Preparation method of methyl levulinate catalyzed by ionic liquid

A technology for catalyzing methyl levulinate and ionic liquids, applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problem of large equipment loss and unfavorable promotion, high catalyst temperature, and low yield. It is beneficial to the development of large-scale industrialization, the conversion rate of raw materials is high, and the equipment requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

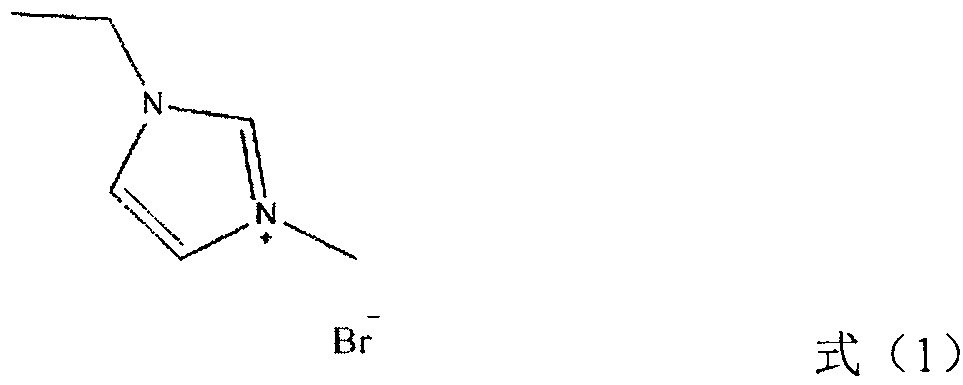

[0023] Preparation of ionic liquid 1-ethyl-3-methylimidazolium bromide bromide: In a 100ml three-necked flask with a condensing reflux device, add 1-methylimidazole (8.2g, 0.1mol), bromoethane (11.99 g, 0.11mol) was stirred at 35°C for 5 hours to obtain a white crystalline powder, which was washed with ethyl acetate to remove ethyl bromide and dried in vacuum at 80°C for 3h. Yield 85%.

Embodiment 2

[0025] In a 50ml reactor, add glucose (0.20g, 1.11mmol), ionic liquid (1-ethyl-3-methylimidazolium bromide bromide) (0.25g, 1.31mmol), SnCl 4 ·5H 2 O (0.039g, 0.11mmol) and methanol (1.6g, about 2ml) were reacted at 100°C for 2 hours, filtered with suction, methanol was distilled off by simple distillation, and then the product was distilled off by vacuum distillation. The yield was 66%.

Embodiment 3

[0027] In a 50ml reactor, add glucose (0.20g, 1.11mmol), ionic liquid (1-ethyl-3-methylimidazolium bromide bromide) (0.25g, 1.31mmol), SnCl 4 ·5H 2 O (0.039g, 0.11mmol) and methanol (1.6g, about 2ml) were reacted at 110°C for 1.5 hours, filtered with suction, methanol was distilled off by simple distillation, and then the product was distilled off by vacuum distillation. The yield was 56%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com