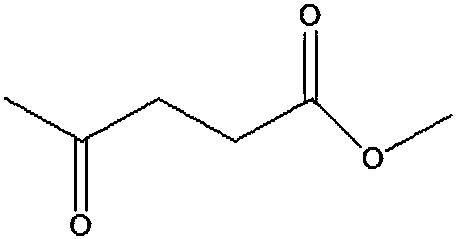

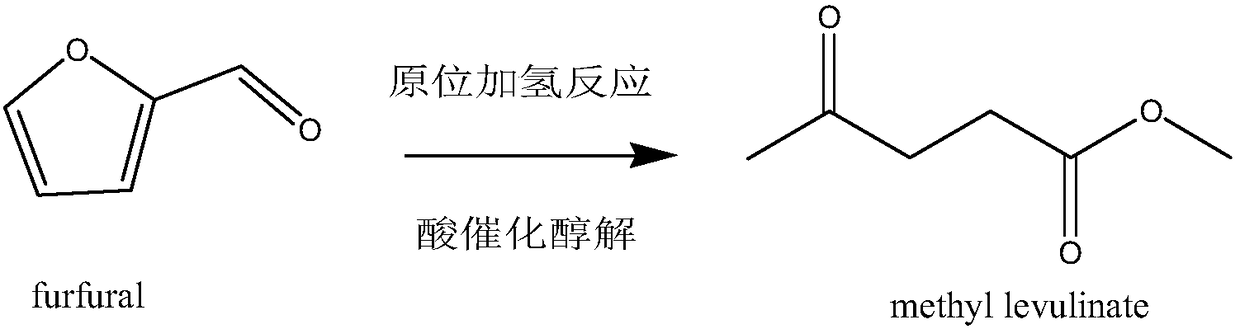

A kind of technique for the continuous preparation of methyl levulinate by furfural two-step method

A technology of methyl levulinate and two-step method, which is applied in the field of continuous preparation of methyl levulinate by furfural two-step method, which can solve the problems of low yield of methyl levulinate, consumption of high-energy-density clean hydrogen, and difficulty in industrialization, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

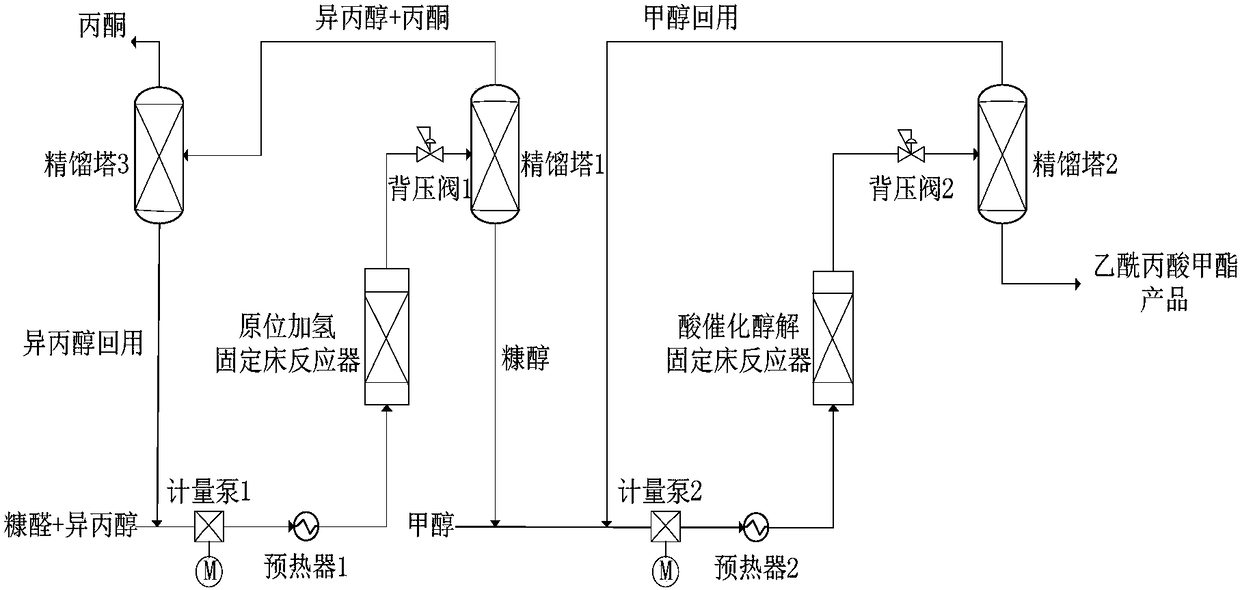

[0038] like figure 1 As shown, in situ hydrogenation fixed bed reactor filled with Cu / MgO-Al 2 o 3 , Amberlyst-21 is filled in the acid-catalyzed alcoholysis fixed-bed reactor; furfural is dissolved in isopropanol to form a homogeneous solution, wherein the mass fraction of furfural is 10%, and the solution is pressurized by metering pump 1 and preheater 1 After preheating, it is continuously added to the in-situ hydrogenation fixed-bed reactor for reaction, wherein the reaction temperature of the in-situ hydrogenation fixed-bed reactor is 150°C, the reaction residence time is 60min, and the reactor pressure is 5MPa; the reaction liquid passes through the back pressure valve 1 Outflow, separated by rectification tower 1, furfuryl alcohol mixed with methanol to form a homogeneous solution at the bottom of the tower, wherein the mass fraction of furfuryl alcohol is 10%, the solution is pressurized by metering pump 2, preheated by preheater 2, and then acid-catalyzed alcohol is ...

Embodiment 2

[0040] Filling Cu / MgO-Al in a fixed-bed reactor for in-situ hydrogenation 2 o 3 , Amberlyst-70 is filled in the acid-catalyzed alcoholysis fixed-bed reactor; furfural is dissolved in isopropanol to form a homogeneous solution, wherein the mass fraction of furfural is 15%, and the solution is pressurized by metering pump 1 and preheater 1 After preheating, it is continuously added to the in-situ hydrogenation fixed-bed reactor for reaction, wherein the reaction temperature of the in-situ hydrogenation fixed-bed reactor is 170°C, the reaction residence time is 40min, and the reactor pressure is 5MPa; the reaction liquid passes through the back pressure valve 1 Outflow, separated by rectification tower 1, furfuryl alcohol mixed with methanol to form a homogeneous solution at the bottom of the tower, wherein the mass fraction of furfuryl alcohol is 15%, the solution is pressurized by metering pump 2, preheated by preheater 2, and then acid-catalyzed alcohol is added continuously ...

Embodiment 3

[0042] Filling Cu / MgO-Al in a fixed-bed reactor for in-situ hydrogenation 2 o 3 , Amberlyst-70 is filled in the acid-catalyzed alcoholysis fixed-bed reactor; furfural is dissolved in isopropanol to form a homogeneous solution, wherein the mass fraction of furfural is 20%, and the solution is pressurized by metering pump 1 and preheater 1 After preheating, it is continuously added to the in-situ hydrogenation fixed-bed reactor for reaction, wherein the reaction temperature of the in-situ hydrogenation fixed-bed reactor is 170°C, the reaction residence time is 40min, and the reactor pressure is 5MPa; the reaction liquid passes through the back pressure valve 1 Outflow, separated by rectification tower 1, furfuryl alcohol mixed with methanol to form a homogeneous solution at the bottom of the tower, wherein the mass fraction of furfuryl alcohol is 20%, the solution is pressurized by metering pump 2, preheated by preheater 2, and then acid-catalyzed alcohol is added continuously ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com