Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Achieving Low Temperature Curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

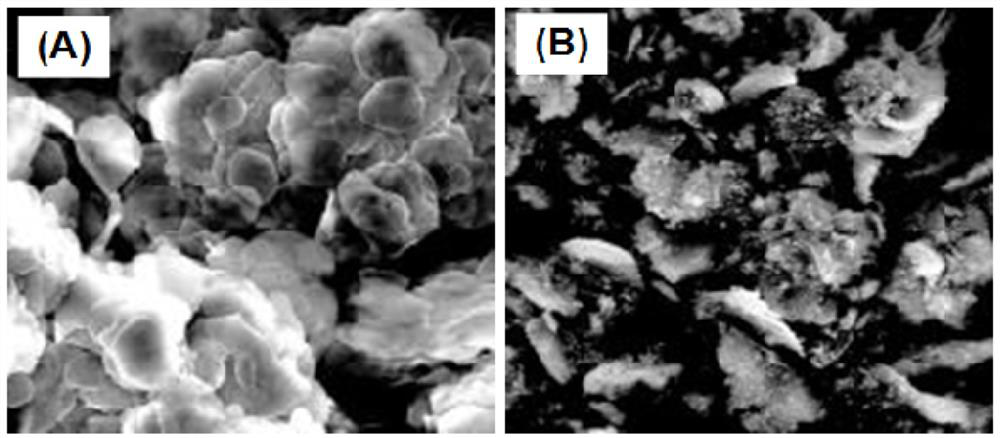

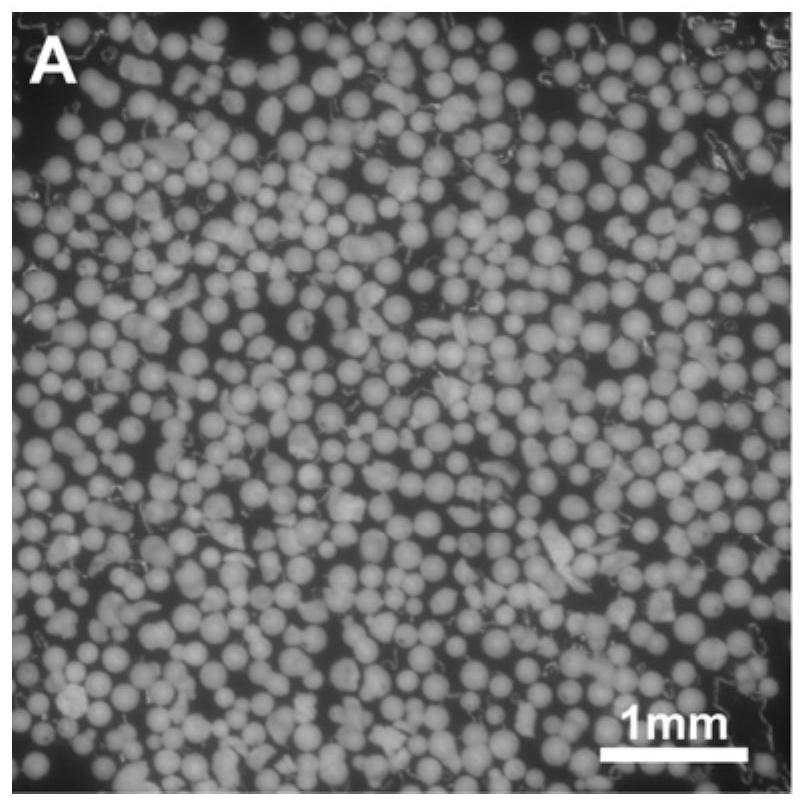

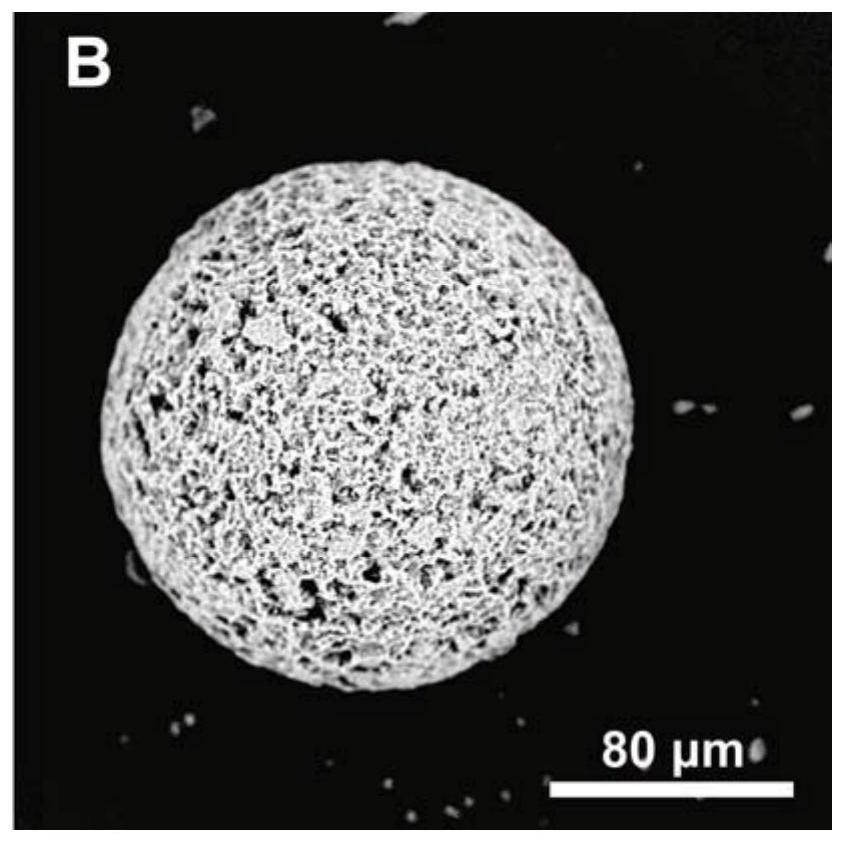

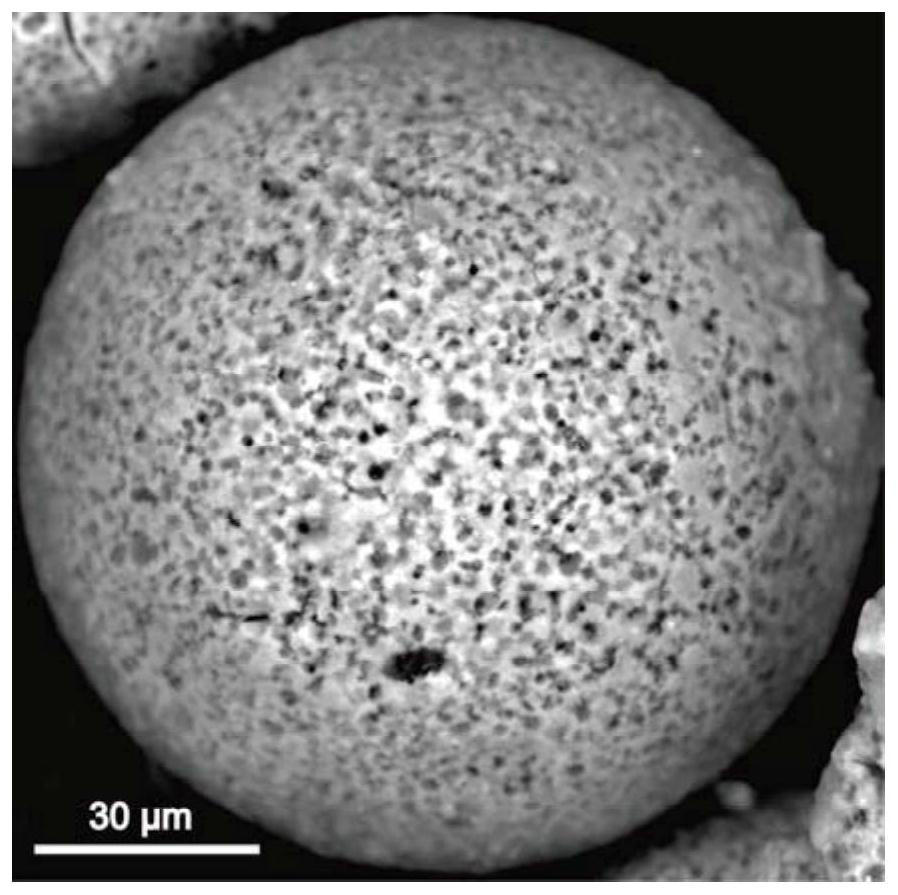

Preparation method and application of porous geological polymer microspheres

ActiveCN107973559AHigh Microsphere EfficiencyParticle size adjustableOther chemical processesRadioactive contaminantsMicrosphereSorbent

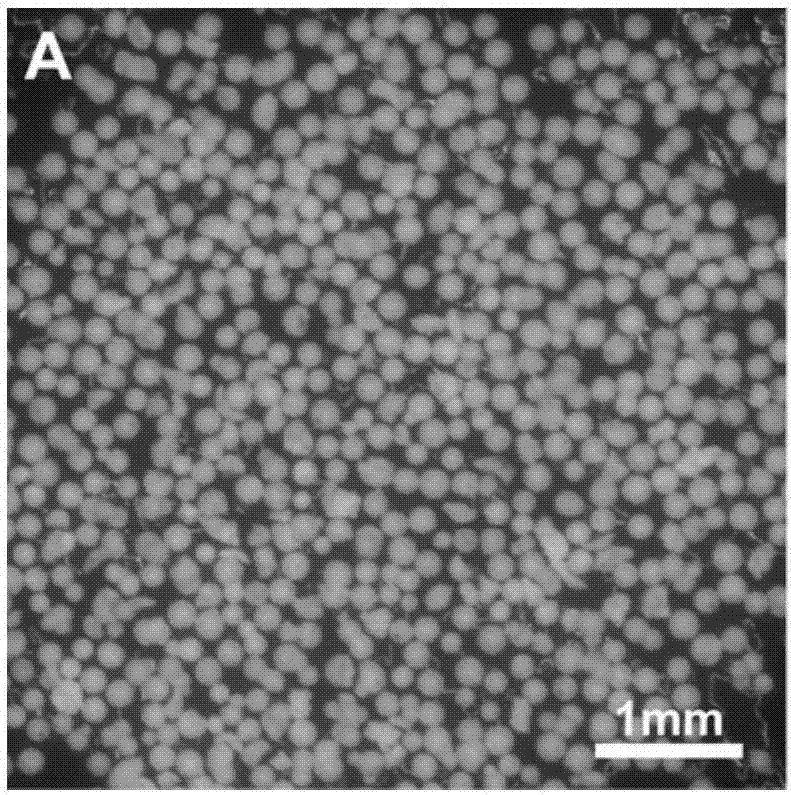

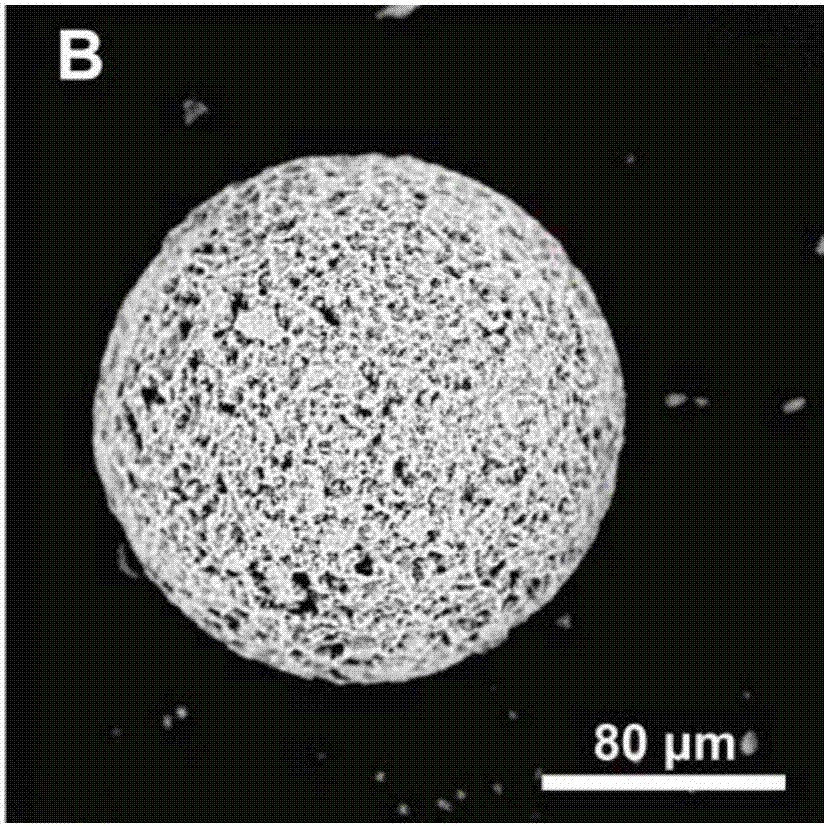

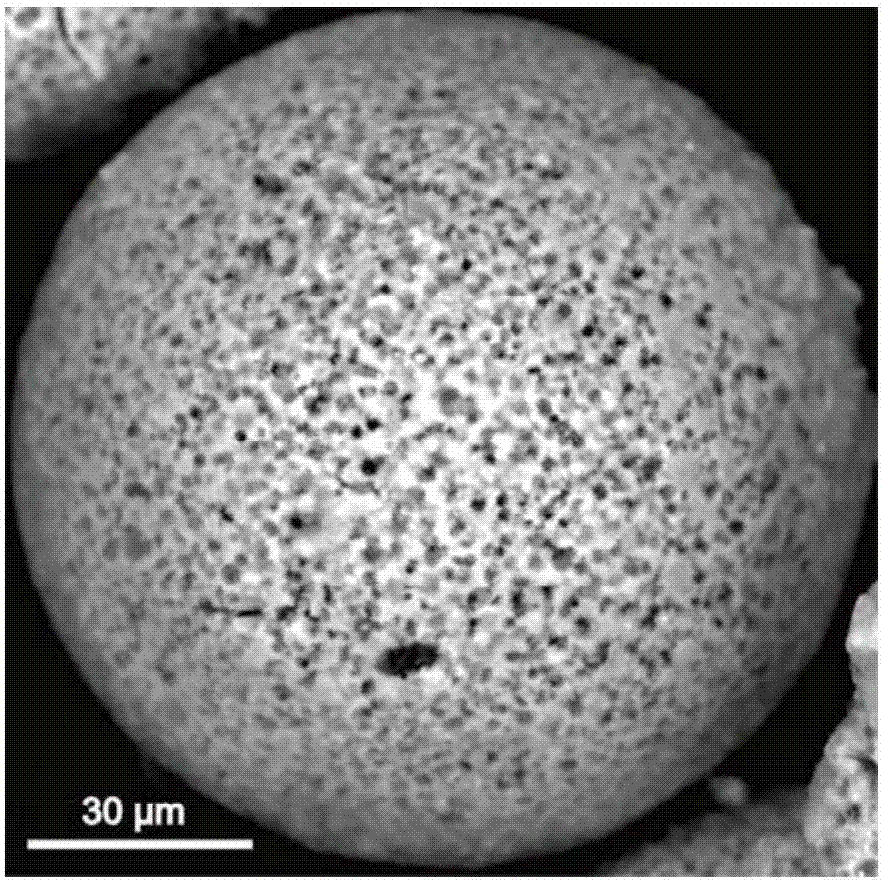

The invention discloses a preparation method of porous geological polymer microspheres. The porous geological polymer microspheres are prepared by a dispersion suspension solidification method. Compared with the prior art, low-temperature curing and one-shot molding granulation are realized without requirements of high-temperature calcination and curing and addition of other auxiliaries; and at the same time, large-scale use of solid wastes is realized, and raw materials are widely available, cost is low, process is simple, and the whole process is non-toxic and pollution-free; in addition, the preparation efficiency is high with a ball-forming degree exceeding 90%; the size of the particles can be adjusted, and the pore size distribution is uniform; the pore volume is large, and can be regulated, and a specific surface area of the microspheres reaches 110m2 / g, thus, the porous geological polymer microspheres can be directly used for packed columns for column separation. Experiments show that the porous geological polymer microspheres have a good adsorption effect on heavy metals, and can be used as adsorbents for heavy metals, and have a broad application prospect in the aspect ofremoving heavy metals and radioactive elements in water.

Owner:GUANGXI UNIV

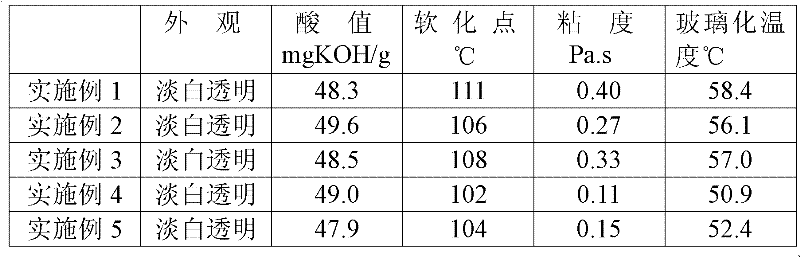

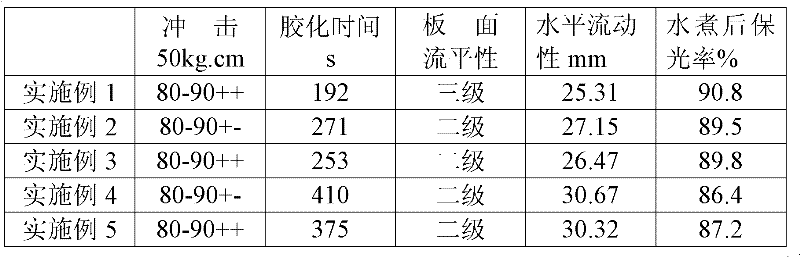

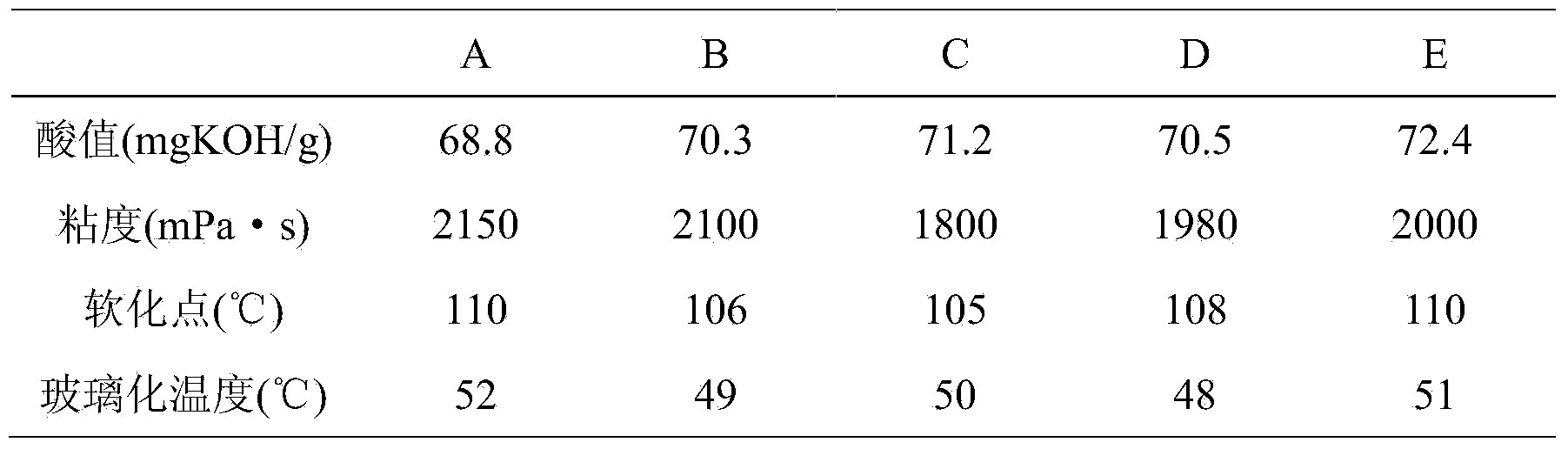

Preparation method for low temperature curing polyester resin with high leveling performance

The invention discloses a preparation method for a thermosetting hybrid polyester resin. The method comprises a synthesis step, a cooling step and a vacuum-pumping and curing step. Compared to the prior art, the invention has the following advantages: considerable long-chain monomers in the fatty group are introduced to improve the toughness of resin; the viscosity of the resin is controlled, andthe amount of auxiliary agents in a later stage is controlled, thereby enabling a plate surface to have high leveling performance and enabling better balance between mechanical performance and glass transition temperature to be obtained. Compared to conventional products, the product prepared in the invention has the following advantages: low temperature curing is realized; the plate surface has good leveling performance and has horizontal fluidity up to more than 30 mm in a horizontal fluidity experiment under the conditions of a temperature of 140 DEG C and a time of 30 min.

Owner:ANHUI SHENJIAN NEW MATERIALS

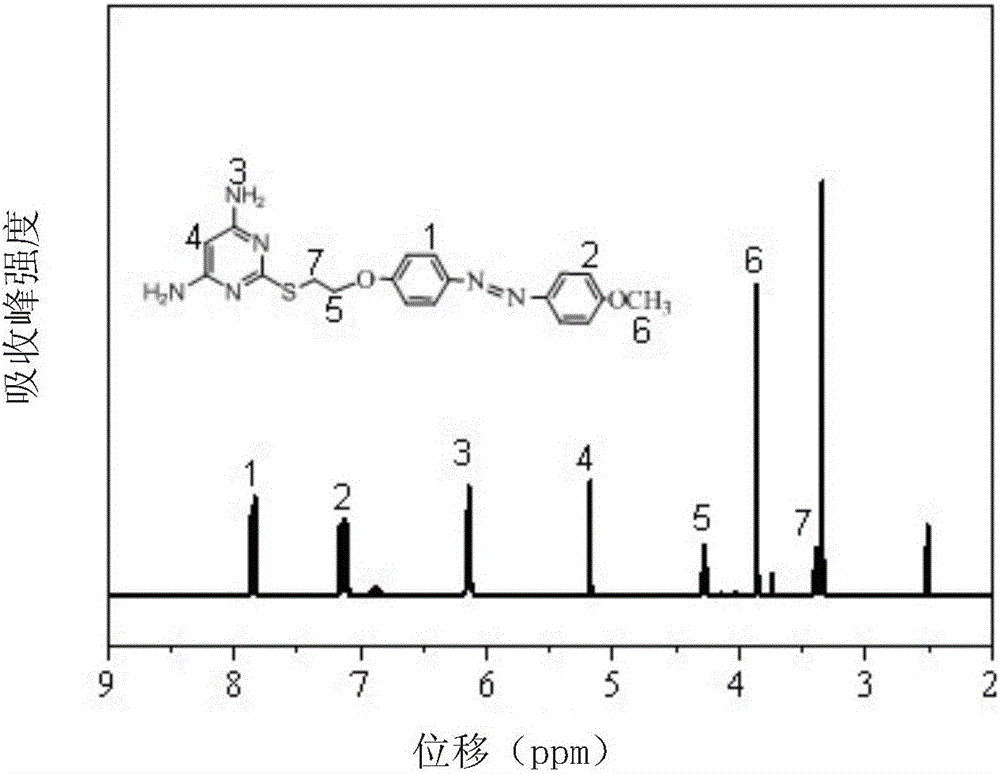

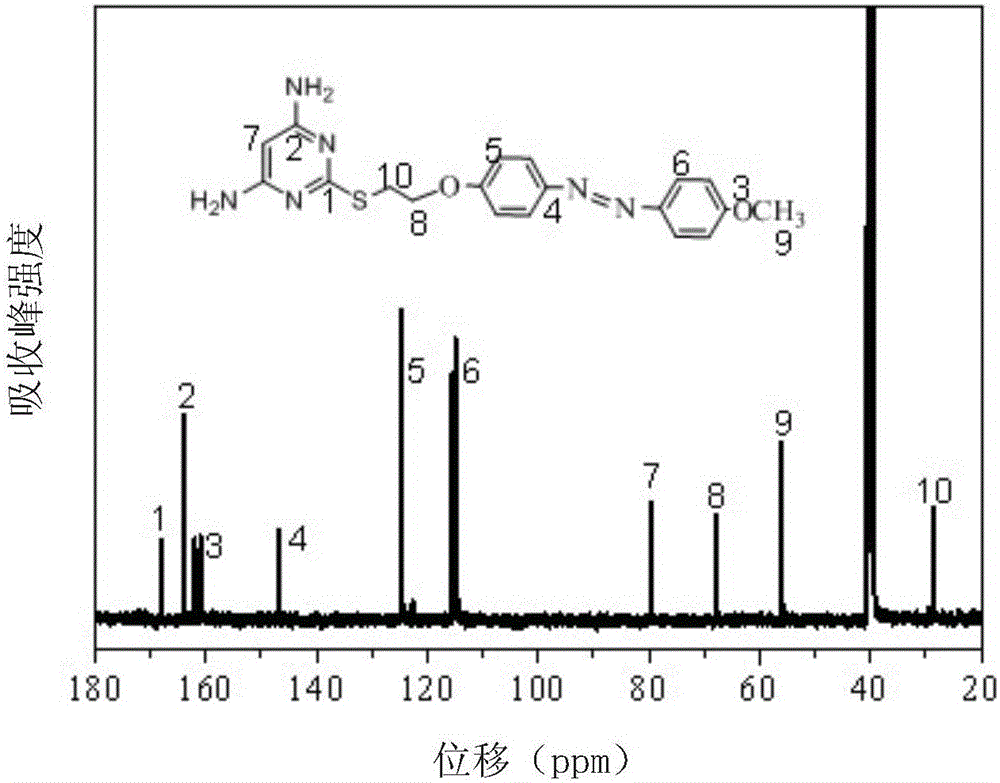

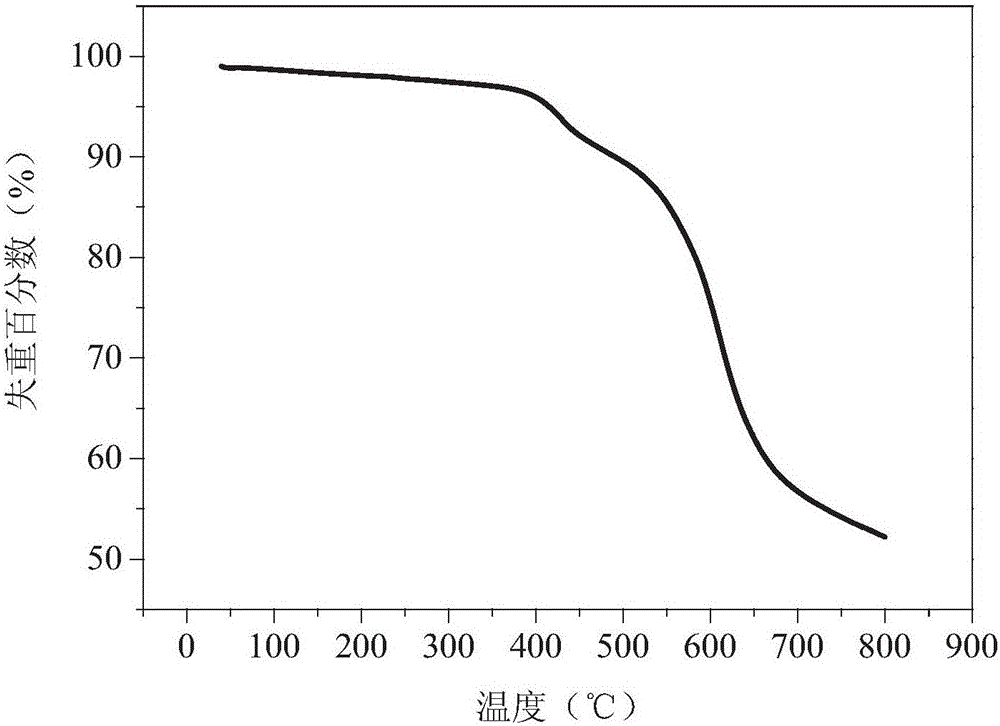

Method for preparing polyimide polymer with azo-pyrimidine structure unit

ActiveCN105693625AReduce aromatic conjugationLower glass transition temperatureOrganic chemistryCharge-transfer complexAniline

The invention relates to a method for preparing a diamine monomer with an azo-pyrimidine structure and a method for preparing a polyimide polymer by adopting the diamine monomer with the azo-pyrimidine structure. The preparation method comprises the following steps: carrying out a coupling reaction on 4-substituted aniline and sodium phenate to obtain 4-hydroxy-4'-substituted azobenzene; and carrying out nucleophilic substitution on the 4-hydroxy-4'-substituted azobenzene and dibromoalkane to generate bromo-azobenzene, and reacting the bromo-azobenzene with 4,6-diamido-2-mercaptopyrimidine to obtain the diamine monomer; and carrying out condensation polymerization on the diamine monomer with dianhydride to obtain polyimide. The pyrimidine structure is introduced into the diamine monomer, so that the charge transfer complex effect of aromatic rings of polyimide is reduced, and the glass transition temperature of the polyimide is reduced; and the azo group has photo-induced anisotropy, and an azo unit is introduced into the polyimide by alkyl chains having different lengths, so that the heterogeneous degree of the azo group can be effectively regulated, and the application of the polyimide in alignment films and other optical fields can be improved to a great extent.

Owner:南通晶爱微电子科技有限公司

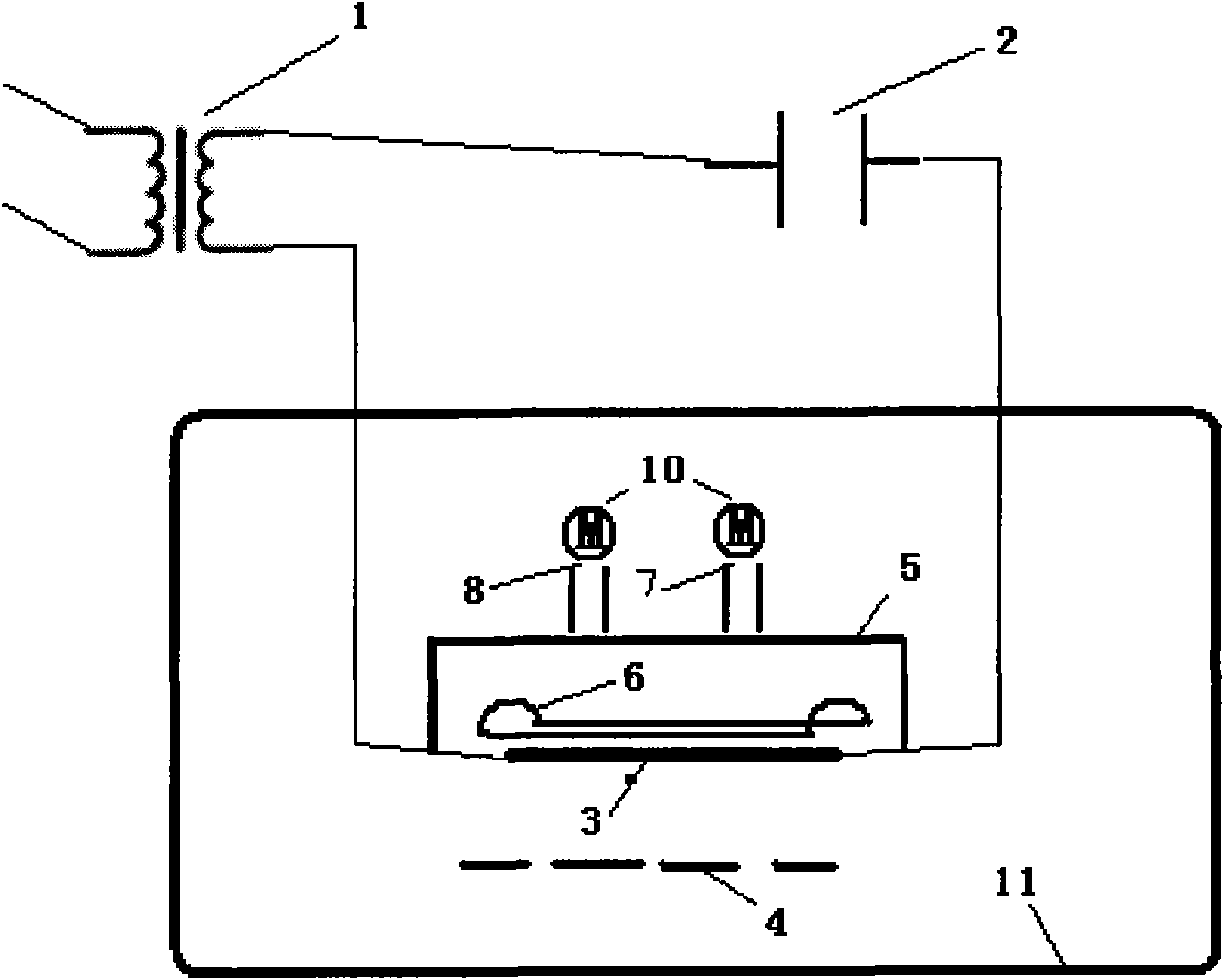

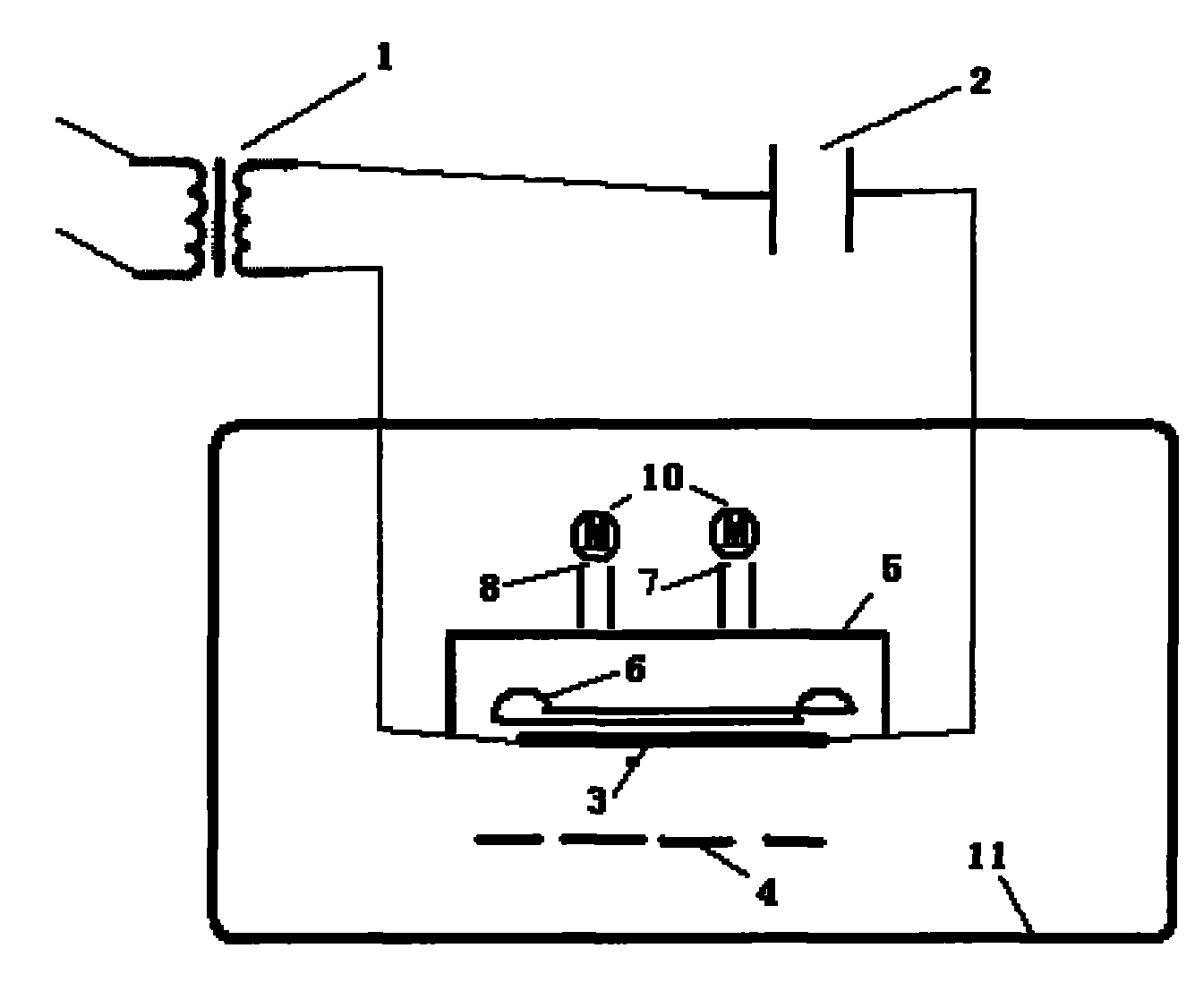

Low-temperature ultraviolet curing equipment

InactiveCN101773900AEliminate deformationReduce the temperaturePretreated surfacesCoatingsHeat resistanceUltraviolet

The invention discloses low-temperature ultraviolet curing equipment which comprises a transformer, a capacitor and a frame, wherein the frame is coiled by a mirror finished stainless steel plate and sequentially provided with a downwards opened lampshade, a light reflecting plate, an ultraviolet lamp and a stand from top to bottom; an air inlet pipe and an air outlet pipe are installed on the lampshade; fans are respectively arranged on the air inlet pipe and the air outlet pipe; and one end of the ultraviolet lamp is connected with one end of the secondary side of the transformer by the capacitor, and the other end of the ultraviolet lamp is connected with the other end of the secondary side of the transformer. The curing equipment is particularly suitable for the surface ultraviolet coating and printing of thin base materials without heat resistance, such as plastics, paper, and the like; when in use, the surface temperature of a cured material can be reduced below 45 DEG C, and the problem of deformation of the base materials at high temperature is effectively prevented.

Owner:杭州博纳特光电科技有限公司

Epoxy resin-based low-temperature conductive silver paste and preparation method thereof

InactiveCN111261320AImprove conductivityHigh curing temperatureNon-conductive material with dispersed conductive materialCable/conductor manufactureScreen printingSilver paste

The invention belongs to the technical field of conductive silver paste and relates to epoxy resin-based low-temperature conductive silver paste and a preparation method thereof. The paste is preparedfrom the following components in parts by weight: 20-40 parts of starch; 55 to 75 parts by weight of silver powder; 5 to 15 parts of epoxy resin; 0.3 to 10 parts of curing agent; 0.05 to 5 parts of curing accelerator; 2 to 18 parts of diluents; 0.01 to 1 part of inhibitor; 0.1 to 3 parts of rheological additive; and 0.5 to 5 parts of additive. The paste has relatively low curing temperature and relatively low viscosity, and is suitable for a silk-screen printing process.

Owner:常州烯奇新材料有限公司

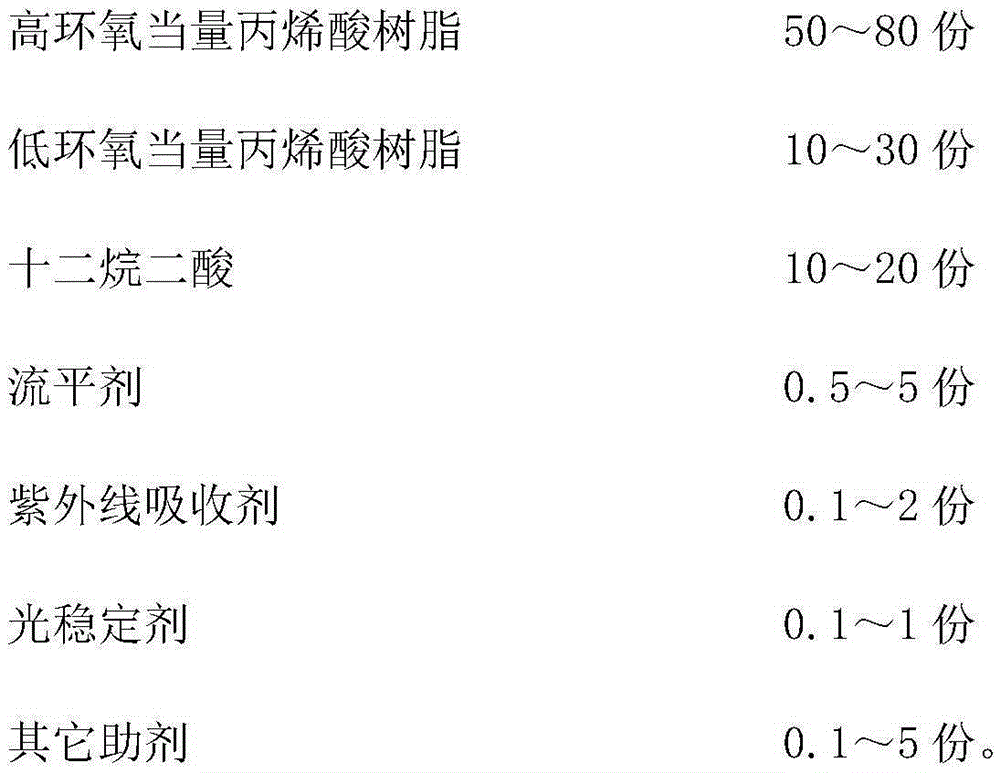

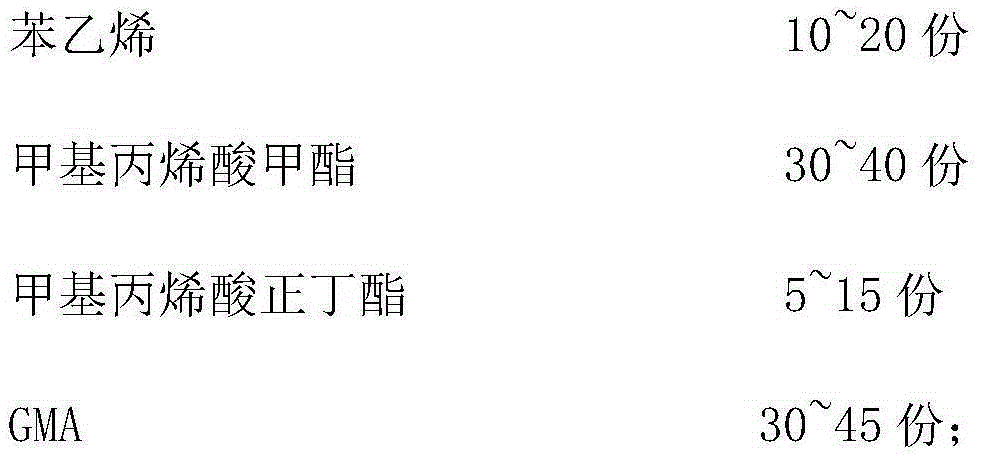

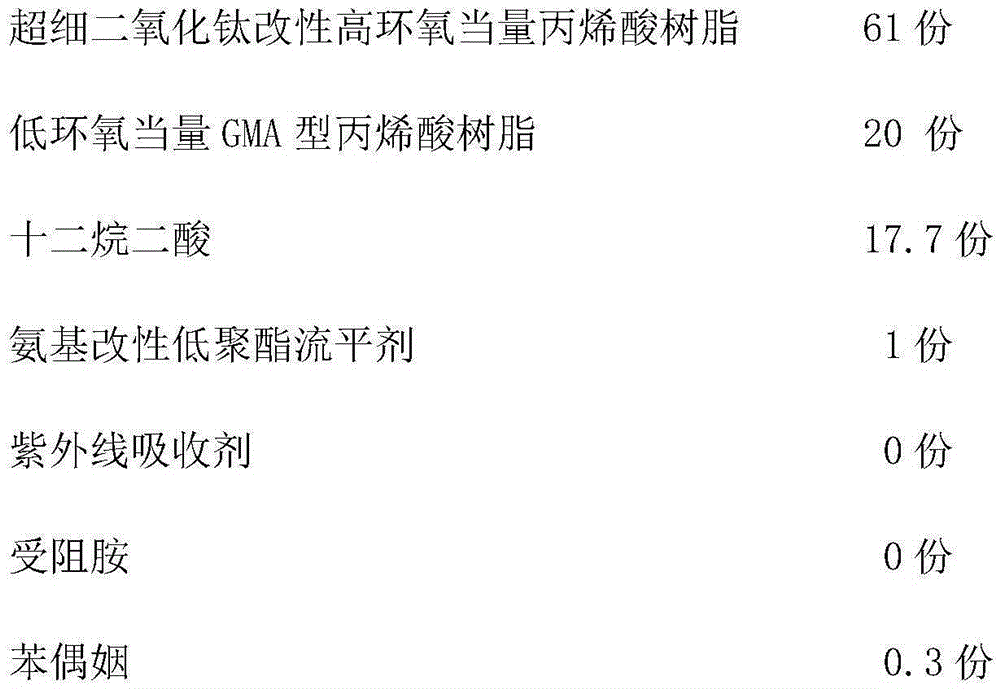

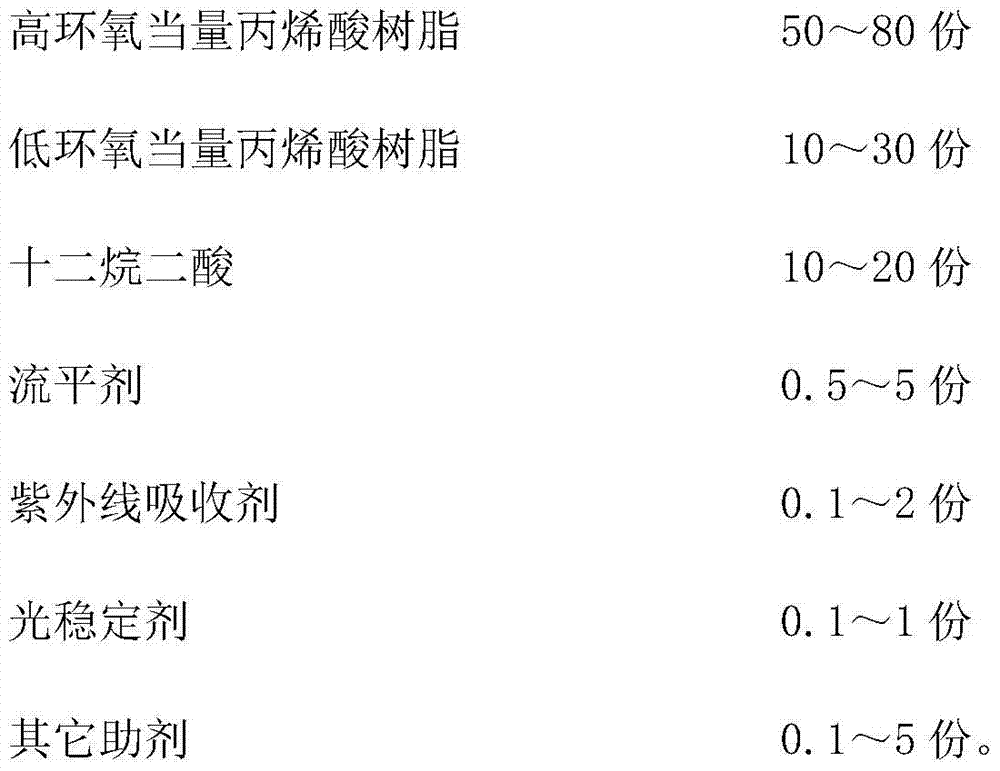

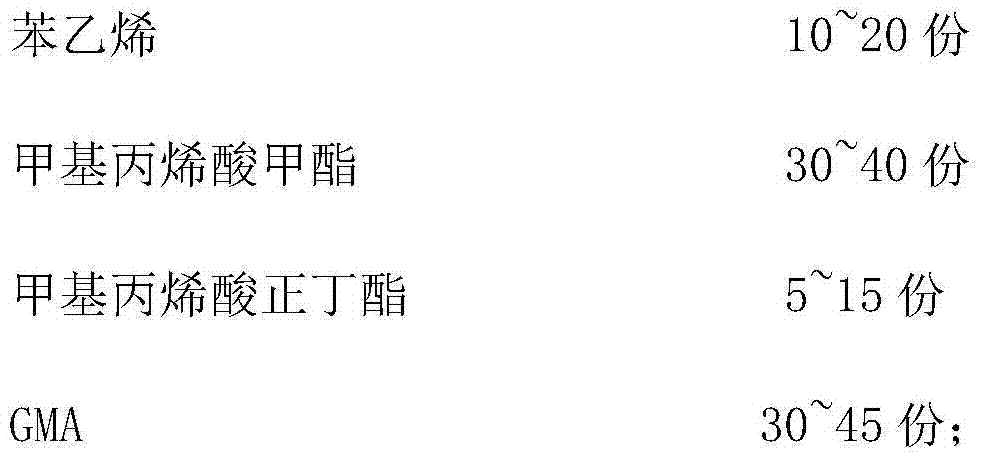

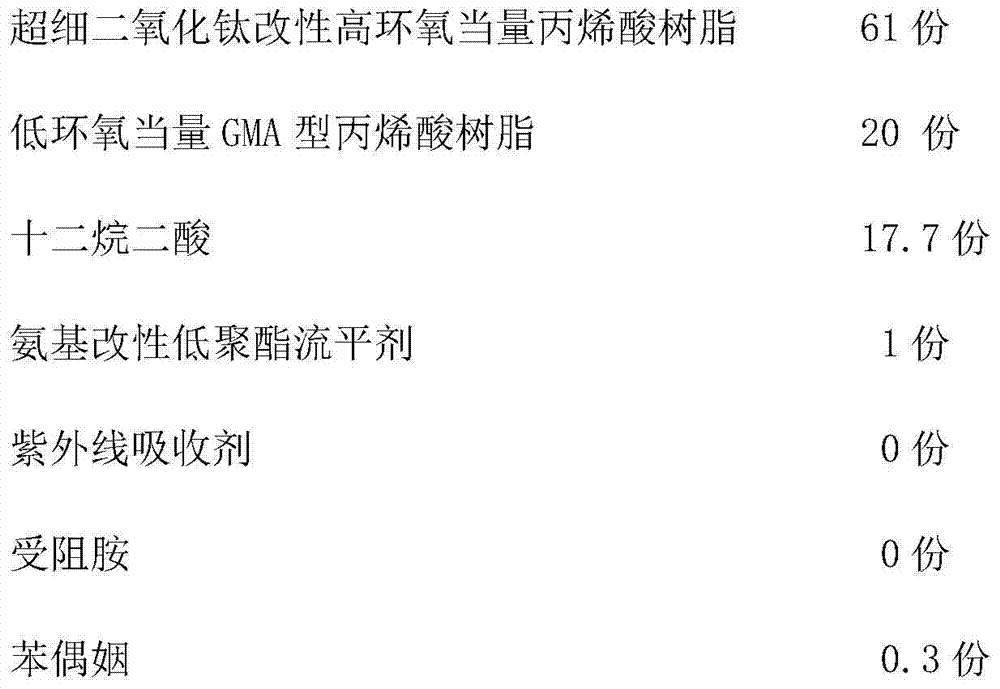

Low-temperature curing type epoxy group acrylic acid transparent powder coating and preparation method thereof

ActiveCN105273558ALower the initial reaction temperatureAchieving Low Temperature CuringPowdery paintsAcrylic resinUltraviolet lights

The invention discloses a low-temperature curing type epoxy group acrylic acid transparent powder coating. The low-temperature curing type epoxy group acrylic acid transparent powder coating is mainly prepared from high-epoxide-equivalent acrylic resin, low-epoxide-equivalent acrylic resin, dodecanedioic acid, an ultraviolet light absorber, a light stabilizer, a flatting agent and other auxiliaries. The high-epoxide-equivalent acrylic resin is modified by ultrafine titanium dioxide, and the low-epoxide-equivalent acrylic resin is in a GMA type. By the adoption of the high-epoxide-equivalent acrylic resin, the low-epoxide-equivalent acrylic resin and the dodecanedioic acid, the initial reaction temperature of the powder coating is decreased, and low-temperature curing is achieved; due to the auxiliary curing of the low-epoxide-equivalent acrylic resin, the enough compactness of the powder coating is improved, and then the corrosion resistance of the coating is improved; by the adoption of the high-epoxide-equivalent acrylic resin modified by the ultrafine titanium dioxide, the best ultraviolet absorption effect is obtained, and the weather resistance of the coating is improved.

Owner:GUANGZHOU KINTE IND

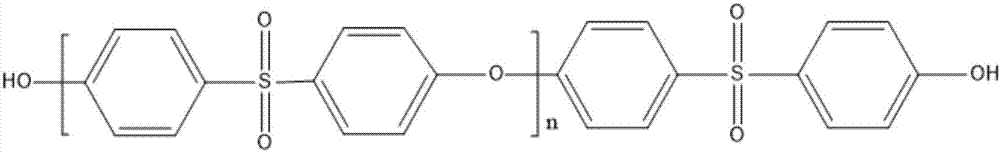

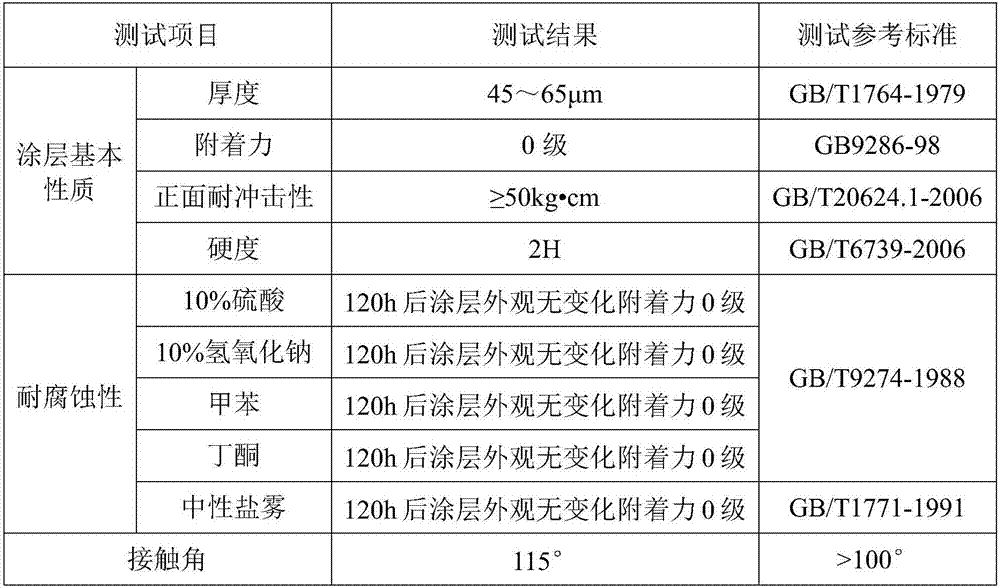

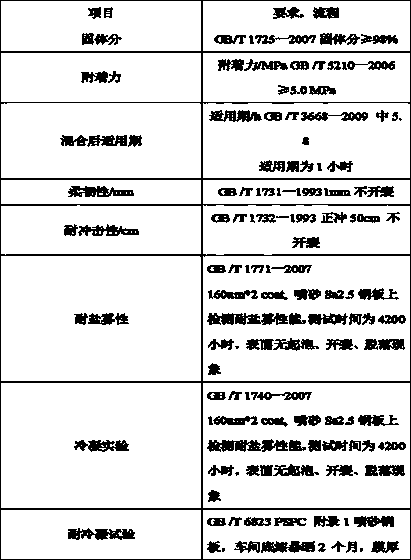

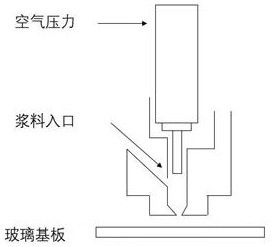

Low-temperature curing polyether sulfone coating composition and preparation method thereof, as well as coating process

ActiveCN106905841AImprove adhesionModerate thicknessPretreated surfacesAnti-corrosive paintsEpoxyLow temperature curing

The invention discloses a low-temperature curing polyether sulfone coating composition and a preparation method thereof, as well as a coating process, and belongs to the technical field of coatings. The low-temperature polyether sulfone coating composition is prepared from polyether sulfone resin, epoxy resin, polytetrafluoroethylene, a curing agent and a diluent. The preparation process comprises the following steps: dissolving the polyether sulfone resin in a composite solvent prepared from dimethylacetamide, methylbenzene and butanone at the stirring speed of 3,200 to 3,800 r / min, then adding the polytetrafluoroethylene and the epoxy resin in sequence, grinding the materials in a grinding machine for 2 to 6 hours, adding the curing agent before spraying, stirring for 0.2 to 0.5 hour for curing, spraying a sandblast metal base material with the cured coating through an air spraying gun and an air compressor, and drying at 150 to 170 DEG C for 2 to 6 hours. According to the preparation method disclosed by the invention, low-temperature curing of the polyether sulfone coating is realized; a prepared coating layer is high in adhesion force, impact resistance, wear resistance, hydrophobicity, corrosion resistance and the like; the preparation and coating process is easy to operate; production equipment is easy to realize and the application range is wide.

Owner:JILIN JITU GAOKE TECH CO LTD

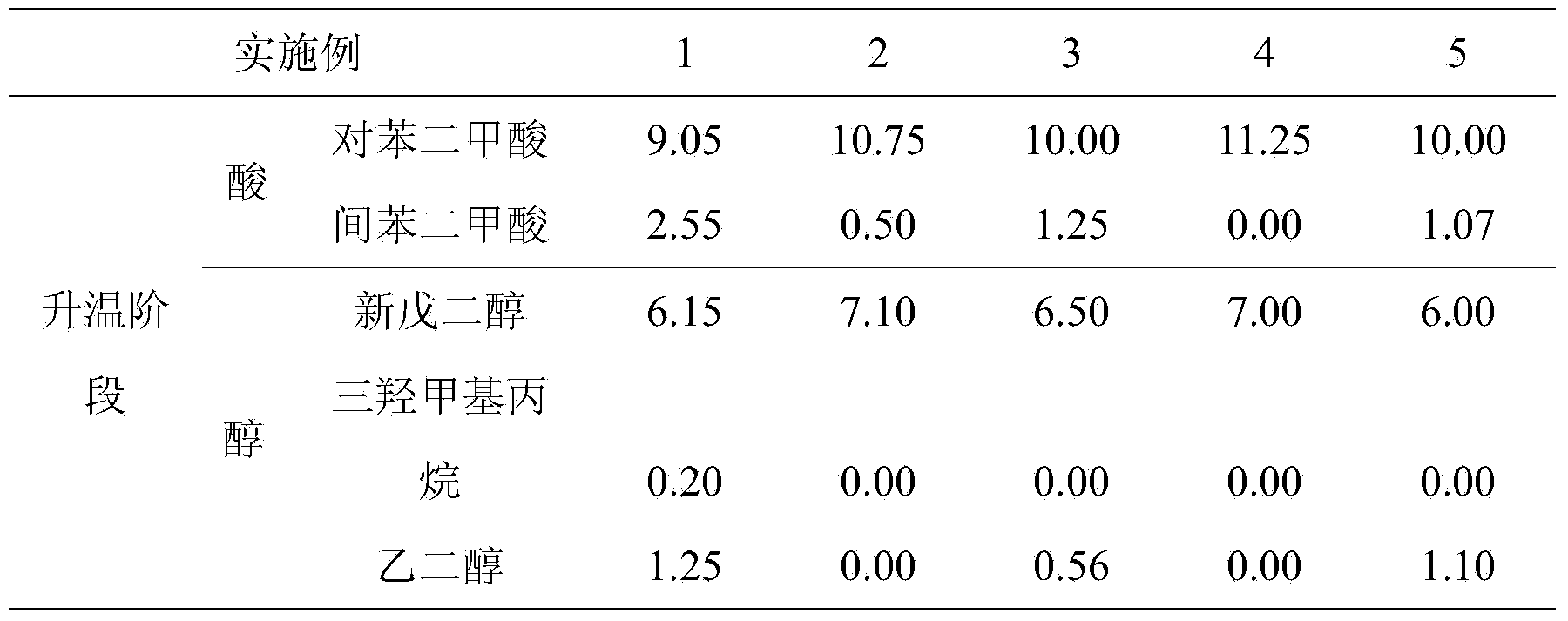

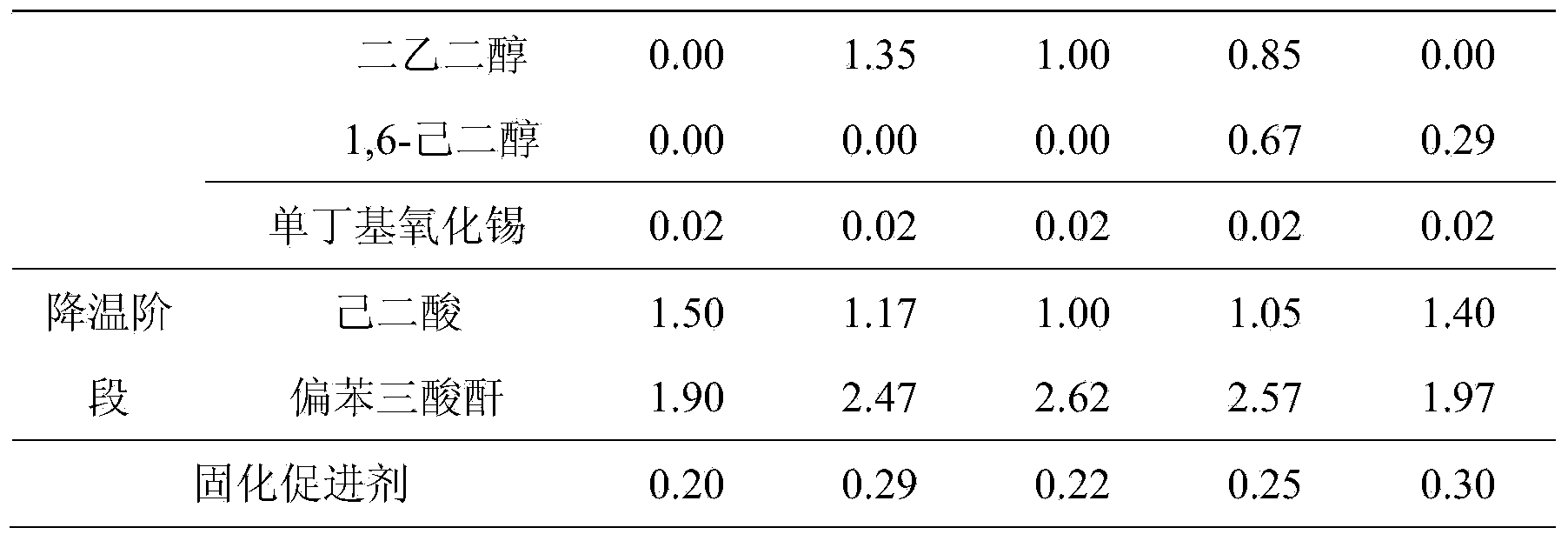

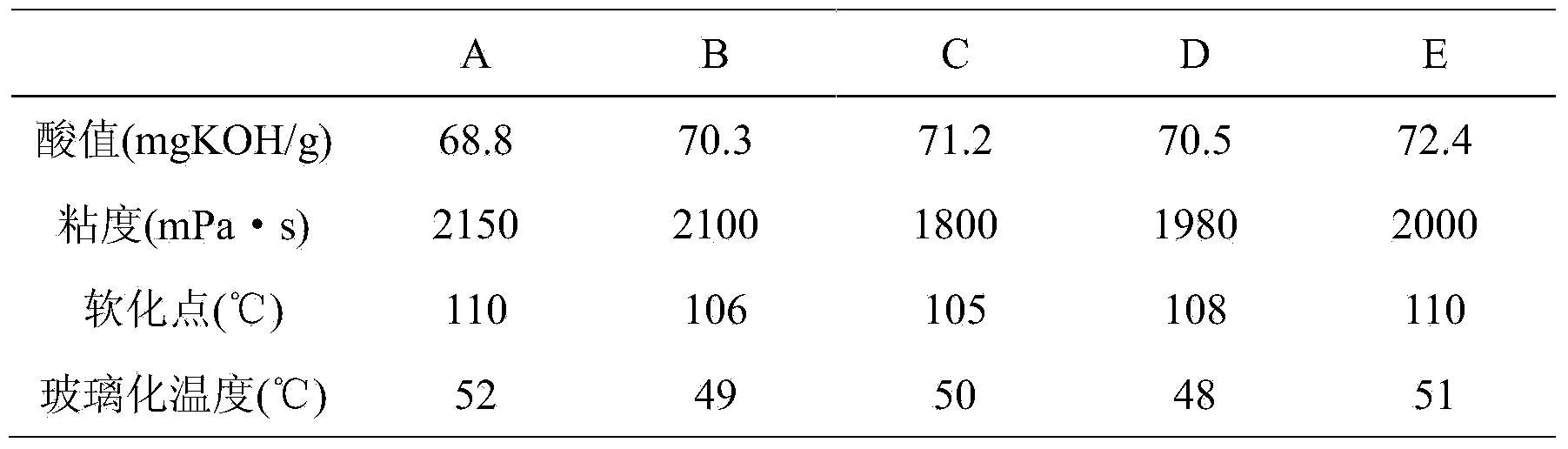

Method for preparing low-temperature cured polyester resin

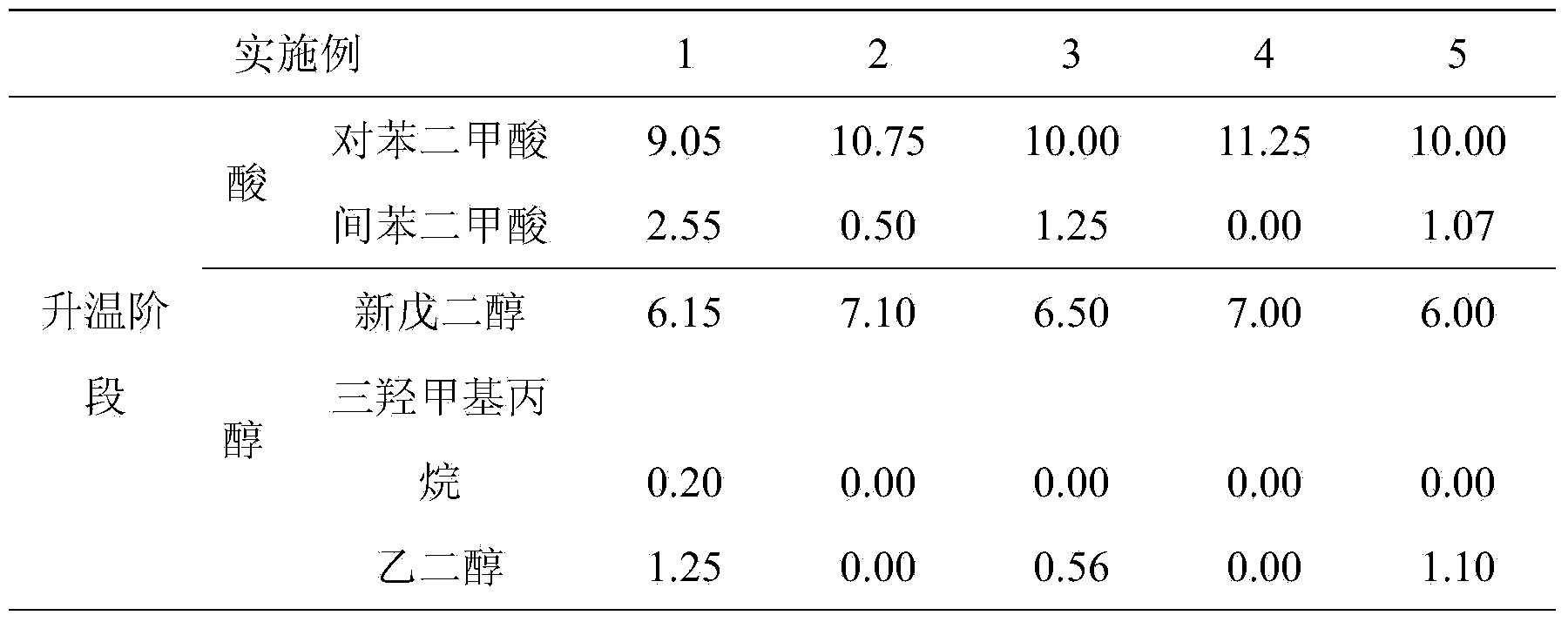

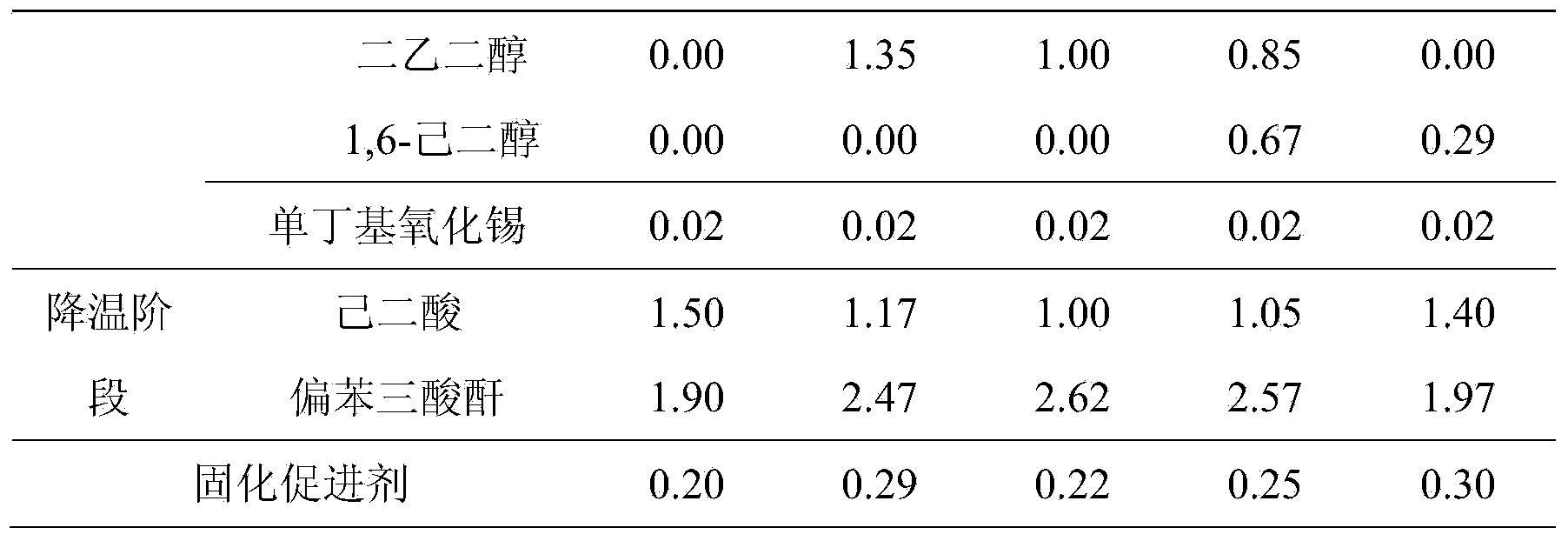

InactiveCN104387570AHigh reactivityGood storage stabilityPowdery paintsPolyester coatingsChemistryPolyresin

The invention relates to a method for preparing low-temperature cured polyester resin. The method comprises the following steps: heating for esterifying, cooling, vacuumizing and curing. By adopting the method provided by the invention, the reaction activity of the resin is greatly improved, the storage stability is relatively good, and when the resin is used in a powder coating, low-temperature curing is well achieved, the coating is relatively good in adhesion to a substrate, and meanwhile relatively good leveling and chemical resistance properties are achieved.

Owner:ANHUI SHENJIAN NEW MATERIALS

Preparation method of tourmalinite fuel oil activator

ActiveCN103980964AStrong NMR propertiesImprove conductivityLiquid carbonaceous fuelsWater useCombustion

The invention discloses a preparation method of a tourmalinite fuel oil activator. The tourmalinite fuel oil activator comprises tourmalinite nano-powder as a main functional component. The preparation method comprises the following steps of compounding the tourmalinite nano-powder and spinel ferrite, mixing the compound and an additive according to a mass ratio of the tourmalinite nano-powder, the spinel ferrite to the additive of 87-93: 5-9: 2-4, carrying out sintering to obtain a solid mixture, and adding water and a surfactant into the mixture, wherein the amount of the used mixture is 1-5% the total amount of the solid-liquid mixture, a water use ratio is in a range of 5-98% and a surfactant use ratio is in a range of 2-30%. The tourmalinite fuel oil activator obtained by the preparation method can improve fuel oil quality, promote full combustion of fuel oil, improve combustion efficiency, save fuel oil, improve fuel oil atomization quality, and realize full combustion of fuel oil thereby reducing discharge of harmful gas so that energy saving and emission reduction are realized.

Owner:丘寿勇 +1

Epoxy curing agent

The invention relates to a waterborne epoxy curing agent for waterborne epoxy resin as well as a preparation method and an application method of the waterborne epoxy curing agent. Mercapto and amino groups are taken as curing reaction groups of the waterborne epoxy curing agent, a curing agent structure comprises a tertiary amine structure which can be dispersed or dissolved in water. Compared with a polyamine curing agent, the prepared quick-drying curing agent is faster in curing and better in impact resistance and can realize low-temperature curing; compared with a thiol curing agent, the prepared quick-drying curing agent is faster in curing, and hardness, bending performance and impact resistance of a film are improved remarkably.

Owner:SUZUKA INTERNATIONAL (SHANGHAI) CO LTD

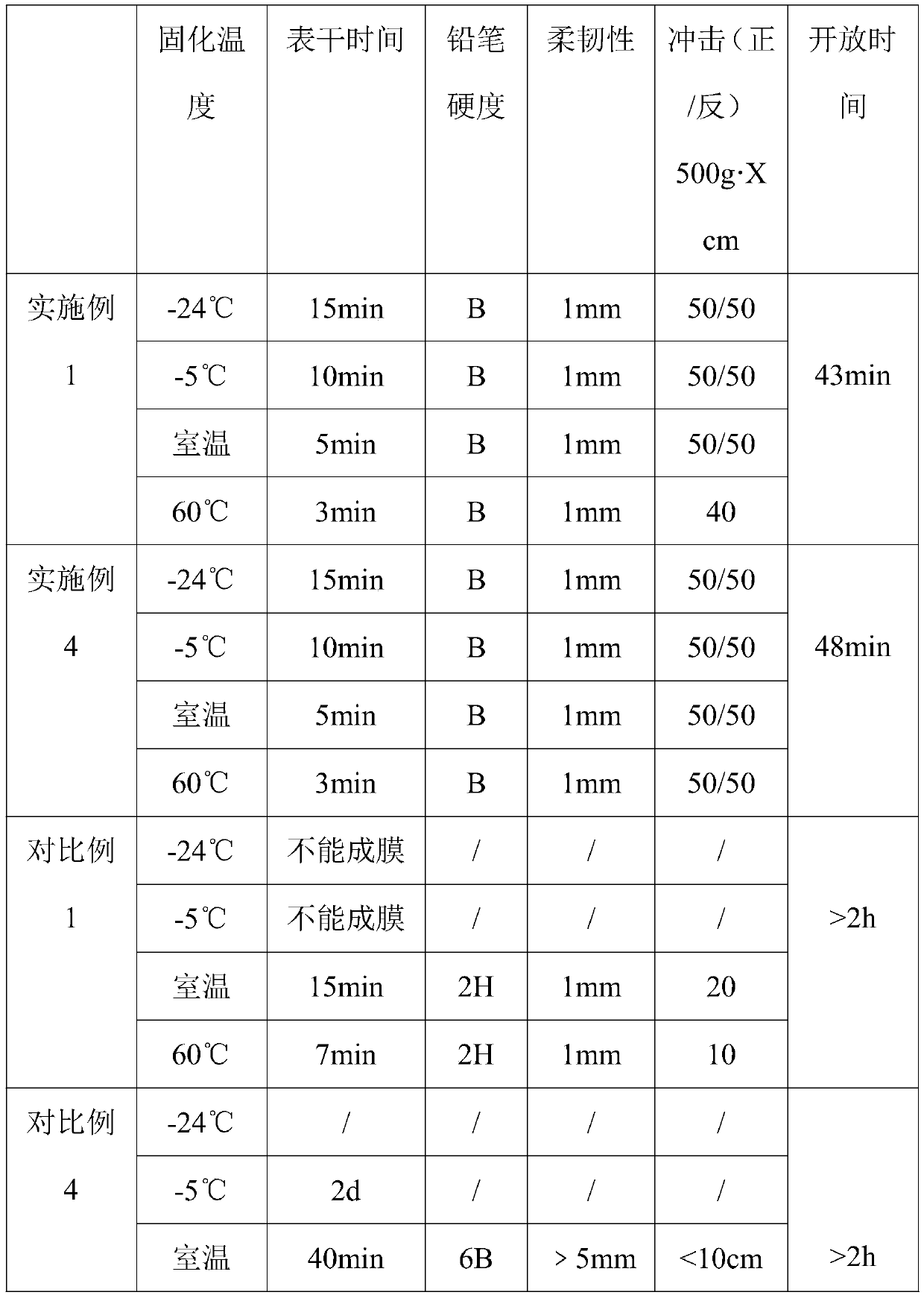

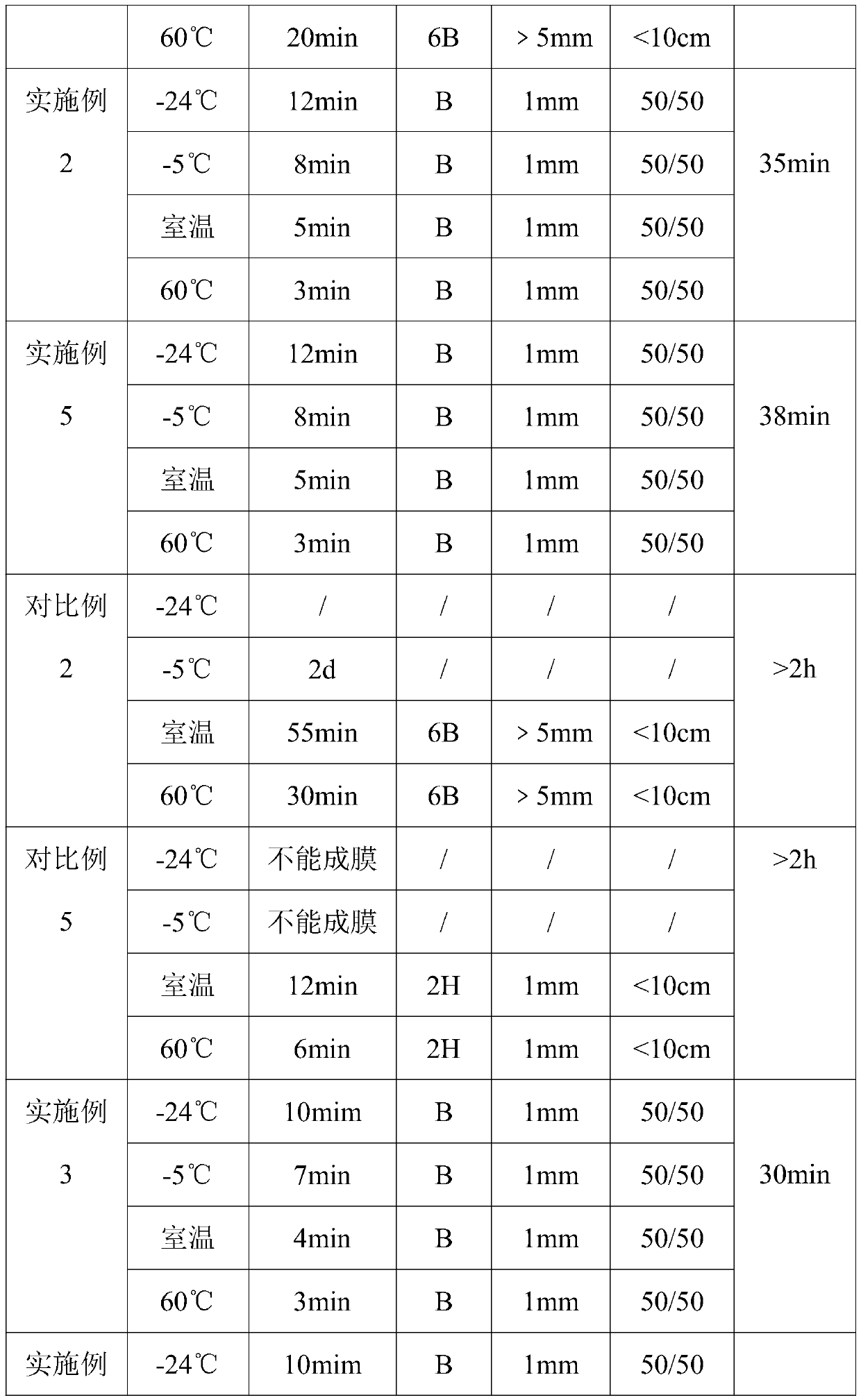

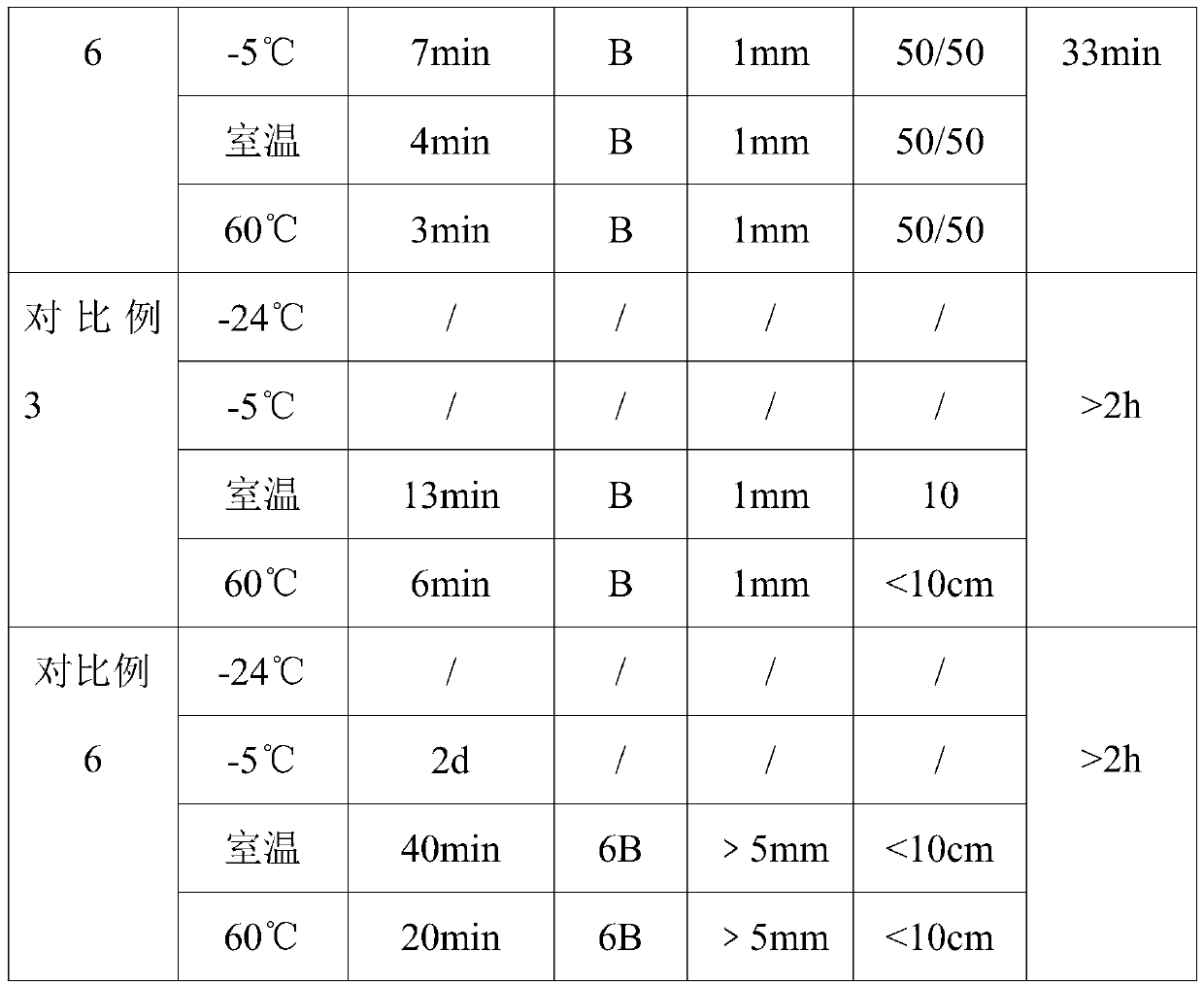

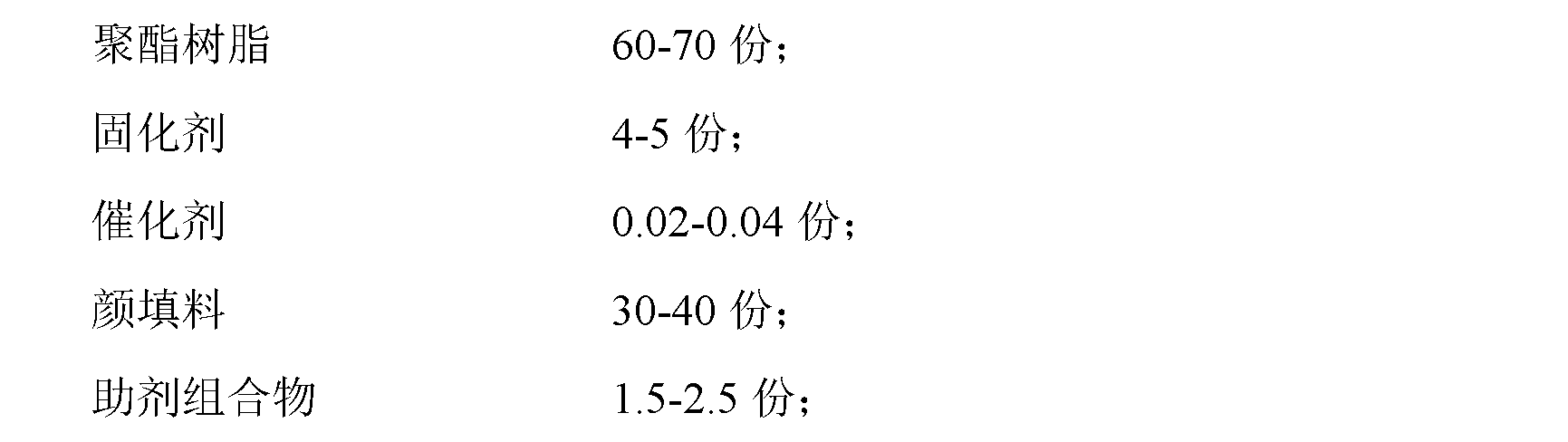

Powder coating for vacuum coating and bottom layer of metal substrate and preparation method of powder coating

InactiveCN103265878AImprove anti-corrosion performanceImprove adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsLow temperature curingPolyester resin

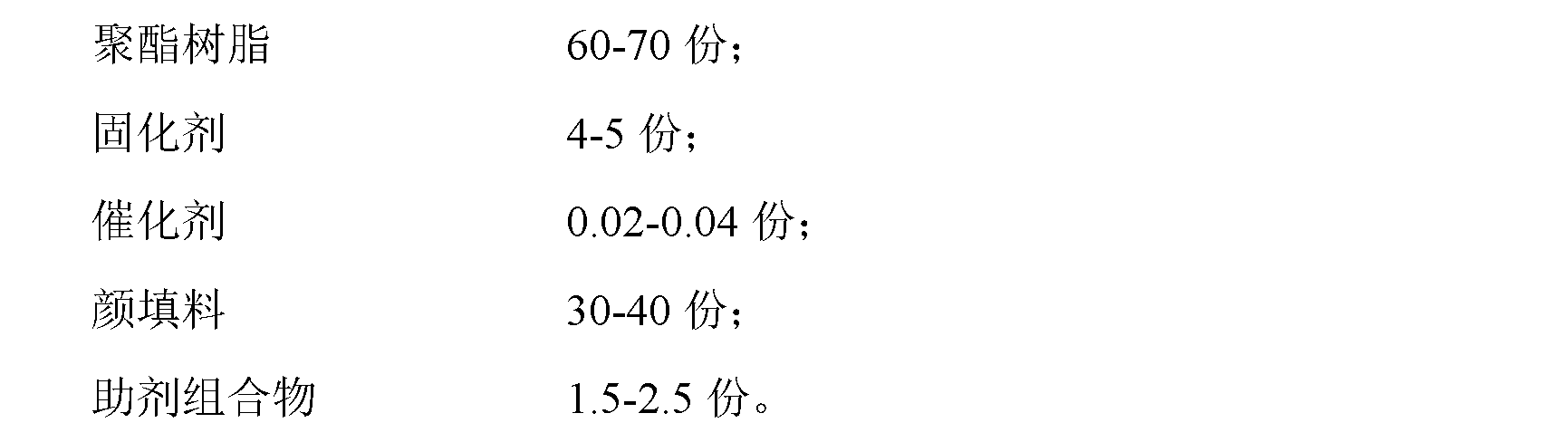

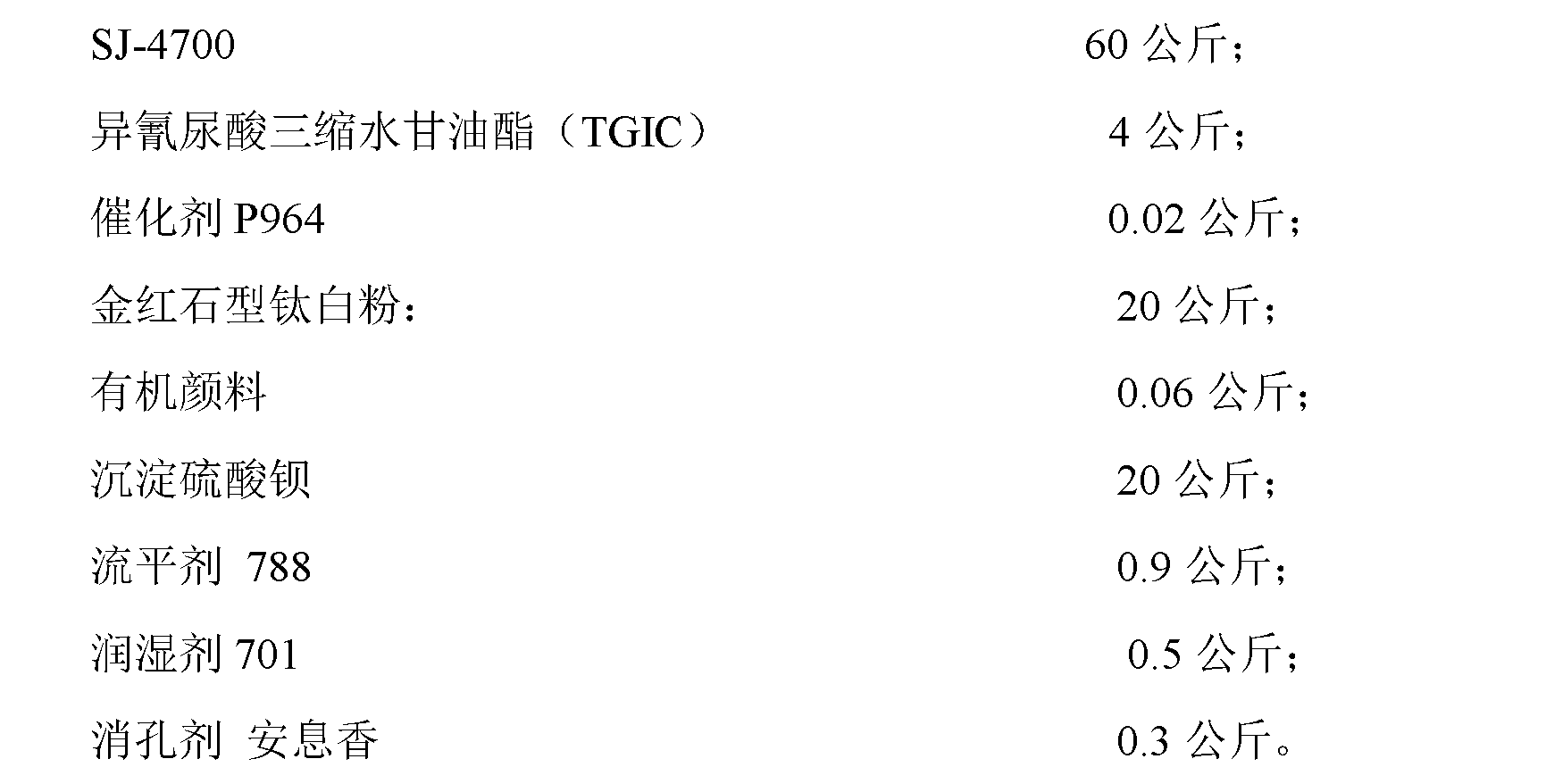

The invention relates to a powder coating for a vacuum coating and a bottom layer of a metal substrate. The powder coating comprises the following components in parts by weight: 60-70 parts of polyester resin, 4-5 parts of curing agent, 0.02-0.04 part of catalyst, 30-40 parts of pigment and filler and 1.5-2.5 parts of additive composition. The powder coating has excellent antiseptic property and super adhesive force with liquid pain, does not give off small molecules, has no influence on the adhesive force of the vacuum coating and the bottom layer and provides a guarantee for firmly attaching the vacuum coating to a liquid paint film; and meanwhile, the powder coating has the advantages of being environment-friendly and energy-saving, realizing the low-temperature curing, having excellent anti-corrosive property, good specular reflection effect, fine and smooth surface, very good decorative effect, excellent day lighting property and excellent quality, being capable of ensuring the high brightness of the vacuum coating and having no phenomena of falling and flooding and can be used for spraying the substrate before the liquid paint is sprayed on the vacuum coating of the metal substrate.

Owner:TIANJIN XIANGSHENG NEW MATERIALS CO LTD

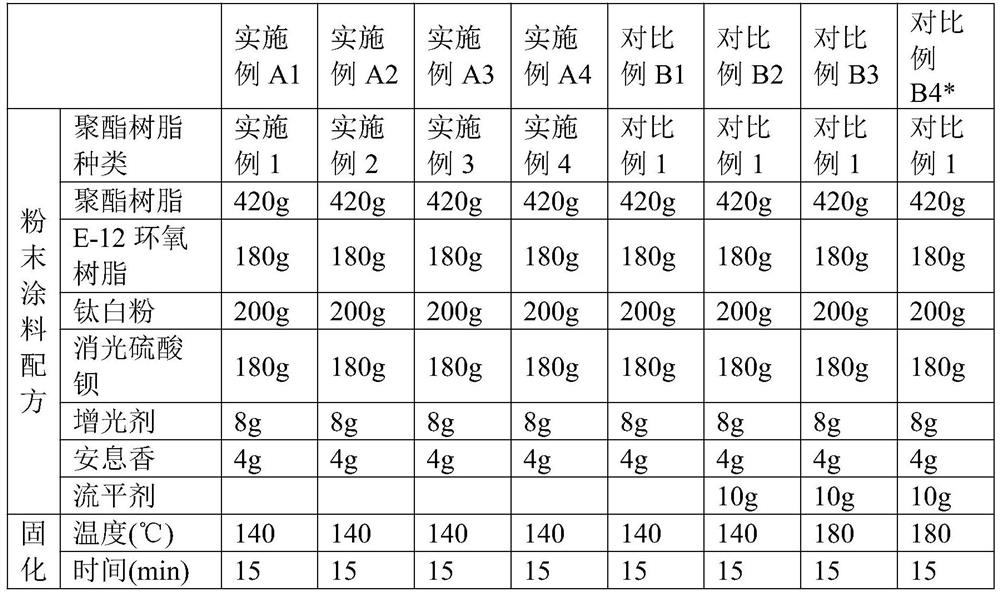

Preparation method for low-temperature curing composite resin powder coating

InactiveCN110041810AGood storage stabilityModerate molecular weightPowdery paintsEpoxy resin coatingsEpoxyHeat resistance

The invention relates to a preparation method for a low-temperature curing composite resin powder coating, and belongs to the technical field of coatings. Terminal carboxyl polyester resin and epoxy resin are taken as raw materials to prepare the low-temperature curing composite resin powder coating. Since the terminal carboxyl polyester resin and the epoxy resin are compounded, the low-temperature curing of the resin powder coating can be effectively realized, power coating application is not limited to the coating of the surface of a thermal-resistance base material, a possibility for applying the power coating to the surface coating film of a thermosensitive base material is greatly increased, the preparation method performs a great function for expanding the application range and the application field of the powder coating, the curing temperature of the low-temperature curing powder coating is low, the cost generated in a baking link in a production process is lowered, the consumption of energy is greatly reduced, resources are saved, the curing time is shortened while the mechanical property of the coating film is guaranteed, a production period is shortened, the production efficiency is improved, and economic benefits are increased.

Owner:江苏海獭新材料科技有限公司

Low-temperature setting polyester resin

ActiveCN104277208AHigh reactivityGood storage stabilityPowdery paintsPolyester coatingsLow temperature curingPolyester resin

The invention relates to low-temperature setting polyester resin. The low-temperature setting polyester resin comprises the following components in parts by mass: 7-9 parts of alcohol, 14-15 parts of acid, 0.02 part of an esterification catalyst and 0.2-0.3 part of curing catalyst. The prepared low-temperature setting polyester resin has the advantages that reaction activity is greatly improved, and storage stability is good; meanwhile, low-temperature setting is realized when the prepared low-temperature setting polyester resin is applied to powder coating, adhesive force of a coating to a base material is good, and good levelling property and chemical resistance are realized.

Owner:ANHUI SHENJIAN NEW MATERIALS

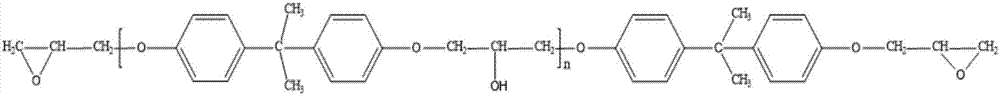

Solvent-free epoxy coating for ballast tank and preparation method thereof

InactiveCN110655848ALow viscosityGood flexibilityAnti-corrosive paintsEpoxy resin coatingsSolvent freeFatty amine

The invention relates to the technical field of coatings, and in particular relates to a solvent-free epoxy coating for a ballast tank and a preparation method of the solvent-free epoxy coating. The solvent-free epoxy coating comprises a component A and a component B, wherein the component A comprises the following components in parts by mass: 25-30 parts of bisphenol F epoxy resin, 3-5 parts of liquid petroleum hydrocarbon resin, 5-10 parts of an active diluent, 0.5-1.0 part of a thixotropic agent, 5-10 parts of titanium dioxide, 40-50 parts of barium sulfate, 0.5-1.0 part of a dispersing agent, 0.5-0.8 part of a defoaming agent and 3-5 parts of a silane coupling agent; the component B is prepared from the following components in parts by mass: 13.2 to 15.36 parts of fatty amine adduct, 2.8 to 3.9 parts of cashew phenolic aldehyde amine and 0.1 to 0.5 part of an accelerant; the bisphenol F epoxy resin is matched with the special reactive diluent, so that the viscosity of the system isreduced, the flexibility is improved, and the crosslinking density is improved; the fatty amine adduct is low in viscosity and matched with the cashew phenolic aldehyde amine, low-temperature curingcan be achieved, the drying speed is increased, meanwhile, the chemical resistance of the cashew phenolic aldehyde amine is excellent, and high corrosion resistance is achieved while the chemical resistance of the solvent-free epoxy coating is improved.

Owner:Jiangsu Jiunuo Architectural Materials Technology Co Ltd

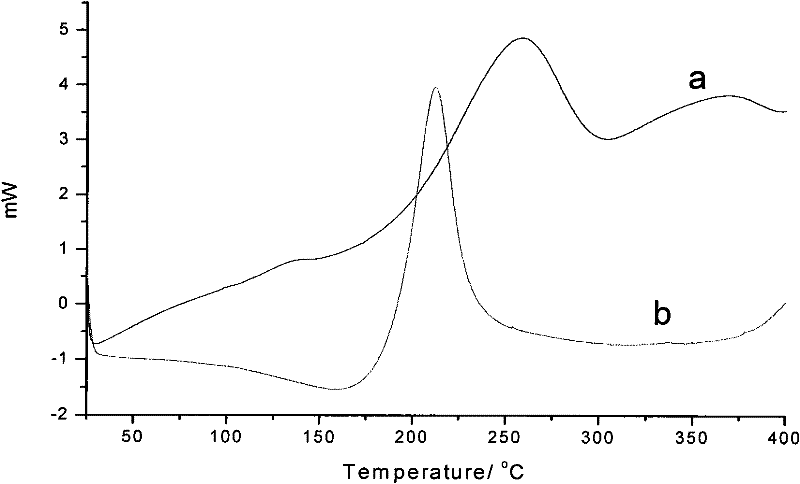

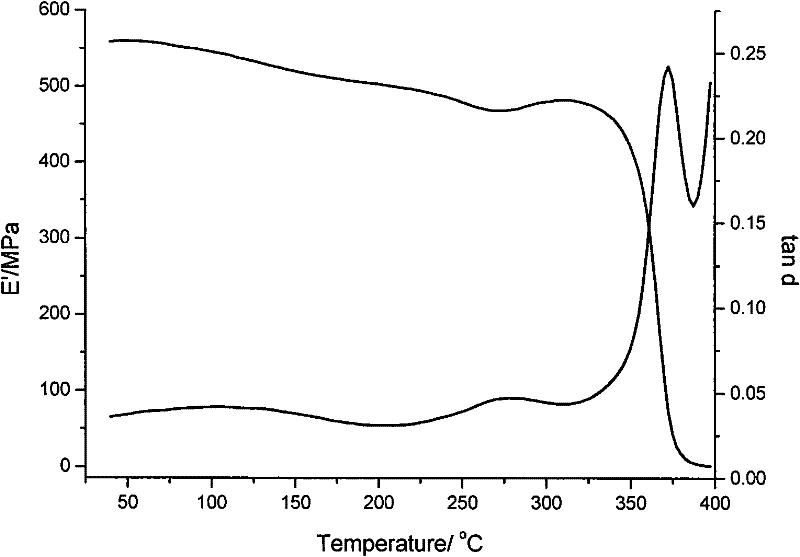

Modified bismaleimide resin as well as preparation method and application thereof

ActiveCN101845143BSimple molding processGood workmanshipPlastic/resin/waxes insulatorsAdhesivesImidePolymer science

The invention discloses a modified bismaleimide resin as well as a preparation method and an application thereof. The preparation method comprises the steps of carrying out high-temperature melting or solution prepolymerization on ethynylaniline, a thermoplastic toughener and a bismaleimide monomer which are mixed according to a certain ratio to obtain a homogeneous and transparent resin. The novel modified bismaleimide resin not only has the characteristics of good forming process properties such as small resin melting viscosity, good solvent solubility, low curing temperature and the like, but also has excellent resistance to high temperature in the form of cured resin. The resin system not only can be used for the matrix resin of the high temperature resistant composite material, and but also can be used in the fields of high temperature resistant adhesives and insulation materials for electronic / electric appliances.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Low-temperature curing epoxy resin and coating containing epoxy resin

ActiveCN108341926AAchieving Low Temperature CuringFast curingEpoxy resin coatingsEpoxyLow temperature curing

The invention provides low-temperature curing epoxy resin. The epoxy resin is epoxy resin of which an epoxy group is modified, and the modified group is a primary amine group or an isocyanate group. The invention also provides a coating containing the epoxy resin. According to the epoxy resin provided by the invention, a chemical modification method is used to convert all epoxy groups on a molecular chain of the epoxy resin into terminal amino-NH2 or isocyanate groups; and when the epoxy resin is applied, modified amino-containing epoxy resin and an isocyanate group-containing curing agent aremixed, or modified isocyanate group-containing epoxy resin and an amino-containing epoxy curing agent are mixed, rapid curing can be performed at the temperature of 0 DEG C or less, and a coating film is stable, and has high strength and wide application prospects.

Owner:西安天元化工有限责任公司

High solid content polyimide coating glue and preparation method and use thereof

PendingCN108753244ASolve the problem of high dielectric constantAchieving a low dielectric constantAdhesivesMicroelectronicsPolyimide

The application provides high solid content polyimide coating glue for chip passivation protection and a preparation method and use thereof, and relates to the technical field of chip passivation protection. The coating glue has high solid content and low viscosity and can be cured at a low temperature. The cured organic soluble polyimide glue coating has excellent dielectric properties, heat resistance and mechanical properties. The coating glue solves the problem that the existing polyamide acid coating glue has low solid content, high viscosity, a high curing temperature, poor heat resistance, poor transparency and high dielectric constant. The high solid content polyimide coating glue has wide application prospects in advanced microelectronics and optoelectronic devices.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

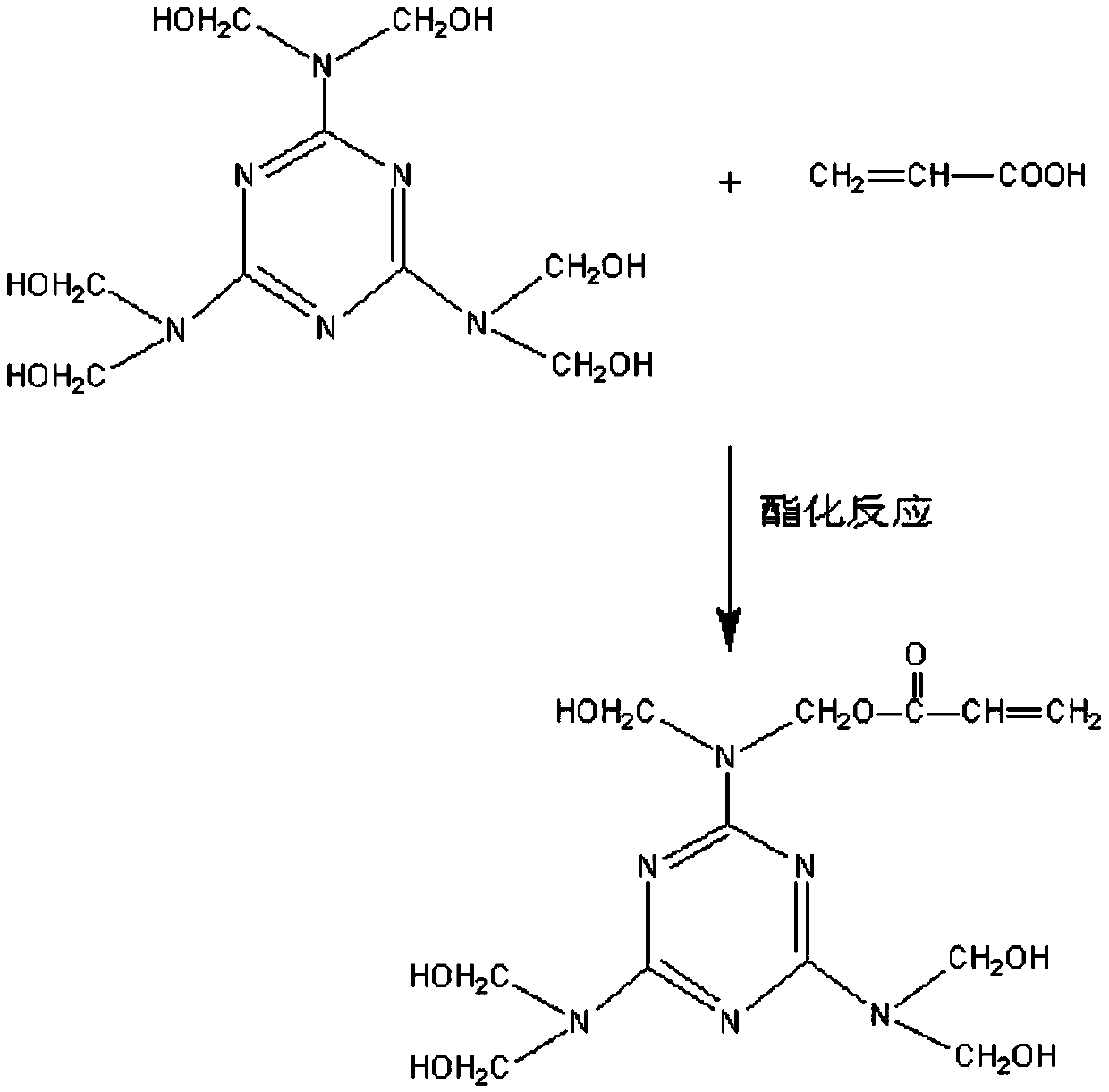

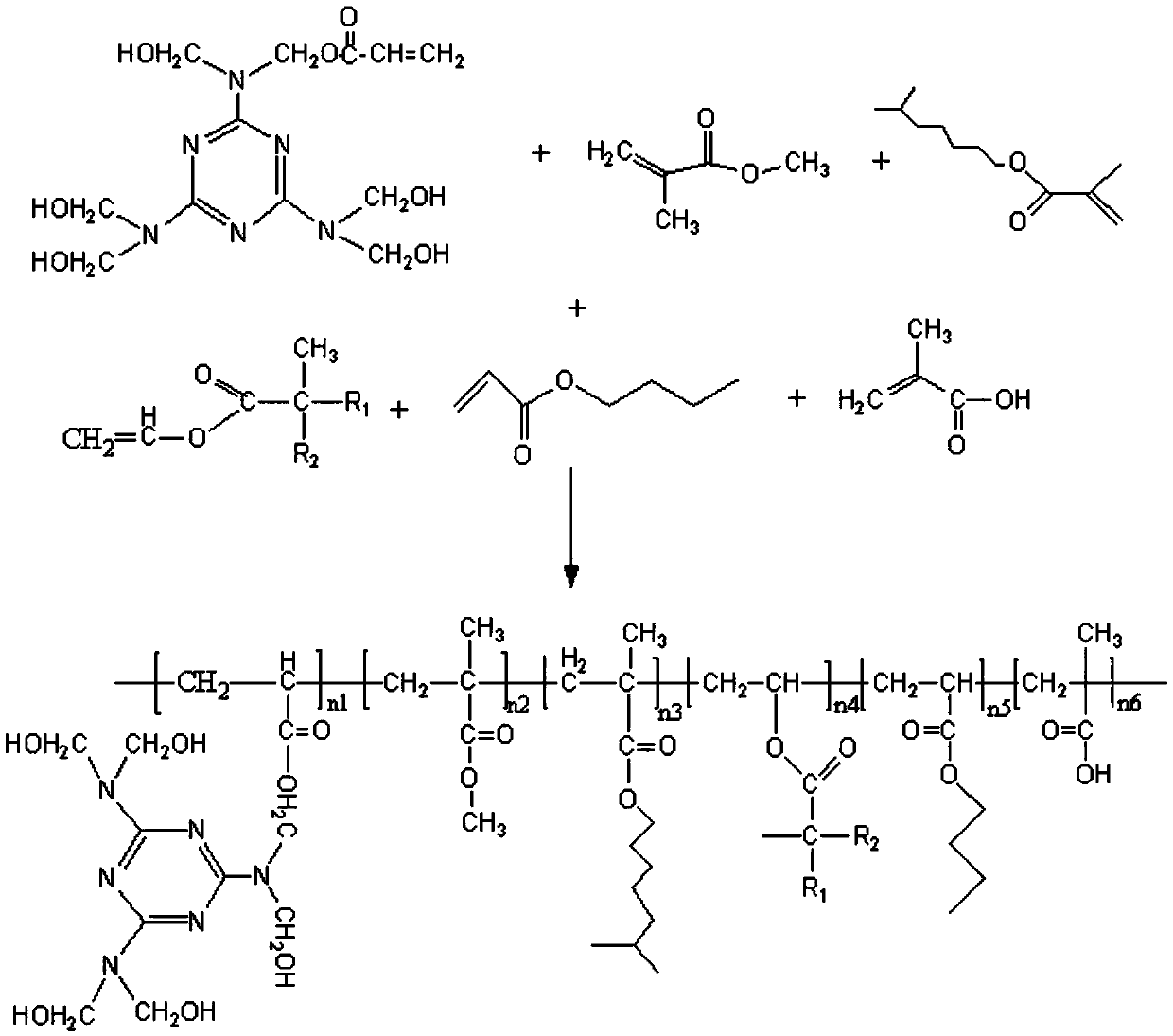

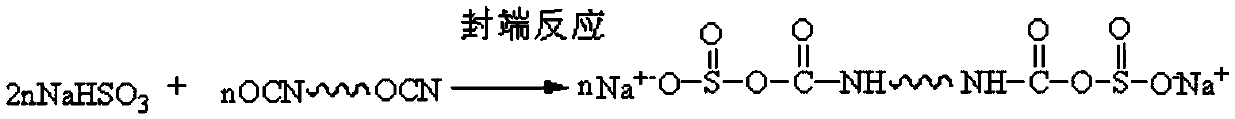

Preparation method of low-temperature curing type waterborne amino acrylic resin

InactiveCN105504145ACorrosion resistanceLow curing temperatureAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinLow temperature curing

The invention discloses a preparation method of low-temperature curing type waterborne amino acrylic resin. The preparation method comprises the following steps of performing esterification reaction on melamine formaldehyde resin and acrylic acid to obtain an amino acrylic ester macromonomer; mixing the amino acrylic ester macromonomer into an acrylic monomer emulsion, and polymerizing to obtain a polyamino acrylic ester emulsion; mixing the polyamino acrylic ester emulsion and water-soluble blocked isocyanate, so as to prepare the low-temperature curing type waterborne amino acrylic resin. The preparation method has the advantages that the melamine formaldehyde resin is mixed into the acrylic acid to prepare the amino acrylic ester, and multiple types of acrylic ester are mixed into the amino acrylic ester, so that the properties of the emulsion and a rubber film are improved, the anti-scratching and anti-corrosive properties of a coating film are improved, and the service life of the coating film is prolonged; after the isocyanate which is blocked by sodium bisulfite is used, the self disadvantages are overcome by the advantages of the isocyanate and the acrylic ester, and the coating film has the water-proof, anti-aging and anti-corrosive properties of the amino acrylic ester, and also has the property of low curing temperature of the isocyanate.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

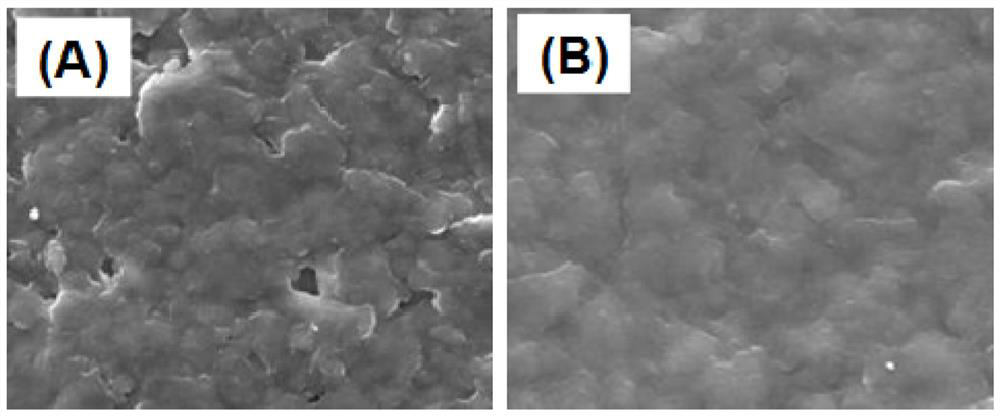

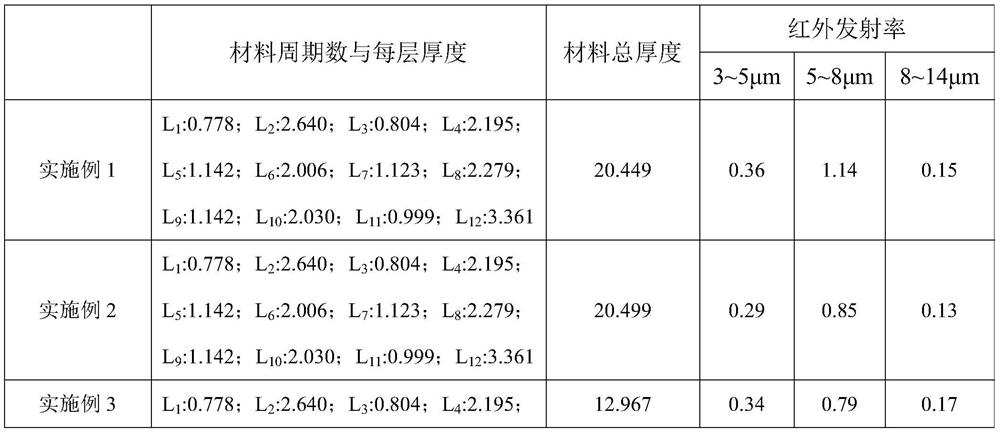

Temperature-resistant environment-friendly infrared stealth material with waveband selection and low emissivity and preparation method thereof

ActiveCN114806254AAchieving low infrared emissivitySelective low hairVacuum evaporation coatingSputtering coatingLow emissivityRefractive index

The invention provides a waveband-selective low-emissivity temperature-resistant environment-friendly infrared stealth material and a preparation method thereof.The material comprises an infrared stealth coating and an infrared stealth film which are alternately arranged on a base material, the refractive index of the infrared stealth coating ranges from 3.55 to 3.74, sheet-shaped aluminum powder is modified through a liquid phase deposition surface coating technology, and the infrared stealth film is prepared. The prepared Al / Cr2O3 composite filler effectively improves the temperature resistance of the infrared coating. The refractive index of the infrared stealth film ranges from 1.12 to 1.25. The material has low infrared emissivity in infrared detection windows (3-5 microns and 8-14 microns) and has high infrared emissivity in a non-infrared detection window. The infrared stealth material disclosed by the invention can resist high temperature of 600 DEG C or above.

Owner:AEROSPACE SCI & IND WUHAN MAGNETISM ELECTRON

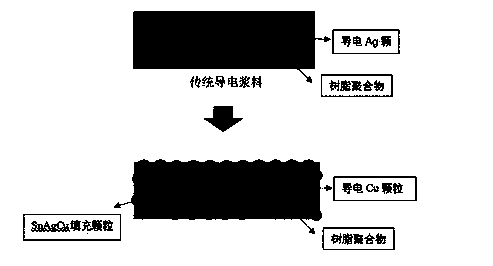

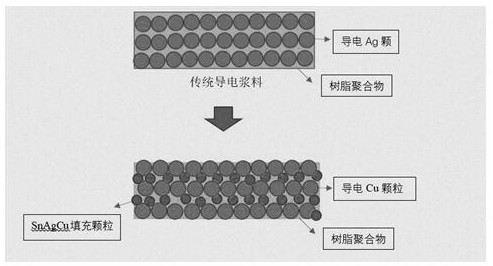

Copper-based composite conductive paste and preparation method and application thereof

ActiveCN110428926AImprove electrical conductivityImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureMicrometerSilver paste

The invention discloses copper-based composite conductive paste and a preparation method and an application thereof. The copper-based composite conductive paste comprises a binder, an organic carrierand metal conductive fillers. In the low-temperature curing of the copper-based composite conductive paste under the temperature of 180 DEG C-250 DEG C, SnAgCu alloy powders in the metal conductive fillers melt and chemically reacts with the surface of copper powders to produce an intermetallic compound, wherein the intermetallic compound comprises a Cu6Sn5 phase and a Cu3Sn phase; and the copperpowders in the cured copper-based composite conductive paste are connected with the SnAgCu alloy powders through the Cu6Sn5 phase and the Cu3Sn phase. Compared with the prior art, the copper-based composite conductive paste adopts the SnAgCu alloy powders and micrometer copper powders to improve the conductivity of a copper film, has a large tap density and a relatively low curing temperature, andis convenient for practical use; the low-cost copper powders are used to replace silver paste prepared by more expensive silver powders in some respects, so that the cost is greatly reduced; and meanwhile, the copper-based composite conductive paste does not cause pollution to the environment, accords with the environmental protection concept, and has a broad application prospect.

Owner:SOUTHEAST UNIV

Synthesis method of silver nanowire ink and preparation method of flexible conductive film

ActiveCN111909570AGood electrical conductivityImprove conductivityTransportation and packagingMetal-working apparatusPoly ethyleneGlycol synthesis

The invention discloses a synthesis method of silver nanowire printing ink, which is specifically implemented according to the following steps: step 1, dissolving a certain amount of polycarbonate fibers, silver nitrate and polyvinylpyrrolidone (PVP) in an ethylene glycol solution, and then adding a ferric trichloride aqueous solution to obtain a mixed solution; step 2, magnetically stirring the mixed solution at 70 DEG C for 40 min, after the color of the solution becomes dark red brown, raising the temperature to 160 DEG C, and magnetically stirring at a constant temperature for 80 min to obtain a mother solution; 3, centrifugally cleaning the mother liquor obtained by the reaction in the step 2 with absolute ethyl alcohol for multiple times to obtain a precipitate; and 4, dispersing theprecipitate obtained in the step 3 in a solvent to obtain the silver nanowire ink. The problem that in the prior art, the nano-silver conductive ink needs to be sintered and cured at high temperatureafter being coated is solved. The invention also discloses a preparation method of the flexible conductive film.

Owner:世大新材料(深圳)有限公司

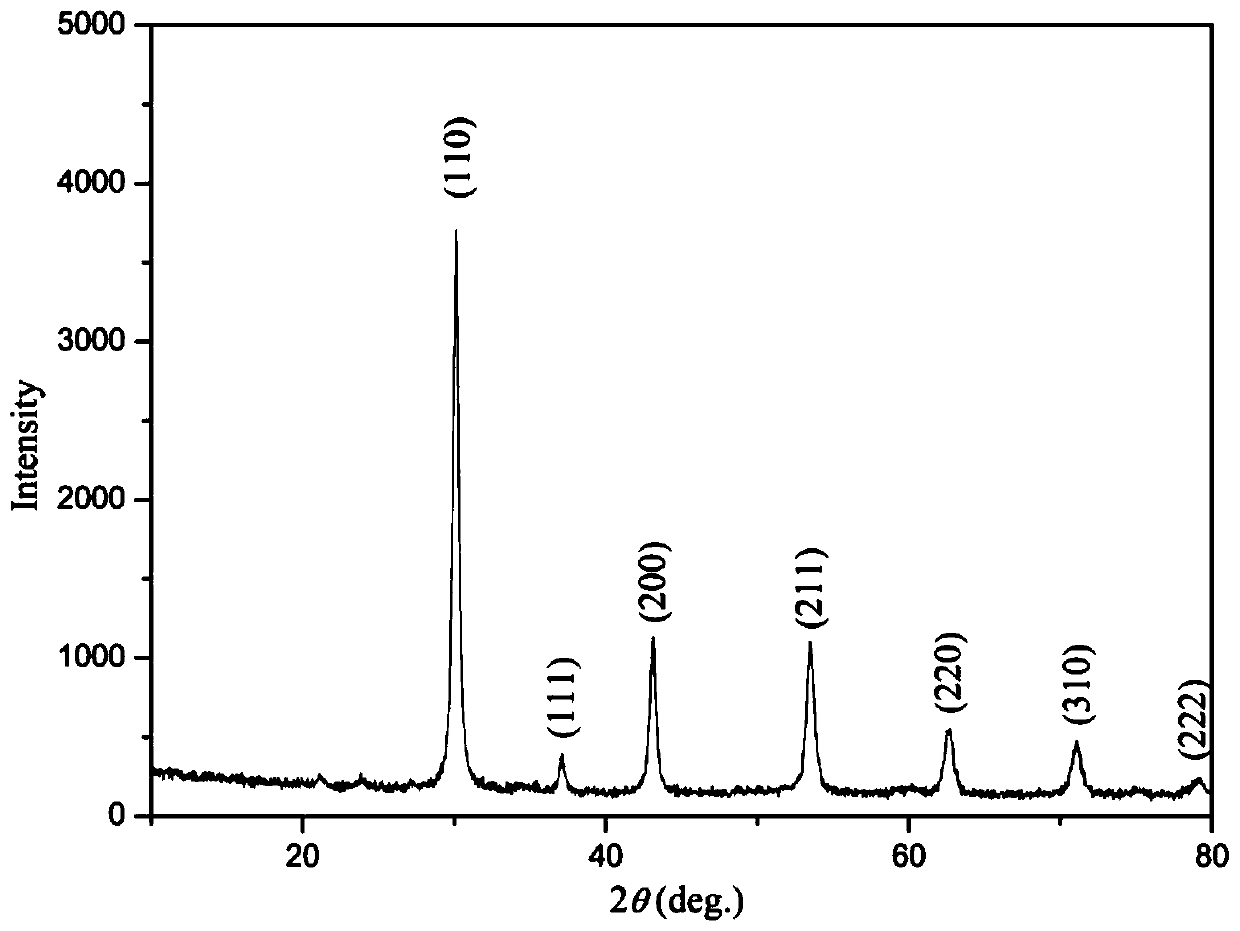

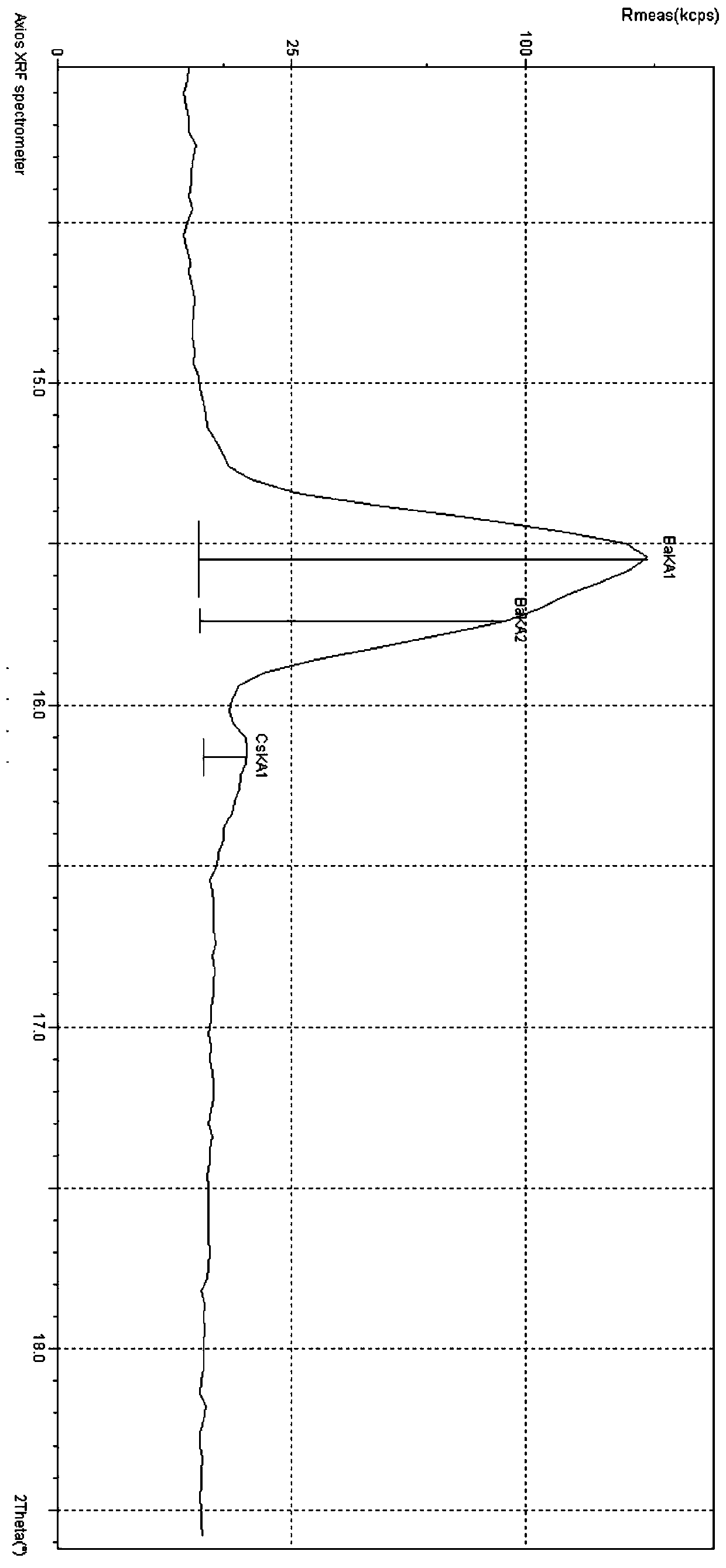

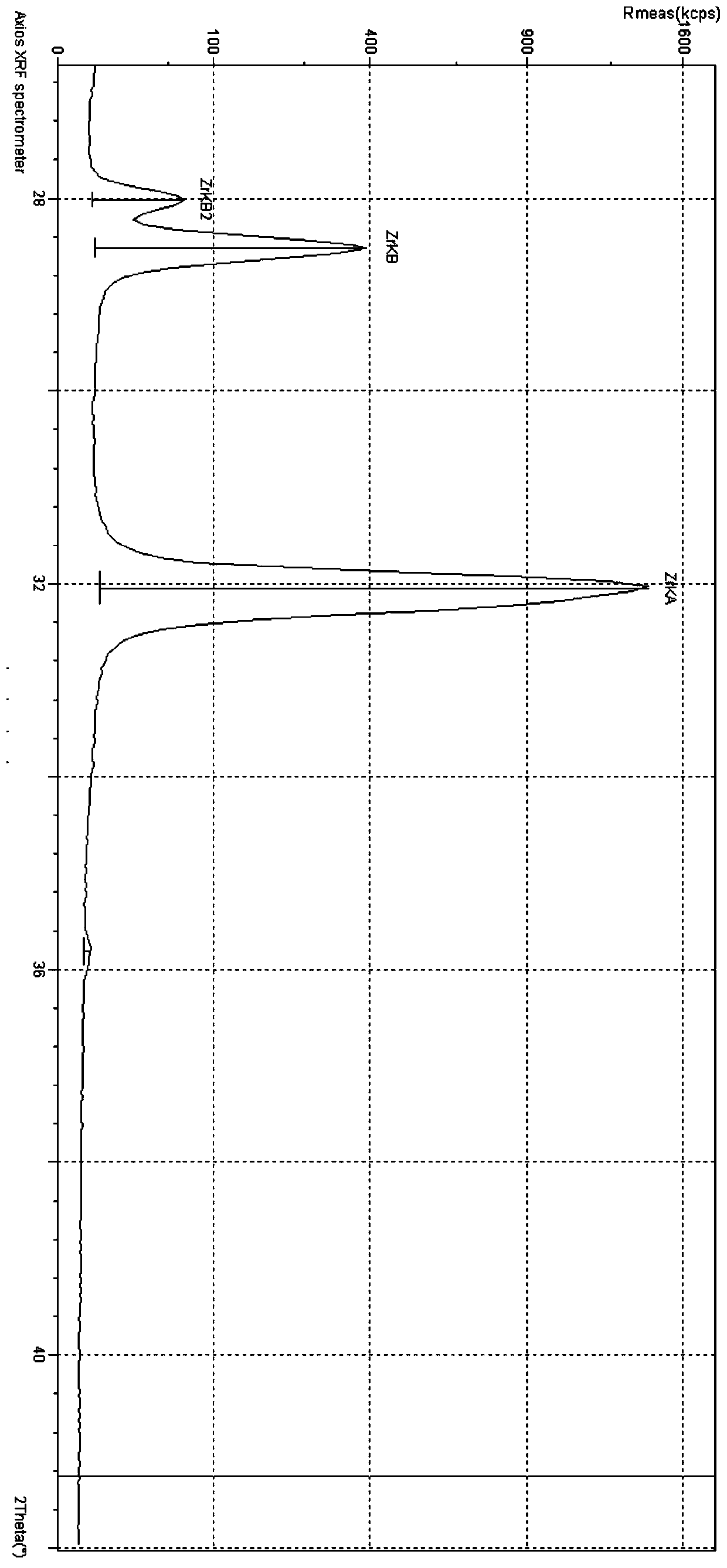

Method for solidifying radioactive nuclide fission product cesium by perovskite structure oxide

ActiveCN110310753AAchieving Low Temperature CuringImprove stabilityRadioactive decontaminationPhase formationHYDROSOL

The invention discloses a method for solidifying radioactive nuclide fission product cesium by perovskite structure oxide. The method comprises the steps that Ba(NO3)2, CsNO3 and Zr(NO3)2.5H2O are taken and added into water for stirring, and a chelating agent is added into the stirred solution for stirring; after a gel is added into the stirred chelated solution for stirring, the temperature is risen slowly until sol becomes gel; the gel is dried, then is placed in a resistance furnace for pre-sintering and is taken out, and after grinding is carried out, a black powder precursor is obtained;the black powder precursor is taken for heat treatment, a nano-powder sample is prepared, the nano powder sample is pressed into blocks, pressure maintaining is carried out, calcination is carried out, and a solidified body is prepared. According to the method for solidifying the radioactive nuclide fission product cesium by the perovskite structure oxide, the perovskite structure oxide with highself-adjusting capability and capable of containing a wide range of elements is adopted as a solidified parent structure, low-temperature phase formation is carried out by a Sol-Ge method, a pressed block sintering process is combined, and low-temperature solidification of Cs is realized by preparing the solidified body; and after Cs is solidified by adopting the solidified matrix structure, the stability is high, and the leaching rate is low.

Owner:SOUTHWEAT UNIV OF SCI & TECH

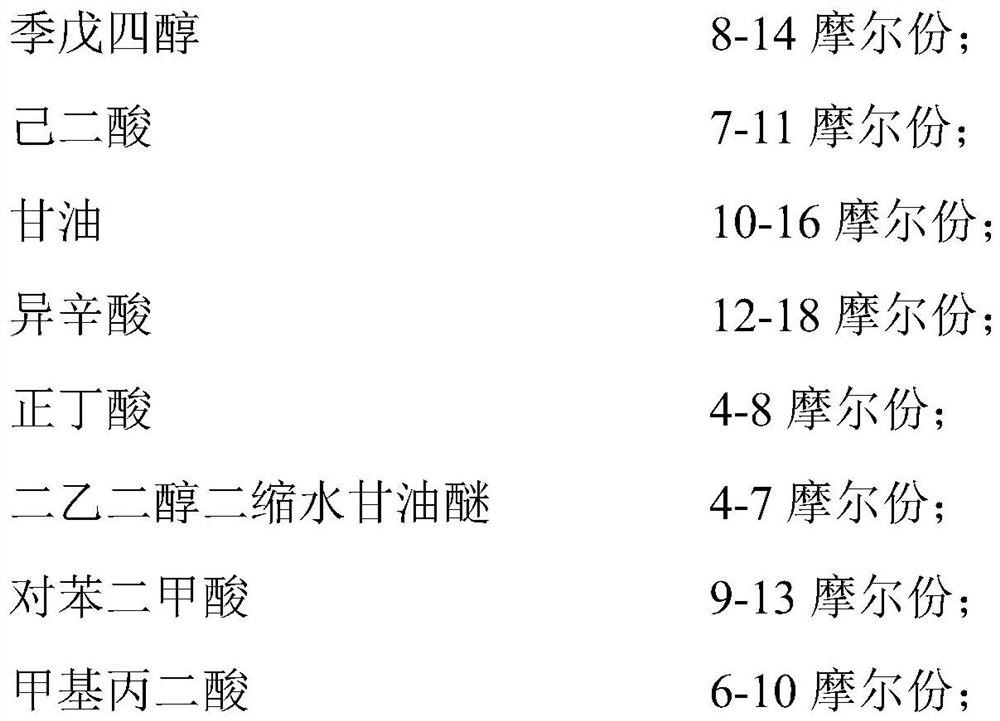

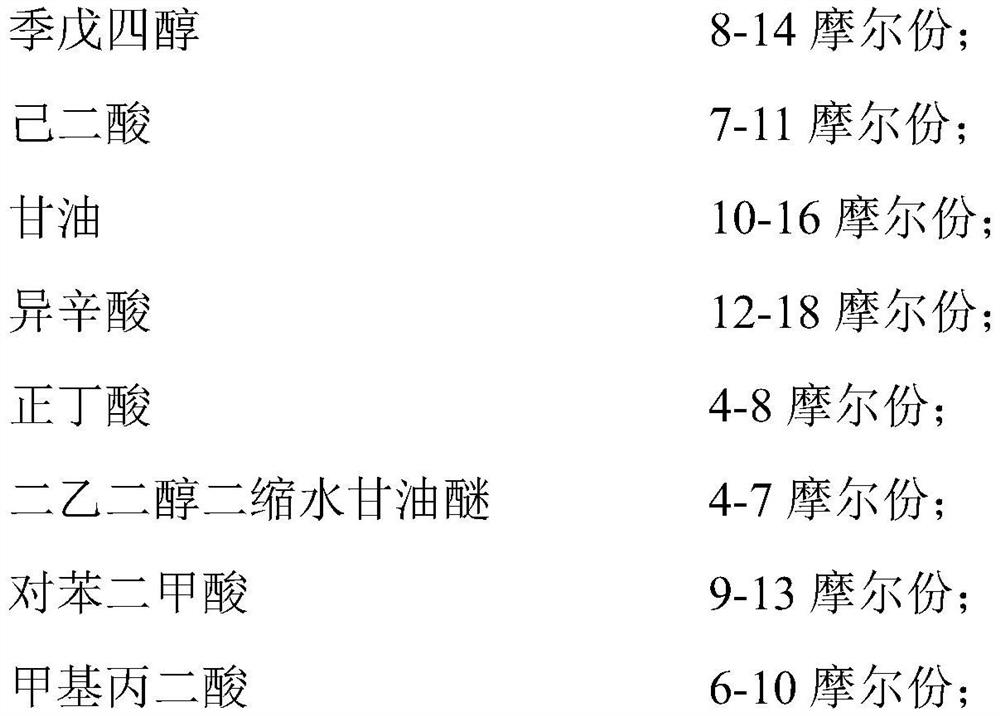

Polyester resin for self-leveling powder coating and preparation method thereof

ActiveCN113549208AOvercoming the problem of insufficient levelingLow softening pointPowdery paintsPolyester coatingsMethylmalonic acidPolymer science

The invention provides polyester resin for the self-leveling powder coating and a preparation method. Pentaerythritol, adipic acid, glycerol, terephthalic acid, isocaprylic acid, n-butyric acid, diethylene glycol diglycidyl ether and methylmalonic acid are used as main raw materials; the polyester resin for the disposable low-temperature curable self-leveling powder coating is obtained by adopting a segmented polymerization mode. The polyester structure has a proper amount of ester groups with low surface tension, so that the softening point of the product is reduced, low-temperature curing is realized, the problem of insufficient leveling property of a low-temperature curing coating film is solved due to excellent self-leveling property, and the ultrahigh-leveling coating film is obtained. According to the preparation process, special raw materials do not need to be prepared in advance, the 70 / 30 self-leveling polyester resin product is directly prepared by adopting a single-kettle synthesis process, the process is simple, and the cost is relatively low.

Owner:黄山嘉恒科技有限公司

Copper-based composite conductive paste, preparation method and application thereof

ActiveCN110428926BImprove conductivityWith high temperature serviceNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteSilver paste

The invention discloses copper-based composite conductive paste and a preparation method and an application thereof. The copper-based composite conductive paste comprises a binder, an organic carrierand metal conductive fillers. In the low-temperature curing of the copper-based composite conductive paste under the temperature of 180 DEG C-250 DEG C, SnAgCu alloy powders in the metal conductive fillers melt and chemically reacts with the surface of copper powders to produce an intermetallic compound, wherein the intermetallic compound comprises a Cu6Sn5 phase and a Cu3Sn phase; and the copperpowders in the cured copper-based composite conductive paste are connected with the SnAgCu alloy powders through the Cu6Sn5 phase and the Cu3Sn phase. Compared with the prior art, the copper-based composite conductive paste adopts the SnAgCu alloy powders and micrometer copper powders to improve the conductivity of a copper film, has a large tap density and a relatively low curing temperature, andis convenient for practical use; the low-cost copper powders are used to replace silver paste prepared by more expensive silver powders in some respects, so that the cost is greatly reduced; and meanwhile, the copper-based composite conductive paste does not cause pollution to the environment, accords with the environmental protection concept, and has a broad application prospect.

Owner:SOUTHEAST UNIV

Ultralow-temperature epoxy cured polyester resin and preparation method thereof

ActiveCN111423565ALow viscosityGood for melt flow solidificationChemical industryPolyester coatingsEpoxyEndcapping

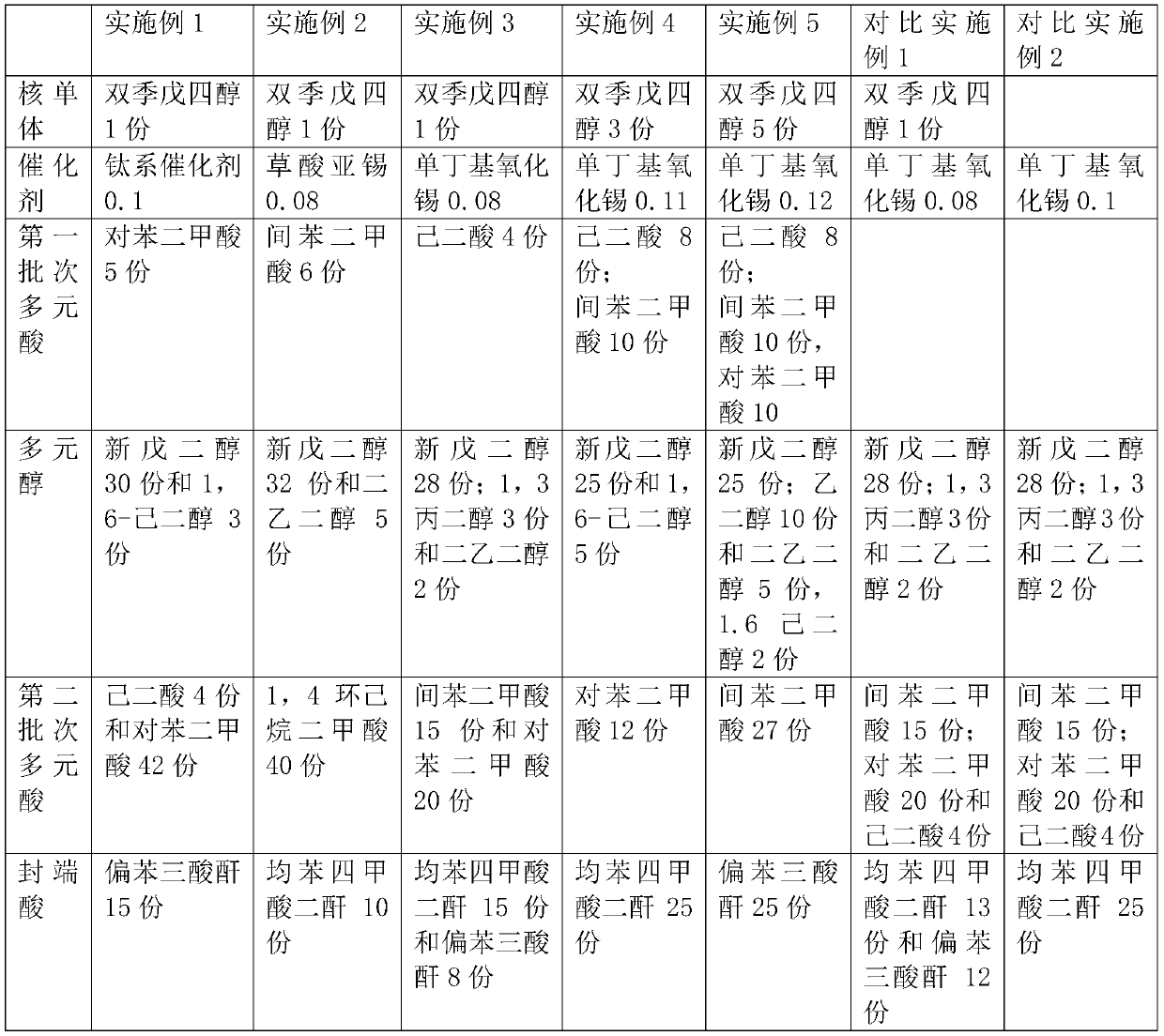

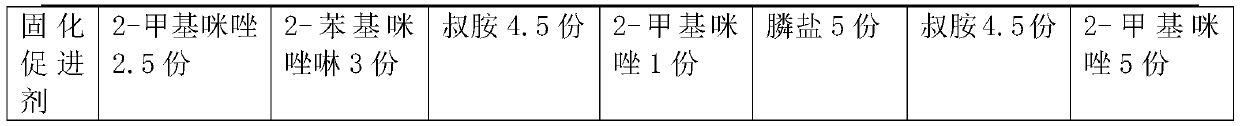

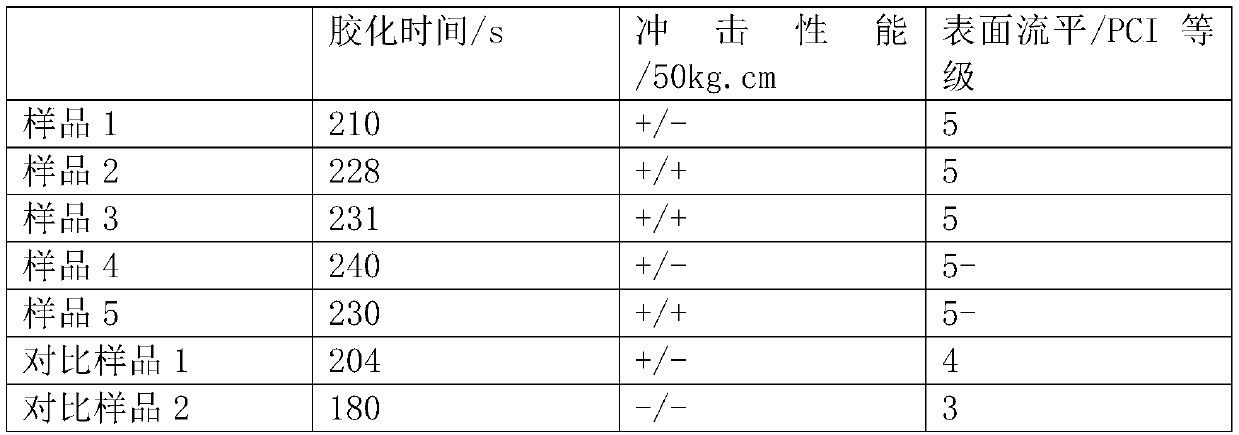

The invention discloses ultralow-temperature epoxy cured polyester resin and a preparation method thereof. The formula comprises the components in parts by mass: 1-5 parts of core monomer dipentaerythritol, 0.08-0.12 part of a catalyst, 30-55 parts of polybasic acid, 30-42 parts of polyhydric alcohol, 10-25 parts of end-capping acid, 0.01-0.12 part of an antioxidant and 1-5 parts of a curing accelerator. The product obtained by adopting the formula provided by the invention has a hyperbranched structure and relatively low viscosity, is beneficial to melt flow curing, realizes low-temperature curing, and has excellent impact property and high leveling grade; according to the preparation method disclosed by the invention, alcohol with six functional groups is firstly introduced as a core monomer, a part of polyatomic acid is firstly added, and then the polyatomic alcohol and the rest of polyatomic acid are added, so that the product obtained by the method has a certain hyperbranched structure, and is good in impact resistance and high in leveling grade.

Owner:新中法高分子材料股份有限公司

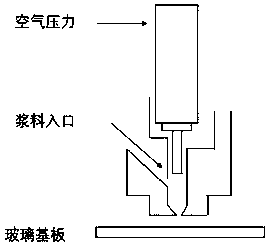

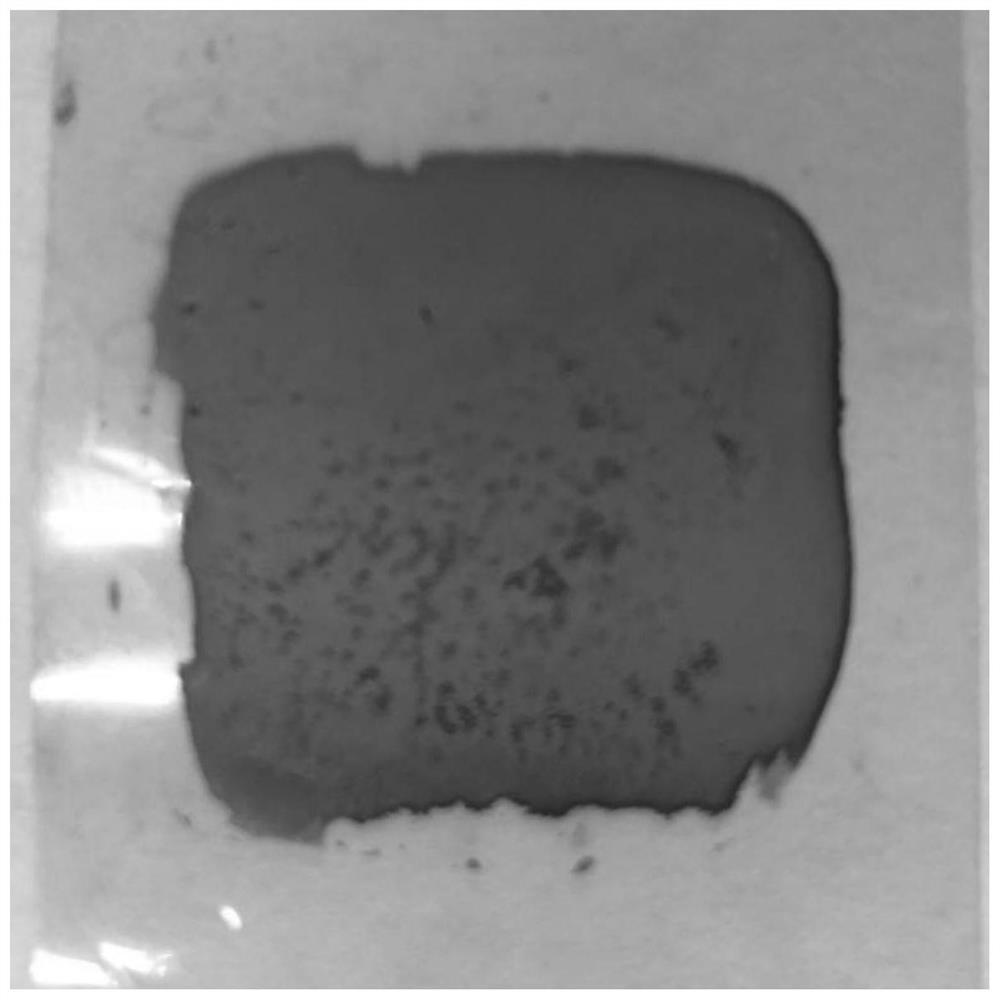

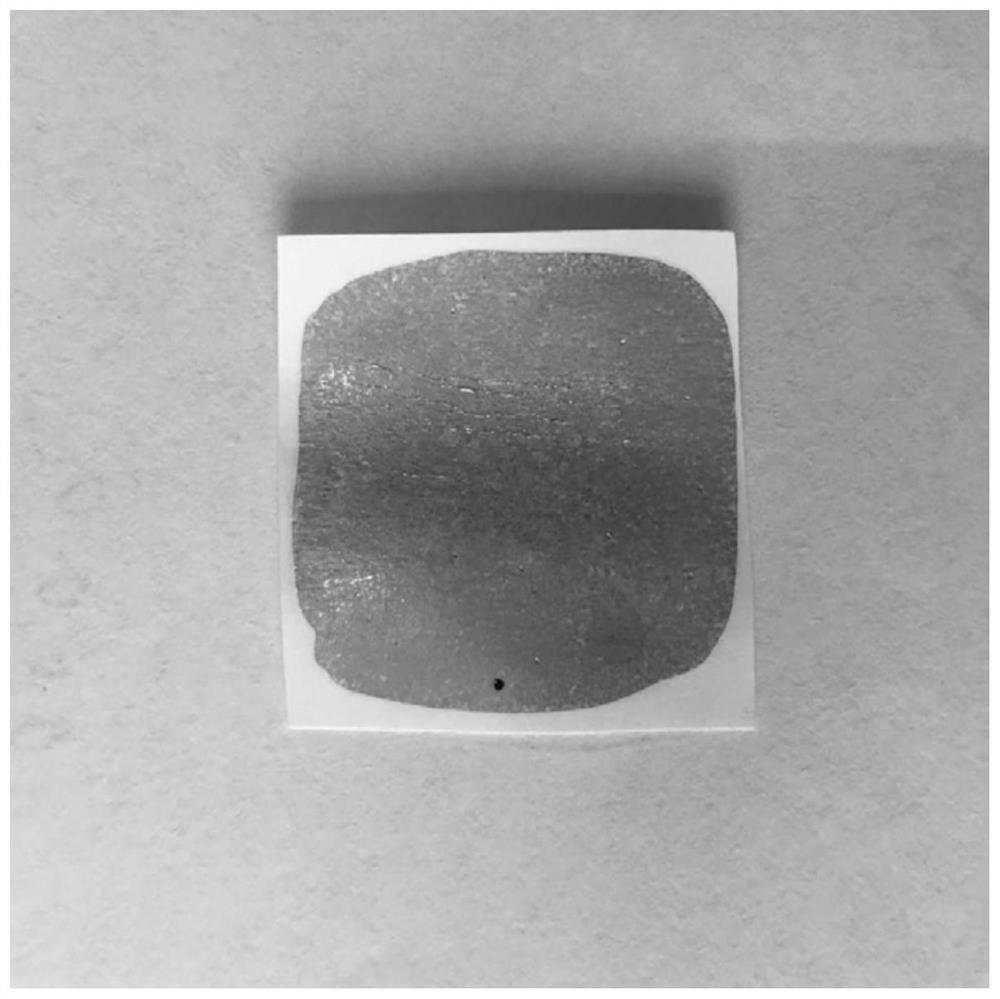

Preparation method for copper slag-based porous geopolymer spheres and application of copper slag-based porous geopolymer spheres

ActiveCN111978021AWide variety of sourcesLow costAluminium silicatesCement productionSorbentPolyethylene glycol

The invention discloses a preparation method for copper slag-based porous geopolymer spheres. According to the method, sodium hydroxide is dissolved in a sodium silicate solution, then copper slag powder is added and is stirred uniformly; a foaming agent aqueous solution is added into the mixture and is stirred uniformly to obtain geopolymer slurry; under the condition of heating in a water bath,the uniformly stirred slurry is dropwise added into polyethylene glycol with a syringe, and liquid drops are quickly solidified into small spheres at 40-70 DEG C and are dispersed and float in the polyethylene glycol to prepare geopolymer spheres; the geopolymer spheres are fished out, are washed with distilled water, are dried, and are cured and solidified at room temperature to obtain the copperslag-based porous geopolymer spheres. The sphere formation rate of the method of the invention is greater than 80%; the method realizes low-temperature solidification and waste recycling; the copperslag-based porous geopolymer spheres are applied to adsorption of heavy metal ions in wastewater, so that the adsorption rate is high; an adsorbent is easy to recycle; secondary pollution of a water body cannot be caused, and the preparation method is more friendly to the environment.

Owner:KUNMING UNIV OF SCI & TECH

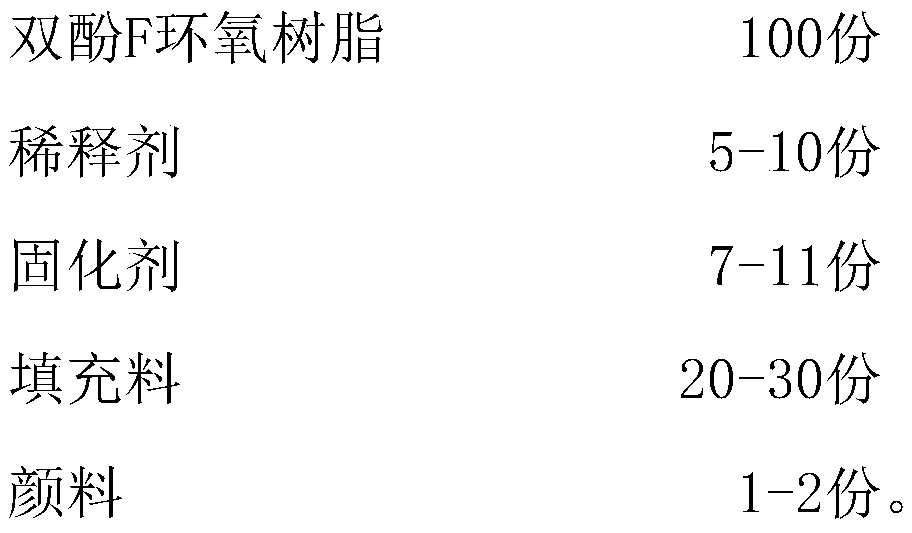

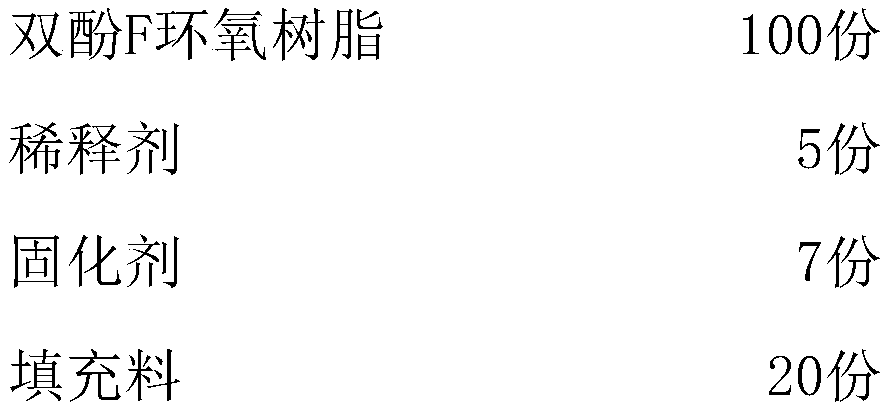

SMT surface mounting process

ActiveCN110602897AHigh bond strengthFast curingPrinted circuit assemblingNon-macromolecular adhesive additivesBonding strengthAdhesive

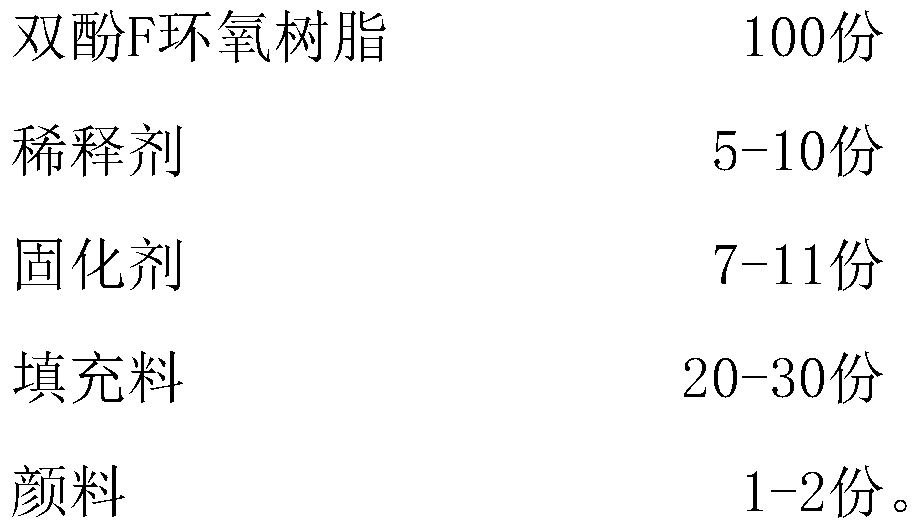

The invention relates to the technical field of surface mounting, in particular to an SMT surface mounting process. The SMT surface mounting process comprises the following steps of: (1) pretreatment:cleaning and drying a PCB; (2) dispensing: coating the preset dispensing position on the PCB with a patch adhesive by using a dispensing machine; (3) chip mounting: mounting the component on the PCBby using a chip mounter; (4) curing: feeding the PCB into curing equipment for curing; (5) reflow soldering: feeding the PCB into a reflow soldering furnace for reflow soldering; and (6) checking: checking the yield of the finished product, wherein the patch adhesive comprises the following raw materials in parts by weight: bisphenol F epoxy resin, a diluent, a curing agent, a filler and a pigment. The chip mounting adhesive adopted in the SMT chip mounting process has the characteristics of the high bonding strength and the high curing speed, low-temperature curing can be achieved at a temperature of 110-130 DEG C, the curing time is only 1-2 minutes, the packaging speed is high, and the production efficiency can be effectively improved.

Owner:东莞市合权电子有限公司

Preparation method and application of porous geopolymer microspheres

ActiveCN107973559BHigh Microsphere EfficiencyParticle size adjustableOther chemical processesRadioactive contaminantsMicrosphereSorbent

The invention discloses a preparation method of porous geological polymer microspheres. The porous geological polymer microspheres are prepared by a dispersion suspension solidification method. Compared with the prior art, low-temperature curing and one-shot molding granulation are realized without requirements of high-temperature calcination and curing and addition of other auxiliaries; and at the same time, large-scale use of solid wastes is realized, and raw materials are widely available, cost is low, process is simple, and the whole process is non-toxic and pollution-free; in addition, the preparation efficiency is high with a ball-forming degree exceeding 90%; the size of the particles can be adjusted, and the pore size distribution is uniform; the pore volume is large, and can be regulated, and a specific surface area of the microspheres reaches 110m2 / g, thus, the porous geological polymer microspheres can be directly used for packed columns for column separation. Experiments show that the porous geological polymer microspheres have a good adsorption effect on heavy metals, and can be used as adsorbents for heavy metals, and have a broad application prospect in the aspect ofremoving heavy metals and radioactive elements in water.

Owner:GUANGXI UNIV

A kind of low-temperature curing type epoxy acrylic transparent powder coating and preparation method thereof

ActiveCN105273558BLower the initial reaction temperatureAchieving Low Temperature CuringPowdery paintsEpoxyAcrylic resin

The invention discloses a low-temperature curing type epoxy group acrylic acid transparent powder coating. The low-temperature curing type epoxy group acrylic acid transparent powder coating is mainly prepared from high-epoxide-equivalent acrylic resin, low-epoxide-equivalent acrylic resin, dodecanedioic acid, an ultraviolet light absorber, a light stabilizer, a flatting agent and other auxiliaries. The high-epoxide-equivalent acrylic resin is modified by ultrafine titanium dioxide, and the low-epoxide-equivalent acrylic resin is in a GMA type. By the adoption of the high-epoxide-equivalent acrylic resin, the low-epoxide-equivalent acrylic resin and the dodecanedioic acid, the initial reaction temperature of the powder coating is decreased, and low-temperature curing is achieved; due to the auxiliary curing of the low-epoxide-equivalent acrylic resin, the enough compactness of the powder coating is improved, and then the corrosion resistance of the coating is improved; by the adoption of the high-epoxide-equivalent acrylic resin modified by the ultrafine titanium dioxide, the best ultraviolet absorption effect is obtained, and the weather resistance of the coating is improved.

Owner:GUANGZHOU KINTE IND

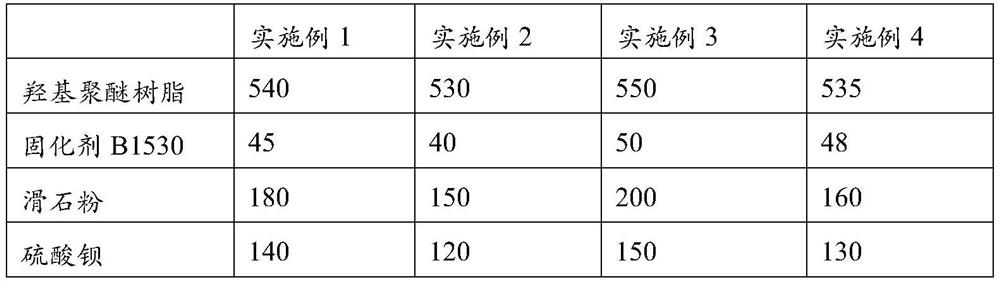

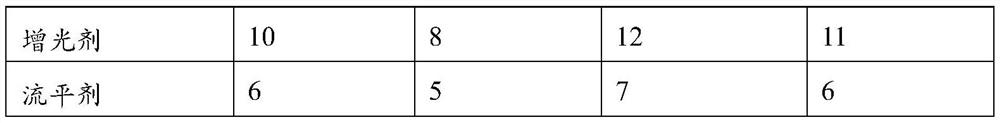

Anti-thick coating pinhole, excellent acid and alkali resistance powder coating and preparation method thereof

ActiveCN112011260BGood acid and alkali resistanceOvercome the shortcomings of poor acid and alkali resistanceAnti-corrosive paintsPolyether coatingsPolymer scienceLow temperature curing

The invention belongs to the technical field of powder coatings, and in particular relates to a powder coating with excellent pinhole resistance and acid and alkali resistance and a preparation method thereof. The parts by weight of the main raw materials of the powder coating of the present invention are: 530-550 parts of hydroxyl polyether resin, 40-50 parts of B1530 curing agent, 150-200 parts of talcum powder, 120-150 parts of barium sulfate, 8-12 parts of brightening agent Parts, 7-10 parts of leveling agent; Hydroxy polyether resin is prepared by polycondensation of materials with the following molar fractions: the molar fractions of each component are: 1,4-cyclohexanedimethanol 4-8 , 1,6-hexanediol 3-6, resorcinol diglycidyl ether 5-10, propylene oxide 30-45, triglycidyl isocyanurate 4-8, octyl glycidyl ether 6-13 . The present invention uses high-functionality hydroxyl polyether resin as the raw material, the hydroxyl value is 15-20mgKOH / g, the amount of B1530 curing agent required for curing is small, the cost of powder coating is low, and it can be cured at 175°C / 15min at low temperature, and The prepared coating film has good resistance to pinholes in thick coating, and the high-functionality polyether has excellent acid and alkali resistance, and can be used for coating metal facilities in industrial cleaning places.

Owner:安徽鑫友高分子新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com