Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Miscible" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brightening agent for vehicle without water washing, and preparation method

A type of anhydrous car washing polish agent is prepared from wax polish, emulsifier, solvent naphtha, oleic acid, additive and distilled water of which emulsified is made of nonylphenol polyethenoxy ether dehydrosorbito oleate polyethenoxy ether -80 or -60 and TA-20 emulsifier. The preparation method is included in operation manual.

Owner:王金环

Environment-friendly long-life cutting fluid and preparation method thereof

ActiveCN104017638AImprove the lubrication effectGood extreme pressure and anti-wear propertiesLubricant compositionElectrolysed waterActive agent

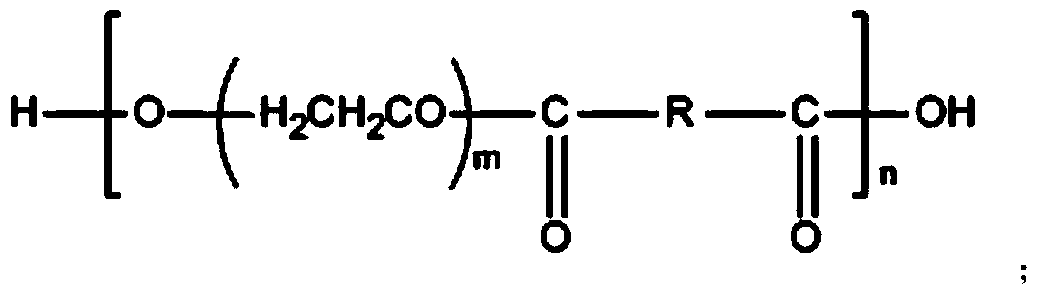

The invention provides an environment-friendly long-life cutting fluid, which is characterized by consisting of the following components by weight percentage: 2-5% of polyethylene glycol succinate, 95-98% of alkaline electrolysis water, 0-0.3% of phosphate, 0-0.3% of borate and 0-0.01% of benzotriazol. The major component polyethylene glycol succinate salt of the cutting fluid system provided by the invention is an anionic and non-ionic surface active agent, so even if a small amount of some other lubricating oil is introduced into a workpiece or a guide in the machining process, polyethylene glycol succinate salt can emulsify the lubricating oil into cutting fluid for usage, without reducing the usage performance.

Owner:株洲开元润滑材料股份有限公司

Powder fine quantitative storage and transportation delivery device and method thereof

ActiveCN106829227ASynchronous change of mass flow rateRealize homogeneous spiral flow conveying technologyLarge containersBulk conveyorsEngineeringNegative feedback

The invention relates to a powder fine quantitative storage and transportation delivery device and a method thereof. The powder fine quantitative storage and transportation delivery device comprises a large storage powder hopper, a small powder hopper, a metering screw pump, a negative-pressure air-powder mixing tube, wherein the large storage powder hopper is provided with a box neck; a fine pattern screw is in threaded connection with a plug and the fine-thread screw and the plug are arranged inside of the large storage powder hopper; the upper end of the fine-thread screw is connected with a rotary drive device; the coarse-thread screw and the fine-thread screw are coaxially arranged, and the coarse-screw rod is positioned in the drive powder section; the large storage powder hopper outlet is connected with the inlet of the small powder hopper; a negative feedback degree measurement and control device is install on the upper end of the small powder hopper and measuring rods of the negative feedback degree measurement and control device extend into the small powder hopper; the outlet of the small powder hopper is connected with the inlet of metering screw pump and the outlet of the metering screw pump is connected to the middle necking of the negative-pressure air-powder mixing tube; the outlet of air-power mixing tube is connected with an air and powder mixed delivery pipe. The powder fine quantitative storage transportation delivery device guarantees the synchronous change of the powder volume flow and the mass flow through the screw plug pump and the equal volume movement principle.

Owner:凭祥市友福中医药科技有限公司

Pulp wrapping equipment

PendingCN107125797AImprove stirring efficiencyImprove preparation efficiencyTransportation and packagingMixing methodsImpellerDisperser

The invention belongs to the technical field of food processing, and discloses pulp wrapping equipment. The pulp wrapping equipment comprises a pulp wrapping body, an anchor agitator, a disperser and an emulsifier, wherein the pulp wrapping body comprises a mixing cavity and a discharging hole; the anchor agitator comprises an agitation driving mechanism, an agitating shaft and anchor blades; a revolving cavity is formed during rotation of the anchor blades around the agitating shaft; the disperser comprises a dispersing motor, a dispersing shaft and an impeller; the emulsifier comprises an emulsifying motor, an emulsifying shaft and a working head. In the pulp wrapping equipment, the anchor agitator is arranged, so that powder carrying seasoning powder is prevented from attaching to an inner wall of the mixing cavity when the powder encounters water; the impeller of the disperser is arranged in the revolving cavity, so that the powder can be dissolved in the water more easily, and the agitating efficiency of the anchor agitator is increased; the working head of the emulsifier is arranged in the revolving cavity, so that emulsification operation can be performed while the powder is dispersed and a mixed solution of the powder and the water is agitated, and the preparation efficiency of pulp is increased.

Owner:JIN MAILANG MIANPIN CO LTD

Purifying and liquefying process for re-injecting oilfield CO2 flooding produced gas

InactiveCN106761659AOffset negative effectsGuaranteed Separation RateFluid removalCo2 floodingCO2 content

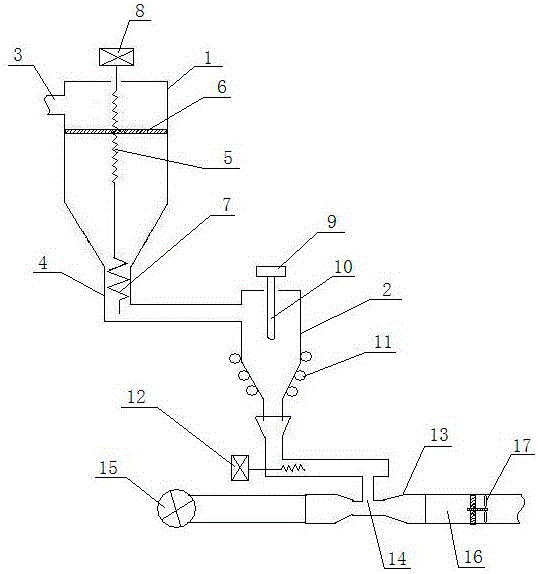

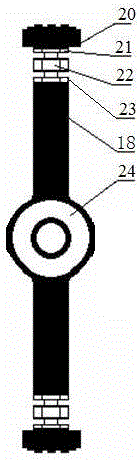

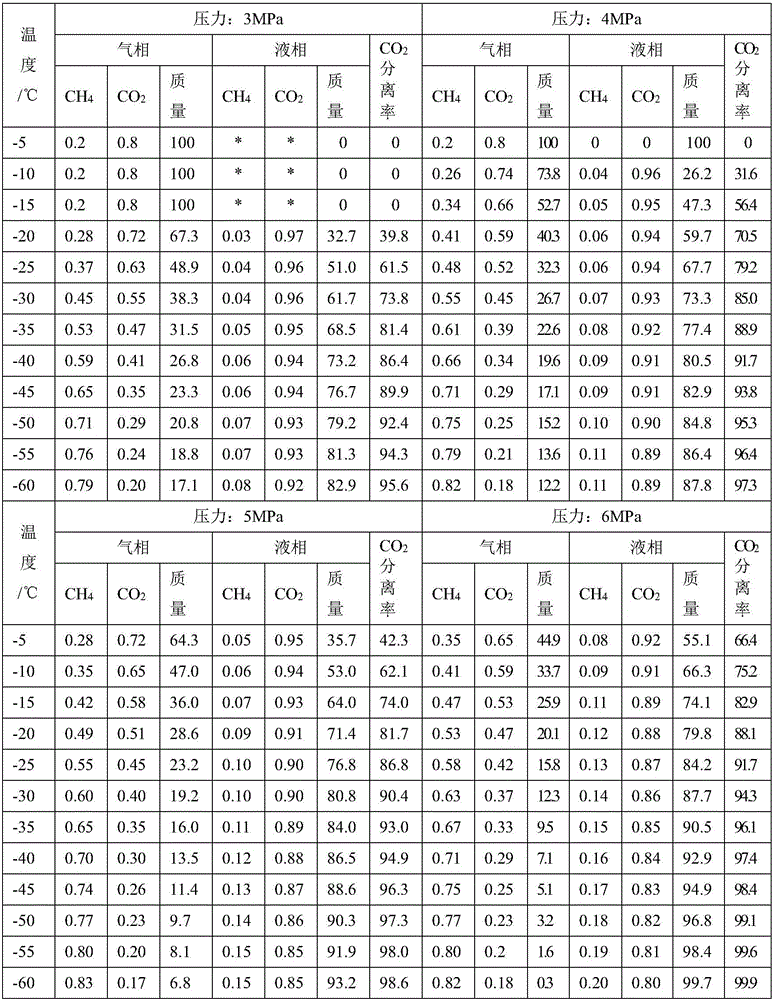

The invention relates to the field of exploration and development of petroleum and gas, and provides a technique for purifying, liquefying and re-injecting oilfield CO2 flooding produced gas. According to the technical point, a method of supercharging by a multi-stage compressor and cooling by five-stage heat exchange is adopted, and the purpose of separating and liquefying the produced gas is achieved. The technique comprises the following process steps: supercharging the pretreated oilfield CO2 flooding produced gas by using a multi-stage compressor unit so as to reduce liquefying temperature of gas; and liquefying CO2 in a five-stage heat exchange cooling mode while the produced gas is separated. The technique has the advantages that for the high-CO2-content produced gas, the liquefying temperature of the gas can be reduced gradually along with rising of pressure in a certain range; and under the same pressure, the liquefying temperature of CO2 is higher than that of CH4 and N2. By the technique, while the produced gas is separated, purified and liquefied, injected liquid CO2 can be heated, energy is saved, and engineering cost is reduced.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

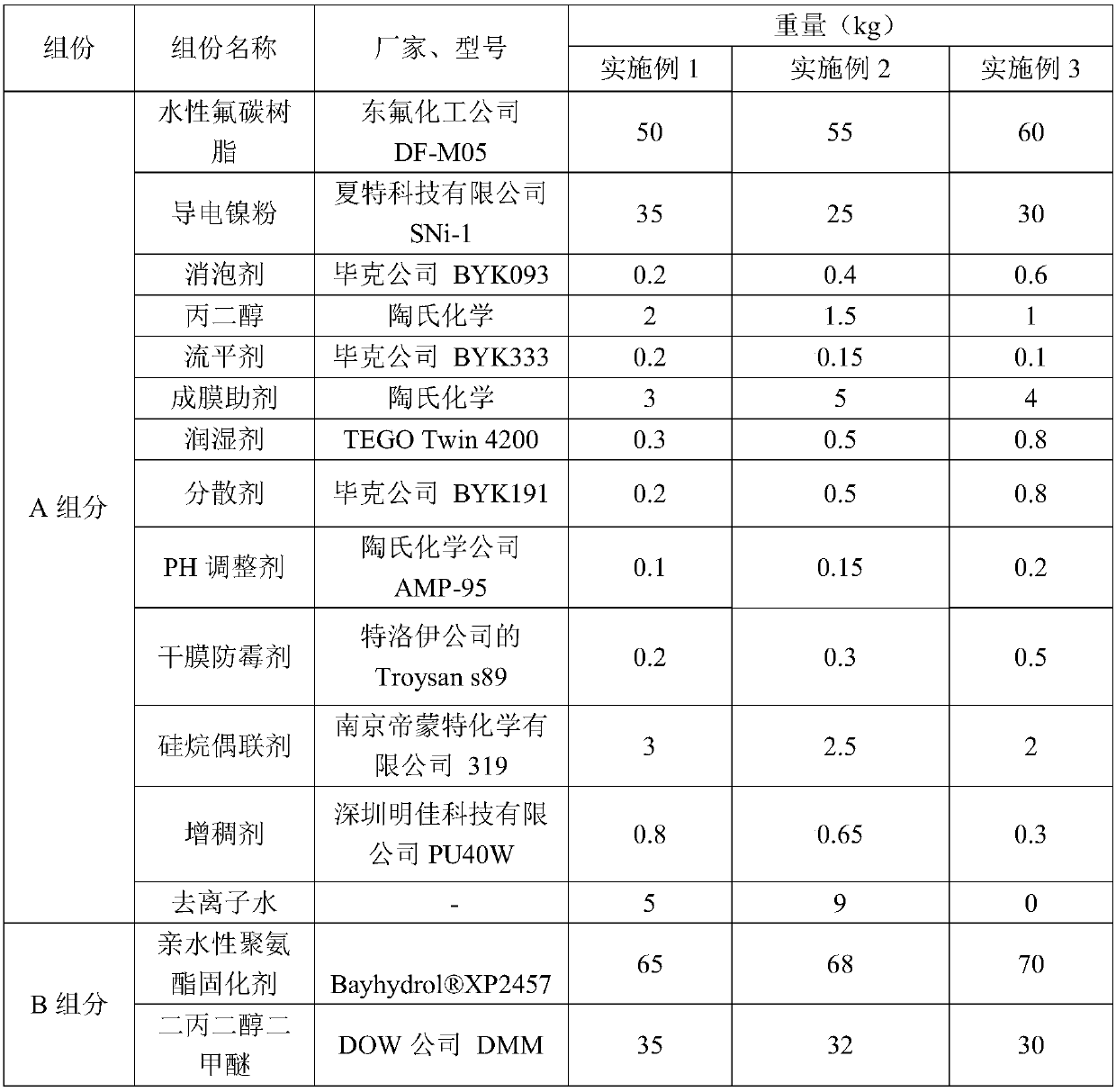

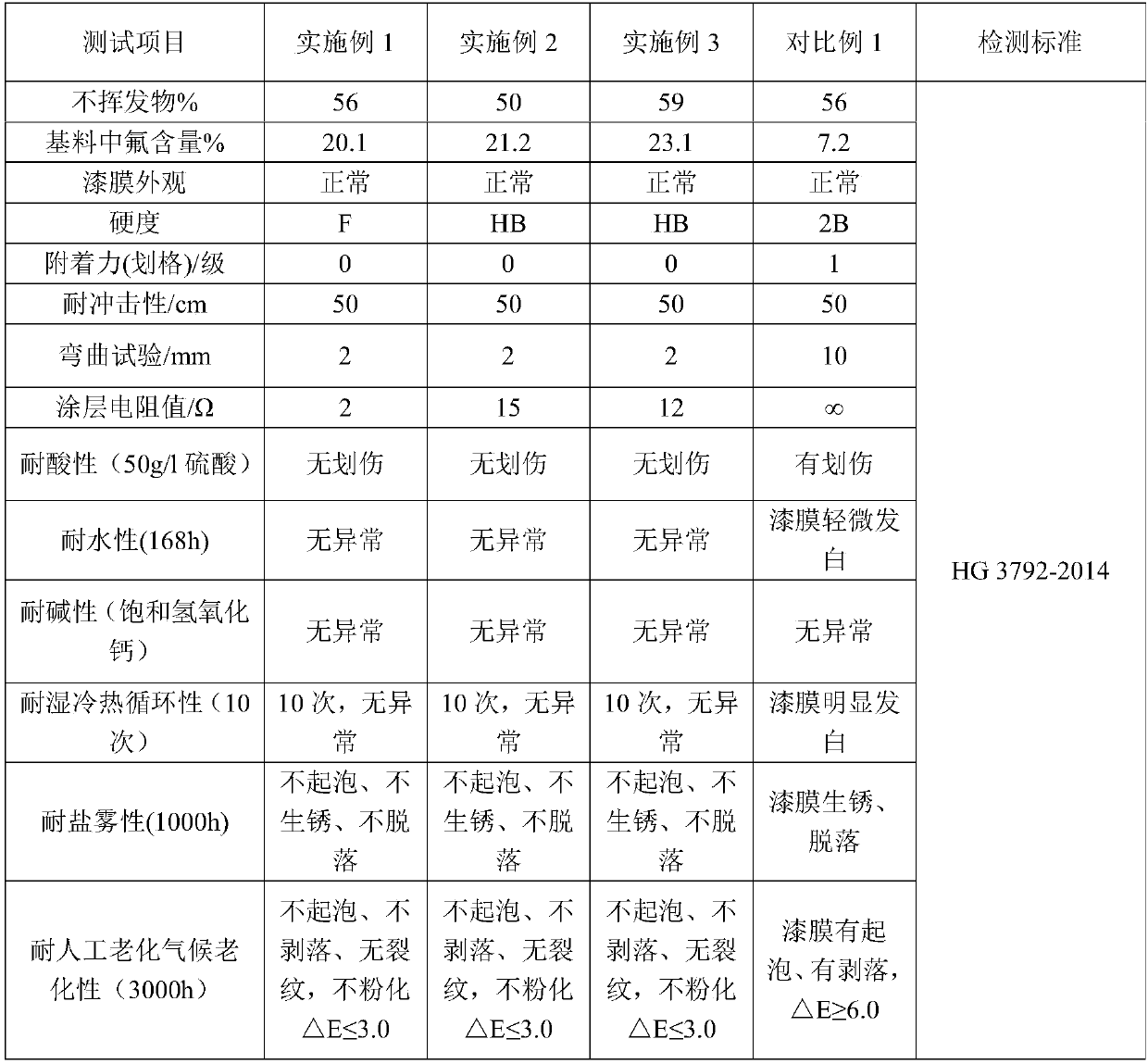

Waterborne bicomponent fluorocarbon conductive anticorrosion paint and preparation method and application method thereof

InactiveCN109575707AImprove crosslink strengthImprove functionalityLiquid surface applicatorsAnti-corrosive paintsDefoaming AgentsMaterials science

The invention provides a waterborne bicomponent fluorocarbon conductive anticorrosion paint, made by mixing component A and component B; the component A comprises, by weight, 50-60 parts of waterbornefluorocarbon resin, 25-35 parts of conductive nickel powder, 1-2 parts of propylene glycol, 0.2-0.6 part of a defoaming agent, 2-3 parts of silane coupling agent, 0.2-0.8 part of a dispersant, 0.1-0.2 part of a leveling agent, 0.1-0.2 part of a PH regulator, 0.3-0.8 part of a wetting agent, 0.2-0.5 part of a dry film mildew preventive, 3-5 parts of a film-forming aid, 0.3-0.8 part of a thickener,and 0-9 parts of deionized water; the component B comprises 65-70 parts of hydrophilic isocyanate curing agent, and 30-35 parts of dipropylene glycol dimethyl ether; the weight ratio of the componentA to the component B is 10:1. film of the waterborne bicomponent fluorocarbon conductive anticorrosion paint has excellent weatherability, water resistance, oil resistance, low temperature resistance, solution resistance, corrosion resistance, and conductivity; static electricity on the surface of a coating layer can be effectively eliminated.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Mineral oil composite emulsifier and preparation method thereof

The invention relates to the technical field of glass cotton production, in particular a mineral oil composite emulsifier and a preparation method thereof. The mineral oil composite emulsifier comprises the following components in part by weight: 50 to 80 parts of bright oil, 10 to 20 parts of oleic acid, 20 to 40 parts of triethanolamine, 20 to 50 parts of sodium dodecyl benzene sulfonate, 10 to 40 parts of surfactant and 60 to 80 parts of distilled water. The mineral oil composite emulsifier mainly solves the technical problem that much silicon dioxide dust is easily generated in the production process of the glass and the glass cotton product, and can soften glass fibre and greatly reduce the silicon dioxide dust in the air.

Owner:上海久安水质稳定剂厂

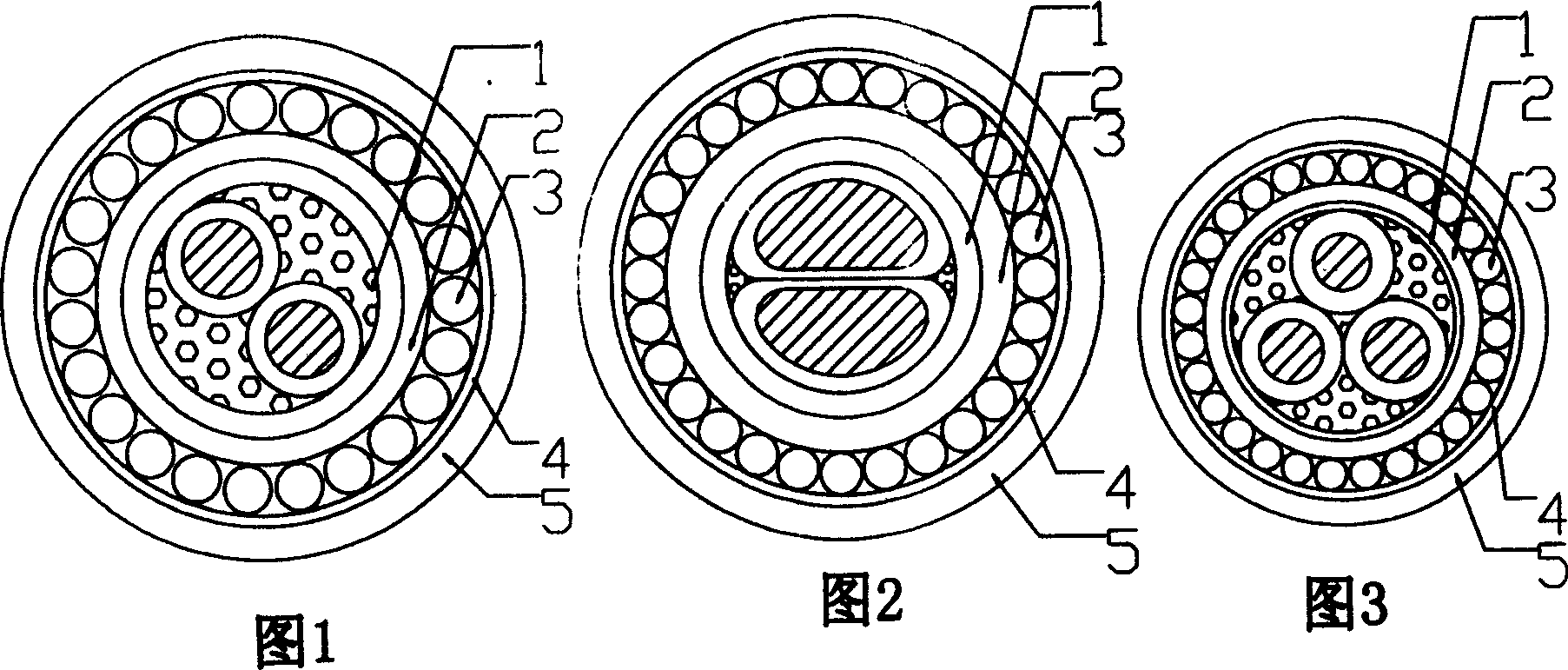

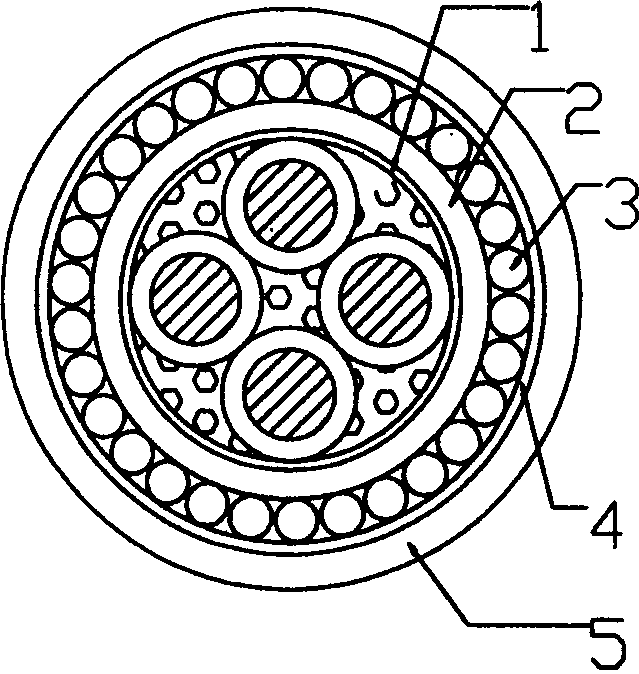

Special electric cables and their pretective covering materials in environment with strong lightings, strong ultraviolet radiation, large temperature differential and cold

InactiveCN1585043AIncreasing the thicknessHigh dielectric strengthPlastic/resin/waxes insulatorsInsulated cablesThunderstormCopper wire

In this invention, the material of the jacket illustrated, which is used for protecting the cable of special-purpose in the environments of high cold, strong ultraviolet, and strong thunderstorm. The material contains (weight portion) the polyvinyl chloride, 65-75, the sulphation butyronitrile rubber 25-35, the light stabilizer 0.1-3. The thickness of the jacket is greater than that of the standard about 20%. The armor layer applies the rough gauge wire with copper wire, which is suitable in applying in the plateau.

Owner:TBEA DEYANG CABLE CO LTD

Brightening agent for vehicle without water washing, and preparation method

InactiveCN1245490CGood emulsifying effectImprove stabilitySurface-active detergent compositionsPolishing compositionsWaxEmulsion

A type of anhydrous car washing polish agent is prepared from wax polish, emulsifier, solvent naphtha, oleic acid, additive and distilled water of which emulsified is made of nonylphenol polyethenoxy ether dehydrosorbito oleate polyethenoxy ether -80 or -60 and TA-20 emulsifier. The preparation method is included in operation manual.

Owner:王金环

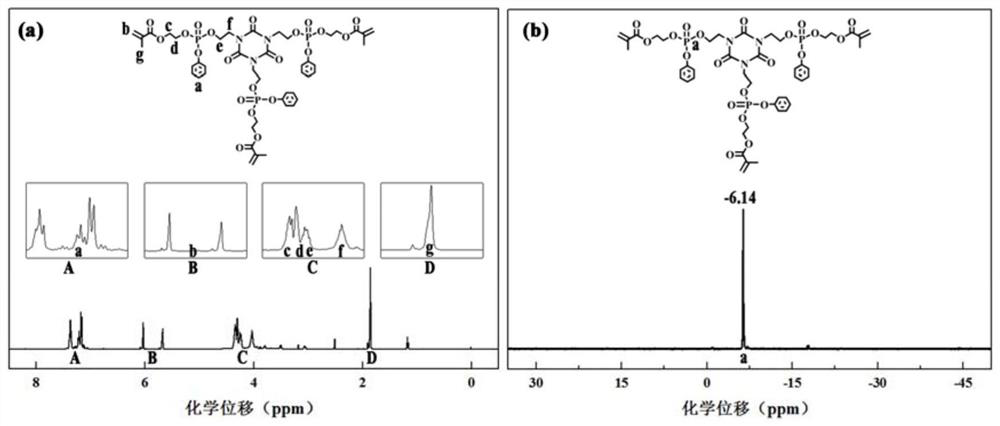

Phosphorus-nitrogen-containing liquid acrylate monomer and flame-retardant vinyl ester resin and preparation method thereof

ActiveCN111777640ASolve the problem of poor process performance due to increased viscosityLow viscosityGroup 5/15 element organic compoundsBulk chemical productionPolymer sciencePhosphoric acid

The invention discloses a phosphorus-nitrogen-containing liquid acrylate monomer and flame-retardant vinyl ester resin and a preparation method thereof. The liquid acrylate monomer containing three phosphorus, three nitrogen and three carbon-carbon double bonds in the molecular structure is synthesized through a substitution reaction among phenyl dichloro-phosphate, partially methacrylated or acrylated alcohol and tris(2-hydroxyethyl) isocyanurate; and can be used as a reactive flame retardant and added into common vinyl ester resin to prepare halogen-free flame retardant vinyl ester resin. The liquid acrylate monomer has the advantages of environmental friendliness, simple preparation method, and controllable process conditions; the problems that the physical and mechanical properties ofthe matrix are reduced due to poor compatibility of an additive flame retardant and a matrix, and the viscosity of the resin is increased and the processing property is poor due to the fact that a solid flame retardant is insoluble in resin are solved, and the flame retardant property and the smoke suppression property of vinyl ester resin can be greatly improved.

Owner:WUHAN UNIV OF TECH

Degreasing agent for glass light guide plates

InactiveCN108410586AMiscibleMiscible fastOrganic detergent compounding agentsPolymeric surface-active compoundsDefoaming AgentsPhotochemistry

The invention provides a degreasing agent for glass light guide plates. The degreasing agent comprises, by weight, 35-50% of glycol ether solvent, 30-50% of acid ester solvent, 5-20% of detergents, 0.1-3% of demulsifiers, 0.1-3% of defoaming agents and 0.005-0.01% of chelating agents. The glycol ether solvent is one of propylene glycol monomethyl ether, dipropylene glycol methyl ether and dipropylene glycol mono butyl ether; the acid ester solvent is one of dimethyl succinate, butyl acetate and dimethyl glutarate. The degreasing agent for the glass light guide plates has the advantages that the degreasing agent is efficient in grease removal capacity, only 3% of degreasing agent needs to be added into each glass light guide plate, and accordingly 95% of grease attached to the surfaces of the glass light guide plates can be removed.

Owner:DONGGUAN YINTAIFENG OPTICAL TECH CO LTD

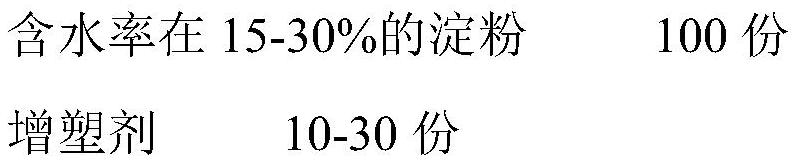

Multi-stage modified thermoplastic starch master batch and application thereof in preparation of starch-based biodegradable film

The invention discloses multi-stage modified thermoplastic starch master batch. According to the invention, starch is subjected to four-stage graded modification treatment. The graded modification treatment comprises the following steps: weighing 100 parts of starch with a water content of 15-30%, and stirring the starch in a high-speed mixer for the first time at a room temperature at a high speed; carrying out heating to 50-70 DEG C, adding polybutadiene, a plasticizer and a chemical modifier, and carrying out high-speed stirring for the second time; carrying out heating to 75-95 DEG C, adding a tackifier, a lubricant, a filler and a chain extender, and carrying out stirring at a high speed for the third time; adding biodegradable resin at the temperature, and carrying out stirring at a high speed for the fourth time; and stopping stirring, keeping the temperature for a period of time, and then adding a formed mixture into a double-screw extruder for melt extrusion. The invention also discloses a preparation method and application of the multi-stage modified thermoplastic starch master batch. The thermoplastic starch master batch disclosed by the invention can effectively improve the compatibility of starch and other biodegradable materials; and meanwhile, the content of starch in a biodegradable film is improved, and relatively good mechanical properties, film surface smoothness and certain transparency are kept.

Owner:NANJING WURUI BIODEGRADABLE NEW MATERIAL RES INST CO LTD

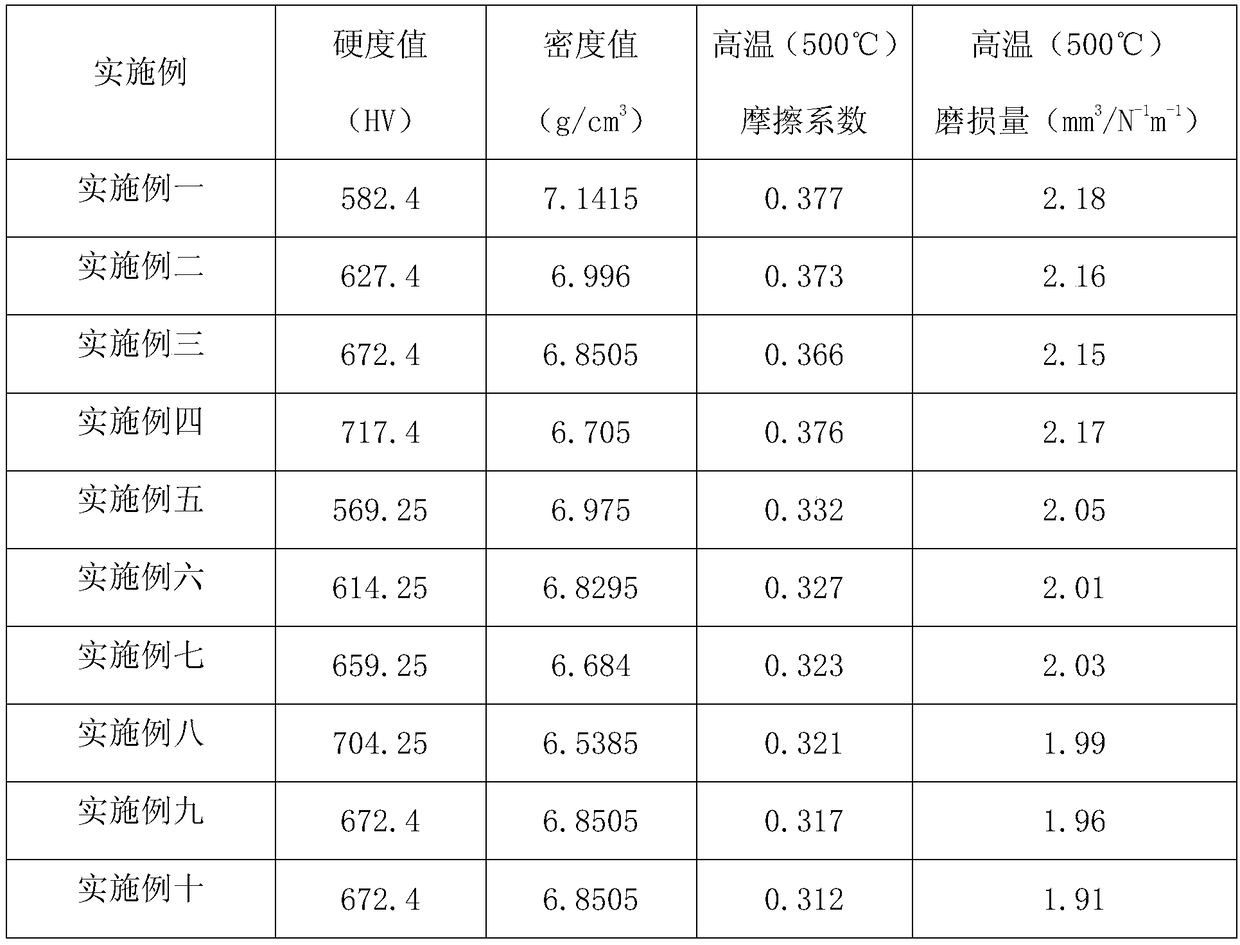

Fe based self-lubricating composite material suitable for high temperature and low temperature and preparation method thereof

ActiveCN109321849AIncrease coefficient of frictionImprove wear rate defectsChemical compositionMetallurgy

The invention provides a Fe based self-lubricating composite material suitable for high temperature and low temperature and a preparation method thereof. The composite material comprises the following chemical components in percentage by volume: 5-20 vol.% of TiCx (x is not smaller than 0.4 and not bigger than 1.1), 10-35 vol.% of Ti3SiC2, 1-7 vol.% of Cu, 0.1-3 vol.% of Ni, 0.1-3 vol.% of Cr, 0.1-7.5 vol.% of onion carbon, and the balance of Fe powder. The preparation method of the composite material is mainly to perform mixing, pre-pressing drying and discharge plasma sintering on the TiCxpowder, the Ti3SiC2 particles, the onion carbons and the Fe base alloy powder to prepare the Fe based self-lubricating composite material suitable for high temperature and low temperature. The preparation method is simple in operation, short in preparation period and suitable for batch production of such anti-friction materials as self-lubricating bearings under bad working conditions.

Owner:YANSHAN UNIV

Fe-based high-temperature-resistant self-lubricating composite material and preparation method thereof

The invention discloses a Fe-based high-temperature-resistant self-lubricating composite material. The Fe-based high-temperature-resistant self-lubricating composite material comprises 5-20 vol.% of TiCx (x is greater than or equal to 0.4 and less than or equal to 1.1), 10-40 vol.% of Ti3SiC2, 1-7 vol.% of Cu, 0.1-3 vol.% of Ni, 0.1-3 vol.% of Cr, and the balance Fe power. The preparation method of the composite material mainly comprises the following steps that uniform ball-mixing, pre-pressing and drying and spark plasma sintering are carried out on TiCx powder, Ti3SiC2 and Fe-based alloy powder so as to prepare the Fe-based high-temperature-resistant self-lubricating composite material with Ti3SiC2 and TiCx as lubricating phases. The preparation method is simple to operate and short inpreparation period, and the prepared Fe-based high-temperature-resistant self-lubricating composite material has low friction coefficient and wear rate, and has the high bearing capacity, high strength and the like, and is suitable for batch production of antifriction materials such as self-lubricating bearings under severe working conditions.

Owner:YANSHAN UNIV

Special graphene master batch for heavy duty anticorrosion dry powder coating and preparation method

InactiveCN109233398AFast curingMiscibleAnti-corrosive paintsPolyurea/polyurethane coatingsUltravioletUrethane acrylate

The invention provides a special graphene master batch for a heavy duty anticorrosion dry powder coating and a preparation method. The preparation method comprises the following steps: adding a flakyinorganic carrier loaded with graphene microchips, a dispersant, a catalyst, an initiator and a photocurable urethane acrylate prepolymer into deionized in sequence, and carrying out ultrasonic treatment to enable the mixture to disperse uniformly to obtain a flaky carrier coated with the photocurable urethane acrylate prepolymer; carrying out ejection atomization pelletizing under radiation of UV(Ultraviolet Rays), and collecting to prepare the special graphene master batch for the heavy duty anticorrosion dry powder coating. By adopting the method, the graphene microchips can be immobilizedin the flaky inorganic carrier through photocuring reactions of the photocurable urethane acrylate prepolymer, the prepared graphene master batch can be directly mixed with the heavy duty anticorrosion dry powder coating for hot melting spraying, the graphene microchips are uniformly dispersed into the coating to form a uniform barrier layer, then the coating is endowed with excellent anticorrosion properties, and the service life of a metal substrate protected by the heavy duty anticorrosion dry powder coating can be greatly prolonged.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Microcapsule suspension-suspending agent containing lambda-cyhalothrin and clothianidin and preparation method thereof

PendingCN111096329AGentle preparationReduce volatilityBiocideAnimal repellantsBiotechnologyClothianidin

The invention provides a microcapsule suspension-suspending agent containing lambda-cyhalothrin and clothianidin, which is obtained by compounding the following components in percentage by weight: 10%-85% of neonicotinoid insecticides, 1%-12% of lambda-cyhalothrin and 1%-12% of a synergistic assistant. According to the invention, a new generation of neonicotinoid insecticides, namely clothianidinand cyhalothrin, are compounded, so that the preparation process of the microcapsule is milder and easier to control, and the requirement of continuous industrial production can be met.

Owner:天津永阔科技发展有限公司

Chemical formula of high-performance environment-friendly oil paint

InactiveCN108276850AImprove adhesionHigh mechanical strengthAnti-corrosive paintsAcrylic resinCellulose acetate

The invention discloses a chemical formula of high-performance environment-friendly oil paint. The chemical formula is prepared from the following raw materials in parts by weight: 28 to 32 parts of modified acrylic resin, 10 to 14 parts of modified nano titanium dioxide, 11 to 13 parts of corn stalk nano cellulose, 8 to 10 parts of nano silicon dioxide, 6 to 8 parts of nano zinc oxide, 4 to 8 parts of cellulose acetate, 2 to 4 parts of lauryl sodium sulfate, 2 to 4 parts of coupling agent, 1 to 3 parts of pigment, 1 to 3 parts of pH adjusting agent, and 13 to 15 parts of solvent. The invention aims at providing the chemical formula of the high-performance environment-friendly oil paint. The oil paint is environmentally friendly, high in adhesive force, high in impact strength, and excellent in antirust performance, and has high practical value and good application prospect.

Owner:东莞市史雷帝三维数控科技有限公司

Preparation method of wall broken bee pollen of Chuzhou chrysanthemum

InactiveCN103892156AProtectiveMiscibleFood shapingFood preparationAfter treatmentAdditive ingredient

A preparation method of wall broken bee pollen of Chuzhou chrysanthemum is characterized by comprising the following preparation steps: washing bee pollen of Chuzhou chrysanthemum with water, removing dust on the surface of the bee pollen of Chuzhou chrysanthemum, filtering and removing the water; adding the water-washed bee pollen of Chuzhou chrysanthemum into cyclodextrin and ingredients, mixing with water according to the ratio of 1:5-1:100, after treatment with a colloid mill, sieving with a 100 to 200 mesh sieve to obtain an even serous fluid of the bee pollen of Chuzhou chrysanthemum; after sterilization at pasteurization temperature of the even serous fluid of the bee pollen of Chuzhou chrysanthemum, using spray drying equipment with the air inlet temperature of 180-210 DEG C and the air outlet temperature of 80-100 DEG C for drying to obtain the wall broken bee pollen of Chuzhou chrysanthemum. The preparation method has the advantages of simple process and low cost, micro capsules of the cyclodextrin have a protective effect on the wall broken bee pollen of Chuzhou chrysanthemum, and the obtained wall broken bee pollen of Chuzhou chrysanthemum is easily miscible with water.

Owner:滁州健颐源蜂业有限公司

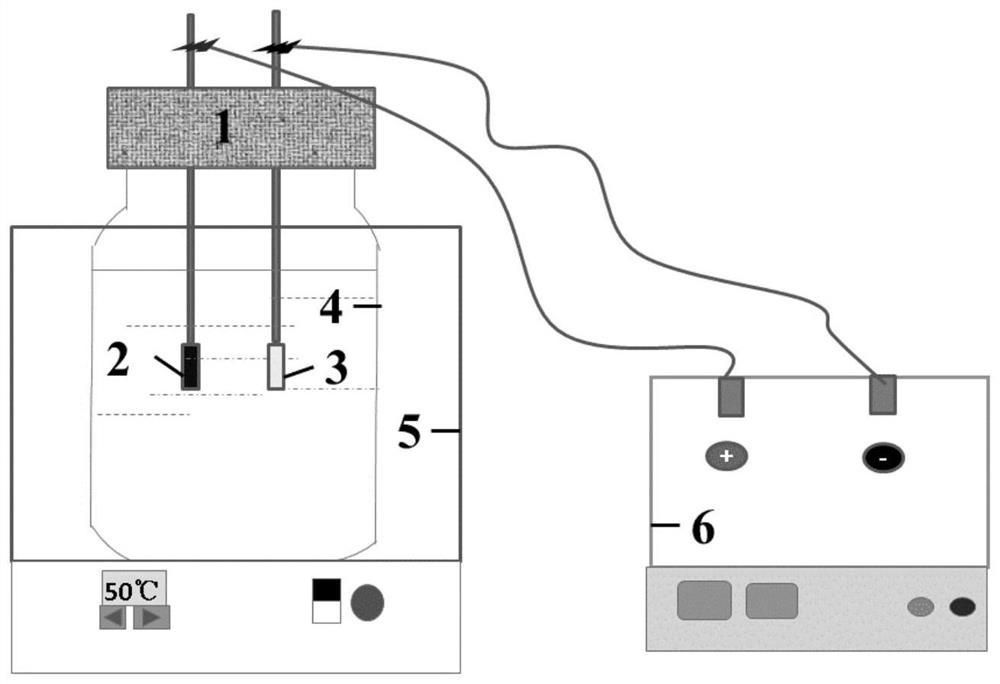

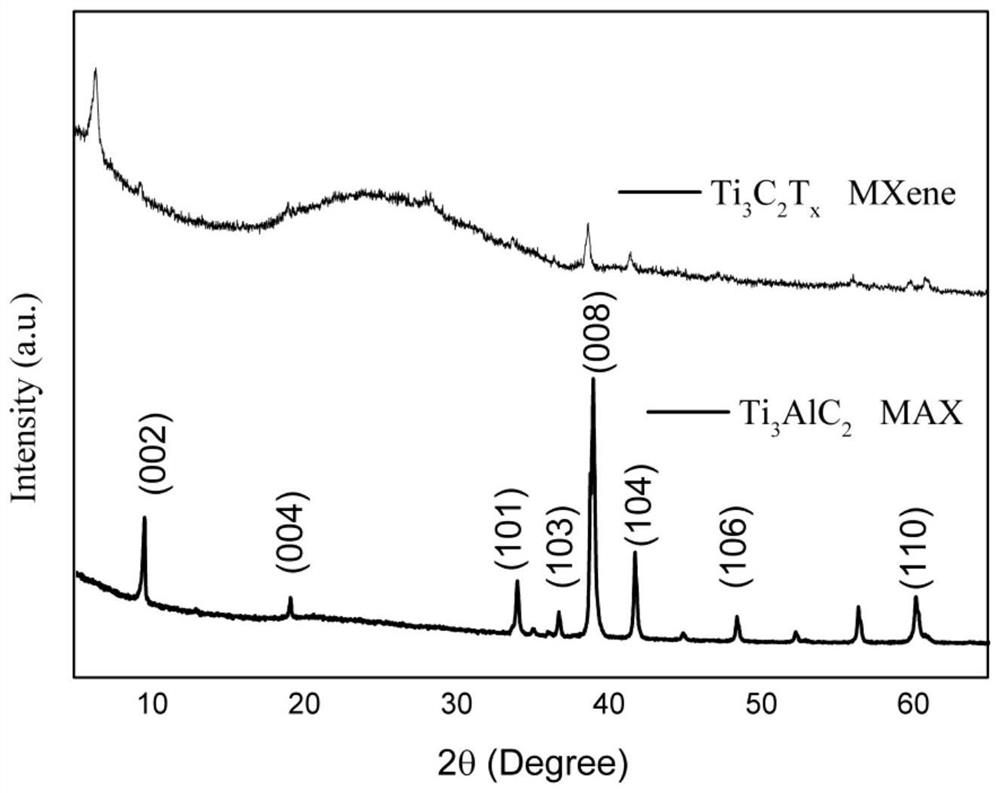

Method for etching MXene based on electrochemistry, MXene turbid liquid and application of MXene turbid liquid

PendingCN114737227AAvoid strong acids and basesThe operation process is economical and simpleCarbon compoundsNitrogen-metal/silicon/boron binary compoundsOrganic solventPhysical chemistry

The invention provides a method for etching MXene based on electrochemical etching, MXene turbid liquid and application of the MXene turbid liquid, an organic solvent of fluoride salt is used as an electric etching solution, an MAX electrode is used as a working electrode, and MXene is obtained under the action of electrochemical etching. According to the method provided by the invention, the powdery or turbid liquid MXene can be prepared according to the post-treatment step of the etching liquid. In addition, by-product metal fluoride can be removed in an environment-friendly manner through post-treatment, few-layer MXene can be directly obtained, and the technological process is simplified.

Owner:JIANGSU UNIV

Surface treatment method for brake caliper piston of vehicle

The invention provides a surface treatment method for a brake caliper piston of a vehicle, and belongs to the technical field of chemistry. The surface treatment method for the brake caliper piston ofthe vehicle solves the problem that an existing method for manufacturing the brake caliper piston of the vehicle is not environmentally friendly. The surface treatment method for the brake caliper piston of the vehicle comprises the steps that 1, pre-treatment is performed; 2, pre-oxidation in air is performed; 3, nitrocarburizing is performed, specifically, the caliper piston is heated to a temperature of 500-600 DEG C, heat preservation is performed for 1-3 hours, ammonia gas is introduced and the formamide is dropped into a furnace during the heat preservation; 4, oxidation is performed, specifically, the temperature of the caliper piston is adjusted to 540-570 DEG C, the heat preservation is performed for 40-60 minutes, and oxygen is introduced into the furnace during the heat preservation; and 5, cooling is performed. According to the surface treatment method for the brake caliper piston of the vehicle, the ammonia gas and the formamide of required raw materials are low in toxicity and easily miscible with water and ethanol, and the advantages that exhaust gas is easy to collect and a tail gas treatment solution is easy to handle are achieved; and therefore, the surface treatment method for the brake caliper piston of the vehicle is more environmentally friendly.

Owner:浙江百达精工股份有限公司

Oil-containing refrigerant and production process thereof

InactiveCN102226074ASolve the cooling effectSolve lubricityHeat-exchange elementsLubricant compositionRefrigerantEngineering

The invention discloses an oil-containing refrigerant and a production process thereof and relates to maintenance of refrigeration equipment. The oil-containing refrigerant mainly comprises a pressure container and a mixture of the refrigerant and lubricating oil, and the mixture is sealed in the pressure container. As for air conditioning, refrigeration and other equipment with mechanical compression mechanisms, when leakage failure occurs, the lubricating oil can also leak along with the refrigerant, thereby causing the loss of the lubricating oil in a refrigeration pipeline system. After a repairman repairs the failure, the refrigerant has to be emptied due to the process need of supplementing and adding the lubricating oil, the inside of the refrigeration pipeline system needs to achieve a certain degree of vacuum, and then the lubricating oil can be conveniently supplemented and added, thereby causing the waste of the refrigerant and the lubricating oil and further exacerbating the environmental pollution. The invention aims at directly supplementing and adding the refrigerant and the lubricating oil without using the vacuum-pumping maintenance process flow under the situation that the refrigerant is arranged in the refrigeration pipeline system, simplifying the maintenance process, reducing the maintenance cost and further reducing the environmental pollution.

Owner:郭伟明

Long-lasting antistatic pearl cotton epe and preparation method thereof

The invention discloses permanent antistatic pearl wool EPE (Expanded Polyethylene) and a preparation method thereof. The Permanent antistatic pearl wool EPE (Expanded Polyethylene) is prepared from the following raw materials in parts by weight: 133-142 parts of polyethylene resin, 25-36 parts of sodium lignin sulfonate, 11-16 parts of zirconium dioxide, 1-5 parts of neodymium oxide, 4-12 parts of tetrabutyl titanate and 10-15 parts of cyclohexane. The preparation method comprises the following steps: adding tetrabutyl titanate and cyclohexane into a reactor, sealing, stirring while heating, adding neodymium oxide, and stirring for 0.5-1h while heating to obtain a mixed solution A for later use; mixing sodium lignin sulfonate and zirconium dioxide and crushing to obtain a mixture B for later use; adding polyethylene resin and the mixture B into the mixed solution A, and stirring while heating to obtain a mixture C; and carrying out blow molding on the mixture C to obtain the permanent antistatic pearl wool EPE (Expanded Polyethylene). The permanent antistatic pearl wool EPE (Expanded Polyethylene) disclosed by the invention has the advantages of excellent antistatic property, stable antistatic value, greatly lowered surface damage degree, greatly lowered shrinkage degree, and greatly lowered pollution diversion degree of electronic product surfaces, no environment pollution, no luminance decrease and resistance to influences of humidity.

Owner:厦门谱睿科技有限公司

Method for removing pollutant on the substrate surface by high-density phase fluid

InactiveCN101209450AIncrease concentrationEfficient removalOrganic non-surface-active detergent compositionsNon-surface-active detergent solventsHigh densityEngineering

The invention relates to a method for removing pollutants from the surface of a base plate by high dense-phase fluid, which comprises the steps that a pressure container is provided; a base plate is provided; high dense-phase solution is provided; spray rinsing work of the base plate is carried out; pollutants removing work of the base plate is carried out; the surface of the base plate is soaked and washed and the base plate is taken out. Through the implementation and application of the invention, the solution can effectively enter the interior of a groove of the base plate, and lead washing solvent evenly to be contacted with the pollutants so as to promote the effect of removing pollutants on the base plate.

Owner:METAL INDS RES & DEV CENT

Multi-purpose surgery biology patching material

InactiveCN101507843BImprove biomechanical propertiesGood biocompatibilitySurgerySurgical operationBiomechanics

The invention relates to a biological patching material for patching defective tissues or organs in various surgical operations, which is characterized in that a composition is prepared from collagen or / and fibroin and polylactic acid or / and polycaprolactone in percentage by mass by electrostatic spinning technology. The obtained biological patching material has the advantages of good biological mechanical property and biocompatibility, convenient preparation and low cost, can be prepared into random specifications, can be remolded and degraded in vivo, and can be used for various surgical patching operations.

Owner:ARMY MEDICAL UNIV

Method for purifying enterocytozoon hepatopenaei of prawns

ActiveCN109628314AHigh purityLess impuritiesProtozoaMicroorganism based processesCentrifugationPrawn

A method for purifying enterocytozoon hepatopenaei of prawns comprises the steps of taking hepatopancreas of a plurality of prawns infected with enterocytozoon hepatopenaei, removing membranes by grinding; diluting them to 35-40 ml with sterile water; conducting alternative centrifugation at 1500-2000 rpm and at 500-600 rpm till no precipitate is observed by the naked eyes; centrifuging the supernatant without precipitate at the high speed of 3000-3500 rpm, and taking and dissolving a precipitate in sterile water to serve as a crude extracting solution; adopting different concentrations of Percoll cell separation solutions for gradient separation; adding 1-1.5 ml of crude extracting solution at the topmost of the liquid level with set gradient; using a centrifugal machine to carry out centrifugation under the conditions of 15 DEG C and 9000-10000 rpm; and obtaining a purified enterocytozoon hepatopenaei suspension by washing. The purified enterocytozoon hepatopenaei has high purity andless impurities, and the operation is simple.

Owner:SHENYANG AGRI UNIV

Surface treatment method of vehicle brake caliper piston

The invention provides a surface treatment method for a brake caliper piston of a vehicle, and belongs to the technical field of chemistry. The surface treatment method for the brake caliper piston ofthe vehicle solves the problem that an existing method for manufacturing the brake caliper piston of the vehicle is not environmentally friendly. The surface treatment method for the brake caliper piston of the vehicle comprises the steps that 1, pre-treatment is performed; 2, pre-oxidation in air is performed; 3, nitrocarburizing is performed, specifically, the caliper piston is heated to a temperature of 500-600 DEG C, heat preservation is performed for 1-3 hours, ammonia gas is introduced and the formamide is dropped into a furnace during the heat preservation; 4, oxidation is performed, specifically, the temperature of the caliper piston is adjusted to 540-570 DEG C, the heat preservation is performed for 40-60 minutes, and oxygen is introduced into the furnace during the heat preservation; and 5, cooling is performed. According to the surface treatment method for the brake caliper piston of the vehicle, the ammonia gas and the formamide of required raw materials are low in toxicity and easily miscible with water and ethanol, and the advantages that exhaust gas is easy to collect and a tail gas treatment solution is easy to handle are achieved; and therefore, the surface treatment method for the brake caliper piston of the vehicle is more environmentally friendly.

Owner:浙江百达精工股份有限公司

Fiber suspension generator for treating fiber-containing wastewater

PendingCN114835190ALarge amount of dissolved airImprove the efficiency of suspensionSustainable biological treatmentWater/sewage treatment by flotationFiberEngineering

The invention discloses a fiber suspension generator for fiber-containing wastewater treatment, which comprises a tank body, the top of the tank body is provided with a water inlet pipe, the tank body is internally provided with a sieve plate, the sieve plate is provided with a polyhedral hollow ball, the tank body is internally provided with a flow guide mechanism, the flow guide mechanism is located above the sieve plate, and the flow guide mechanism is located above the sieve plate. The flow guide mechanism is used for changing the flow direction and state of fiber-containing wastewater flowing into the tank body from the water inlet pipe, so that the fiber-containing wastewater is jetted and impacted in a vortex state to rotate in the tank body. By arranging the flow direction impeller, after fiber-containing wastewater and compressed air enter the tank body respectively, the fiber-containing wastewater flows through the flow direction impeller through the water inlet pipe and the communicating pipe, is jetted into the tank body in a vortex state under the flow guide acting force of blades on the flow direction impeller, and then impacts the polyhedral hollow ball; the polyhedral hollow balls are driven to rotate in the tank body, so that the contact area of the compressed air, the wastewater and fibers in the wastewater is increased.

Owner:西安兴晟生态环境有限公司

A method for purifying Enterocystoma hepatica of prawns

A kind of method that is used for purifying prawn enterocystoma hepatica, the steps are: take a plurality of prawn hepatopancreas infected with enterococcus hepatica, remove the membrane and grind; dilute to 35-40ml with sterile water; alternately at 1500-2000rpm and 500-600rpm Centrifuge until no precipitation is observed with the naked eye; then centrifuge the supernatant without precipitation at 3000-3500rpm to obtain the precipitation, dissolve the precipitation in sterile water as the crude extract; use different concentrations of Percoll cell separation medium for gradient separation; Add 1ml-1.5ml of the crude extract to the top of the gradient layer; use a centrifuge to centrifuge at 15°C and 9000-10000rpm; wash to obtain a purified suspension of Enterocystis hepatica. The purified worm body of the invention has high purity, less impurities and simple operation.

Owner:SHENYANG AGRI UNIV

A preparation method for improving the acid resistance of common method caramel color

The invention discloses a preparation method for improving the acid resistance of common caramel color, which includes metering and concentration of raw materials and catalytic reaction. The specific steps of catalytic reaction are as follows: 1) One-time reaction: adding hydrochloric acid and other acid solutions to raw material starch syrup, heating and adding 2) Secondary reaction: Add Grignard reagent to the material obtained in the first reaction, and react at normal temperature and pressure. During the reaction, according to the amount of raw material syrup, continue to feed gas carbon dioxide to the required 3) three times of reaction: add liquid caustic soda to the material after the secondary reaction is terminated to adjust the pH to 6.5-7.0, heat up for 30 minutes, cool to terminate the reaction, and filter to obtain acid-resistant caramel color. The method for improving the acid resistance of ordinary caramel color of the present invention can improve the acid resistance of ordinary caramel color through a three-step reaction, ensure stability in acidic environments such as vinegar, and prevent turbidity and precipitation.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Crispy nutritional ice cream and production method thereof

PendingCN110934220AUniform colorDelicious colorFrozen sweetsFood ingredient as mouthfeel improving agentBiotechnologyVegetable Proteins

The invention relates to crispy nutritional ice cream and a production method thereof, which belong to the field of food processing. The ice cream comprises the following raw materials in parts by weight: 15-20 parts of fresh milk or 10-15 parts of milk powder, 3-5 parts of cream, 10-30 parts of composite plant polypeptide, 1-5 parts of fruit and vegetable superfine powder, 15-20 parts of white granulated sugar, 3-6 parts of maltodextrin, 0.1-0.3 part of sodium alginate, 0.15-0.2 part of soluble starch and a proper amount of water. A refraction drying technology is adopted for treatment, the variety of ice cream is enriched, and the competitive advantage of the product market is increased; the composite vegetable protein is added into the ice cream, so that the nutrition and functionalityof the ice cream are increased, and the taste and texture of the ice cream are improved; the market vacancy of ice cream except summer is filled; and the ice cream has the advantages of simple formula, easily controlled dosage, simple production method, low cost, economy, practicability, convenient carrying, wide application range and suitability for large-scale industrial production.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com