Method for preparing methyl levulinate from cellulose under mild conditions of mechanical force chemocatalysis

A technology of methyl levulinate and mechanochemistry, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of low acid concentration, few by-products, strong corrosion, etc., and achieve low reaction temperature , high synthesis yield, and the effect of deepening the degree of depolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036](1) Disperse 30g of cellulose in 150ml of diethyl ether (3g of 98wt% sulfuric acid has been added to the diethyl ether) solvent, mix well and then stir with magnetic force for 30min (speed 300r / min), place the solvent diethyl ether in a fume hood at normal temperature and pressure to dry naturally (about 24h) to obtain sulfuric acid impregnated cellulose. The obtained sulfuric acid impregnated cellulose was ball milled with CJM-SY-B type high-energy nano-impact mill (tank volume is 2L) for 60min, and the ball milling medium (the ball milling medium was zirconia balls, the zirconia balls with diameters of 6mm, 8mm and 10mm) mixed use) the filling rate is 30%, and the temperature of the tank body during the ball milling process is below 30° C. to obtain ball-milled cellulose impregnated with sulfuric acid, wherein the mass fraction of sulfuric acid in the cellulose is 10%.

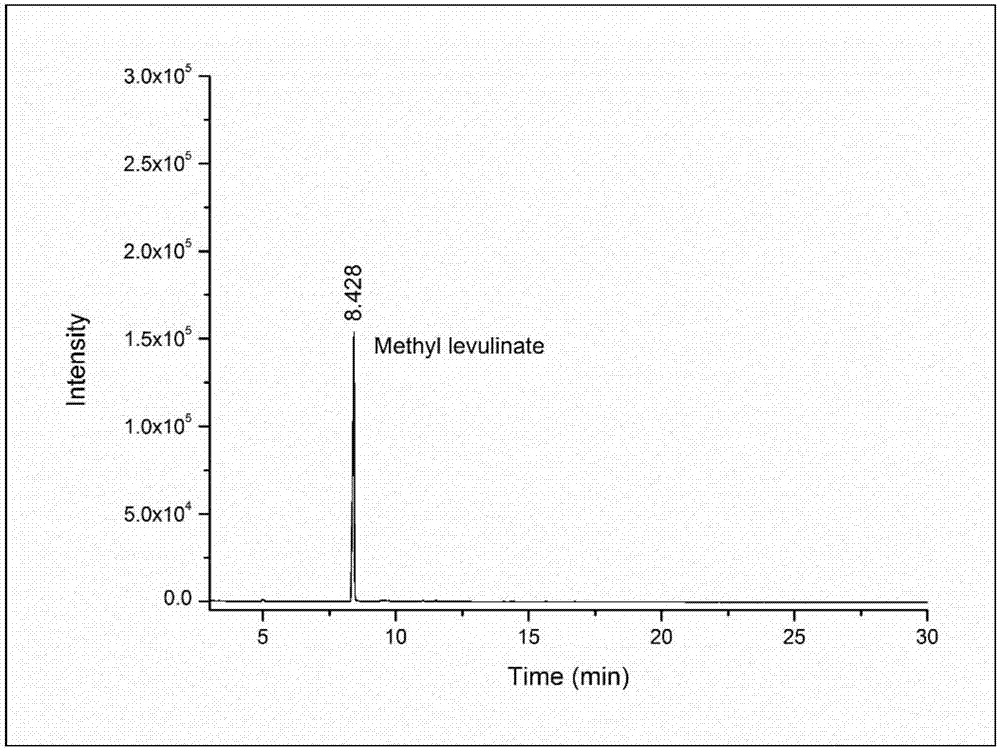

[0037] (2) Add 1.1g sulfuric acid impregnated ball-milled cellulose, 20g methyl alcohol, 0.1g sulfu...

Embodiment 2

[0039] (1) The specific steps are the same as the step (1) in Example 1.

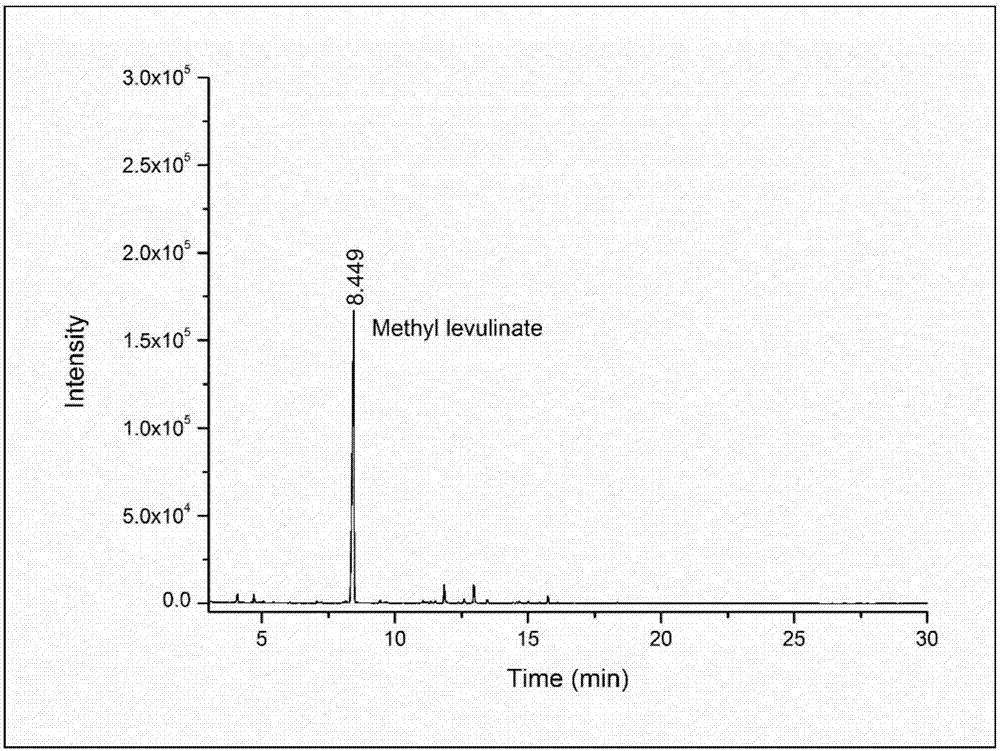

[0040] (2) Add 1.1g sulfuric acid impregnated ball-milled cellulose, 20g methyl alcohol, 0.1g sulfuric acid in polytetrafluoroethylene tank, make sulfuric acid account for the mass concentration of methanol to be 1wt%, liquid-solid ratio (the mass ratio of methanol and cellulose) 20:1, add a stirrer, put it into the microwave reaction chamber after installation, first use the microwave instrument magnetic stirring system to pre-stir for 1min, set the heating program: 2min to 160°C, microwave power 800w; 160°C for 120min, microwave The power is 600w; the reaction process keeps stirring at a constant speed. After the reaction was completed, cool in an ice-water bath, lower the temperature to below 15°C, and then open the can to take out the entire reaction mixture. The reaction mixture was taken and analyzed by gas chromatography to calculate that the yield of methyl levulinate was 55.70 mol%.

Embodiment 3

[0042] (1) Concrete steps are identical with step (1) in embodiment 1;

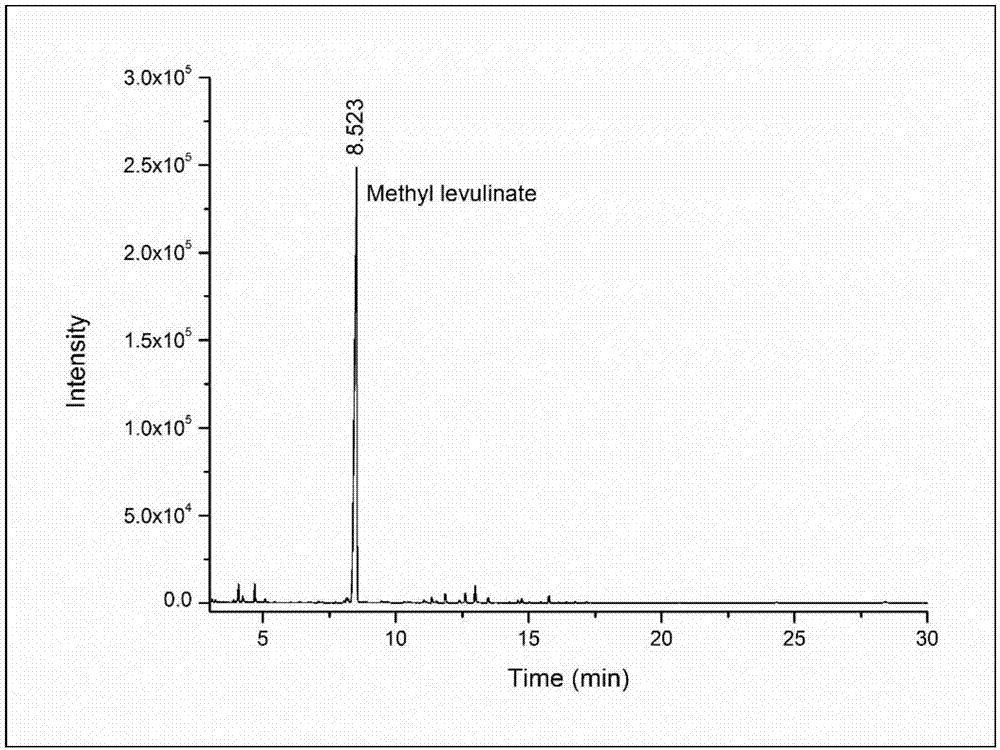

[0043] (2) Add 1.1g sulfuric acid-impregnated ball-milled cellulose and 20g methyl alcohol in the polytetrafluoroethylene tank, so that the mass concentration of sulfuric acid in methanol is 0.5wt%, and the liquid-solid ratio (the mass ratio of methanol to cellulose) is 20: 1. Add a stirrer, put it into the microwave reaction chamber after installation, pre-stir with the magnetic stirring system of the microwave instrument for 1min, set the heating program: 2min to 170°C, microwave power 800w; 170°C for 120min, microwave power 600w; The reaction process was kept stirring at a constant speed. After the reaction was completed, cool in an ice-water bath, lower the temperature to below 15°C, and then open the can to take out the entire reaction mixture. The reaction mixture was taken and analyzed by gas chromatography to calculate that the yield of methyl levulinate was 49.61mol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com