High solid content polyimide coating glue and preparation method and use thereof

A technology of polyimide coating and high solid content, applied in the direction of adhesives, etc., can solve the problems of low transparency of PI coating, limited application, increase of coating viscosity, etc., achieve low dielectric constant, solve The effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

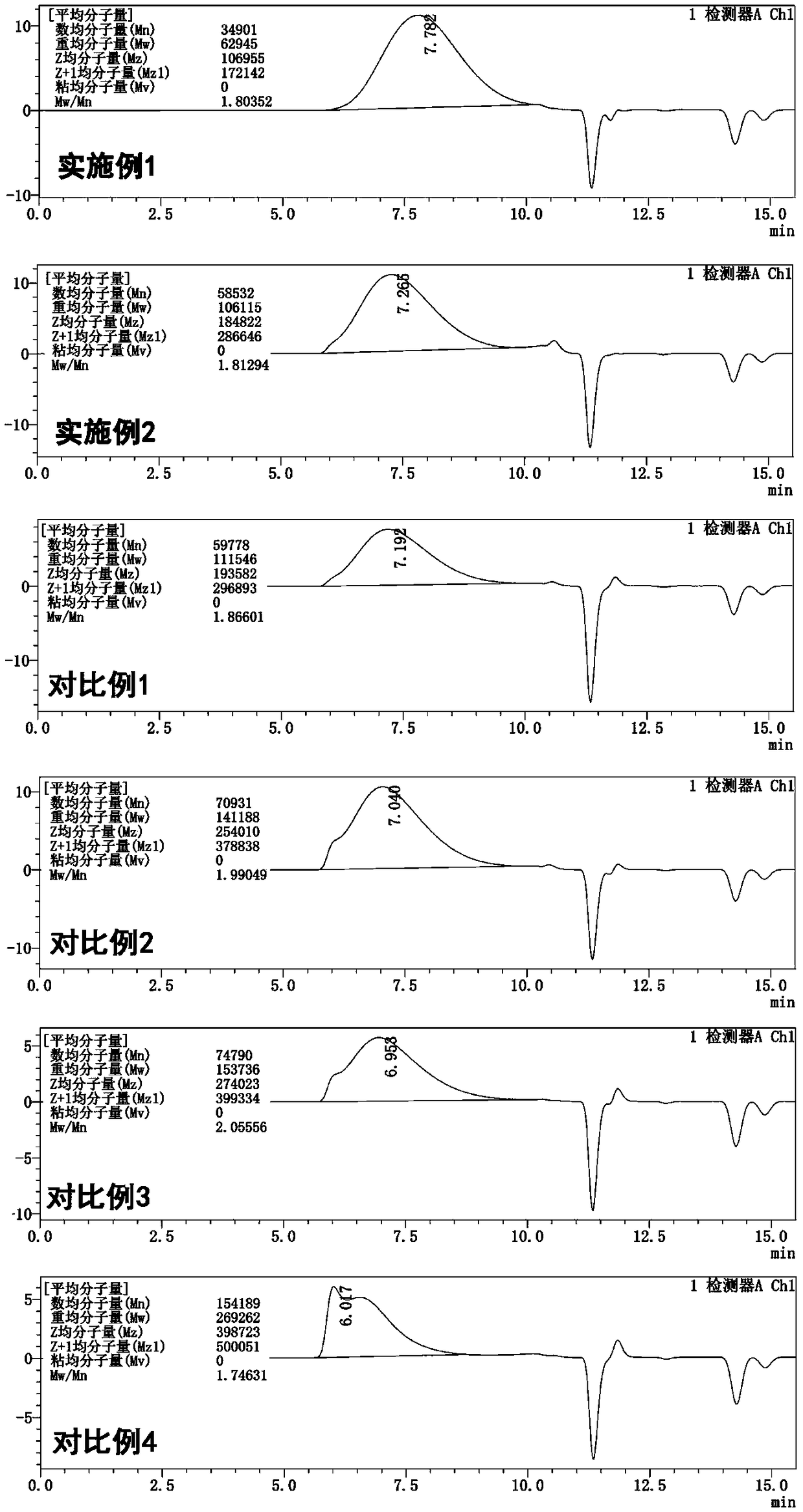

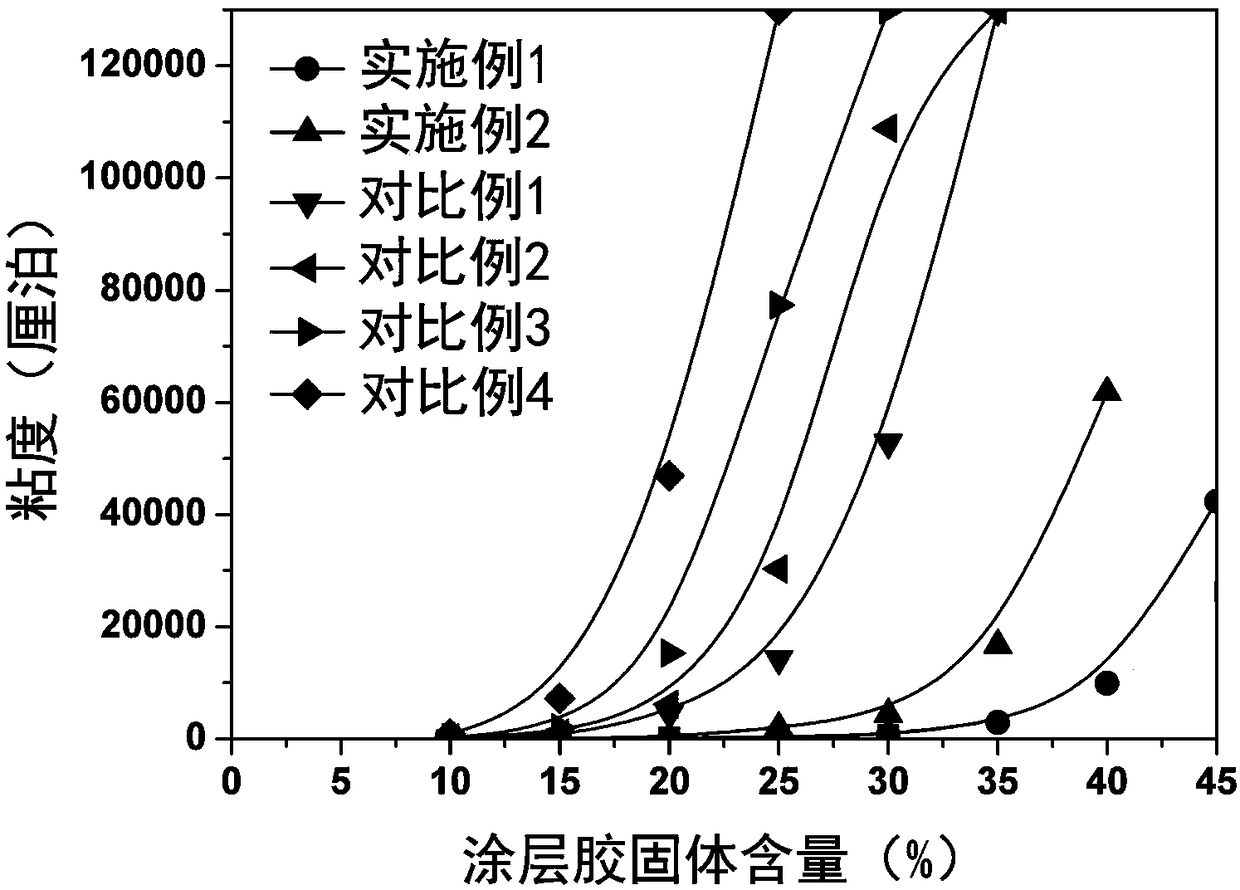

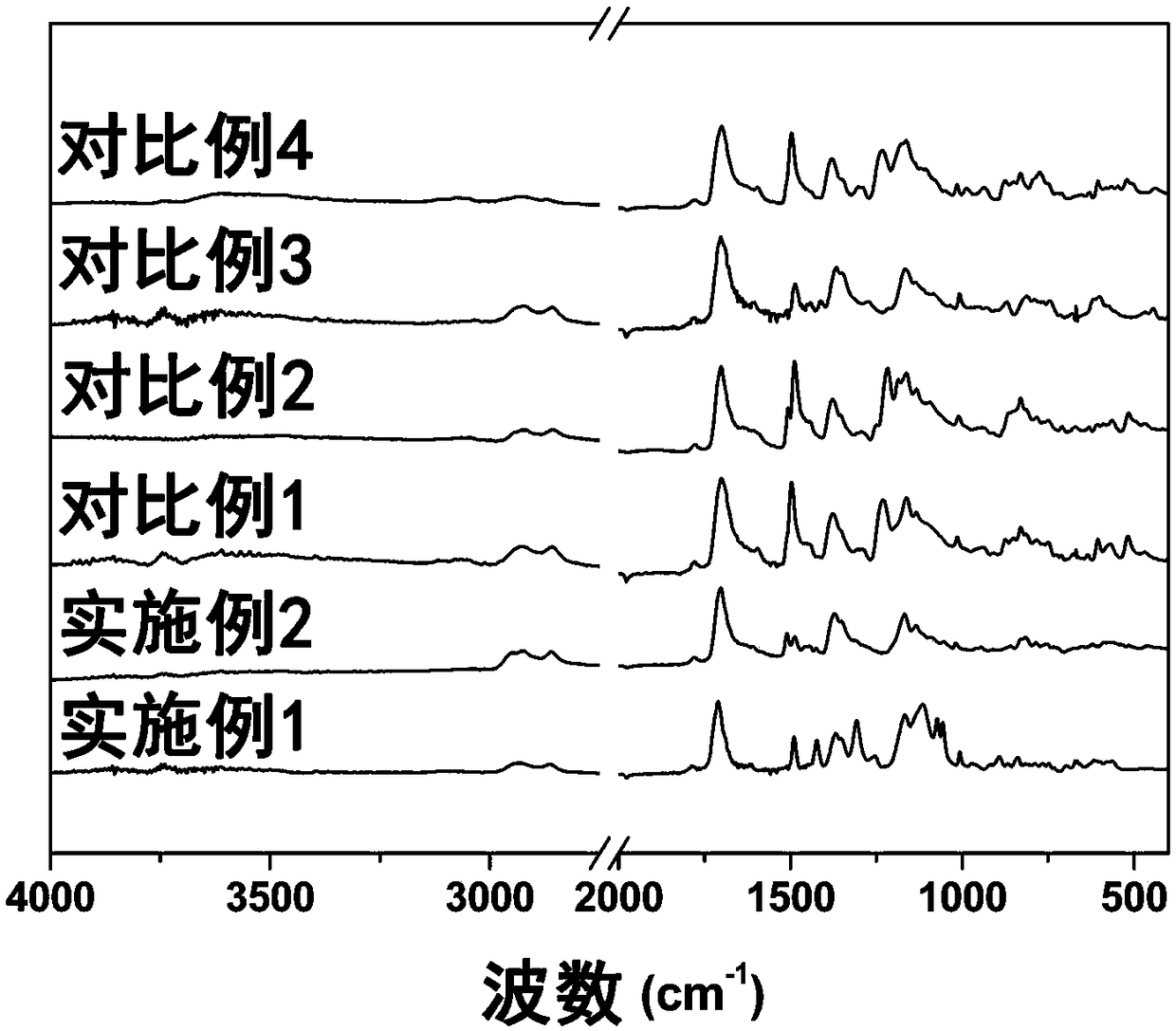

[0065] Embodiment 1 prepares soluble PI coating glue by HBPDA and TFMB

[0066] Add 32.023g (100mmol) TFMB and 150g m-cresol in a 1000mL three-necked flask equipped with a nitrogen inlet, water separator and thermometer, and stir until dissolved to form a homogeneous solution; add 30.631g (100mmol) HBPDA and 38g m-cresol solvent, after adding the material, stirred and reacted at 15°C for 20h to obtain a viscous polyamic acid (PAA) solution with a solid content of 25wt%. Add 3 g of isoquinoline and 350 g of toluene to the polyamic acid solution, heat and dehydrate for 3 hours, and then distill off the toluene. Adjust the reaction temperature to 180°C and react for 5h. Cool down, spin and pulverize to obtain polyimide (PI) resin powder. The structure of this PI resin is as follows:

[0067]

[0068] The molecular formula of the compound is shown in formula I, the number average molecular weight is 34901 g / mol, and the weight average molecular weight is 62945 g / mol; n=59. ...

Embodiment 2

[0076] Embodiment 2 prepares soluble PI coating glue by HBPDA and PIDA

[0077] Add 26.638g (100mmol) PIDA and 150g m-cresol in a 1000mL three-neck flask equipped with nitrogen inlet, water separator and thermometer, stir until dissolved to form a homogeneous solution; add 30.631g (100mmol) HBPDA and 22g m-cresol solvent, after adding the material, stirred and reacted at 15°C for 20h to obtain a viscous polyamic acid (PAA) solution with a solid content of 25wt%. Add 3 g of isoquinoline and 350 g of toluene to the polyamic acid solution, heat and dehydrate for 3 hours, and then distill off the toluene. Adjust the reaction temperature to 180°C and react for 5h. Cool down, spin and pulverize to obtain polyimide (PI) resin powder. The structure of this PI resin is as follows:

[0078]

[0079] The molecular formula of the compound is shown as formula II, the number average molecular weight is 58532 g / mol, and the weight average molecular weight is 106115 g / mol; n=109.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com