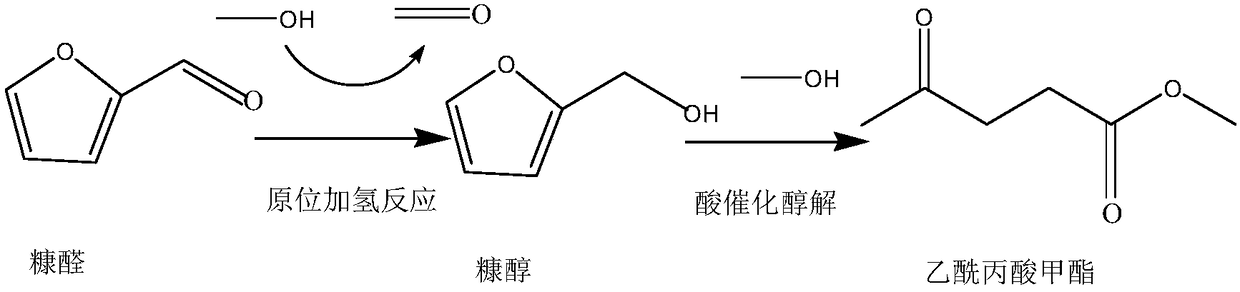

One-pot method for preparing methyl levulinate by mesoporous molecular sieve catalyzed furfural in a near-critical methanol medium

A molecular sieve technology for catalyzing furfural and methyl levulinate, which is applied in molecular sieve catalysts, chemical instruments and methods, preparation of organic compounds, etc. Industrialization and other issues, to achieve the effect of easy recycling, good industrial application prospects, and green process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

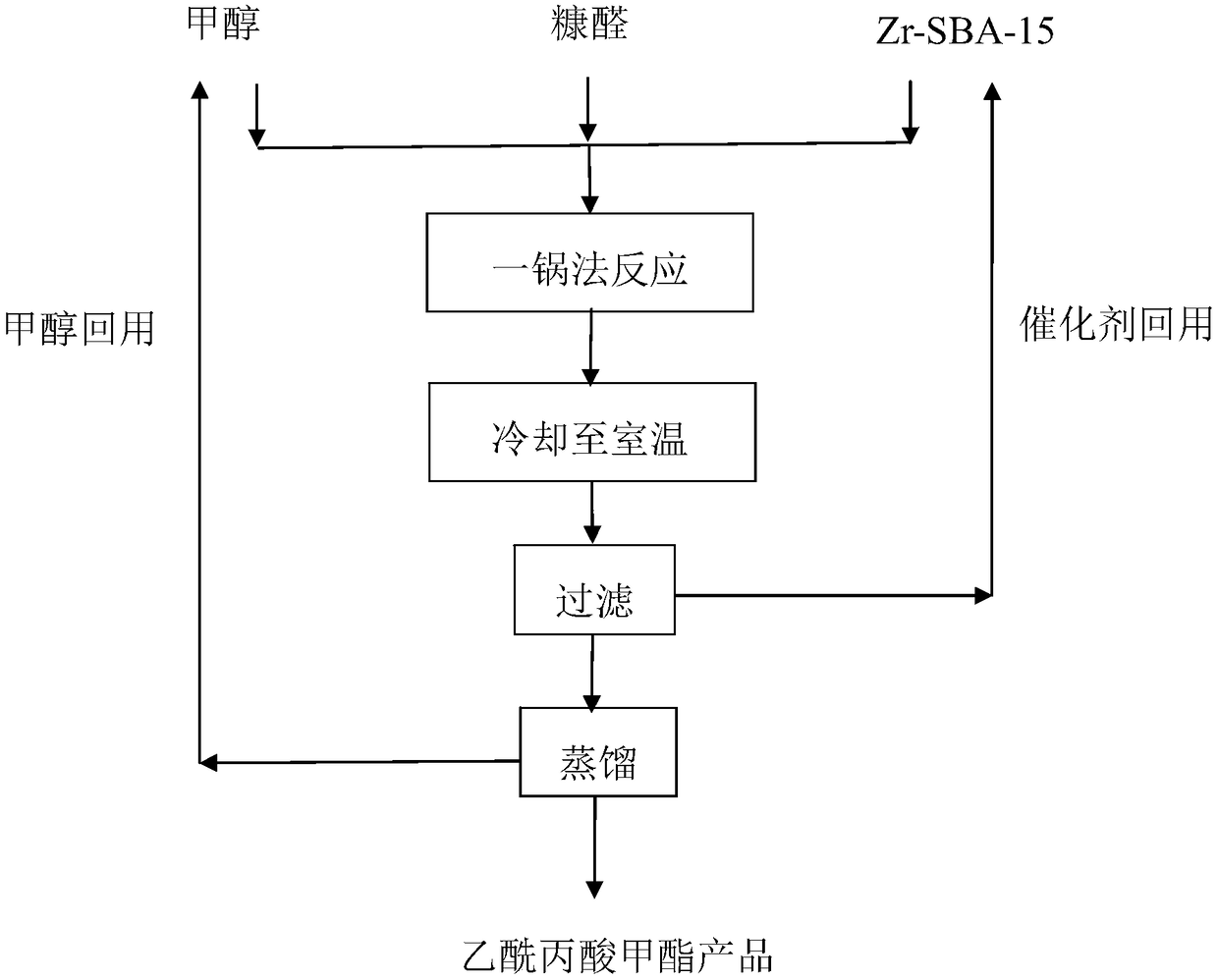

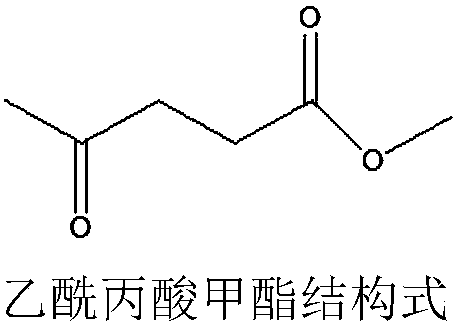

[0036] Such as figure 1 As shown, add 60g furfural and 300g methanol to a 500mL stirred high temperature and high pressure reactor, the mass ratio of methanol to furfural is 1:5, then add 30g Zr-SBA-15-10, furfural and Zr-SBA-15- The mass ratio of 10 is 2:1; start stirring, heat up to 280 ° C, and react in one pot for 1 h; after the reaction is completed, cool to room temperature, filter, and the filtrate (after sampling, analyzed by GC, the molar yield of methyl levulinate The yield is 18.8%) to obtain methyl levulinate product after distillation, methanol reuse; filter residue to obtain Zr-SBA-15-10 mesoporous molecular sieve, wash with methanol, dry and roast and reuse.

Embodiment 2

[0038] Add 30g of furfural and 300g of methanol into a 500mL stirred high-temperature and high-pressure reactor. The ratio is 3:1; start stirring, heat up to 270°C, and react in one pot for 6h; after the reaction is completed, cool to room temperature, filter, and the filtrate (analyzed by GC after sampling, the molar yield of methyl levulinate is 35.4 %) is distilled to obtain methyl levulinate product, and the methanol is reused; the filter residue is Zr-SBA-15-20 mesoporous molecular sieve, which is washed with methanol, dried and roasted, and then reused.

Embodiment 3

[0040] Add 15g of furfural and 300g of methanol into a 500mL stirred high-temperature and high-pressure reactor. The mass ratio of methanol to furfural is 1:20, and then add 3g of Zr-SBA-15-40. The ratio is 5:1; start stirring, heat up to 260°C, and react in one pot for 8h; after the reaction is completed, cool to room temperature, filter, and the filtrate (analyzed by GC after sampling, the molar yield of methyl levulinate is 35.9 %) is distilled to obtain methyl levulinate product, and the methanol is reused; the filter residue is Zr-SBA-15-40 mesoporous molecular sieve, which is washed with methanol, dried and roasted, and then reused.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com