Biodiesel fuel and preparation method thereof

A bio-based, diesel technology, used in the preparation of organic compounds, biofuels, and carboxylate esters, etc., can solve the problems of unrealizable development routes, poor low-temperature fluidity and oxidation stability, and high raw material costs, and achieve great economic value. and social benefits, reducing pollution and saving mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

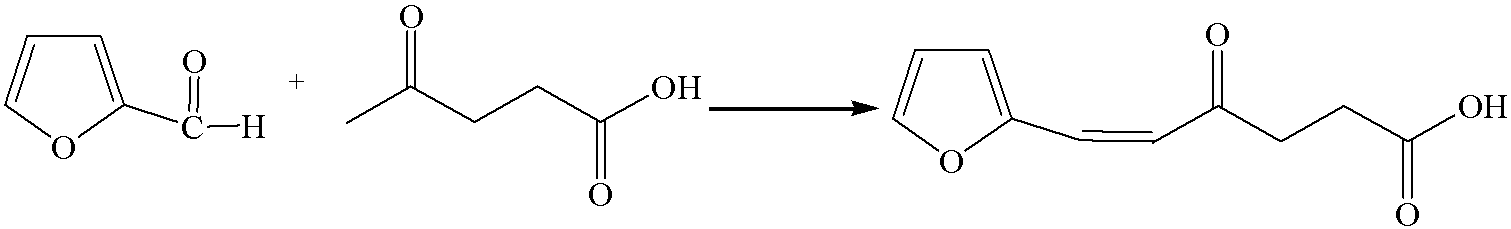

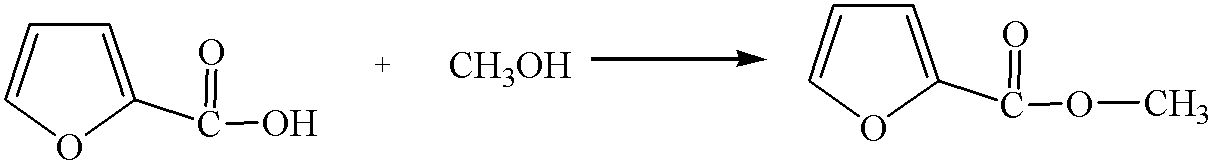

[0032] 1. Add the prepared saturated sodium chloride solution of sodium hydroxide to the reaction kettle, and then add levulinic acid and furfural with a molar ratio of 1:1 in sequence. Turn on the stirring, raise the temperature to 35°C at 0.5°C / min, and the pressure is 0.2MPa. After 30 minutes of reaction, the yield of 6-furfurylidene levulinic acid is 38%.

[0033] 2. Select the mixed alcohols as methanol, butanol and octanol, and the molar ratio is 4:2:1. Add the mixed alcohol and 6-furfurylidene levulinic acid with a molar ratio of 4:1 into the esterification reaction kettle. The esterification reaction temperature is 240° C., the relative pressure is 2 MPa, and the reaction time is 60 minutes. The conversion rate of 6-furfurylidene levulinic acid is 100%, and the yield of methyl 6-furfurylidene levulinate, butyl 6-furfurylidene levulinate and octyl 6-furfurylidene levulinate in the product The rate is 95%.

[0034] 3. Prepare copper-silver-cerium catalyst by co-precip...

Embodiment 2

[0040] 1. Add the prepared saturated sodium chloride solution of sodium hydroxide to the reaction kettle, and then add levulinic acid and furfural with a molar ratio of 1:2 in sequence. Start the stirring, raise the temperature to 35°C at 0.5°C / min, and the pressure is 0.4MPa. After 30 minutes of reaction, the yield of 6-furfurylidene levulinic acid is 43%.

[0041] 2. Select the mixed alcohols as butanol, pentanol and octanol, and the molar ratio is 4:2:1. Add the mixed alcohol and 6-furfurylidene levulinic acid with a molar ratio of 2:1 into the esterification reaction kettle. The esterification reaction temperature is 240° C., the relative pressure is 2 MPa, and the reaction time is 60 minutes. The conversion rate of 6-furfurylidene levulinic acid is 100%, and the yield of 6-furfurylidene levulinate butyl, 6-furfurylidene levulinate pentyl, 6-furfurylidene octyl levulinate in the product is 100%. The rate is 92%.

Embodiment 3

[0048] 1. Add the prepared saturated sodium chloride solution of sodium hydroxide to the reaction kettle, and then add levulinic acid and furfural with a molar ratio of 1:2 in sequence. Start the stirring, raise the temperature to 40°C at 0.5°C / min, and the pressure is 0.6MPa. After 30 minutes of reaction, the yield of 6-furfurylidene levulinic acid is 45%.

[0049] 2. Select the mixed alcohols as methanol, isobutanol, cyclopropanol, octanol, and the molar ratio is 4:4:1:1. Add the mixed alcohol and 6-furfurylidene levulinic acid with a molar ratio of 8:1 into the esterification reaction kettle. The esterification reaction temperature is 280° C., the relative pressure is 4 MPa, and the reaction time is 40 minutes. The conversion rate of 6-furfurylidene levulinic acid is 100%, and the yield of 6-furfurylidene levulinate butyl, 6-furfurylidene levulinate pentyl, 6-furfurylidene octyl levulinate in the product is 100%. The rate is 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com