparationGlutaric acidChemical dehydration

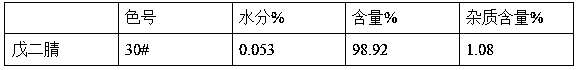

The invention provides a production method for preparing glutaronitrile by aminolysis of ester substances. The production method comprises the following steps: ester aminolysis reaction, amide dehydration nitrile-forming reaction, coarse treatment and refining treatment, and the ester aminolysis reaction is carried out in a microreactor with an umbrella-shaped channel structure by using dimethyl glutarate and ammonia water as raw materials, so that rapid and complete mass transfer reaction of the materials is realized, the conversion efficiency of the raw materials is improved, and the reaction time is greatly shortened. A chemical dehydrating agent is adopted to participate in the reaction, so that the reaction temperature is reduced, the side reaction is inhibited, and the dehydration reaction time is shortened. Through coarse treatment, trace impurities in the material can be removed, product decomposition caused in the subsequent refining process is reduced, according to the production method, the content of the finally prepared glutaronitrile reaches 98.9-99.5%, the color number is 25-30 #, and the quality of the prepared glutaronitrile product is excellent.

Owner:山东元利科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com