Method using furan to prepare methyl levulinate

A technology for methyl levulinate and furan, which is applied in the field of preparing methyl levulinate from furan, can solve the problems of many steps, complicated process, increased energy consumption, etc., and achieves the effects of mild reaction conditions, simple method, and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

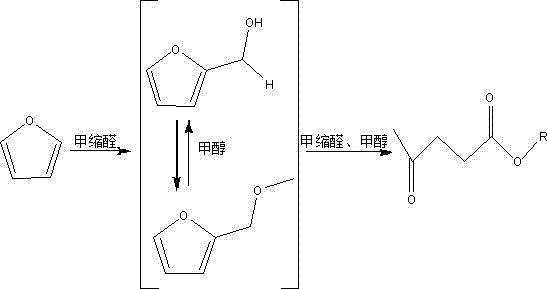

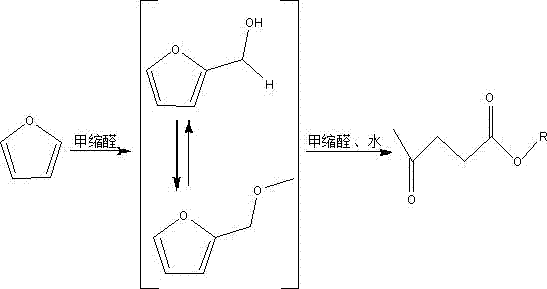

Method used

Image

Examples

Embodiment 1

[0032] The present embodiment provides a kind of method that furan prepares methyl levulinate, described method is carried out as follows:

[0033] Add 1.8g of furan, 3.6g of cation exchange resin 70, 25ml of methylal, and 15ml of methanol into the reactor respectively, then use an autoclave to heat to 140°C within 10min, and stir at 500rpm for 2h under autonomous steam pressure to obtain acetyl Methyl propionate and levulinic acid products.

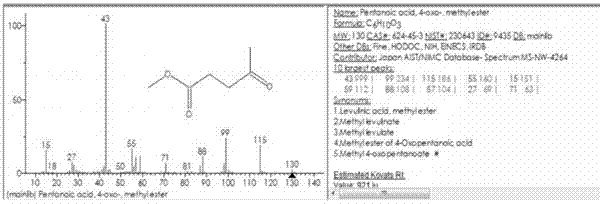

[0034] The obtained product was detected by GC-MS, and obtained as figure 1 The results shown by figure 1 It can be seen that the product obtained in this embodiment is methyl levulinate.

Embodiment 2

[0036] The present embodiment provides a kind of method that furan prepares methyl levulinate, described method is carried out as follows:

[0037] Add 1.5g of furan, 3.2g of cation exchange resin 70, 20ml of methylal, and 12ml of methanol into the reactor respectively, then use an autoclave to heat to 150°C within 10min, and stir for 1.8h at a speed of 500rpm under autonomous steam pressure to obtain Methyl levulinate and levulinic acid products.

Embodiment 3

[0039] The present embodiment provides a kind of method that furan prepares methyl levulinate, described method is carried out as follows:

[0040] Add 2.0g of furan, 4.0g of cation exchange resin 70, 35ml of methylal, and 21ml of methanol into the reactor respectively, and then use an autoclave to heat to 160°C within 10min, and stir for 2.2h at a speed of 500rpm under autonomous steam pressure to obtain Methyl levulinate and levulinic acid products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com