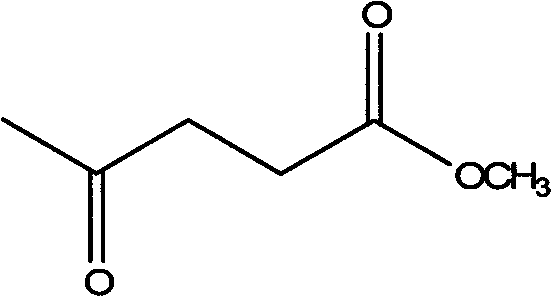

Method for preparing methyl levulinate in near-critical methanol by plant polysaccharide alcoholysis one-pot method

A technology of methyl levulinate and plant polysaccharide, which is applied in the field of biomass resource utilization, can solve the problems of many side reactions, high energy consumption, influence on the development of downstream products, etc., and achieves simple preparation process, high product yield and purity, The effect of good industrial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

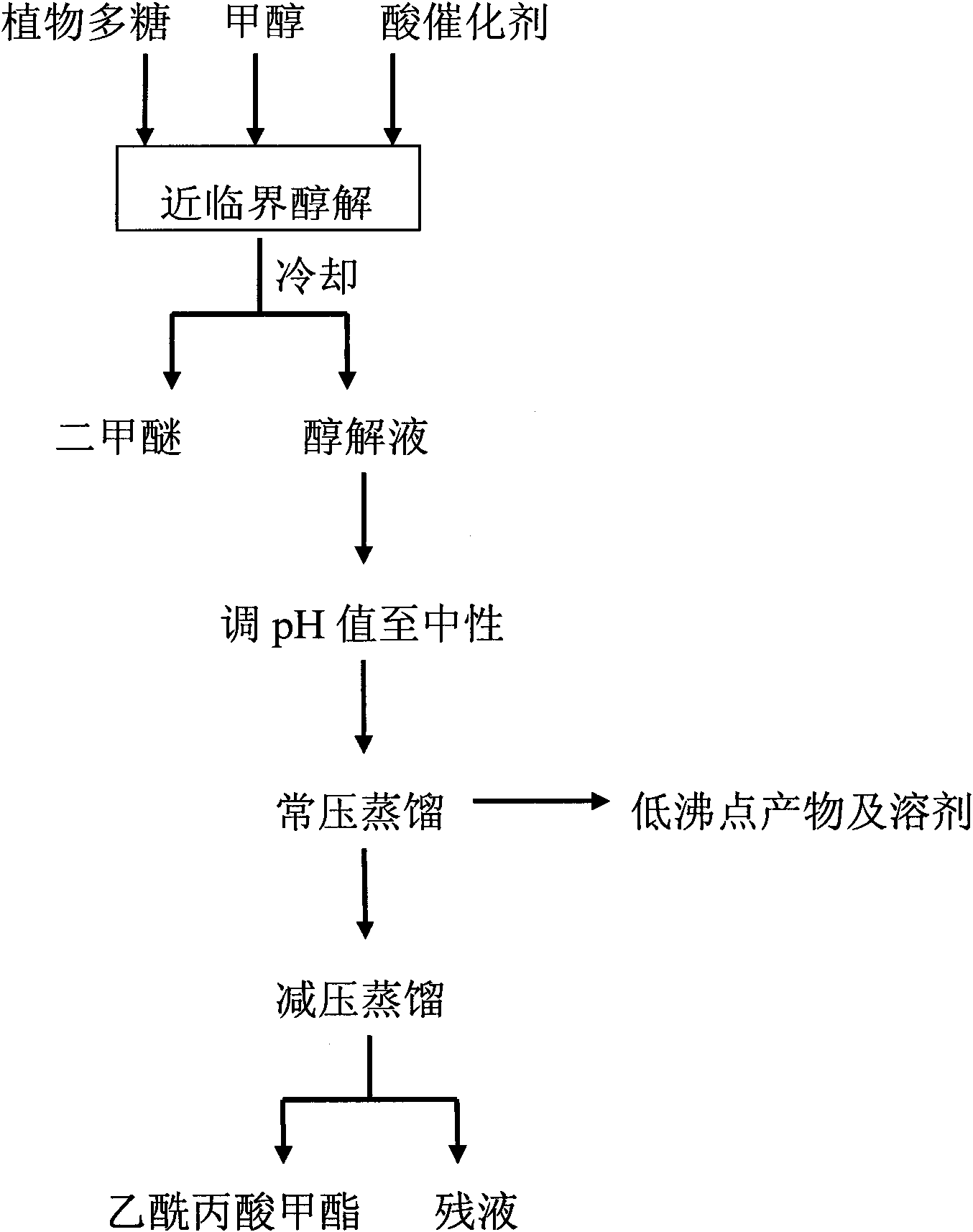

Method used

Image

Examples

Embodiment 1

[0031] Add methanol 300mL, cellulose 3g and sulfuric acid (98%) 0.6g (cellulose mass concentration is 10g / L, sulfuric acid molar concentration 0.02mol / L) in 500mL intermittent autoclave, airtightly replace the air in the kettle with nitrogen, Start stirring; heat up to 170°C for alcoholysis for 5 hours; after the end of alcoholysis, cool to room temperature, open the exhaust valve to collect dimethyl ether; add sodium bicarbonate aqueous solution to the alcoholysis solution to adjust the pH value to neutral, and distill under normal pressure Low-boiling products and solvents were distilled under reduced pressure to obtain 0.53 g of methyl levulinate, with a mass yield of 17.6% and a purity of 98.5% (GC).

Embodiment 2

[0033] Add methanol 300mL, cellulose 6g and sulfuric acid (98%) 0.3g (cellulose mass concentration is 20g / L, sulfuric acid molar concentration 0.01mol / L) in 500mL intermittent autoclave, airtightly replace the air in the kettle with nitrogen, Start stirring; heat up to 170°C for alcoholysis for 5 hours; after the end of alcoholysis, cool to room temperature, open the exhaust valve to collect dimethyl ether; add sodium bicarbonate aqueous solution to the alcoholysis solution to adjust the pH value to neutral, and distill under normal pressure Low-boiling point products and solvents were distilled under reduced pressure to obtain 0.69 g of methyl levulinate, with a mass yield of 11.6% and a purity of 98.9% (GC).

Embodiment 3

[0035] Add methanol 300mL, cellulose 6g and sulfuric acid (98%) 1.2g (cellulose mass concentration is 20g / L, sulfuric acid molar concentration 0.04mol / L) in 500mL intermittent autoclave, airtightly replace the air in the kettle with nitrogen, Start stirring; heat up to 170°C for alcoholysis for 5 hours; after the end of alcoholysis, cool to room temperature, open the exhaust valve to collect dimethyl ether; add sodium hydroxide aqueous solution to the alcoholysis solution to adjust the pH value to neutral, and distill it off under normal pressure Low-boiling point products and solvents were distilled under reduced pressure to obtain 1.67 g of methyl levulinate, with a mass yield of 27.9% and a purity of 98.1% (GC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com