Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Titanium(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium(III) oxide (Ti₂O₃) is a chemical compound of titanium and oxygen. It is prepared by reacting titanium dioxide with titanium metal at 1600 °C. Ti₂O₃ has the Al₂O₃, corundum structure. It is reactive with oxidising acids. At around 200 °C there is a transition from semiconducting to metallic conducting. Natural titanium(III) oxide is known as the extremely rare mineral tistarite.

Promoter for generation of gas hydrate, and preparation method and application thereof

InactiveCN102784604APromote generationAchieve a high degree of dispersionPressurized chemical processGaseous fuelsGeneration rateSesquioxide

The invention discloses a promoter for generation of gas hydrates, and a preparation method and application thereof. The promoter for generation of gas hydrates is a dry powdery solution formed after high speed shearing and dispersion of a surfactant solution and strong hydrophobic solid particles in a high intensity stirrer, wherein the surfactant solution is an aqueous solution of one or more anionic surfactants, cationic surfactants or nonionic surfactants, and the strong hydrophobic solid particles are one or more selected from the hydrophobically modified particles consisting of silica, titanium dioxide, titanium sesquioxide, alumina, zinc oxide, calcium carbonate, montmorillonite, diatomite, fly ash, zeolite, talcum and mica particles, etc. The promoter provided by the invention is highly dispersed solution microdroplets and has a great gas-liquid contact area, the dispersed microdroplets contain surfactants, which enables gas-liquid contact during growth process of hydrates to be further reinforced, and therefore, a generation rate of gas hydrates and gas storage amount in a static system are substantially improved; meanwhile, the promoter has the advantages of low cost, no pollution and convenient preparation and usage.

Owner:SOUTH CHINA UNIV OF TECH

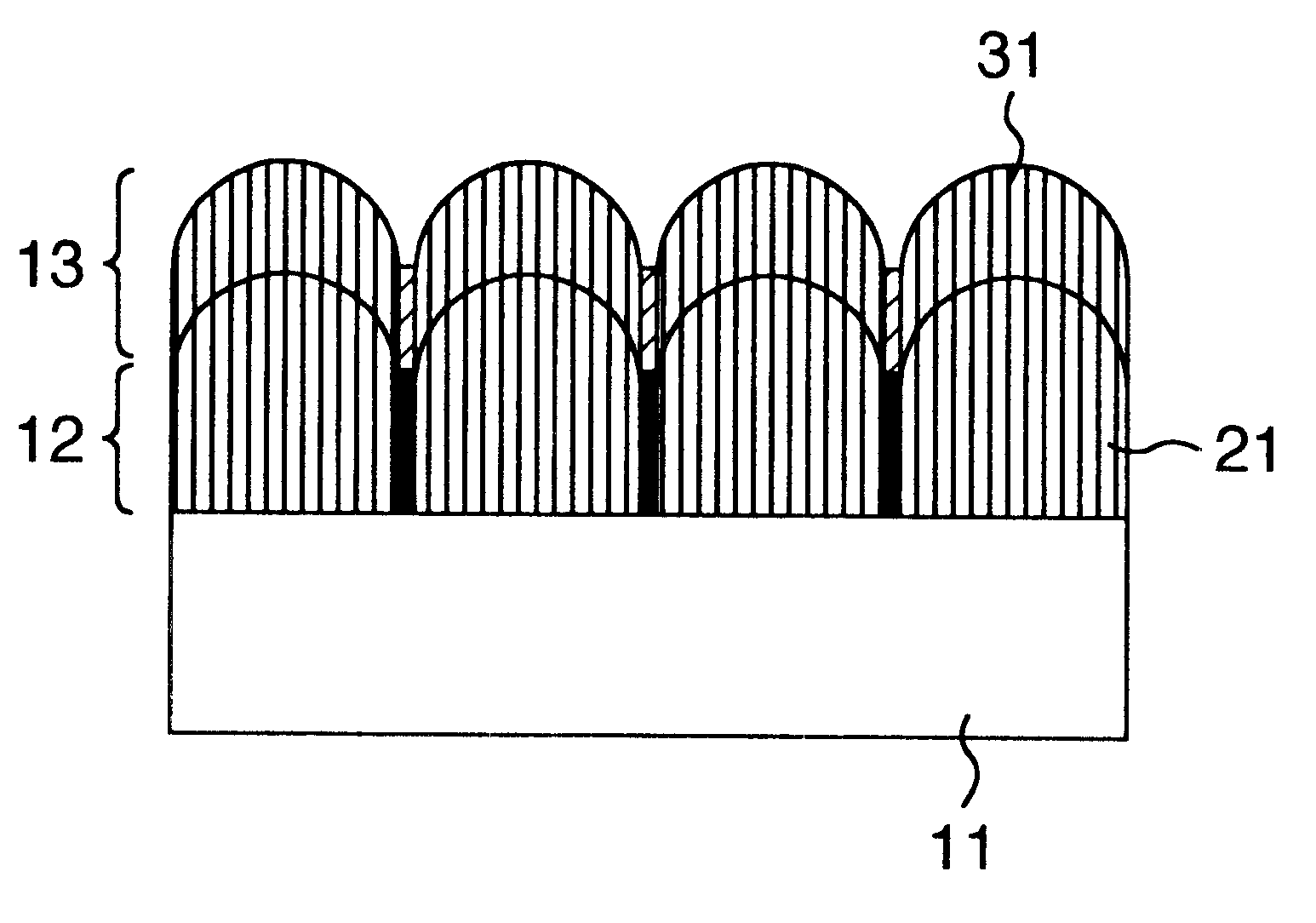

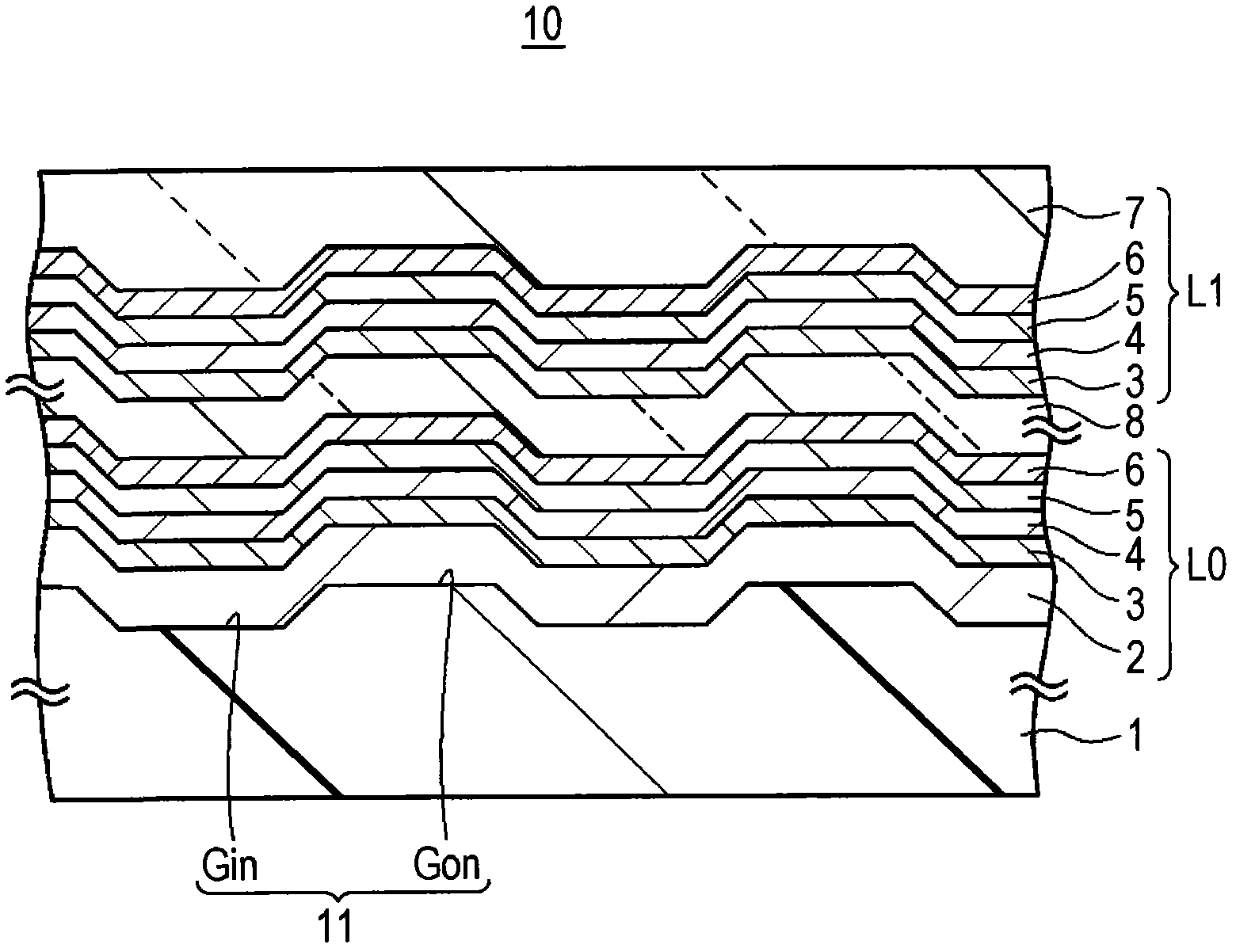

Magnetic recording disk

InactiveUS6472047B1Reduced magnetic interactionReduce demagnetizationBase layers for recording layersVacuum evaporation coatingSilicon oxideTitanium oxide

The magnetic recording medium includes an underlayer 12 formed of an inorganic compound layer, and a magnetic layer 13 formed over the underlayer 12. The inorganic compound layer as the underlayer 12 has crystal grains and at least one kind of oxide, the crystal grains having as main elements at least one of cobalt oxide, chromium oxide, iron oxide and nickel oxide, the at least one kind of oxide lying as a non-crystalline phase in grain boundaries between the crystal grains and selected from among silicon oxide, aluminum oxide, titanium oxide, tantalum oxide and zinc oxide.

Owner:HITACHT MAXELL LTD +1

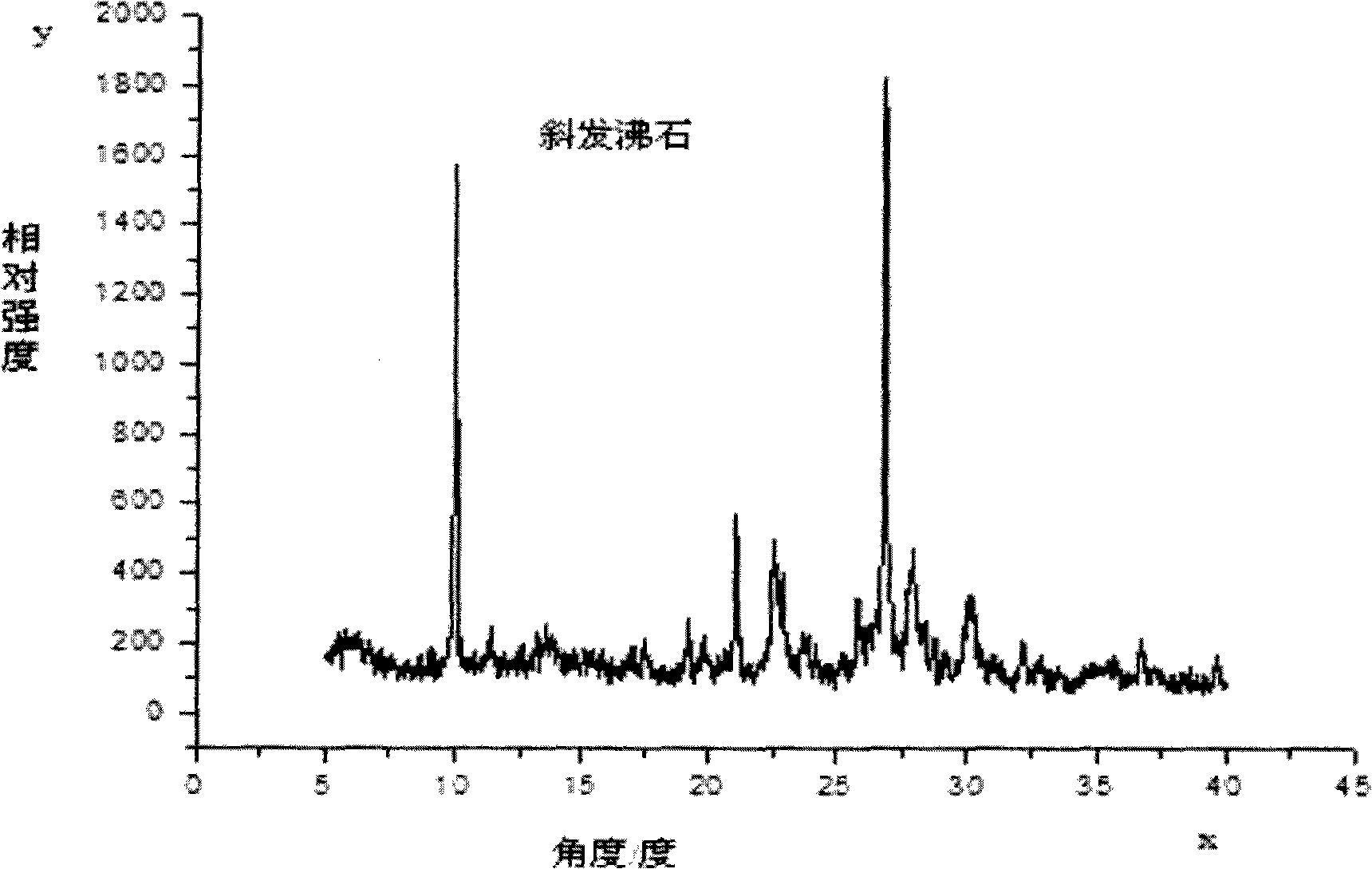

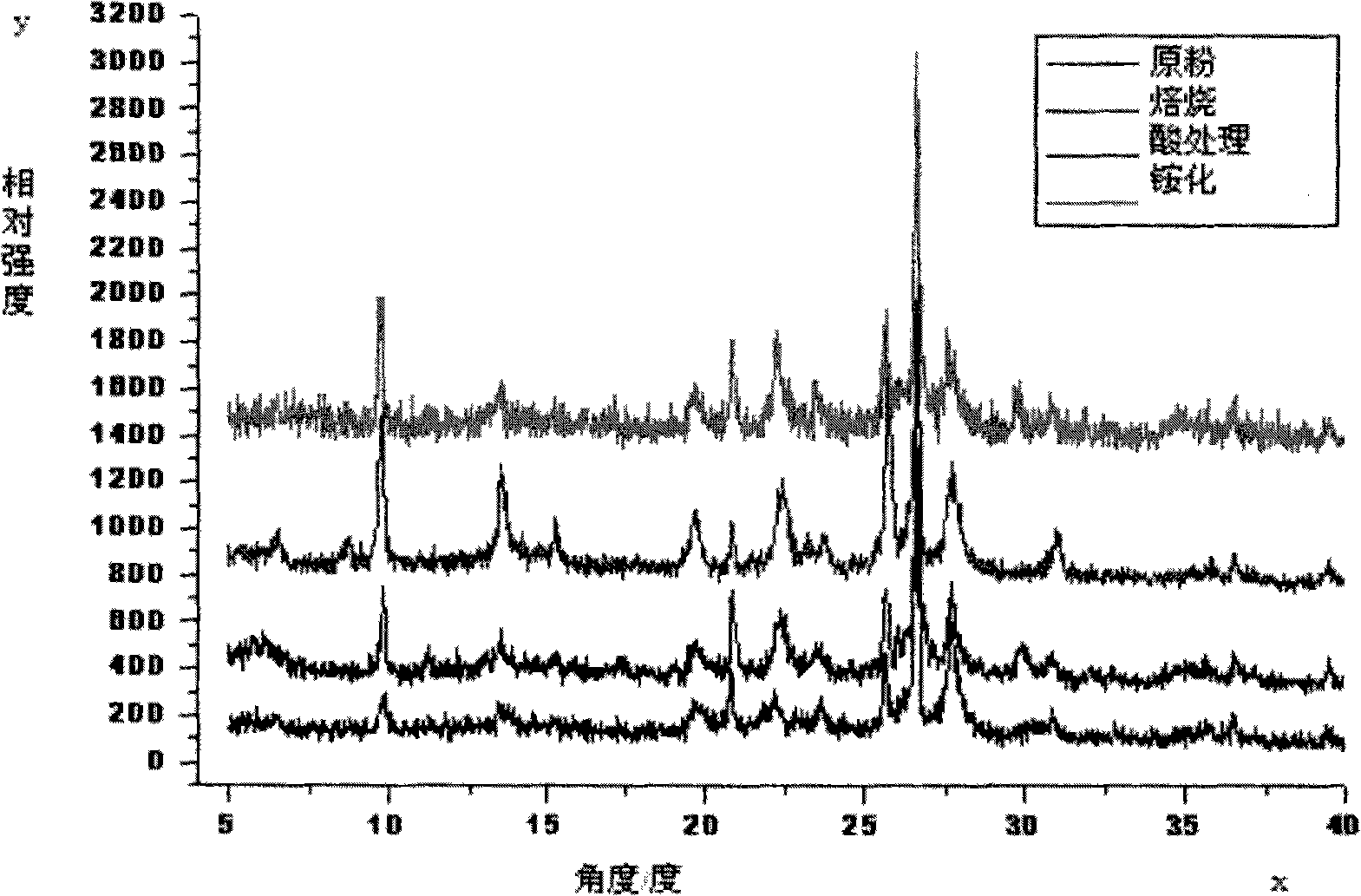

Natural zeolite emergence haemostatic and preparation method thereof

InactiveCN101357138AEasy to operateAbundant raw materialsInorganic active ingredientsBlood disorderSilicon oxideTitanium oxide

The invention relates to an external natural zeolite emergency survival haemostatic which adopts a natural zeolite haemostatic or a modified natural zeolite haemostatic directly; the raw materials of the natural zeolite comprises the following components: silicon oxide, aluminum oxide, titanium oxide, ferric oxide, magnesium oxide, calcium oxide, sodium oxide and potassium oxide; wherein, the total content of the silicon oxide and the aluminum oxide is more than 70 percent; the aperture of the natural zeolite is 0.3 to 0.2nm, the specific surface area is 30 to 1,000m<2> / g and the pore volume is 0.2 to 1.0cm<3> / g, and the diameter of particles of the natural zeolite haemostatic is 1mum to 1mm. The preparation method is simple and the hemostatic effect is good, thus being used for hemostasis in different medical situations.

Owner:ZHEJIANG UNIV

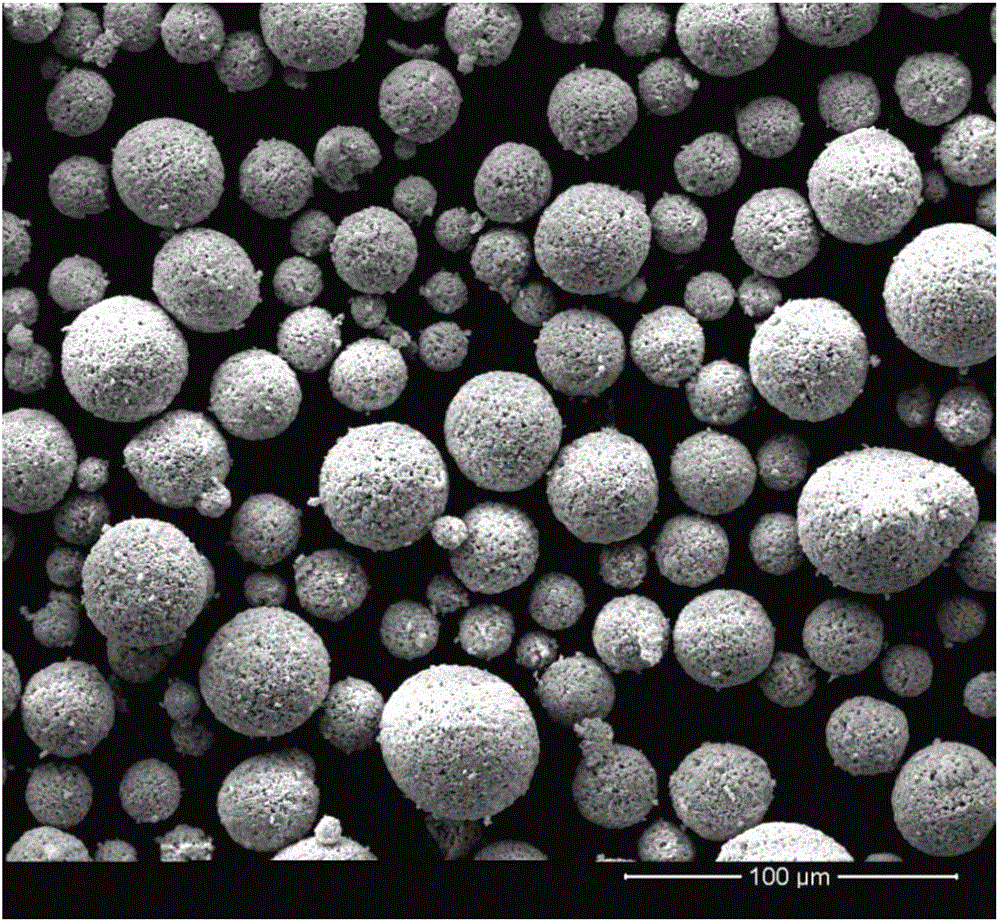

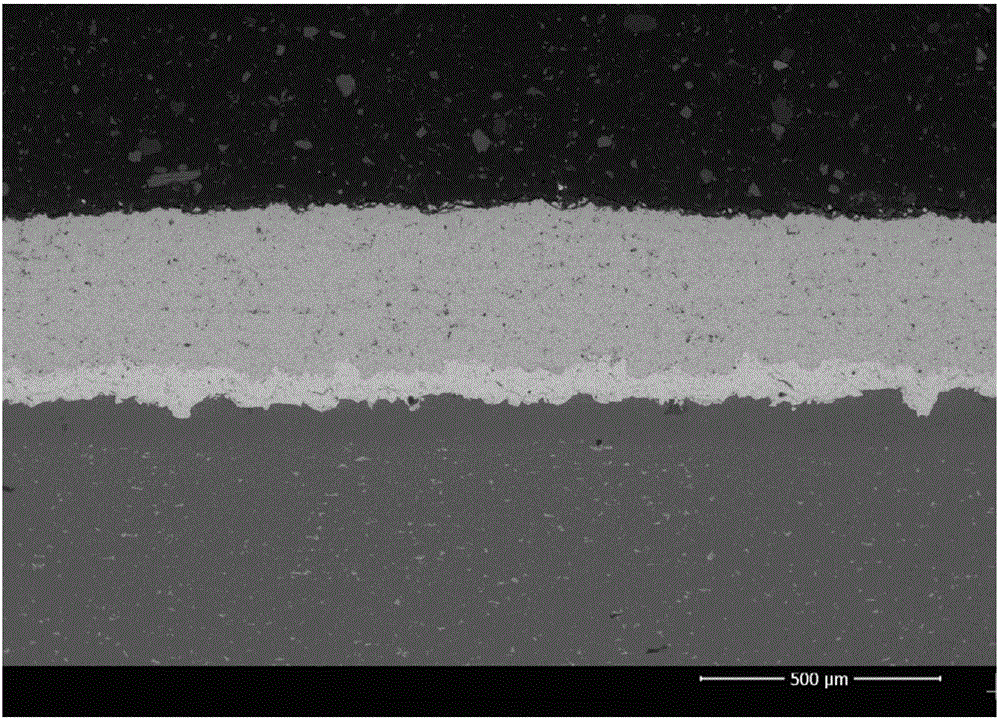

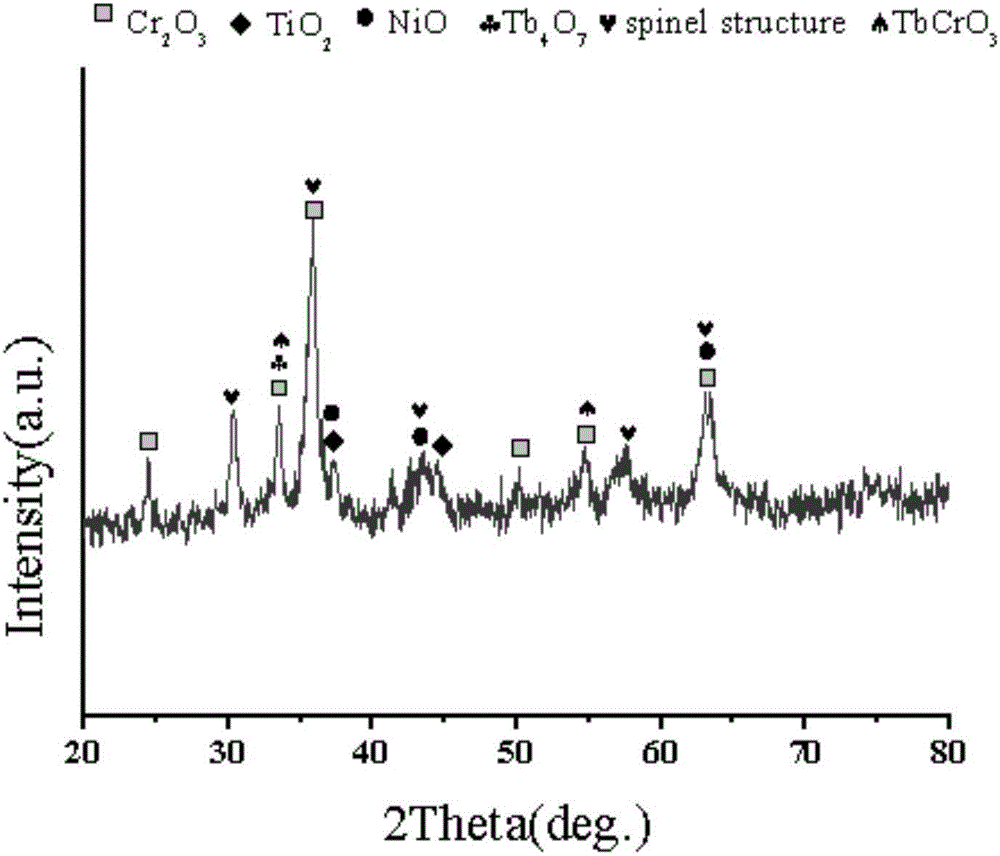

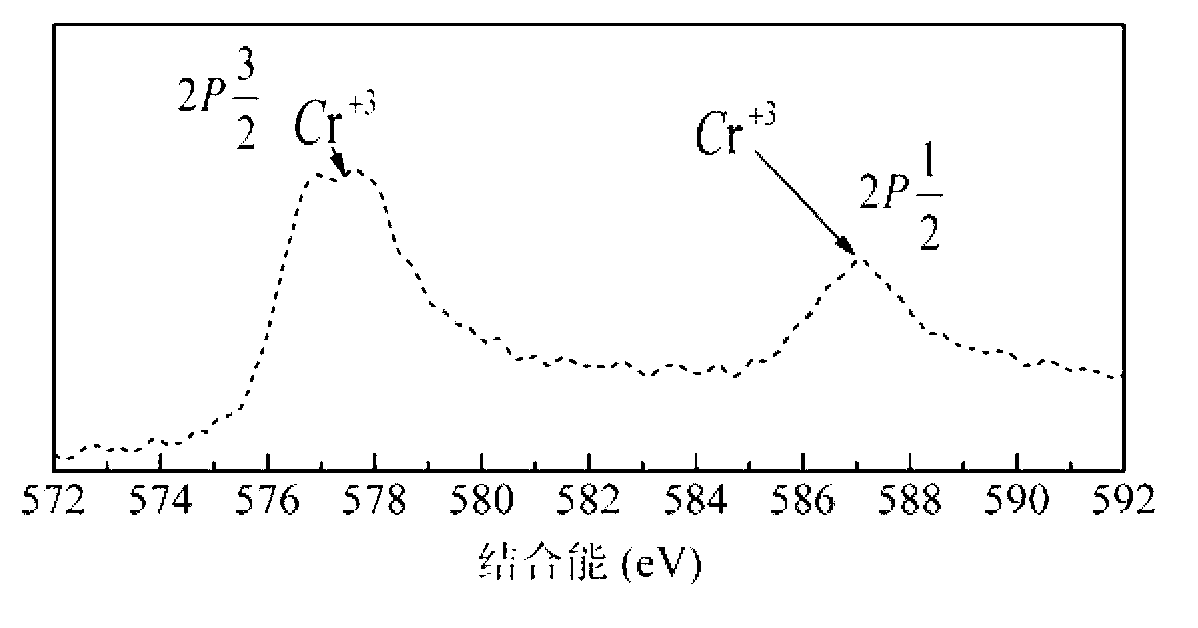

Chromic oxide-titanium oxide based high-temperature and high-emissivity coating and preparation method thereof

InactiveCN105861972AGood sphericityMeet the requirements of plasma sprayingMolten spray coatingThermal sprayingStructural phase

The invention discloses a preparation method of a chromic oxide-titanium oxide based high-temperature and high-emissivity coating and belongs to the technical field of thermal spraying. According to the preparation method, compound powder which is subjected to doping modification with rare earth oxide and contains multiple uniformly distributed oxides is prepared through agglomerating granulation; the compound powder is put in a muffle furnace and subjected to high-temperature sintering densification, dense organic-solvent-free powder with a spinel structural phase is obtained, and the advantageous feature of oxygen cavity defect filling of the rare earth oxide is played. The chromic oxide-titanium oxide based high-temperature and high-emissivity coating is prepared through plasma spraying, the generation of the spinel structural phase in the powder is promoted, and the stability of the coating keeping higher emissivity at the high temperature is improved. The compound powder has better degree of sphericity, the flowing property is 30-60 s / 50 g, and the apparent density is 1.0-3.0 g / cm<3>; the bonding strength of the prepared chromic oxide-titanium oxide based high-temperature and high-emissivity coating is higher than or equal to 20 MPa, and the emissivity at the temperature of 400-600 DEG C is higher than or equal to 0.88.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Method for producing inorganic film central layer

InactiveCN101371972ASmall apertureThe pore size is as small as 50-2nmSemi-permeable membranesMetallic materialsComposite oxide

The present invention discloses a method for preparing for inorganic membrane interface layer and belongs to the technical field of chemical engineering. The present invention is characterized by developing a heat coating method, carrying out two separated traditional processes of coating and drying instantly and synchronously and overcoming the disadvantages that the traditional coating method for manufacturing membrane is chapped easily, has disadvantage and has thick membrane layer; the present invention prepares the inorganic membrane interface layer that the aperture can be adjusted within the range between 50 and 2nm and mainly relates to the preparation of sol gel, a new method for coating the sol gel and the adjustment and control of the aperture of the interface layer. The method has very strong popularity and is used for preparing the adaptive interface layer which synthesizes chemical atmosphere such as alkalescence or acidity towards a separation layer by selecting suitable ceramic material, and the method can meet the requirement of the preparation of the separation layer by adjusting and controlling the aperture. The present invention can be used for preparing the interface layer of the materials such as disilicon trioxide, dizirconium trioxide, dititanium trioxide, the composite oxide thereof, and the like, by dense or porous ceramic, quartz, glass, silicon chip or metal material substrate.

Owner:DALIAN UNIV OF TECH

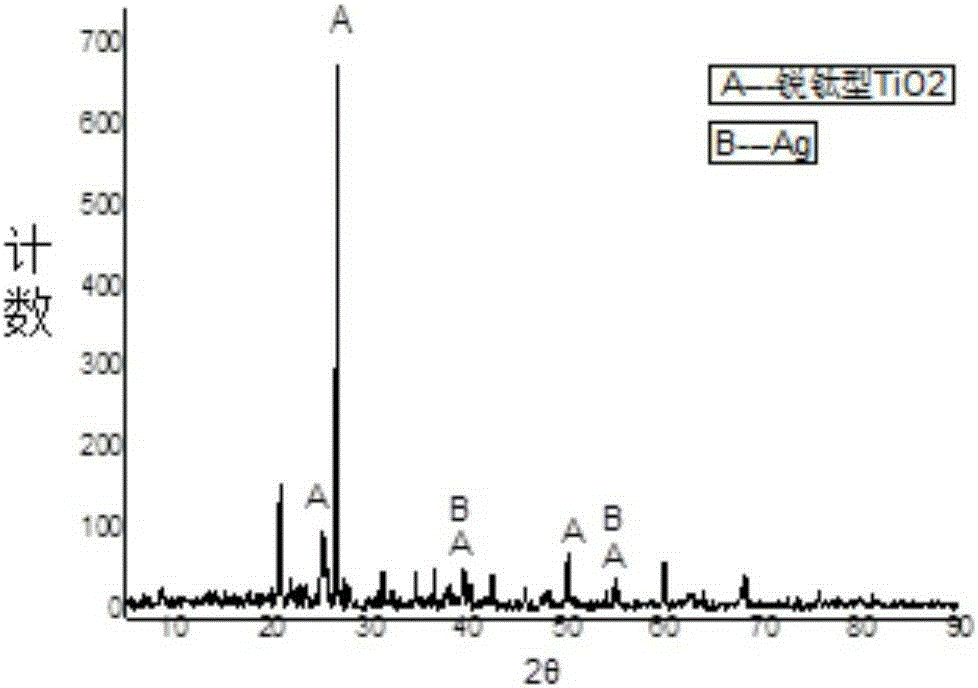

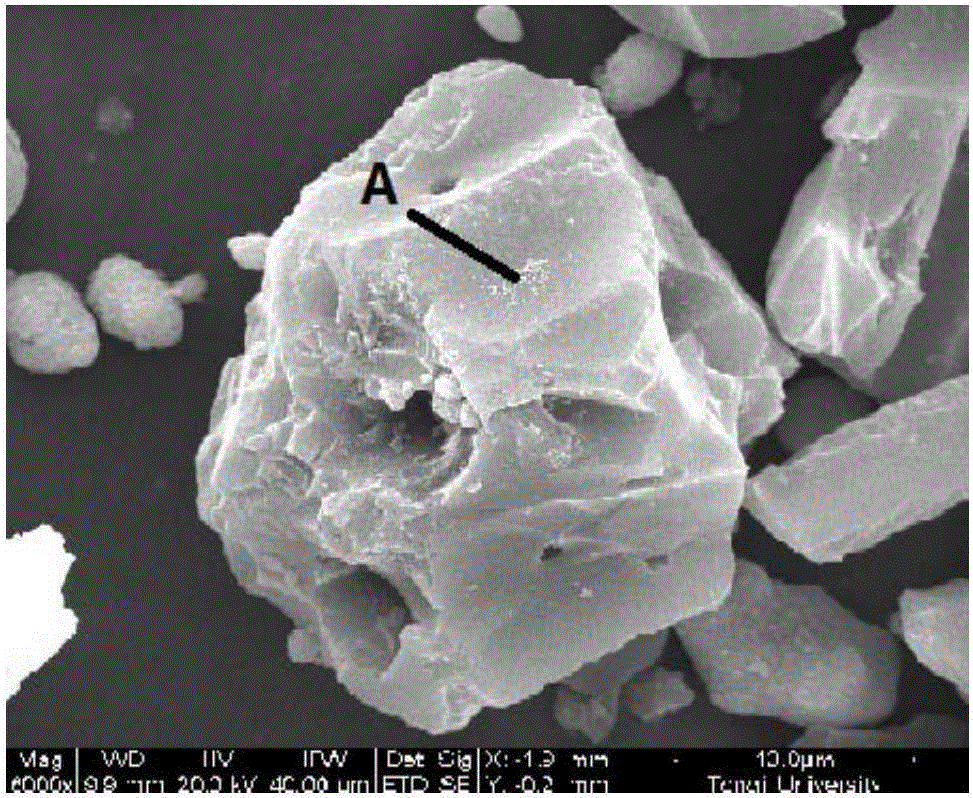

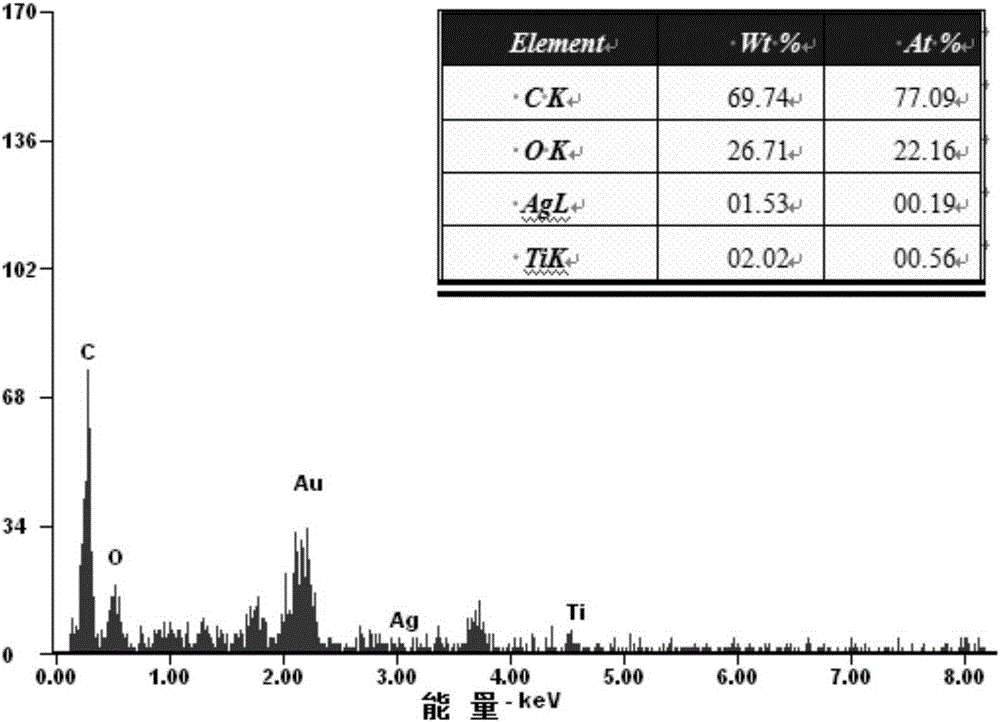

Ag-embedding titanium oxide-bamboo charcoal composite powder and preparation method thereof

InactiveCN105211098APlay the effect of red shift modificationImprove the bactericidal effectBiocideFungicidesOxygenTitanium oxide

The invention relates to an Ag-embedding titanium oxide-bamboo charcoal composite powder and a preparation method thereof. The composite powder comprises Ag-embedding titanium oxide and porous bamboo charcoal, wherein the weight ratio of the Ag-embedding titanium oxide to the bamboo charcoal is 1-5:100 and is preferred to 3-5:100. The preparation method of the composite powder includes the steps that Ag-embedding titanium oxide is dispersed in deionized water, after a mixed solution is heated to boiling, bamboo charcoal is added, boiling is kept, reaction lasts for 1-3 h under the condition of strong stirring, then reaction products are calcined for a period of time in an oxygen insulating manner, and therefore the Ag-embedding titanium oxide-bamboo charcoal composite powder can be obtained. Compared with the prior art, the technology is simple, preparation cost is low, and the prepared composite powder has excellent bactericidal performance under visual light.

Owner:TONGJI UNIV

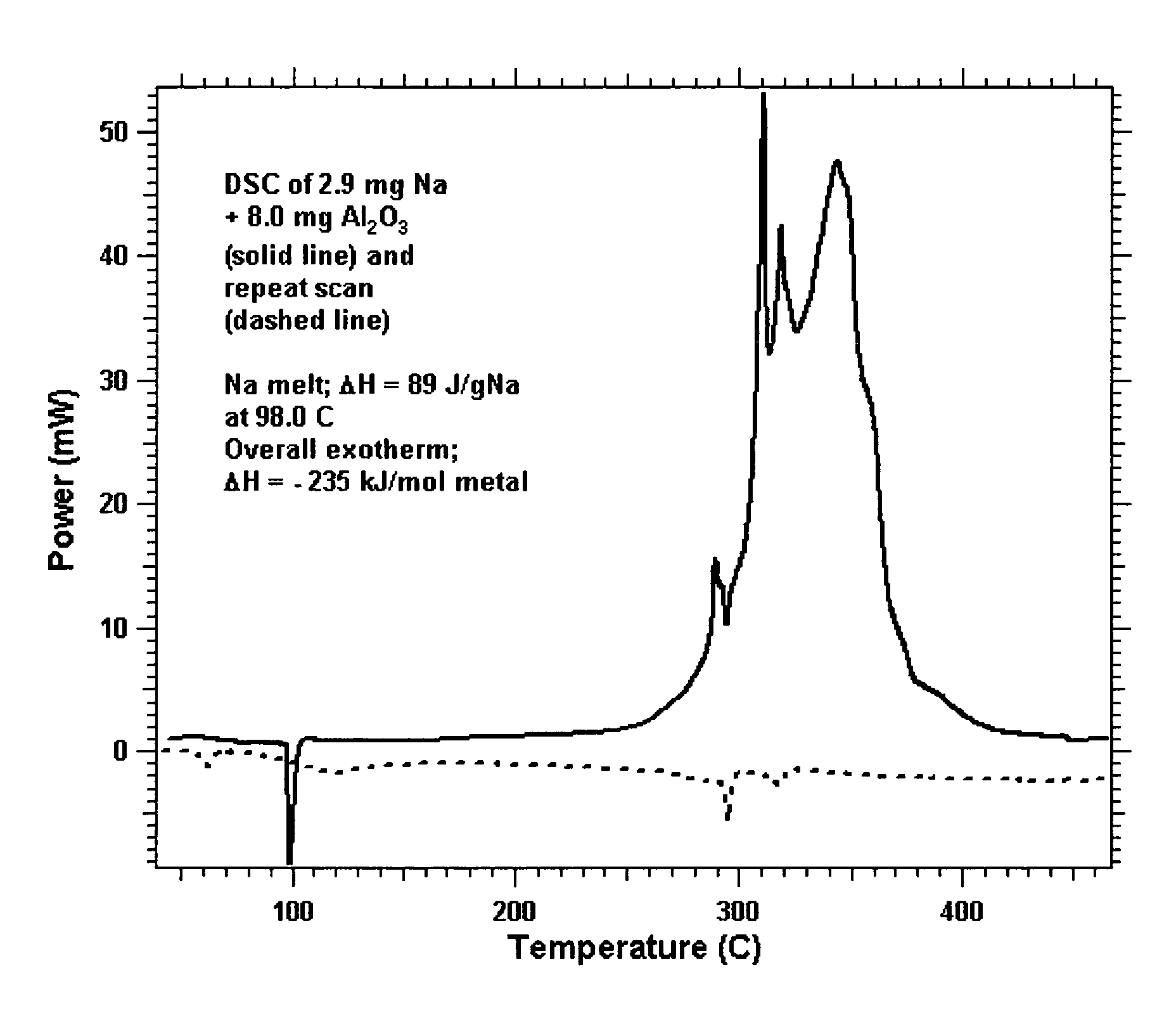

Titanium oxide and alumina alkali metal compositions

ActiveUS7259128B2Preparation by dehalogenationOther chemical processesChemical reactionSodium-potassium alloy

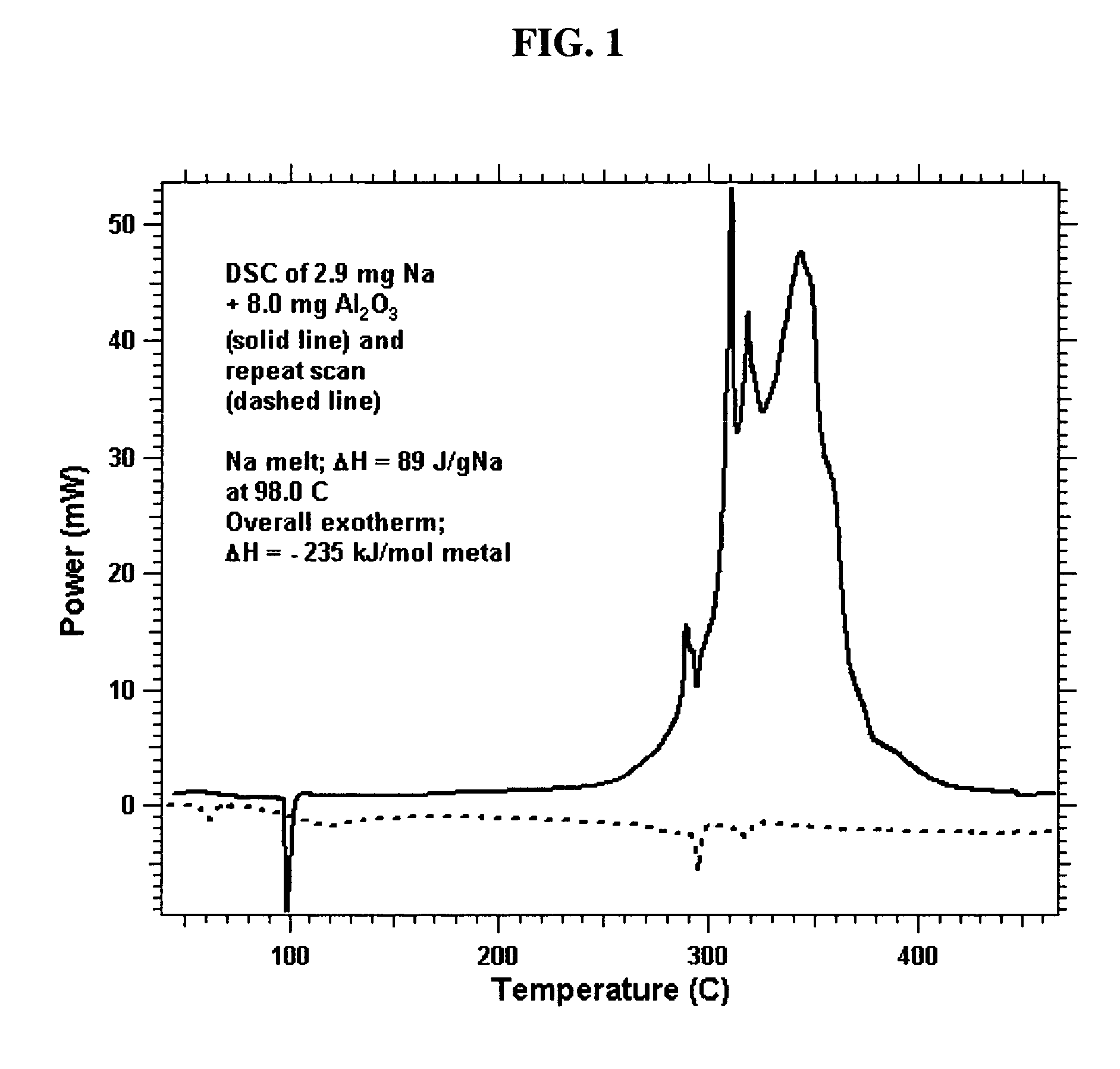

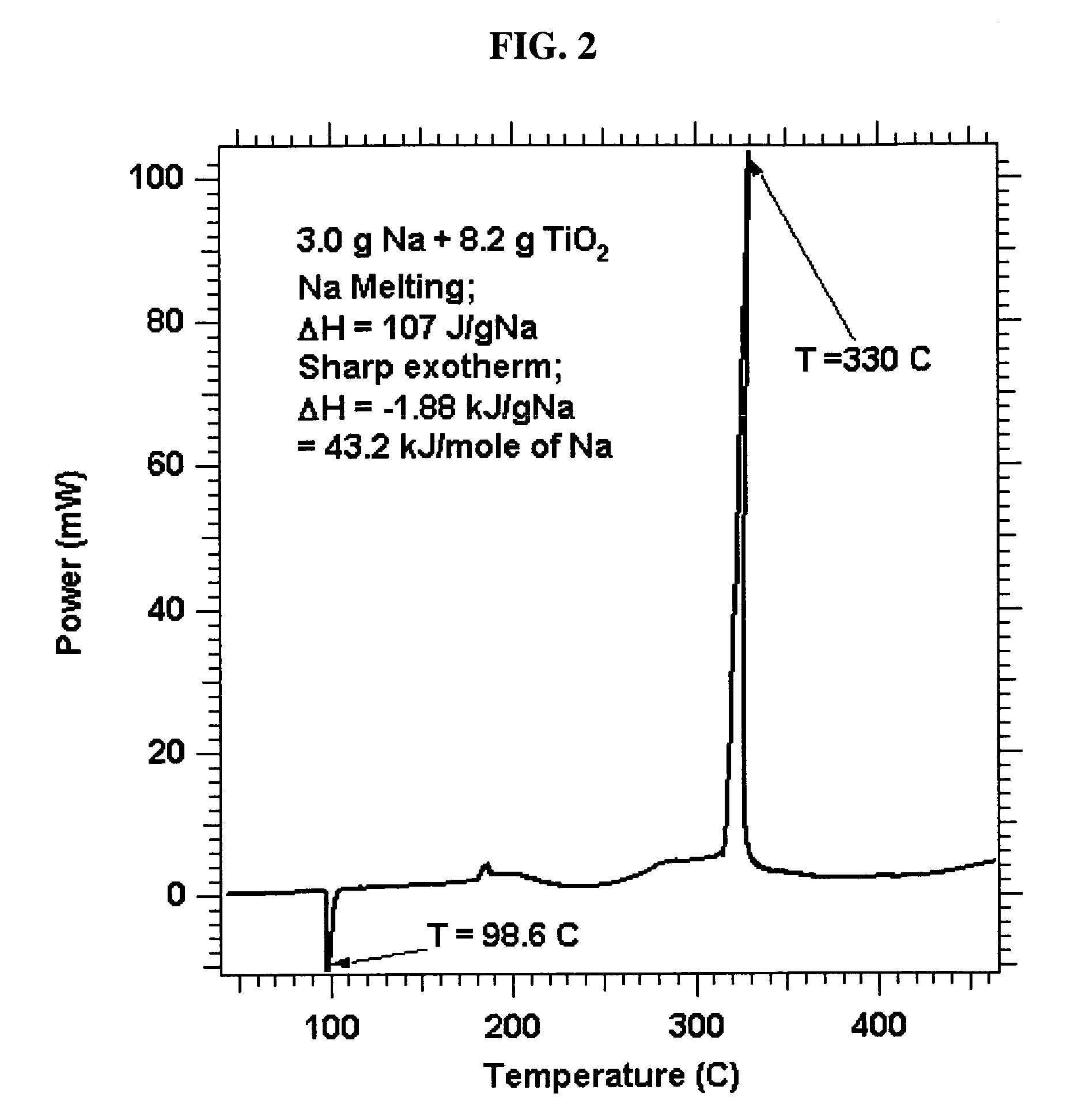

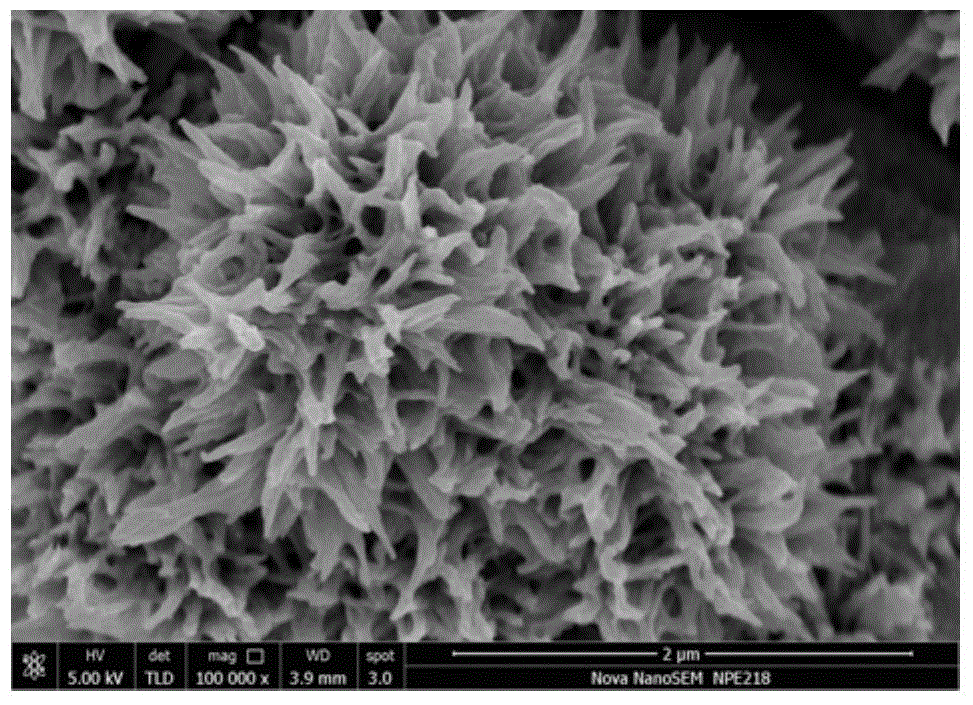

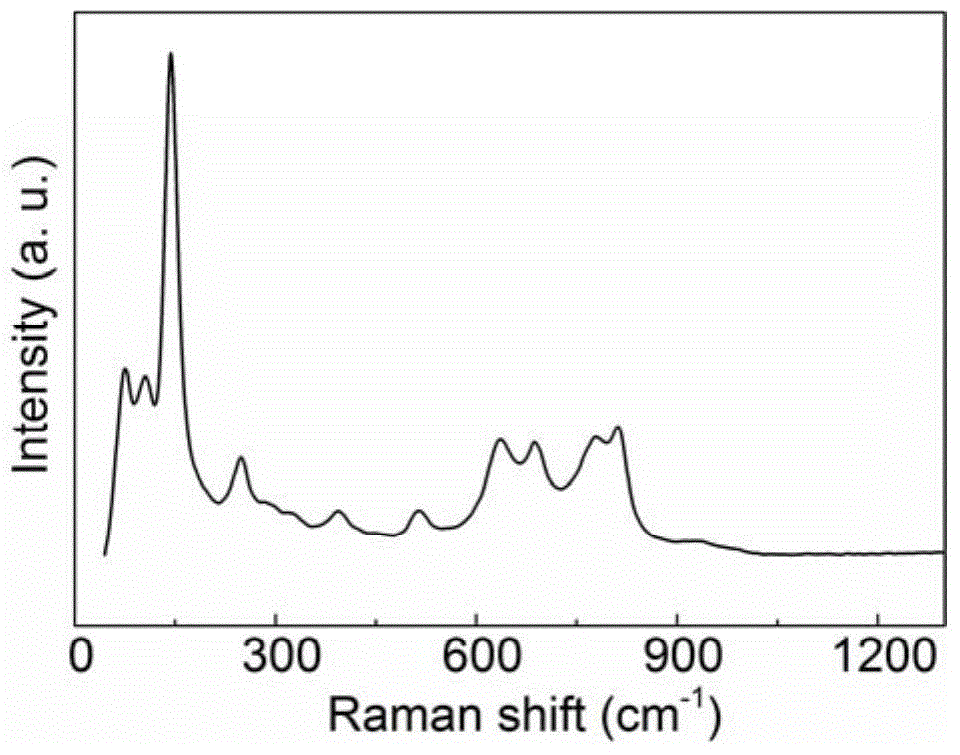

The invention relates to Group 1 metal / porous metal oxide compositions comprising porous metal oxide selected from porous titanium oxide and porous alumina and an alkali metal or an alkali metal alloy. The compositions of the inventions are described as Stage 0 and I materials. These materials differ in their preparation and chemical reactivity. Each successive stage may be prepared directly using the methods described below or from an earlier stage material. Stage 0 materials may, for example, be prepared using liquid alloys of Na and K which are rapidly absorbed by porous metal oxide under isothermal conditions, preferably at or just above room temperature, to form loose black powders that retain much of the reducing ability of the parent metals. When the low melting Group 1 metals are absorbed into the porous metal oxide at about 150° C., an exothermic reaction produces Stage I material, loose black powders that are stable in dry air. Further heating forms higher stage materials of unknown composition. It is believed that Stage I higher materials represent reductions of the porous metal oxide after absorption of the Group 1 metal. Preferred Group 1 metal / porous metal oxide compositions of the invention are those containing sodium, potassium, or sodium-potassium alloys with sodium and sodium-potassium alloys being most preferred. Each stage of the Group 1 metal / porous metal oxide composition of the invention may be used as a reducing agent reacting with a number of reducible organic materials in the same manner known for alkali metals and their alloys.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV +1

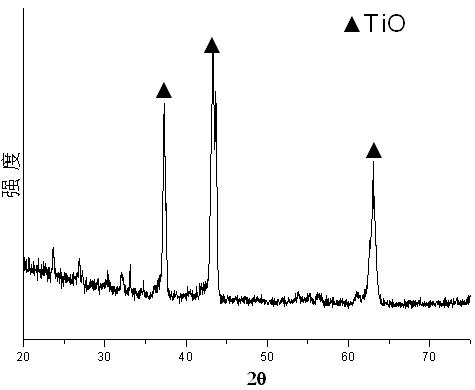

Titanium-reinforced corundum refractory material and preparation method thereof

The invention relates to a titanium-reinforced corundum material and a preparation method thereof, and belongs to the field of refractory materials. According to the product, the titanium-reinforced corundum synthetic raw material is prepared from slag obtained after rutile concentrate is reduced by metallic aluminum through regulation and control of chemical components and physical components. The content of Fe in used rutile minerals is high, obtained metal is ferrotitanium alloy, and metal inclusions in slag are reduced through electric smelting. Main chemical components (expressed by positive-valence oxide content) of the product are Al2O3 and TiO2, and the product contains a small amount of MgO, Fe2O3, CaO, SiO2 and Na2O. The main crystalline phase is corundum, and the secondary crystalline phase is titanium trioxide, and other phases are spinel and calcium hexaluminate. The apparent porosity is less than or equal to 10%; and the volume density ranges from 3.5 g / cm < 3 > to 3.9 g / cm < 3 >. The product realizes efficient utilization of slag, and a refractory material with high performance and high application value is obtained. Meanwhile, the material has environmental protection significance and economic value.

Owner:UNIV OF SCI & TECH BEIJING

Titanium oxide/tungsten oxide nano-composite film on surface of metallic titanium, preparation and application

ActiveCN104801295AHigh purityGood photocatalysisMetal/metal-oxides/metal-hydroxide catalystsComposite filmSurface oxidation

The invention relates to a titanium oxide / tungsten oxide nano-composite film on the surface of metallic titanium, preparation and an application. The metallic titanium is cleaned and etched, then the metallic titanium is impregnated in an oxidation liquid containing peroxotungstic acid sol and hydrogen peroxide and is kept for a period of time at a certain temperature, a titanic acid and peroxotungstic acid containing nano-film formed through crystal in-situ growth and deposition is obtained, and finally, the titanium oxide / tungsten oxide nano-composite film on the surface of the metallic titanium is obtained through calcination; the film mainly comprises a titanium dioxide and tungsten trioxide compound with a nanobelt structure, the nanobelt width is in a range from 10 nm to 150 nm, and the length is in a range from 0.5 mu m to 20 mu m; the mass percentage of titanium oxide is in a range from 1% to 99.5%, and titanium oxide mainly adopts a rutile or anatase crystalline phase; the mass percentage of tungsten oxide is in a range from 0.5%-99%, and tungsten oxide mainly adopts a hexagonal or monoclinic crystal phase. Compared with the prior art, the preparation is simple and easy and is suitable for large-scale industrial production; the prepared titanic oxide film has important application value in the related fields of photoelectrocatalysis, metal corrosion prevention, electrochemical sensing and the like.

Owner:SHANGHAI JIAO TONG UNIV

Carbon fiber surface anti-oxidation coating preparation method

InactiveCN107700205AImprove antioxidant capacityReduced diffusion rateCarbon fibresFiberCarbon fibers

The present invention relates to a carbon fiber surface anti-oxidation coating preparation method, which comprises: 1) adding polycarbosilane into xylene, and stirring and dissolving to prepare a precursor solution; 2) placing carbon fiber into the precursor solution obtained in the step 1), impregnating, and carrying out curing treatment for 2 h at a temperature of 185 DEG C to obtain a preform;3) placing the preform obtained in the step 2) into a xylene solution with dissolved tetraethyl orthosilicate and dissolved boric acid, impregnating, and carrying out curing treatment for 1 h at a temperature of 150 DEG C; and 4) carrying out high temperature cracking on the preform obtained in the step 3). According to the present invention, the silicon carbide / titanium oxide and boron oxide coating is prepared on the surface of the carbon fiber, wherein the crack gap of the silicon carbide is filled with the titanium oxide and the boron oxide during the cracking while the diffusion rate of oxygen in the titanium oxide and the boron oxide is extremely low so as to substantially improve the anti-oxidation performance of the carbon fiber.

Owner:六安成邦新材料有限公司

Method for preparing titanium monoxide powder material

InactiveCN102502806ASimple manufacturing processHigh purityTitanium oxides/hydroxidesHydrogenTitanium

A method for preparing titanium monoxide powder materials relates to a method for preparing high-purity titanium monoxide powder materials through adopting a thermal reduction method, particularly to a method for preparing high-purity titanium monoxide powder materials. The method is characterized in that dititanium trioxide and high-purity hydrogen are taken as basic materials to carry out the high-temperature thermal reduction reaction. In the invention, hydrogen and dititanium trioxide are reduced to titanium monoxide at a high temperature through changing base materials (namely, replacing titanium dioxide with dititanium trioxide), so that the high-purity titanium monoxide is obtained.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

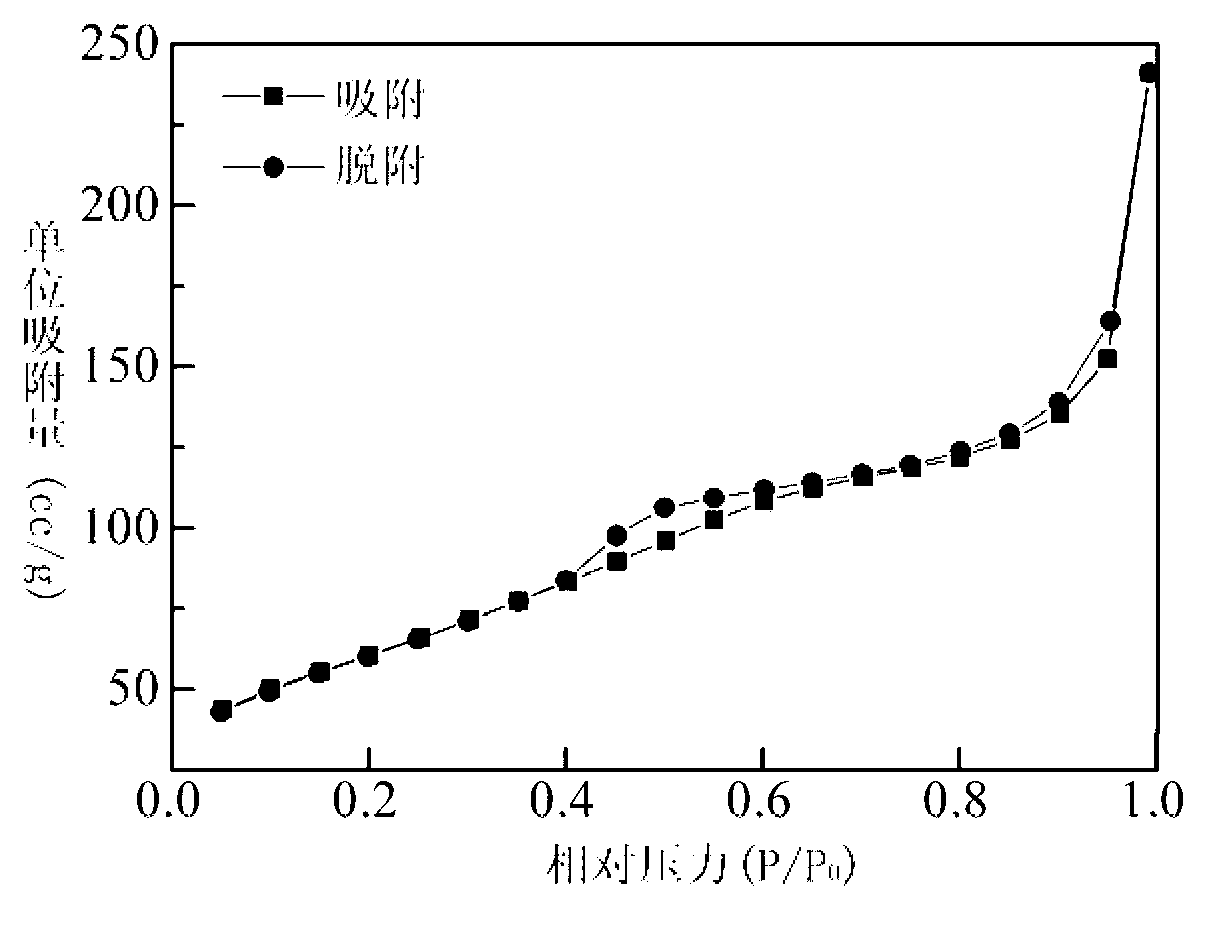

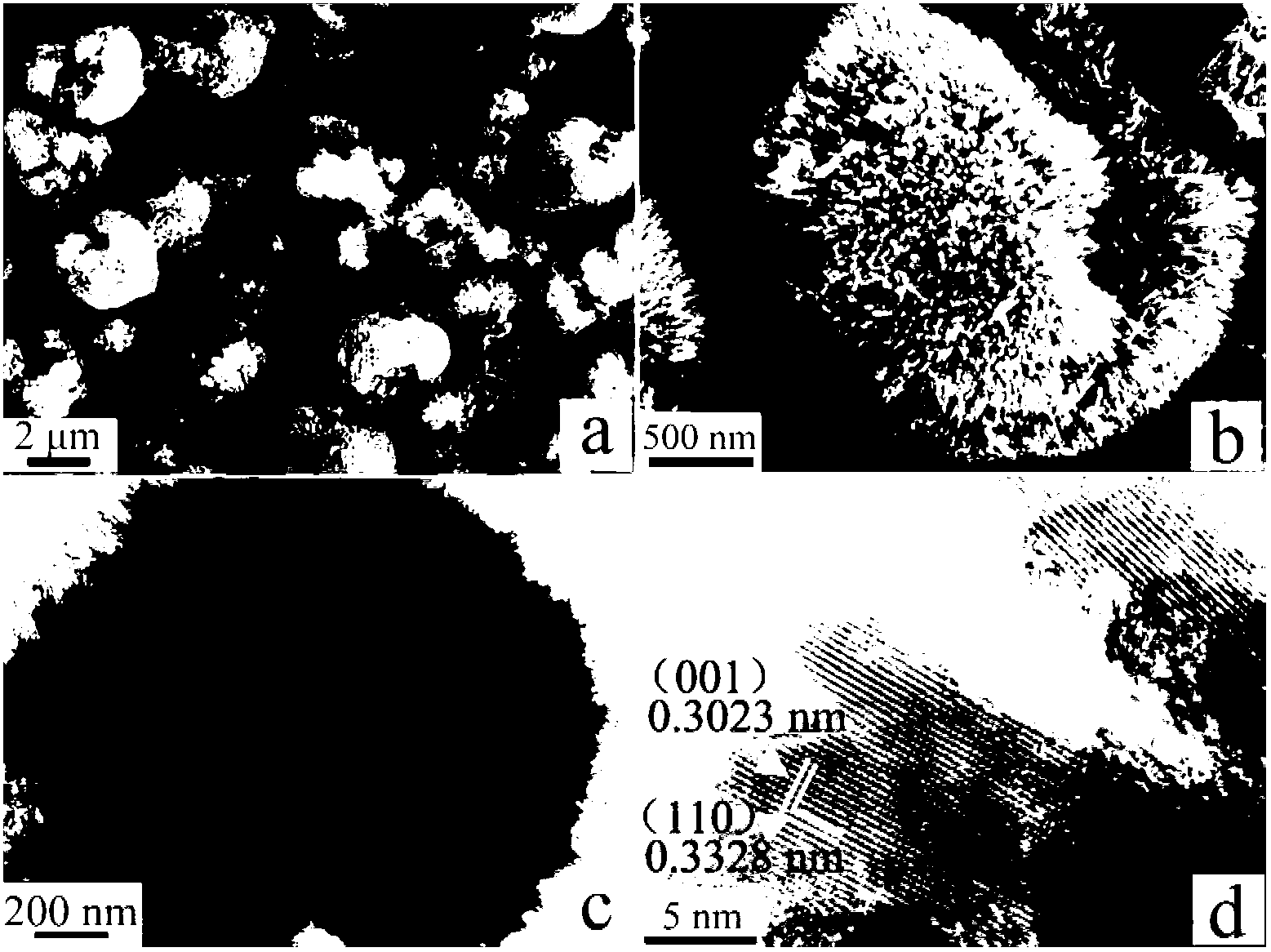

Rutile crystal form titanium oxide having hierarchical structure, and preparation method and use thereof

ActiveCN103058275ALarge specific surface areaImprove removal efficiencyPhysical/chemical process catalystsWater/sewage treatment by irradiationSingle crystalPhotocatalytic degradation

The invention discloses a rutile crystal form titanium oxide having a hierarchical structure, and a preparation method and a use thereof. Titanium oxide is many rutile phase titanium oxide micrometer hollow balls with the surfaces being standing mono-crystalline nanorods and the side surfaces being open, wherein the specific surface area of the micrometer hollow balls is not less than 224.4m<2> / g, the ball diameter is 2-3mum, the diameters of the mono-crystalline nanorods are in a range of 5-8nm, and the rod length is not less than 200nm. The preparation method comprises the following steps: mixing titanyl sulfate hydrate, ethanol, glycerin and deionized water according to a molar ratio of the titanyl sulfate hydrate to ethanol to glycerin to the deionized water of 1:16-26:10-15:15-20, stirring for at least 1h to obtain a mixed solution, placing the mixed solution in a closing state, reacting at 140-160DEG C for at least 30h to obtain a reaction mixture, removing the supernatant of the reaction mixture, cleaning the obtained sediment by industrial alcohol at least 3 times, and drying the cleaned sediment at 75-85DEG C for at least 1h to obtain the rutile crystal form titanium oxide having a hierarchical structure. The rutile crystal form titanium oxide having a hierarchical structure can be widely used in chromium polluted solutions for photo-catalytic degradation adsorption.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

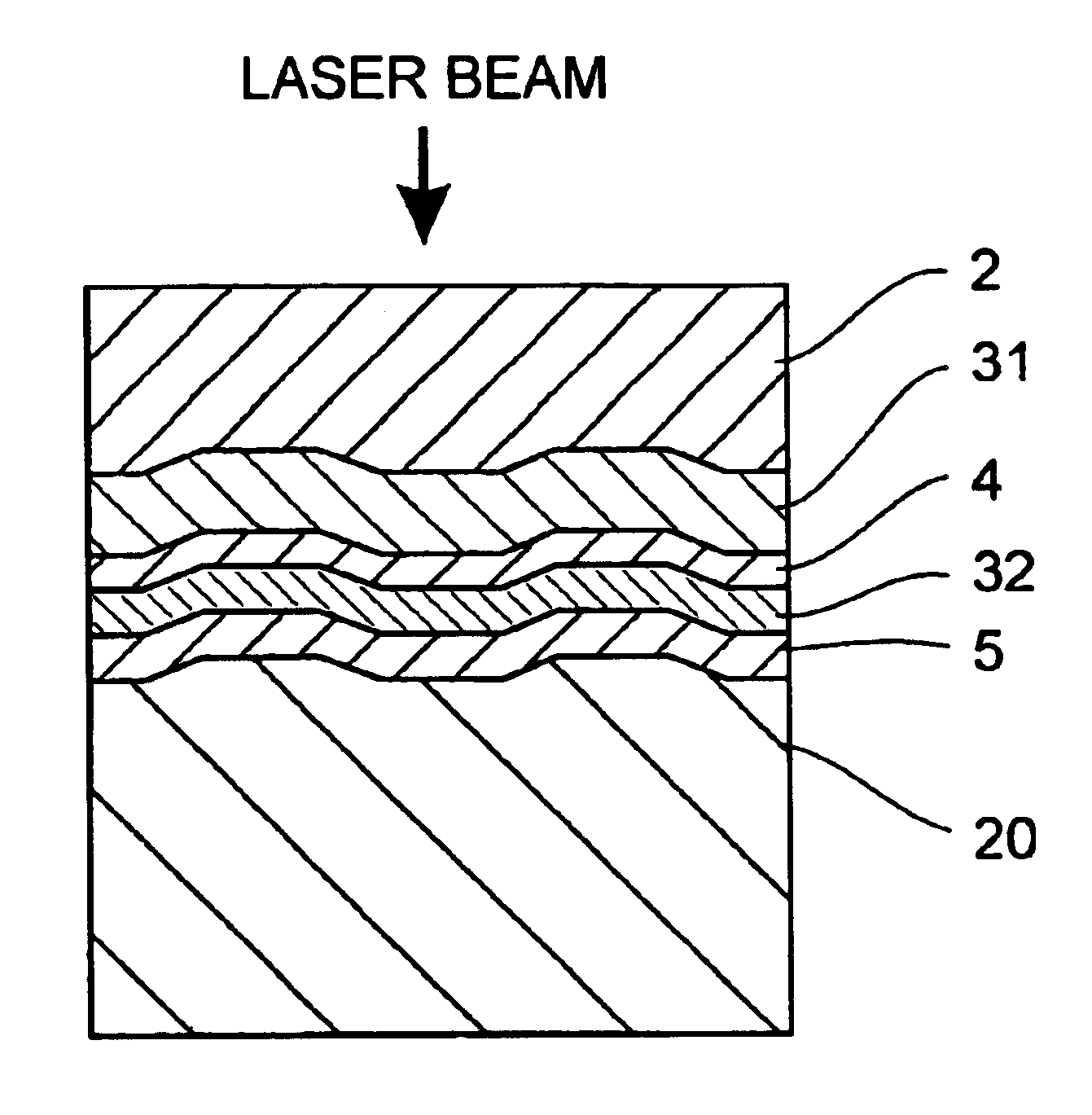

Optical recording medium

InactiveUS6921568B2Improve reliabilitySatisfactory recording/reading characteristicLayered productsOptical overwritingManganese oxideRecording layer

The optical recording medium of the invention comprises a recording layer and at least one mixed dielectric layer. The mixed dielectric layer contains cerium oxide and an additive compound. The additive compound is at least one compound selected from among aluminum oxide, chromium oxide, iron oxide, manganese oxide, niobium oxide, magnesium oxide, zinc oxide, titanium oxide, yttrium oxide, tantalum oxide, antimony oxide, zirconium oxide, bismuth oxide and magnesium fluoride. The optical recording medium has a high storage reliability and satisfactory recording / reading characteristics.

Owner:TDK CORPARATION

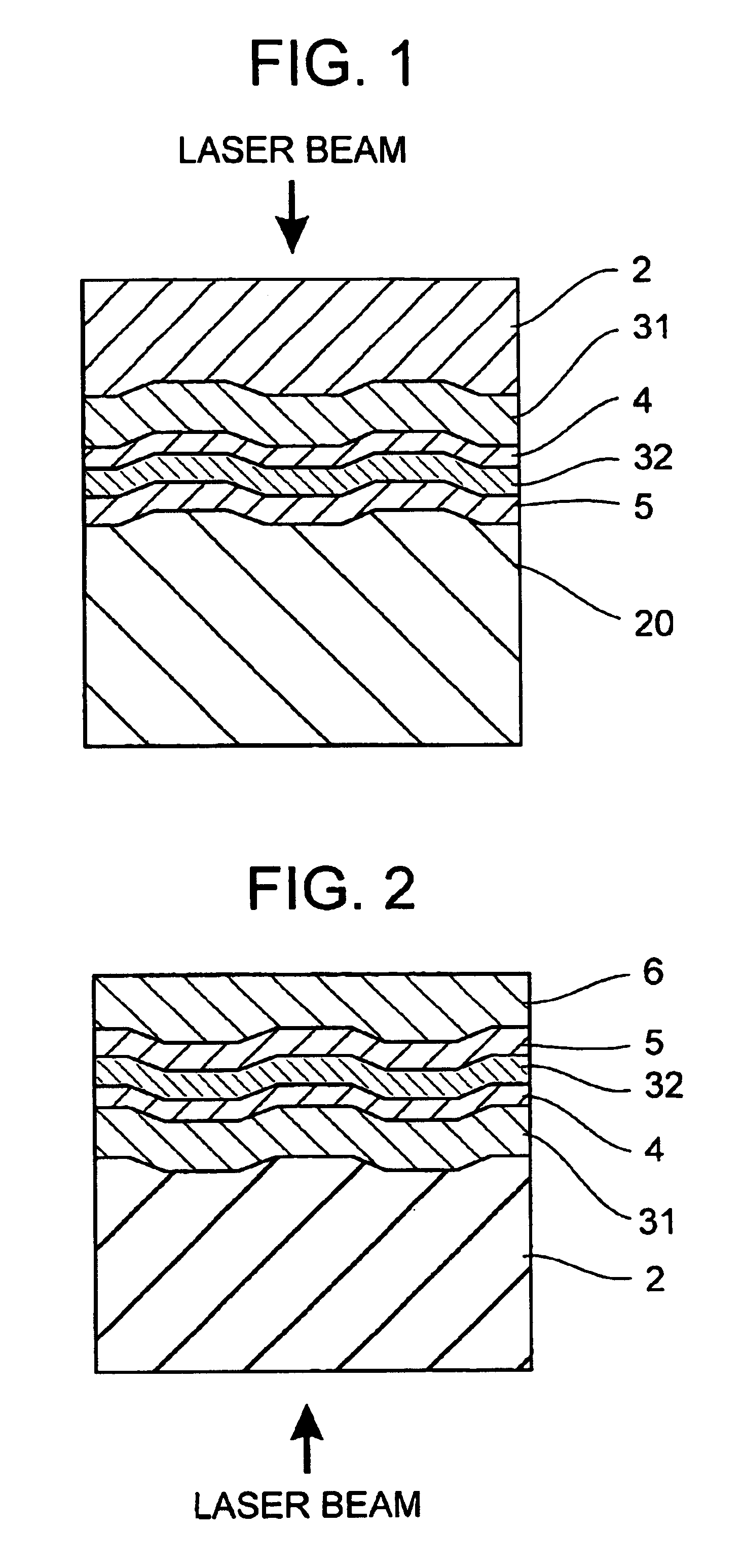

Titanium oxide production process

InactiveUS20030068268A1Easy to produceImprove photocatalytic activityMaterial nanotechnologyCatalyst activation/preparationTitanium hydroxideTitanium

A process for producing a titanium oxide is provided which comprises the steps of (i) reacting a titanium compound with ammonia in an amount exceeding the stoichiometric amount necessary to convert the titanium compound to a titanium hydroxide or reacting a titanium compound with a base at pH of from about 2 to about 7, to obtain a reaction product and (ii) calcining the obtained product. The titanium oxide exhibits a high photocatalytic activity by visible light radiation.

Owner:SUMITOMO CHEM CO LTD

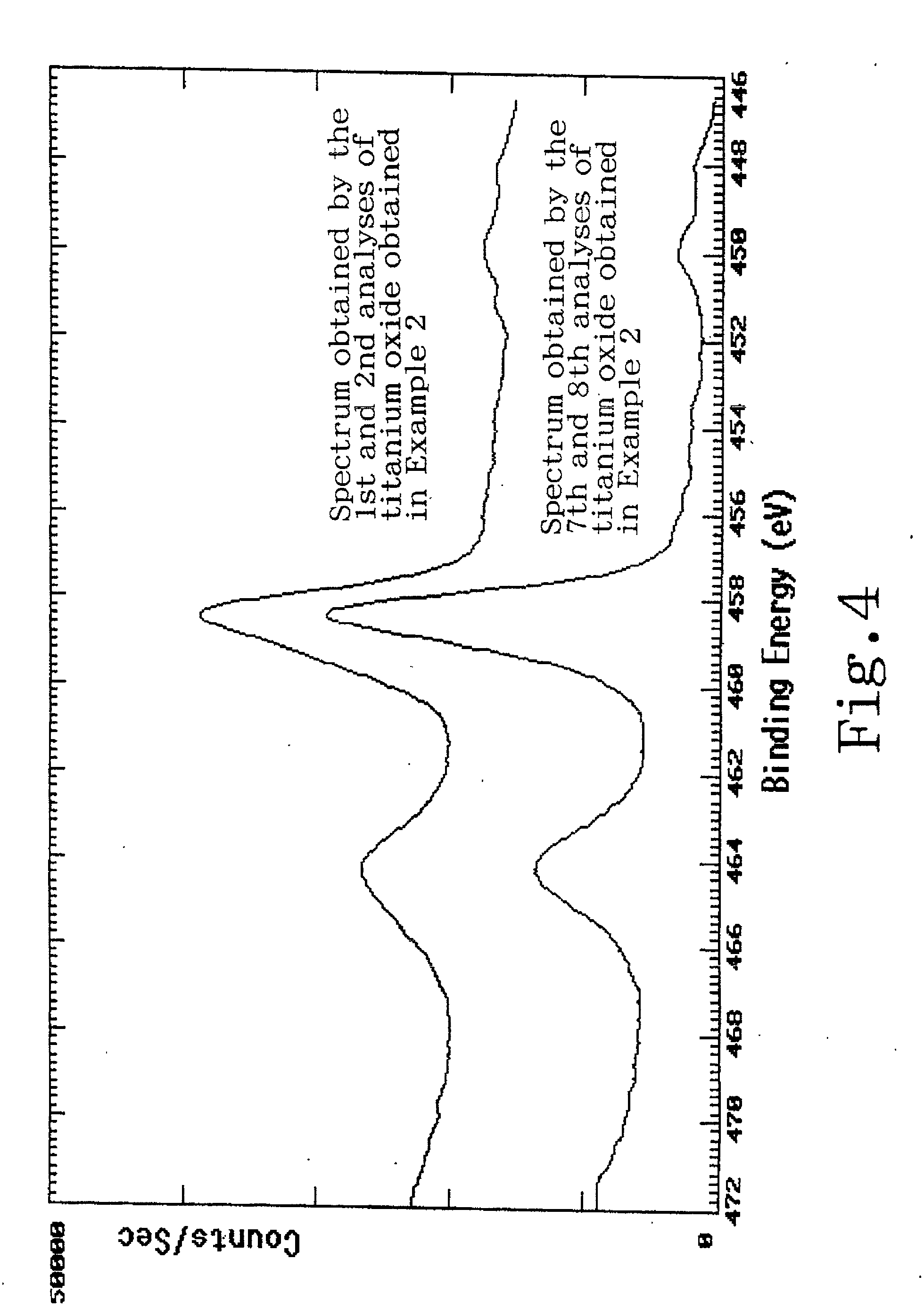

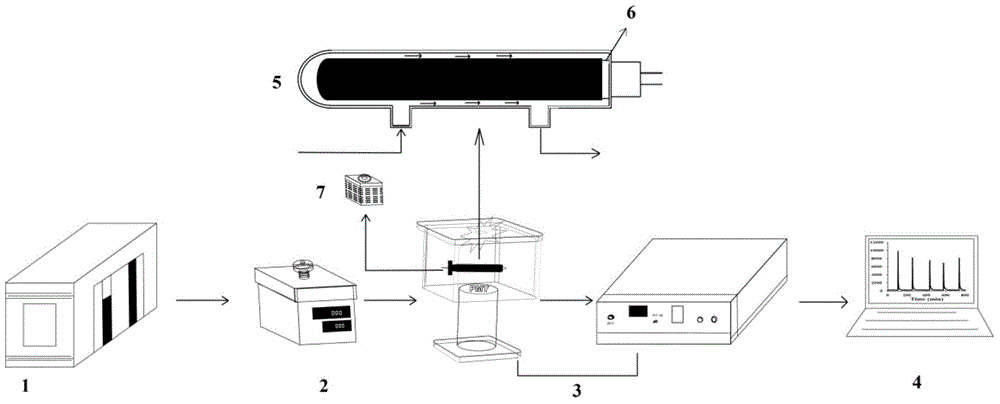

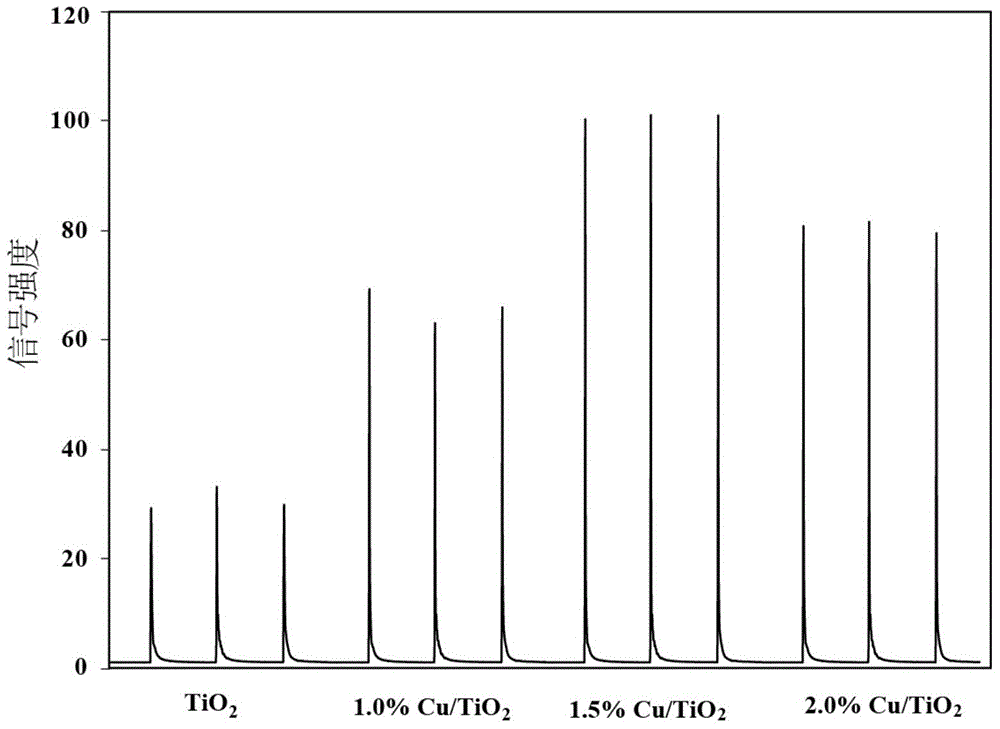

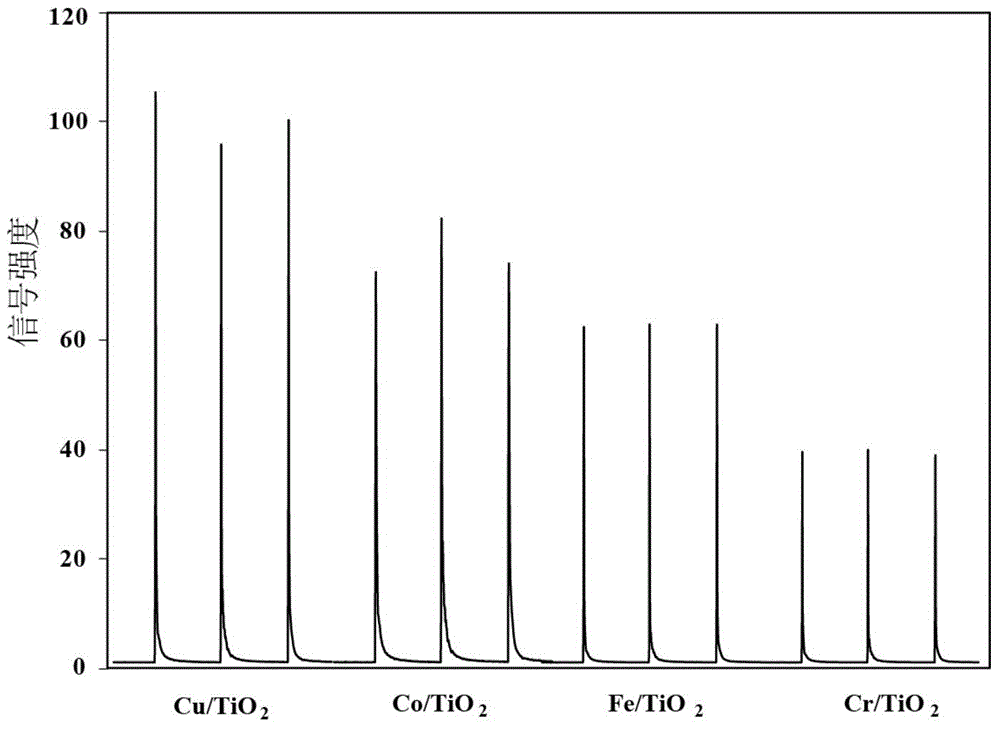

Method for rapidly detecting oxygen vacancy in titanium oxide

InactiveCN104897655ASimple methodFast wayChemiluminescene/bioluminescenceOxygen vacancyChemical adsorption

The invention discloses a method for rapidly detecting an oxygen vacancy in titanium oxide. The method includes that gas molecule ether and oxygen are diffused to the titanium oxide surface; since the oxygen vacancy on the titanium oxide surface has strong capacity of adsorbing an oxygen molecule, the oxygen adsorbed to the oxygen vacancy forms a super-oxygen kind (O2<->) quite strong in oxidability by capturing a free electron, then, an ether molecule in the chemical adsorption state reacts with the O2<-> to form an acetaldehyde molecule (CH3CHO*) in the excited state, a certain energy can be produced in a process that the acetaldehyde molecule in the excited state returns to the ground state, and is released in a photology form, and a chemiluminescent analyzer detects a luminescence signal value of luminescence so as to obtain a value of the oxygen vacancy in the titanium oxide according to the direct proportion relation between the content of the oxygen vacancy and the luminescence signal. The method has the advantages of simple equipment, rapidity, easiness in operation and wide application prospect for assessment of the oxygen vacancy of extensive research significance in defective oxides.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature

ActiveCN109879311ALow costMass productionTitanium oxides/hydroxidesTitanium oxideTitanium tetrachloride

The invention discloses a method for preparing titanium oxide through reducing titanium-containing complexes at normal temperature. The method is characterized in that reduction reaction occurs in a normal temperature liquid phase; the potential safety hazards due to mixing of reducing agents and air are eliminated; the reduction is performed in the liquid phase, the microscopic uniformity is high; the firing temperature is low; the time is short. The method has the following principle and steps that titanium sulfate or titanium tetrachloride and ammonium hydroxide or sodium hydroxide take a reaction to obtain titanic acid; the titanic acid reacts with oxalic acid or citric acid to form an oxalate oxytitanate complex-ion or oxytitanate citrate complex-ion solution; next, reaction is performed with zinc powder; the complex ions are reduced into low-valent titanium complex ions; the pH value of the solution is regulated to 12 by ammonium hydroxide; precipitates of dark brown color to dark violet color are generated; washing is performed for 3 to 5 times by 3 to 5 times of deionized water; the zin is washed away in an ion ZnO2<2-> form to obtain pure titanium hydroxide precipitates; oxalic acid is added until the pH is 0.5 to 1.5; drying is performed to 2 to 5 hours at 120 to 180 DEG C; the temperature is raised from room temperature to 820 to 950 DEG C by a muffle furnace; roasting is performed for 2 to 6 hours; titanium oxide spherical powder with the Ti4O7 content being 90 percent or higher is obtained.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

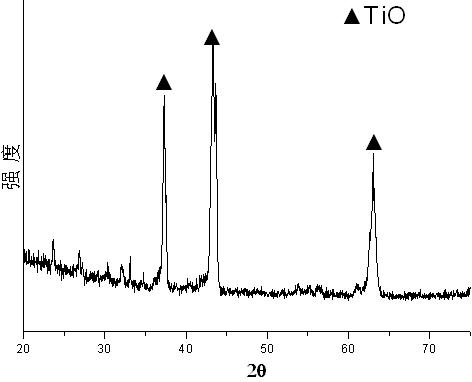

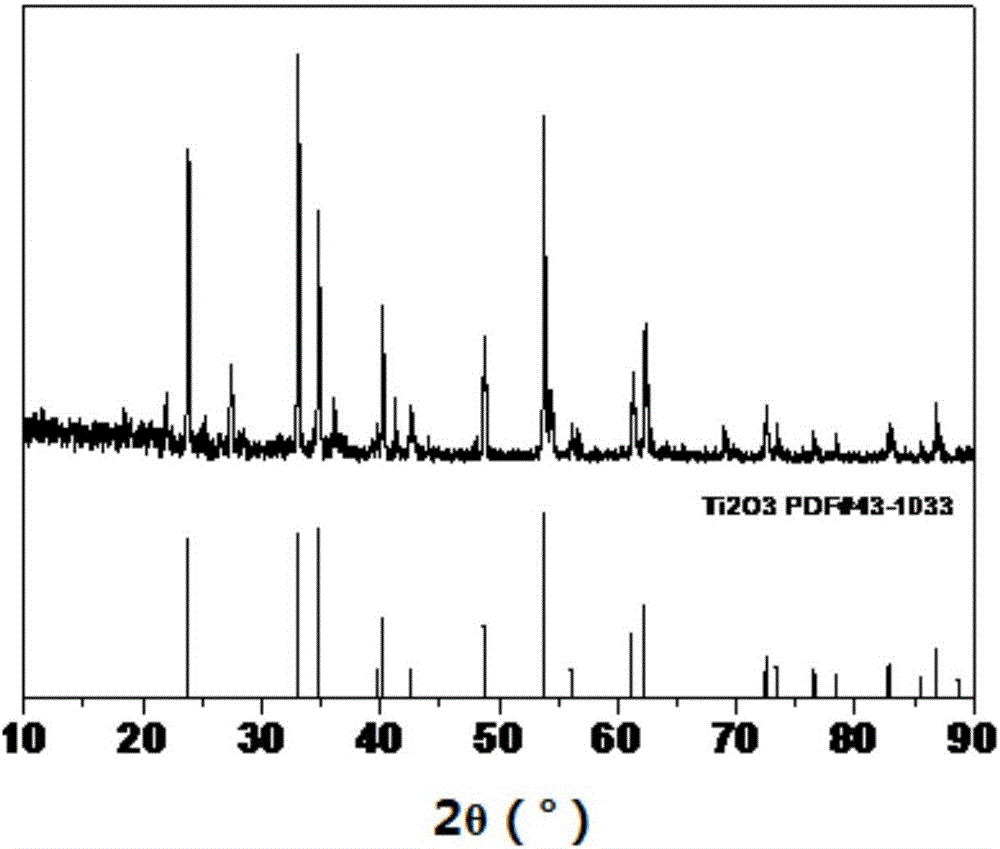

Method for preparing titanium sesquioxide material

InactiveCN102491413AReduce harmSimple manufacturing processTitanium oxides/hydroxidesHazardous substanceSesquioxide

The invention relates to a method for preparing a titanium sesquioxide material. The method is characterized in that a preparation process uses titanium dioxide and graphite as basic raw materials and carries out the preparation by a hot reduction reaction. The method for preparing the titanium sesquioxide material of the invention uses titanium dioxide and graphite as basic raw materials and carries out the preparation by a high temperature thermal reduction method. The titanium sesquioxide is prepared directly by a one-step carbothermic process, so as to save technological steps and reduce usage of a restorable harmful substance titanium tetrachloride. Therefore, the method reduces cost as well as mitigates environmental pollution.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Organic conductive coating and preparation method thereof

InactiveCN103740246AStrong adhesionImprove conductivityElectrically-conductive paintsPolyester coatingsEpoxySesquioxide

The invention provides an organic conductive coating and a preparation method thereof, wherein the organic conductive coating comprises the following components in parts by weight: 8-15 parts of graphite, 1-6 parts of titanium dioxide, 0.05-0.15 part of antimony trioxide, 0.3-1.2 parts of magnesium oxide, 0.5-1.8 parts of lead oxide, 1-5 parts of titanium sesquioxide, 10-30 parts of alkyd resin, 0.2-0.8 part of silicone oil, 0.05-0.12 part of xylene, 0.1-0.8 part of epoxy resin and 0.3-0.7 part of barium carbonate. The preparation method comprises the following steps: firstly uniformly mixing the graphite, the titanium dioxide, the antimony trioxide, the magnesium oxide, the lead oxide, the titanium sesquioxide and the barium carbonate, then adding the alkyd resin, the epoxy resin and the silicone oil, uniformly stirring, further adding the xylene and uniformly mixing for preparation. The organic conductive coating provided by the invention has high adhesion force of above 98%, which is better than similar products; and furthermore, the electric conductivity is good, and the electric resistance is less than 60 ohm.

Owner:吴江市东泰电力特种开关有限公司

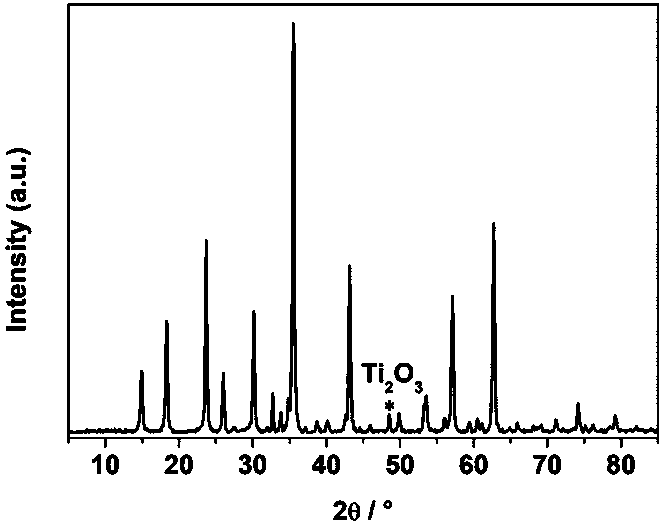

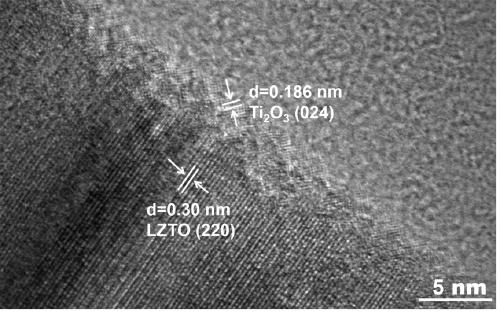

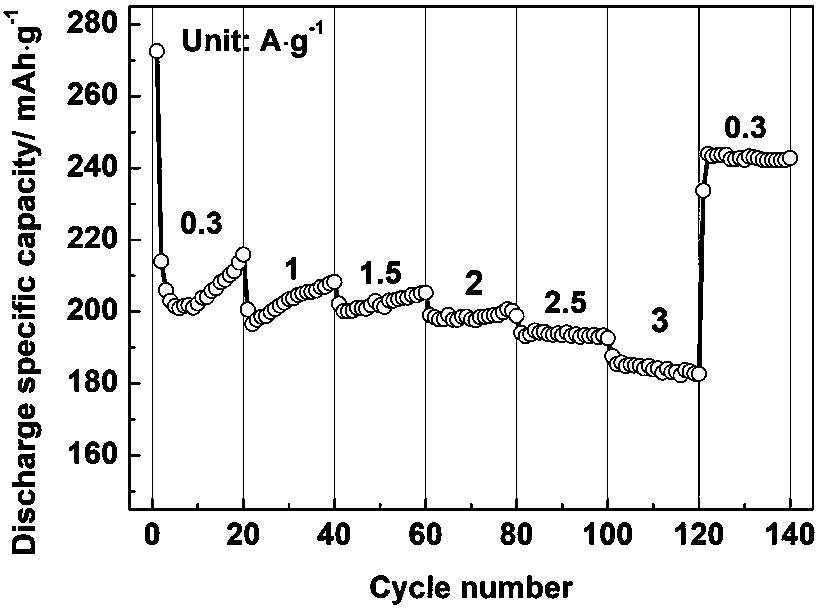

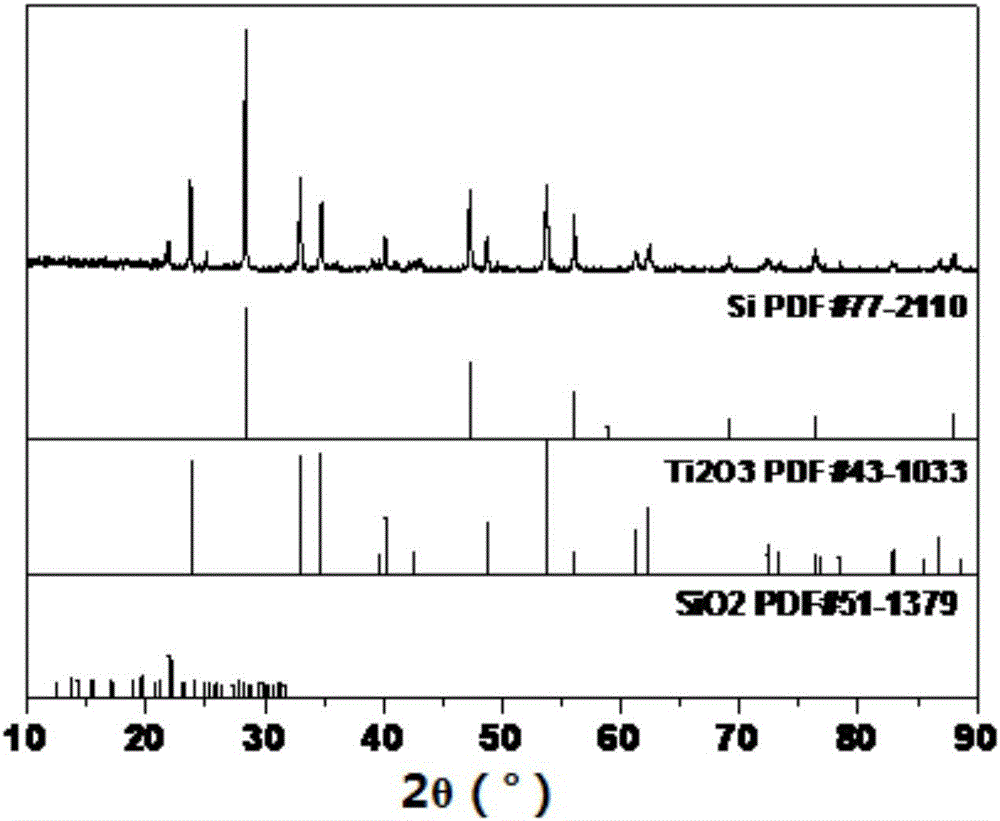

Lanthanum-doped titanium trioxide coated co-modified lithium zinc titanate composite material and preparation method thereof

ActiveCN111554906AStable structureDiffusion fastHybrid capacitor electrodesNegative electrodesZinc titanateBattery cell

The invention discloses a lanthanum-doped titanium trioxide coated co-modified lithium zinc titanate composite material and a preparation method thereof. The molecular formula of the composite material is Li(2-x)LaxZnTi3O8@Ti2O3, wherein x is 0.03-0.05; and the composite material is formed by mixing and sintering lithium salt, a lanthanum source, a zinc source and a titanium source according to the mass ratio: nLi:nLa:nZn:nTi=(2-2.3)-x:x:1:3. The composite material disclosed by the invention is high in specific discharge capacity and good in cycle and rate performance, and the preparation method is simple, convenient, rapid, low in energy consumption, low in cost and environment-friendly; and the prepared composite material can be widely applied to lithium ion batteries and lithium ion capacitor negative electrode materials, and has a relatively good application prospect.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Method for loading noble metal on silicon oxide, aluminum oxide or titanium oxide

ActiveCN102380376AEasy to prepareImprove operating conditionsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsIridiumSilicon oxide

The invention discloses a method for loading a noble metal on a silicon oxide, an aluminum oxide or a titanium oxide. The method comprises the following steps of: heating and hydrolyzing silicate ester, aluminic acid ester or titanic acid ester in a water or water-alcohol medium in the presence or absence of alkali and a stabilizing agent to prepare a corresponding silicon oxide, aluminum oxide or titanium oxide; locally reducing alcohol generated by hydrolyzing halogen-containing acid or halide of platinum, rhodium or iridium in the same reaction system or alcohol replenished into the system into simple substance platinum, rhodium or iridium, and loading the simple substance platinum, rhodium or iridium onto the generated silicon oxide, aluminum oxide or titanium oxide; and filtering and separating to obtain a product. The method has the advantages of readily-available reagents, easy and convenient operating conditions, completion of the reaction of reaction raw materials in one pot, and convenience for preparing catalysts or catalyst precursors of noble metal-loaded silicon oxides, aluminum oxides or titanium oxides on a large scale.

Owner:SHANGHAI ZHONGHUA TECH CO LTD

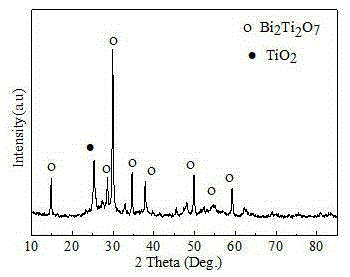

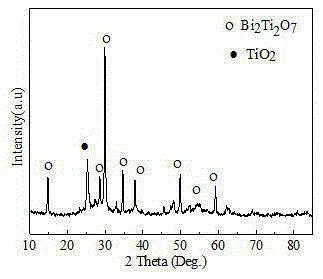

A method for preparing pure phase bismuth titanate and titanium oxide composite material by alcohol thermal method

ActiveCN104069848BLow costSimple preparation processMetal/metal-oxides/metal-hydroxide catalystsTemperature controlAlcohol

Owner:NANJING NORMAL UNIVERSITY

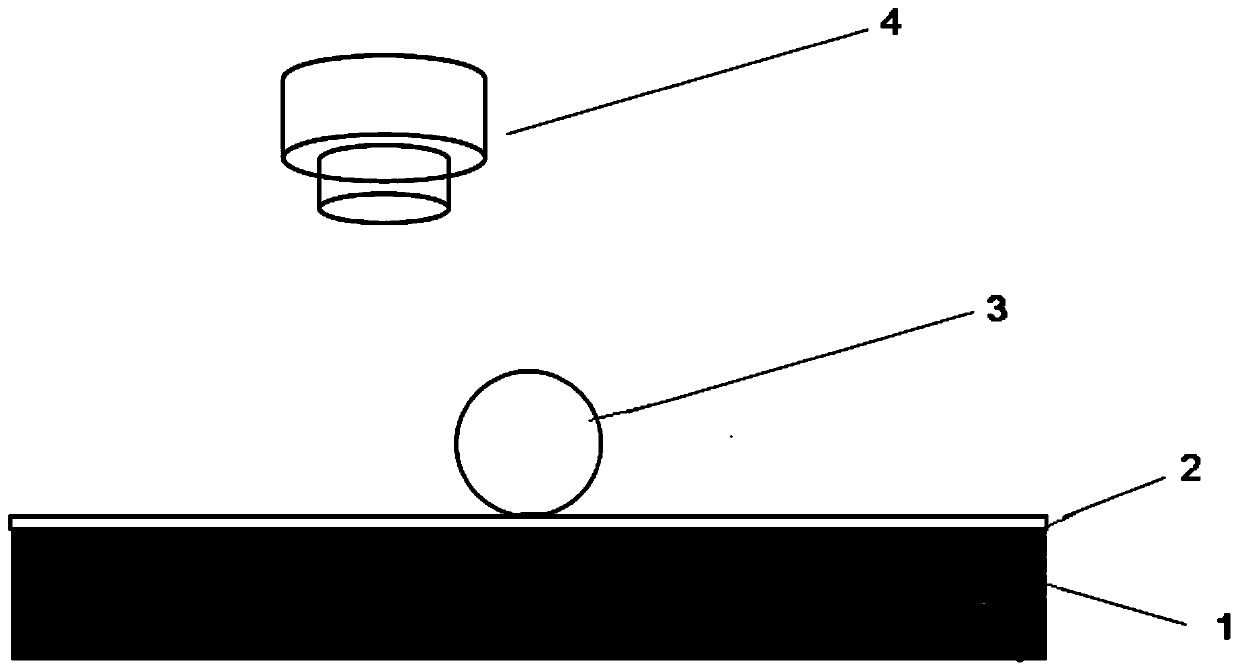

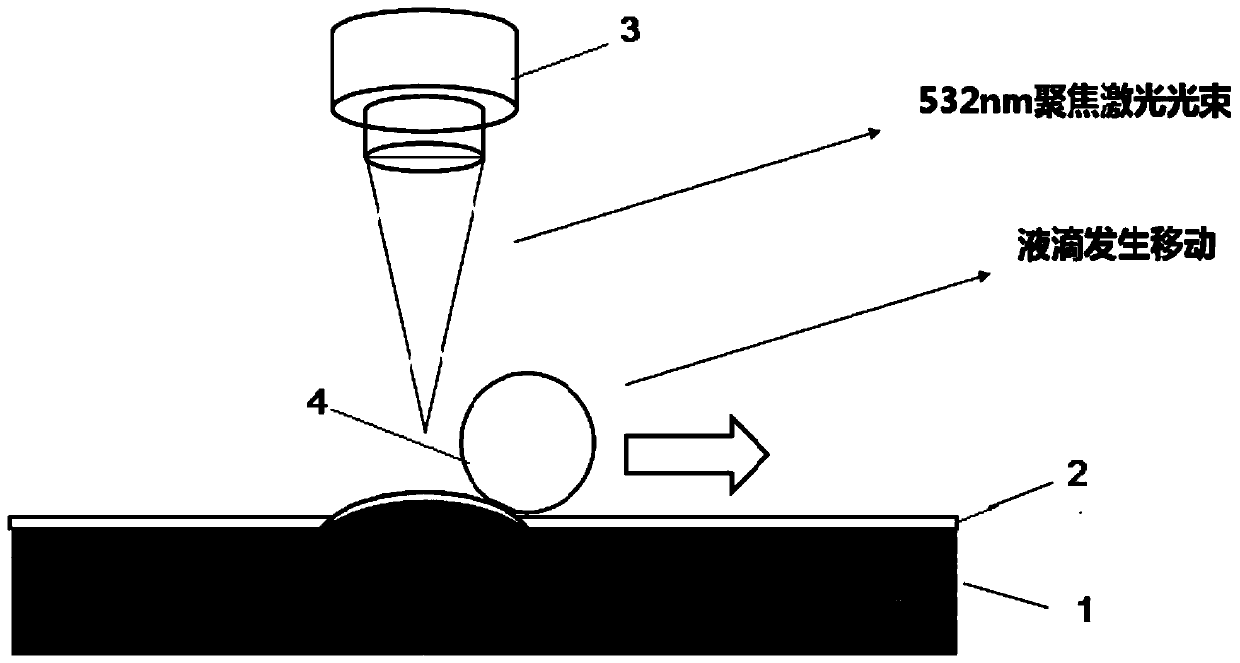

Photothermal directional control elastic superhydrophobic surface liquid drop migration device and using method thereof

The invention discloses a photothermal directional control elastic superhydrophobic surface liquid drop migration device and a using method thereof. The photothermal directional control elastic superhydrophobic surface liquid drop migration device comprises a substrate, and is characterized in that the substrate is formed by mixing polydimethylsiloxane and heat absorbing material titanium dioxidepowder or ferroferric oxide powder, a transparent superhydrophobic layer is etched or sprayed on the surface of the substrate, and a green laser is arranged above the transparent superhydrophobic layer. According to the photothermal directional control elastic superhydrophobic surface liquid drop migration device and the using method thereof, the green laser is utilized to heat the substrate, titanium dioxide in the substrate is subjected to photo-thermal conversion and heat is transferred to polydimethylsiloxane, the polydimethylsiloxane is heated to generate deformation protrusions, and whenliquid drops arranged on the surface of the transparent superhydrophobic layer reach rolling angles on slopes formed by the deformation protrusions, the liquid drops roll downwards, so that the rolling migration of the directionally controlled liquid drops is realized, the precise control of micro-fluid is realized, and the photothermal directional control elastic superhydrophobic surface liquiddrop migration device can be widely applied to the fields of fluid transportation, chemical analysis, medical detection and the like.

Owner:CHONGQING UNIV

Novel glass curtain wall sealant

The invention discloses a novel glass curtain wall sealant which comprises the following components in parts by weight: 5-8 parts of methyltrimethoxy silane, 10-20 parts n-butyl borate, 3-6 parts of gas phase white carbon black, 1-3 parts of copper oxide, 1-3 parts of titanium sesquioxide, 3-6 parts of titanium white, 10-20 parts of ethyl orthosilicate and 4-8 parts of phthalate. A preparation method of the novel glass curtain wall sealant comprises the following steps: proportionally mixing the components, and uniformly stirring and dispersing to obtain the finished product. Compared with the prior art, the novel glass curtain wall sealant has favorable properties such as heat resistance, aging resistance, water resistance and the like, and has low-temperature flexibility and favorable elasticity, thus being a sealant which can be widely used.

Owner:江华瑶族自治县金牛开发建设有限公司

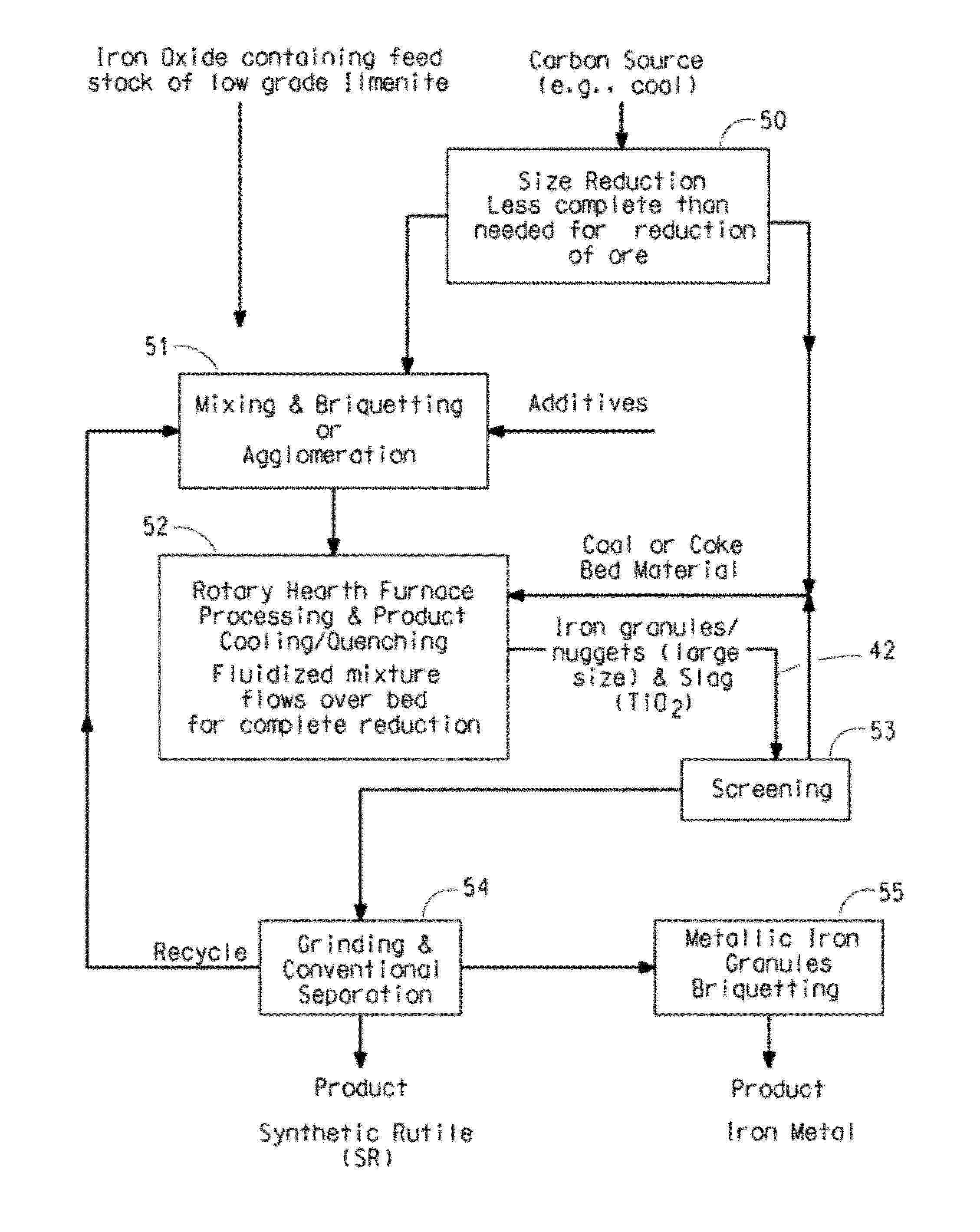

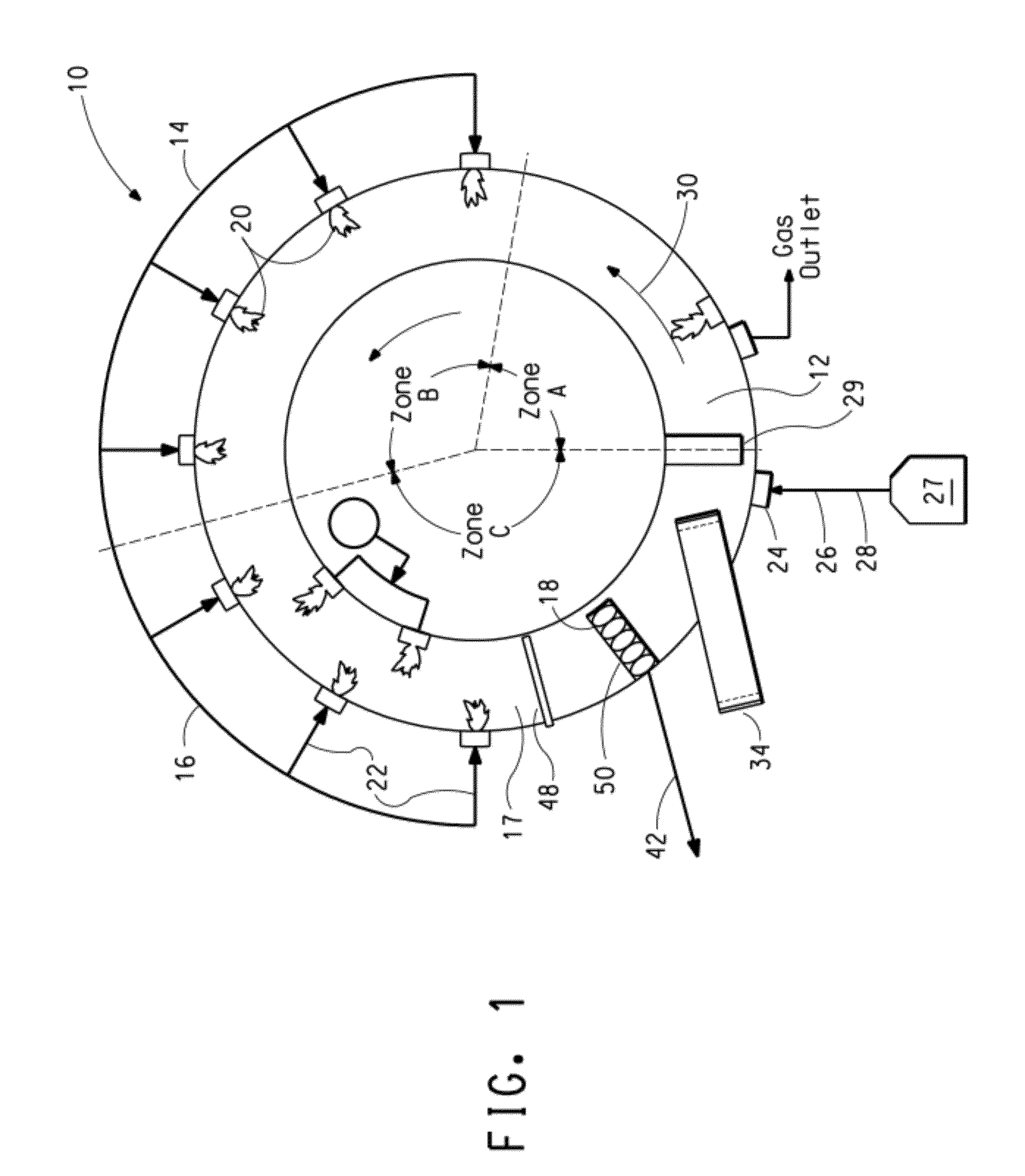

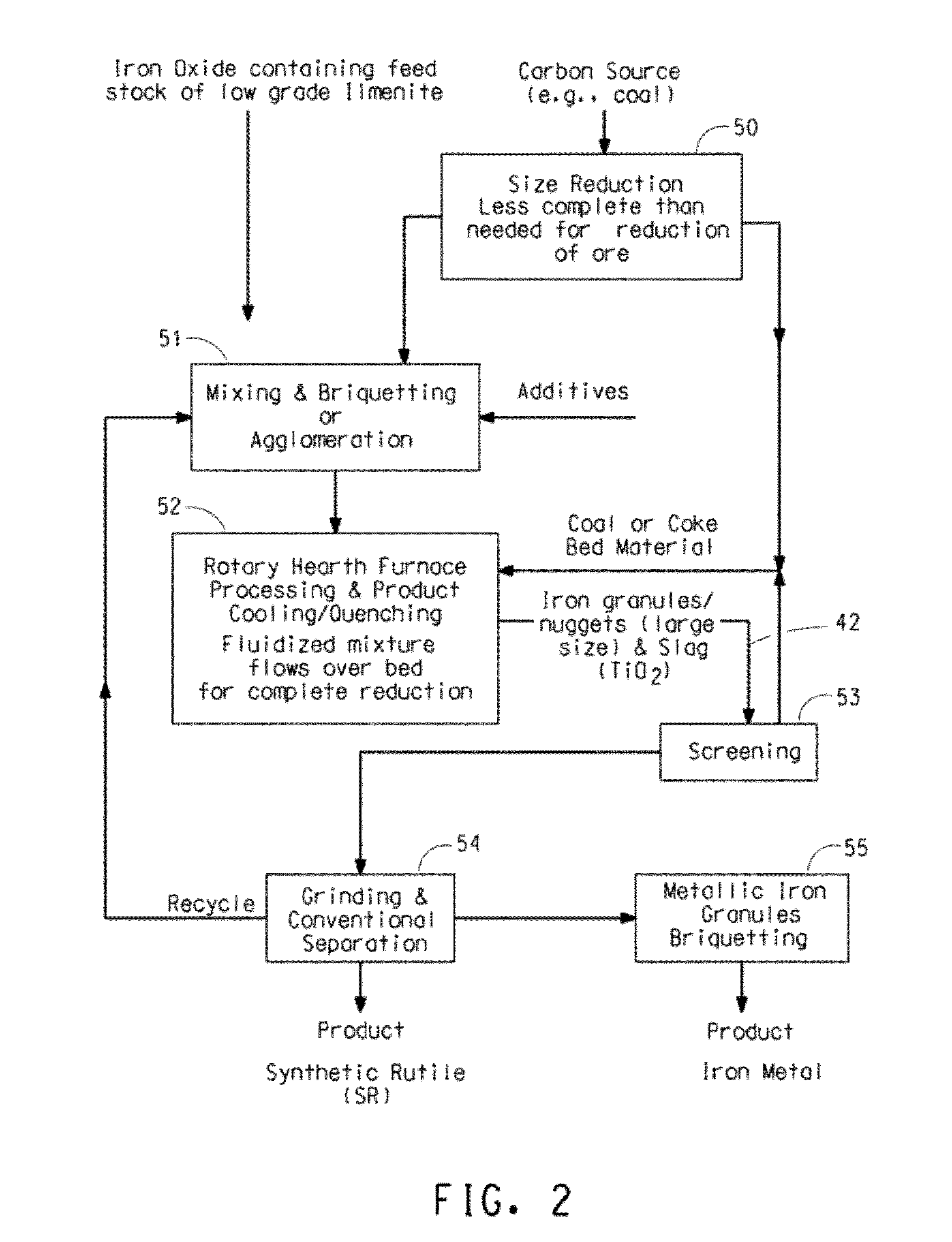

Ore reduction process using carbon based materials having a low sulfur content and titanium oxide and iron metallization product therefrom

The present invention is one or more processes for producing separable iron and titanium oxides from an ore comprising titanium oxide and iron oxide, comprising: (a) forming agglomerates comprising carbon-based material and the ore, the quantity of carbon of the agglomerates being at least sufficient for forming a ferrous oxide-containing molten slag, at an elevated temperature; (b) introducing the agglomerates onto a bed of carbon-based material in a moving hearth furnace, wherein the carbon-based materials used for both the agglomerates and the bed have a low sulfur content; (c) heating the agglomerates in the moving hearth furnace to a temperature sufficient for liquefying the agglomerates to produce a liquid comprising ferrous oxide-containing slag; (d) metallizing the ferrous oxide of the slag by reaction of the ferrous oxide and the carbon of the carbon bed at a furnace temperature sufficient for maintaining the slag in a liquid state; (e) solidifying the slag after metallization of the ferrous oxide to form a matrix of titanium oxide-rich slag having a plurality of metallic iron granules distributed there through; and (f) separating the metallic iron granules from the slag, the slag comprising greater than 85% titanium dioxide based on the entire weight of the matrix after separation of the metallic iron.

Owner:THE CHEMOURS CO FC LLC

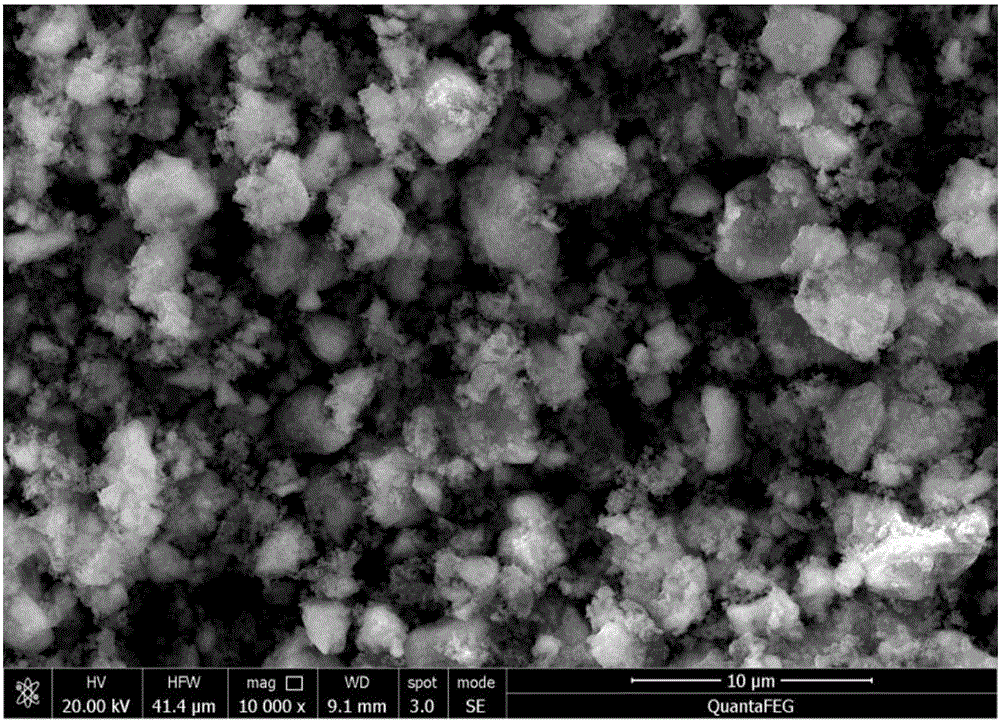

Method for preparing porous titanium with titanium sesquioxide

The invention relates to a method for preparing porous titanium with titanium sesquioxide and belongs to the technical field of porous titanium preparation. According to the method, titanium sesquioxide powder and calcium chloride are mixed evenly to obtain Ti2O3 / CaCl2 mixed powder; the Ti2O3 / CaCl2 mixed powder is subjected to pressing formation to obtain a preformed body; the preformed body is put in a vacuum or argon atmosphere to be sintered for 30-120 min under the condition of the temperature of 850-1000 DEG C, and a porous precursor is obtained; under the conditions that pressure intensity is 10<-1>-10 Pa and temperature is 900-1200 DEG C, and calcium vapor is adopted for reducing the porous precursor for 4-12 h; dilute hydrochloric acid solution is adopted for immersing reduction products for 30-240 min, and solid-liquid separation is conducted to obtain a solid A and pickle liquor; deionized water and absolute ethyl alcohol are used for alternately washing the solid A, and thenvacuum drying is conducted to obtain sheet porous titanium; and the sheet porous titanium is put at the temperature of 1200-1400 DEG C, vacuum sintering is conducted for 2-4 h, and the porous titanium is obtained. The porous titanium prepared by the method has two pore diameter distributions which are large pores of the pore diameter of 50-200 [mu]m and micropores of the pore diameter of 4-15 [mu]m correspondingly.

Owner:KUNMING UNIV OF SCI & TECH

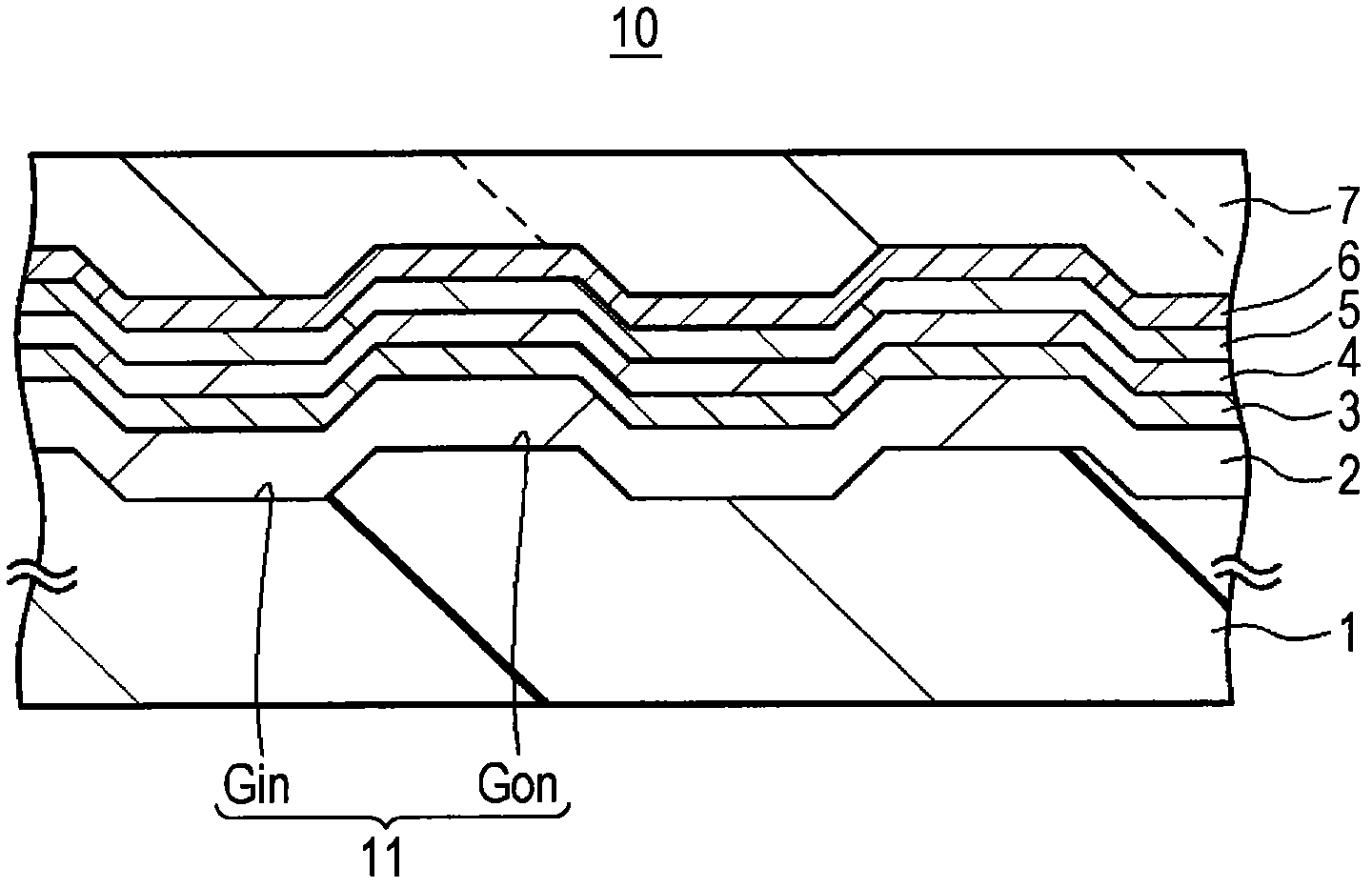

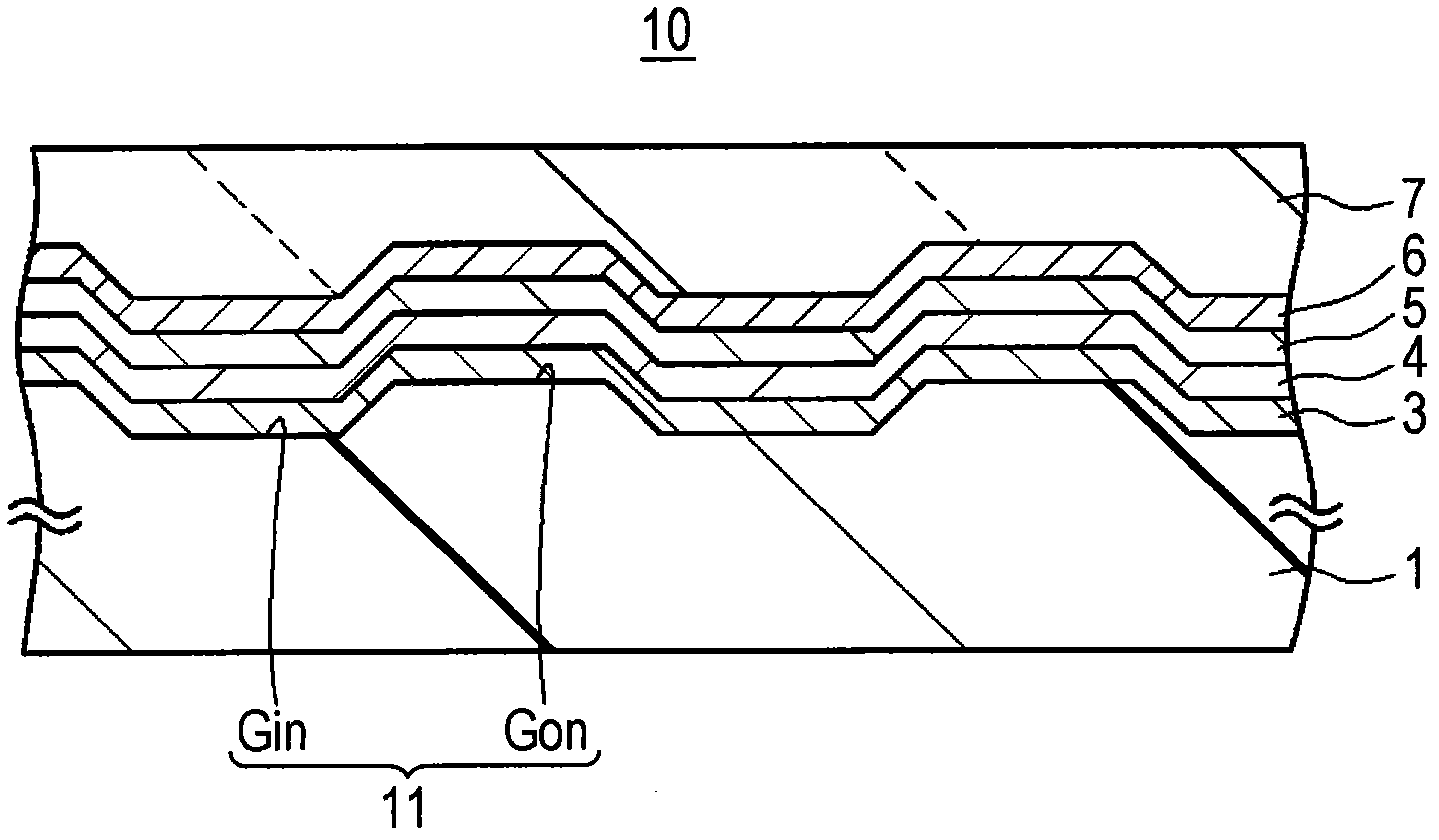

Honeycomb structure

InactiveCN104797333AImprove purification effectIncreased durabilityDispersed particle separationCatalyst activation/preparationTungsten(IV) oxideTungsten atom

Provided is a honeycomb structure which uses a TiO2 / V2O5 / WO3 catalyst, and which has excellent NOX conversion efficiency and thermal durability. This honeycomb structure is provided with a honeycomb unit in a shape in which multiple cells are partitioned by cell walls, said cells containing at least titanium oxide, vanadium oxide, tungsten oxide and an inorganic binder and extending in the longitudinal direction from one end surface to the other end surface, and is characterized in that the hydrogen consumption from vanadium reduction in temperature-programmed reduction with hydrogen (H2-TPR) is 0.6mmol or more per 1g of the honeycomb structure, and the molar ratio (W / V) of tungsten atoms to vanadium atoms is 0.8-1.2.

Owner:IBIDEN CO LTD

Optical recording medium

An optical recording medium includes an inorganic recording layer, a first protective layer provided on at least one surface of the inorganic recording layer and containing indium oxide, and a second protective layer provided so as to be adjacent to the first protective layer and containing titanium oxide, zirconium oxide, or tin oxide.

Owner:SONY CORP

Concrete additive and preparation method

The invention discloses a concrete additive. The concrete additive contains the following raw materials in parts by weight: 40-50 parts of bentonite, 20-35 parts of coal gangue, 10-15 parts of calciumchloride, 15-20 parts of polydimethylsiloxane, 8-15 parts of melamine, 5-10 parts of methyl silicone oil and 2-6 parts of titanium sesquioxide. A preparation method of the concrete additive comprisesthe following steps: (1) mixing bentonite, coal gangue and calcium chloride, sieving by virtue of a 200-mesh sieve, and baking at 200-400 DEG C for 30-40 minute; and (2) adding polydimethylsiloxane,melamine, methyl silicone oil and titanium sesquioxide, and adequately stirring and mixing. According to the concrete additive, the freezing resistance of the concrete can be effectively improved, thestrength of the concrete in a low-temperature environment is improved, and the service life of the concrete in the low-temperature environment is prolonged.

Owner:徐州和合新型建材有限公司

Titanium sesquioxide and preparation process and application thereof

The invention relates to the field of inorganic material preparation, in particular to a preparation method of titanium sesquioxide. The titanium sesquioxide preparation process comprises the steps of step a, mixing titanium dioxide and silica fume in the weight ratio of 1:0.25-0.5, forming to obtain formed material; step b, making the silica fume cover the surface of the material obtained in step a, heating the material to 1400-1500 DEG C in an airy atmosphere, keeping the temperature for 5-25 minutes, cooling and ball-grinding the material to obtain an original product; adding alkaline solution into the original product obtained in step b, making the product soak in alkaline solution for 60-120 minutes, filtering the product to obtain the final product. The titanium sesquioxide and preparation process is simple in process, short in reduction time, capable of preparing middle product in the airy atmosphere, and low in the requirements of production equipment and production environment. The final product is high in titanium sesquioxide purity. The application scope is wide, and the preparation process has a big market potential and application value.

Owner:山东临港智能制造产业园有限公司

Magnetic recording tape

InactiveUS6936338B2Improve surface smoothnessSmall surface roughnessMagnetic materials for record carriersLayered productsNon magneticTitanium oxide

A magnetic recording tape comprising: a magnetic layer comprising a ferromagnetic powder and a binder; a nonmagnetic layer; a support; and a back coating layer, in this order, wherein the magnetic layer has a surface lubricant index of from 1.3 to 3.5, the back coating layer comprises titanium oxide, α-iron oxide or a mixture thereof as an inorganic oxide powder and carbon black and further comprises from 10 to 30 parts by weight, based on 100 parts by weight of a total amount of the inorganic oxide powder and the carbon black, of a binder, and the back coating layer has a surface lubricant index of from 1.10 to 3.0.

Owner:FUJIFILM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com