Powder fine quantitative storage and transportation delivery device and method thereof

A conveying device, powder technology, applied in the directions of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of unstable powder gathering and transportation process, clogging, unsynchronized volume flow and mass flow, etc., to achieve homogeneous Spiral flow conveying technology, the effect of synchronous change of mass flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

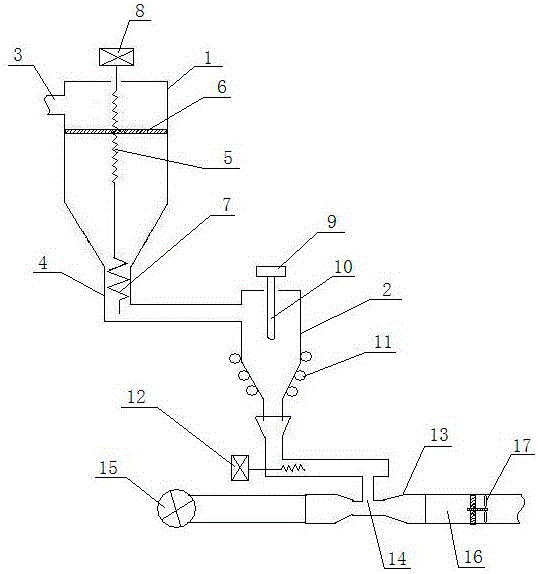

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

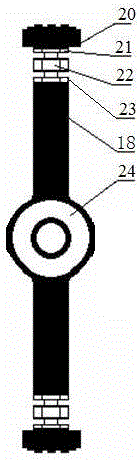

[0024] to combine figure 1 , figure 2 As shown, this powder fine quantitative storage and transportation device includes a large powder storage box 1, a small powder box 2, a metering screw pump 12, a negative pressure gas-powder mixing tube 13, and the side wall of the large powder storage box 1 is provided with powder Inlet 3, the large powder storage box 1 has a box neck 4, the box neck 4 is the powder driving section, the fine thread screw 5 is threaded with the plate plug 6, the fine thread screw 5 and the plate plug 6 are located in the large powder storage box 1, and the fine thread The upper end of the screw 5 is connected to the rotary drive device 8, the coarse-grain screw 7 and the fine-grain screw 5 are coaxially arranged, the coarse-grain screw 7 is located in the powder driving section, and the rotary drive device 8 includes a motor; the outlet of the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com